Land Cruiser URJ200 URJ202 GRJ200 VDJ200 - 3UR-FE FUEL

FUEL SUB TANK - INSTALLATION

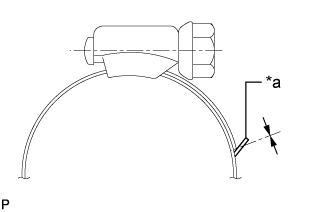

| 1. INSTALL FUEL TANK TO FILLER PIPE HOSE |

Install the hose to the fuel sub tank as shown in the illustration.

| *a | Tank Side Mark |

| *b | Hose Side Mark |

- HINT:

| *a | Stopper |

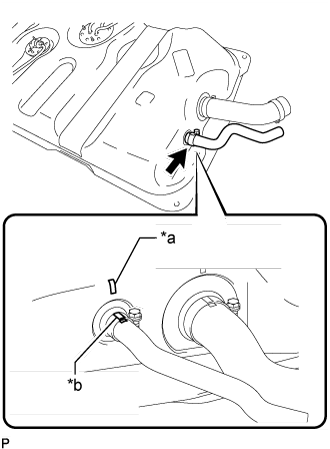

| 2. INSTALL NO. 3 FUEL HOSE |

Install the fuel hose to the fuel sub tank as shown in the illustration.

| *a | Tank Side Mark |

| *b | Hose Side Mark |

- HINT:

| *a | Stopper |

| 3. INSTALL FUEL TANK BREATHER HOSE |

Install the breather hose to the fuel sub tank.

| 4. INSTALL FUEL AND EVAPORATION VENT TUBE SUB-ASSEMBLY |

Install a new gasket to the fuel and evaporation vent tube.

Install the fuel and evaporation vent tube with the 6 bolts.

- Torque:

- 3.5 N*m{ 36 kgf*cm, 31 in.*lbf}

| 5. INSTALL FUEL TANK EVAPORATION VENT TUBE SUB-ASSEMBLY |

except G.C.C. Countries:

Install the 2 fuel tank evaporation vent tubes.

for G.C.C. Countries:

Install the fuel tank evaporation vent tube.

| 6. INSTALL FUEL HOSE |

Install the fuel hose.

| 7. INSTALL FUEL SENDER GAUGE ASSEMBLY |

Install a new gasket to the sender gauge.

- NOTICE:

- Be careful not to bend the arm of the fuel sender gauge.

Install the sender gauge with the 5 screws.

- Torque:

- 1.5 N*m{ 15 kgf*cm, 13 in.*lbf}

| 8. INSTALL FLOOR NO. 3 WIRE |

Attach the wire harness clamp to the fuel sub tank.

Connect the sender gauge connector.

| 9. INSTALL FUEL SUB TANK SUB-ASSEMBLY |

Set the fuel sub tank on a transmission jack and raise the fuel sub tank.

Connect the 2 fuel tank bands with the 2 bolts.

- Torque:

- 40 N*m{ 408 kgf*cm, 30 ft.*lbf}

Connect the floor No. 3 wire connector.

Attach the 3 wire harness clamps.

| 10. CONNECT FUEL TANK TO FILLER PIPE HOSE |

Connect the hose to the filler pipe.

| 11. CONNECT NO. 3 FUEL HOSE |

Connect the fuel hose to the filler pipe.

| 12. CONNECT FUEL TANK BREATHER HOSE |

Connect the breather hose to the filler pipe.

| 13. CONNECT FUEL HOSE |

Connect the fuel hose.

| 14. CONNECT FUEL TANK EVAPORATION VENT TUBE SUB-ASSEMBLY |

except G.C.C. Countries:

Connect the 2 fuel tank evaporation vent tubes.

for G.C.C. Countries:

Connect the fuel tank evaporation vent tube.

| 15. INSTALL FUEL TANK CAP ASSEMBLY |

| 16. INSTALL NO. 1 SPARE WHEEL STOPPER |

Install the spare wheel stopper with the 2 bolts.

- Torque:

- 32 N*m{ 326 kgf*cm, 24 ft.*lbf}

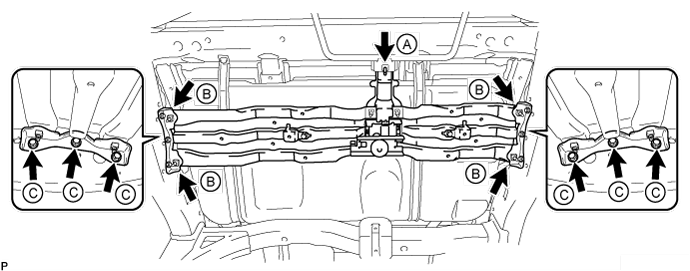

| 17. INSTALL SPARE WHEEL CARRIER CROSSMEMBER AND SPARE WHEEL CARRIER BRACKET |

Install the spare wheel carrier crossmember and 2 brackets to the vehicle with the 6 bolts labeled C.

- Torque:

- for bolt C:

- 20 N*m{ 204 kgf*cm, 15 ft.*lbf}

Temporarily install the bolt labeled A, and then tighten the bolt labeled A and bolts labeled B.

- Torque:

- for bolt A:

- 29 N*m{ 296 kgf*cm, 21 ft.*lbf}

- for bolt B:

- 20 N*m{ 204 kgf*cm, 15 ft.*lbf}

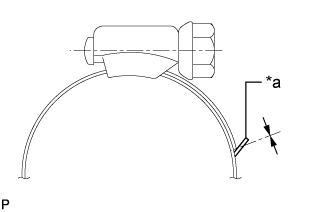

| 18. INSTALL TAILPIPE ASSEMBLY |

Install the tailpipe to the 2 exhaust pipe supports.

Install a new gasket to the center exhaust pipe.

Connect the tailpipe to the center exhaust pipe.

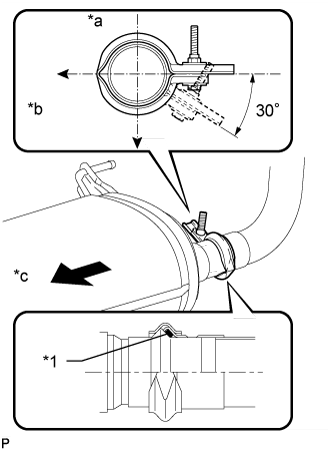

Attach a new clamp to the tailpipe and center exhaust pipe. Then install the bolt to the clamp.

- Torque:

- 32 N*m{ 326 kgf*cm, 24 ft.*lbf}

| *1 | Gasket |

| *a | Top |

| *b | LH Side |

| *c | Front |

- HINT:

- Install the clamp within the angle range shown in the illustration.

| 19. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

- NOTICE:

- When disconnecting the cable, some systems need to be initialized after the cable is reconnected ().

| 20. INSPECT FOR FUEL LEAK |

Connect the intelligent tester to the DLC3.

Turn the engine switch on (IG) and intelligent tester main switch on.

- NOTICE:

- Do not start the engine.

Enter the following menus: Powertrain / Engine and ECT / Active Test / Control the Fuel Pump / Speed.

Check that there are no fuel leaks after doing maintenance anywhere on the fuel system.

| 21. INSPECT FOR EXHAUST GAS LEAK |

If gas is leaking, tighten the areas necessary to stop the leak. Replace damaged parts as necessary.

| 22. INSTALL SPARE TIRE |