Land Cruiser URJ200 URJ202 GRJ200 VDJ200 - 1VD-FTV FUEL

FUEL INJECTOR (w/ DPF) - INSTALLATION

- NOTICE:

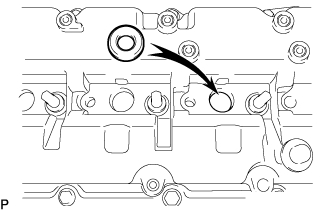

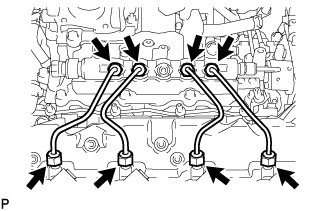

| 1. INSTALL FUEL INJECTOR LH |

- NOTICE:

Install 4 new injection nozzle seats to the cylinder head.

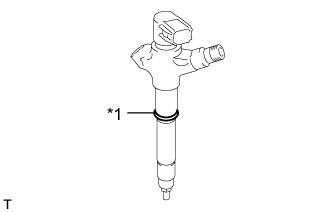

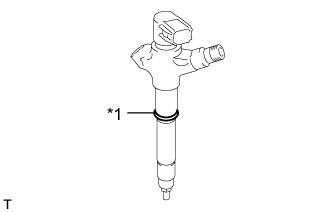

Apply a light coat of clean engine oil to 4 new O-rings.

| *1 | New O-Ring |

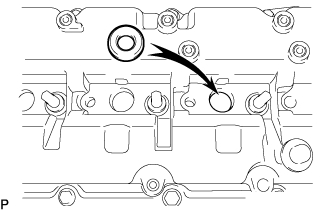

Install the O-rings to each injector as shown in the illustration.

Insert the 4 injectors into the cylinder head.

- NOTICE:

For an injector that has been replaced with a new injector, register the injector compensation code ().

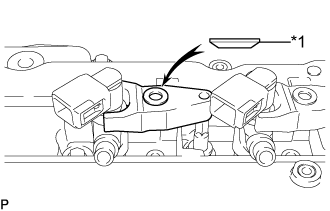

Temporarily install 4 new washers and the 4 nozzle holder clamps with the 4 clamp bolts.

| *1 | New Washer |

- NOTICE:

| *1 | Nozzle Holder Clamp |

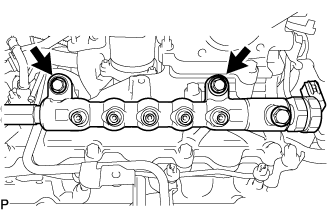

Temporarily install the common rail LH with the 2 bolts.

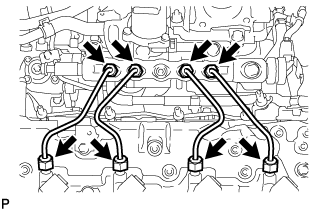

Temporarily install 4 new injection pipes to the common rail and injector.

Check the nozzle leakage pipe. Check there are no scratches or dents on the union seal surfaces. If scratches or dents are present, replace the nozzle leakage pipe.

Temporarily install the No. 2 leakage pipe and 4 new gaskets with the 4 injector hollow screws and 2 bolts.

| Injector Hollow Screw |

| Bolt |

- HINT:

- To position the injectors, loosely tighten the 4 hollow screws and 2 bolts.

Tighten the 4 holder clamp bolts.

- Torque:

- 25 N*m{ 255 kgf*cm, 18 ft.*lbf}

Remove the 4 injection pipes.

Remove the 2 bolts and common rail LH.

| 2. INSTALL NO. 2 NOZZLE LEAKAGE PIPE |

Tighten the 4 injector hollow screws and 2 bolts.

- Torque:

- for injector hollow screw:

- 18 N*m{ 184 kgf*cm, 13 ft.*lbf}

- for bolt:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

| 3. INSTALL FUEL INJECTOR RH |

- NOTICE:

Install 4 new injection nozzle seats to the cylinder head.

Apply a light coat of clean engine oil to 4 new O-rings.

| *1 | New O-Ring |

Install the O-rings to each injector as shown in the illustration.

Insert the 4 injectors into the cylinder head.

- NOTICE:

For an injector that has been replaced with a new injector, register the injector compensation code ().

