Land Cruiser URJ200 URJ202 GRJ200 VDJ200 - 1VD-FTV LUBRICATION

SCAVENGING PUMP - INSTALLATION

- NOTICE:

When fuel lines are disconnected, air may enter the fuel lines, leading to engine starting trouble. Therefore, perform forced regeneration and bleed the air from the fuel lines ().

| 1. INSTALL SCAVENGING PUMP ASSEMBLY |

Install the scavenging pump with the 4 bolts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

| 2. INSTALL REAR CRANKSHAFT OIL SEAL |

Place the oil seal retainer on wooden blocks.

Using SST and a hammer, tap in a new oil seal as shown in the illustration.

- SST

- 09223-56010

- Standard depth A:

- 2.7 to 3.7 mm (0.106 to 0.147 in.)

- NOTICE:

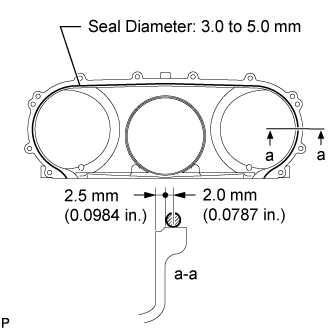

| 3. INSTALL REAR ENGINE OIL SEAL RETAINER |

- NOTICE:

- When the contact surfaces shown below are wet, wipe them with an oil-free cloth before applying seal packing.

Apply seal packing in a continuous line as shown in the illustration.

- Seal diameter:

- 3.0 to 5.0 mm (0.118 to 0.197 in.)

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- NOTICE:

Apply engine oil to the oil seal lip.

Make sure that the lip of the oil seal is properly installed.

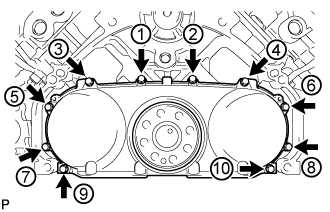

Install and uniformly tighten the 10 bolts in the order shown in the illustration.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

- NOTICE:

| 4. INSTALL NO. 1 OIL PAN SUB-ASSEMBLY |

- NOTICE:

- When the contact surfaces shown below are wet, wipe them with an oil-free cloth before applying seal packing.

Install the cylinder block oil hole gasket.

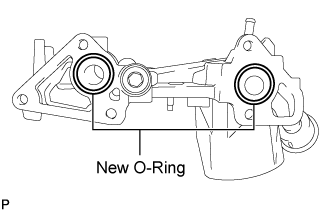

Apply a light coat of engine oil to 3 new O-rings and set the 3 O-rings to the oil regulator and scavenging pump.

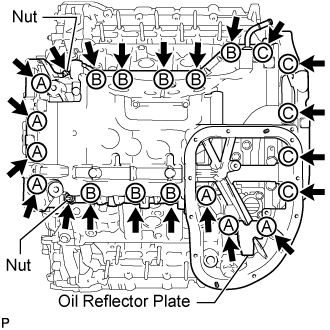

Apply seal packing to the No. 1 oil pan as shown in the illustration.

- Standard seal diameter:

- 3.5 to 4.0 mm (0.134 to 0.157 in.)

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- NOTICE:

Install the No. 1 oil pan and oil reflector plate with the 20 bolts and 2 nuts.

- Torque:

- 25 N*m{ 250 kgf*cm, 18 ft.*lbf}

| Item | Quantity | Length |

| Bolt A | 7 | 70 mm (2.76 in.) |

| Bolt B | 8 | 20 mm (0.787 in.) |

| Bolt C | 5 | 30 mm (1.18 in.) |

| 5. INSTALL OIL STRAINER SUB-ASSEMBLY |

Apply a light coat of engine oil to a new O-ring, and install it to the oil strainer.

Install the oil strainer with the 2 bolts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

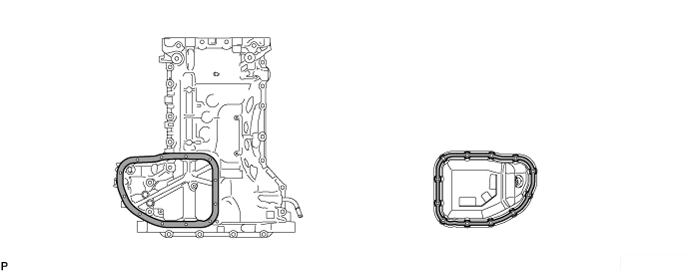

| 6. INSTALL NO. 2 OIL PAN SUB-ASSEMBLY |

- NOTICE:

- When the contact surfaces shown below are wet, wipe them with an oil-free cloth before applying seal packing.

Apply seal packing to the No. 2 oil pan as shown in the illustration.

- Standard seal diameter:

- 5.0 to 6.0 mm (0.197 to 0.236 in.)

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- NOTICE:

Install the No. 2 oil pan with the 10 bolts and 2 nuts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

| 7. INSTALL ENGINE OIL LEVEL SENSOR |

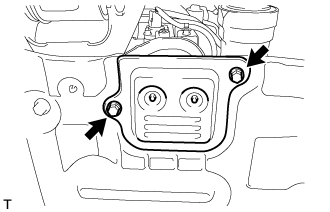

Install a new gasket and the sensor with the 4 bolts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

| 8. INSTALL OIL FILTER BRACKET SUB-ASSEMBLY |

Apply a light coat of engine oil to 2 new O-rings, and set them to the oil filter bracket.

Install the oil filter bracket with the 3 bolts and 2 nuts.