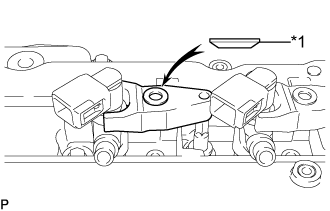

Temporarily install 4 new washers and the 4 nozzle holder clamps with the 4 clamp bolts.

| *1 | New Washer |

- NOTICE:

| *1 | Nozzle Holder Clamp |

Temporarily install 4 new injection pipes to the common rail and injector.

Check the nozzle leakage pipe. Check that there are no scratches or dents on the union seal surfaces. If scratches or dents are present, replace the nozzle leakage pipe.

Temporarily install the No. 1 leakage pipe and 4 new gaskets with the 4 injector hollow screws and union bolt.

- HINT:

- To position the injectors, loosely tighten the 4 hollow screws and union bolt.

| Injector Hollow Screw |

| Union Bolt |

Tighten the 4 holder clamp bolts.

- Torque:

- 25 N*m{ 255 kgf*cm, 18 ft.*lbf}

Remove the 4 injection pipes.

| 4. INSTALL NO. 1 NOZZLE LEAKAGE PIPE |

Tighten the union bolt and 4 injector hollow screws.

- Torque:

- for union bolt:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

- for injector hollow screw:

- 18 N*m{ 184 kgf*cm, 13 ft.*lbf}

Install the fuel tube and No. 1 nozzle leakage pipe with the check valve and new gasket.

- Torque:

- 32 N*m{ 321 kgf*cm, 23 ft.*lbf}

| 5. INSTALL NO. 3 NOZZLE LEAKAGE PIPE |

Temporarily install 2 new gaskets and the No. 3 nozzle leakage pipe with the 2 injector hollow screws and 3 bolts.

Tighten the 2 injector hollow screws and 3 bolts.

- Torque:

- for injector hollow screw:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

- for bolt:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

- HINT:

- Tighten the injector hollow screws first, and then tighten the bolts.

| 6. CONNECT CONNECTING WIRE |

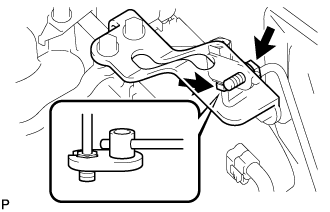

Attach the 2 clamps to install the connecting wire.

| 7. INSTALL CYLINDER HEAD COVER INSULATOR RH |

| 8. INSTALL NO. 2 ENGINE WIRE |

Connect the No. 2 engine wire with the 3 bolts.

- Torque:

- for bolt A:

- 13 N*m{ 133 kgf*cm, 10 ft.*lbf}

- for bolt B:

- 32 N*m{ 326 kgf*cm, 24 ft.*lbf}

Attach the 2 wire harness clamps.

| 9. INSTALL INJECTION PIPE RH |

Using a union nut wrench, install 4 new injection pipes.

- Torque:

- 34 N*m{ 347 kgf*cm, 25 ft.*lbf}

- NOTICE:

w/ Intercooler:

Install the 4 injection pipe clamps with the 2 nuts.

- Torque:

- 5.0 N*m{ 51 kgf*cm, 44 in.*lbf}

| 10. INSTALL NO. 1 FUEL INJECTOR PROTECTOR |

Install the No. 1 fuel injector protector with the bolt.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

- HINT:

- Press the ventilation hose clip against the No. 1 fuel injector protector as shown in the illustration.

| 11. INSTALL CYLINDER HEAD COVER SILENCER RH |

Install the cylinder head cover silencer with the 4 bolts.

- Torque:

- 5.0 N*m{ 51 kgf*cm, 44 in.*lbf}

| 12. INSTALL FUEL FILTER TO INJECTION PUMP FUEL PIPE SUB-ASSEMBLY |

w/ DPF:

- NOTICE:

- Check for damage and foreign matter on the fuel pipe installation surface of the fuel supply pump.

- If there is foreign matter, remove it from the installation surface.

- If the installation surface is damaged, replace the fuel supply pump.

Temporarily install a new gasket and fuel filter to injection pump fuel pipe with the nut, bolt and union bolt.

Install the No. 2 injection pipe clamp with the bolt.

- Torque:

- 4.0 N*m{ 41 kgf*cm, 35 in.*lbf}

Tighten the union bolt, bolt and nut.