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

Connect the 2 wire harness clamps.

| 9. INSTALL OIL FILTER ELEMENT |

Clean the inside of the oil filter cap, its threads and its O-ring groove.

Apply a small amount of engine oil to a new O-ring and install it to the oil filter cap.

Set a new oil filter element in the oil filter cap.

Remove any dirt or foreign matter from the installation surface of the engine.

Apply a small amount of engine oil to the O-ring again and temporarily install the oil filter cap by hand.

Using SST, tighten the oil filter cap.

- SST

- 09228-06501

- Torque:

- 25 N*m{ 255 kgf*cm, 18 ft.*lbf}

- NOTICE:

Install the No. 2 engine under cover seal to the No. 2 engine under cover with the 2 bolts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

| 10. INSTALL TIMING GEAR COVER SPACER (w/ Intercooler) |

Install the timing gear cover spacer with the 2 bolts.

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

| 11. INSTALL CRANKSHAFT PULLEY |

- NOTICE:

- This procedure is intended for removal/installation of the crankshaft pulley only. Do not use this procedure for removal/installation of the flywheel or the drive plate and ring gear.

Align the crankshaft pulley and the crankshaft knock pin, and temporarily install the crankshaft pulley with the 3 bolts.

| *1 | Service Hole |

| *2 | Protrusion |

Install the 2 bolts to the bolt holes of the crankshaft rear side.

Using a bar, turn the crankshaft until the crankshaft pulley service hole is a little to the right of bottom dead center.

Install a 14 mm x 1.5 pitch service bolt with a length of 70 mm or more to the crankshaft pulley service hole, and hold the crankshaft using the timing chain cover protrusion.

Uniformly tighten the 3 bolts in 2 passes in the order shown in the illustration.

- Torque:

- 115 N*m{ 1168 kgf*cm, 84 ft.*lbf}

Remove the service bolt.

| 12. INSTALL V-RIBBED BELT TENSIONER ASSEMBLY |

Install the V-ribbed belt tensioner with the 5 bolts.

- Torque:

- for bolt A and C:

- 43 N*m{ 438 kgf*cm, 32 ft.*lbf}

- for bolt B:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

| Item | Quantity | Length |

| Bolt A | 1 | 116 mm (4.57 in.) |

| Bolt B | 2 | 40 mm (1.58 in.) |

| Bolt C | 2 | 95 mm (3.74 in.) |

Install the No. 1 idler pulley with the bolt.

- Torque:

- 43 N*m{ 438 kgf*cm, 32 ft.*lbf}

Install the V-ribbed belt tensioner bracket with the 3 bolts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

| 13. CONNECT NO. 2 OIL COOLER HOSE |

Align the white paint marks on the oil cooler hose and oil filter bracket and connect the hose.

- NOTICE:

- Make sure to maintain a space between the oil cooler hose and crankshaft pulley and the oil cooler hose and V-ribbed belt idler pulley.

| 14. CONNECT NO. 1 OIL COOLER HOSE |

Face the pink paint mark on the oil cooler hose toward the front side of the engine and connect the hose to the oil filter bracket.

- NOTICE:

- Make sure to maintain a space between the oil cooler hose and crankshaft pulley.

| 15. INSTALL STIFFENER INSULATOR RH (w/ Intercooler) |

Install the stiffener insulator RH with the 2 bolts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

| 16. INSTALL NO. 2 INLET TURBO OIL PIPE SUB-ASSEMBLY |

Install a new gasket and connect the No. 2 inlet turbo oil pipe with the union bolt.

- Torque:

- 29 N*m{ 296 kgf*cm, 21 ft.*lbf}

| 17. CONNECT NO. 2 OUTLET TURBO OIL HOSE |

| 18. INSTALL NO. 1 ENGINE OIL LEVEL DIPSTICK GUIDE |

Apply a light coat of engine oil to a new O-ring, and install it to the No. 1 engine oil level dipstick guide.

Install the No. 1 engine oil level dipstick guide with the 2 bolts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

| 19. CONNECT NO. 1 OUTLET TURBO OIL HOSE |

| 20. INSTALL GENERATOR ASSEMBLY |

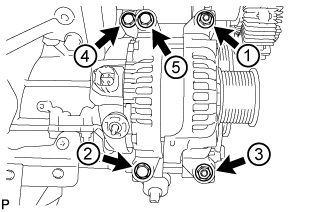

Temporarily install the generator with the 3 bolts and 2 nuts.

Uniformly tighten the 3 bolts and 2 nuts in the order shown in the illustration.

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

Connect the generator cable and install the nut and bolt.

- Torque:

- for bolt:

- 13 N*m{ 133 kgf*cm, 10 ft.*lbf}

- for nut (130A Type and 150A Type:):

- 9.8 N*m{ 100 kgf*cm, 87 in.*lbf}

- for nut (180A Type:):

- 12 N*m{ 122 kgf*cm, 9 ft.*lbf}

| 21. INSTALL NO. 1 INTAKE AIR CONNECTOR PIPE |

Install the No. 1 intake air connector pipe with the bolt. Then tighten the hose clamp.

- Torque:

- for bolt:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

- for hose clamp:

- 6.0 N*m{ 61 kgf*cm, 53 in.*lbf}

Connect the 4 connectors and attach the 5 wire harness clamps.

| 22. INSTALL ENGINE ASSEMBLY |

Install the engine assembly to the vehicle ().

| 23. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

- NOTICE:

- When disconnecting the cable, some systems need to be initialized after the cable is reconnected ().

Connect the cables to negative (-) main battery and sub-battery terminals.