- Torque:

- for union bolt:

- 12 N*m{ 125 kgf*cm, 9 ft.*lbf}

- for bolt and nut:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

Connect the fuel hose.

w/o DPF:

Install the fuel filter to injection pump fuel pipe with the bolt.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

Connect the 2 hoses to the fuel pipe.

| 13. INSTALL COMMON RAIL ASSEMBLY LH |

Install the common rail with the 2 bolts.

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

| 14. INSTALL CYLINDER HEAD COVER INSULATOR LH |

| 15. INSTALL INJECTION PIPE LH |

Using a union nut wrench, install the 4 new injection pipes.

- Torque:

- 34 N*m{ 347 kgf*cm, 25 ft.*lbf}

- NOTICE:

w/ Intercooler:

Install the 4 injection pipe clamps with the 2 nuts.

- Torque:

- 5.0 N*m{ 51 kgf*cm, 44 in.*lbf}

| 16. INSTALL NO. 2 FUEL INJECTOR PROTECTOR |

Install the No. 2 fuel injector protector with the bolt.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

- HINT:

- Press the ventilation hose clip against the No. 2 fuel injector protector as shown in the illustration.

Attach the hose clamp.

| 17. INSTALL NO. 4 NOZZLE LEAKAGE PIPE |

Temporarily install a new gasket and No. 4 nozzle leakage pipe with the fuel check valve.

Tighten the fuel check valve.

- Torque:

- 32 N*m{ 321 kgf*cm, 23 ft.*lbf}

Connect the fuel hose.

| 18. INSTALL CYLINDER HEAD COVER SILENCER LH |

Install the cylinder head cover silencer with the 4 bolts.

- Torque:

- 5.0 N*m{ 51 kgf*cm, 44 in.*lbf}

| 19. INSTALL NO. 1 VACUUM TRANSMITTING PIPE SUB-ASSEMBLY |

Install the vacuum transmitting pipe with the 3 bolts.

- Torque:

- 6.0 N*m{ 61 kgf*cm, 53 in.*lbf}

Connect the 2 vacuum hoses.

| 20. INSTALL NO. 1 VACUUM SWITCHING VALVE ASSEMBLY (for Engine Mounting) |

Install the vacuum switching valve with the bolt.

- Torque:

- 6.0 N*m{ 61 kgf*cm, 53 in.*lbf}

Connect the 2 vacuum hoses.

| 21. INSTALL NO. 6 INJECTION PIPE SUB-ASSEMBLY |

w/ EGR System:

Temporarily install a new No. 6 injection pipe to the common rail LH and RH.

- NOTICE:

- Make sure there is no damage or foreign matter on the seal surfaces.

Install the 2 No. 2 injection pipe clamps with the 2 nuts.

- Torque:

- 5.0 N*m{ 51 kgf*cm, 44 in.*lbf}

Using a union nut wrench, tighten the No. 6 injection pipe ends.

- Torque:

- 34 N*m{ 347 kgf*cm, 25 ft.*lbf}

- NOTICE:

- Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench ().

w/o EGR System:

Temporarily install a new No. 6 injection pipe to the common rail LH and RH.

- NOTICE:

- Make sure there is no damage or foreign matter on the seal surfaces.

Install the bracket to the No. 3 intake manifold with the bolt.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

Install the No. 2 injection pipe clamp with the nut.

- Torque:

- 5.0 N*m{ 51 kgf*cm, 44 in.*lbf}

Using a union nut wrench, tighten the No. 6 injection pipe ends.

- Torque:

- 34 N*m{ 347 kgf*cm, 25 ft.*lbf}

- NOTICE:

- Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench ().

| 22. CONNECT ENGINE WIRE |

LH Side:

Install the engine wire protector with the 2 bolts.

Connect the 8 connectors.

Attach the wire harness clamp.

Install the engine wire harness bracket with the bolt.

for RHD:

Connect the wire harness with the wire harness clamp holder.

Attach the 3 wire harness clamps and connect the 2 connectors.

Attach the 3 wire harness clamps and connect the 4 connectors.

RH Side:

Install the engine wire harness protector with the 3 bolts.

Connect the 7 connectors.

Attach the wire harness clamp.

Install the wire harness bracket with the bolt.

Install the glow plug wire harness with the nut and screw grommet.

- Torque:

- 4.0 N*m{ 41 kgf*cm, 35 in.*lbf}

for RHD:

Install the wire harness clamp holder with the bolt.

for RHD:

Connect the wire harness with the wire harness clamp holder.

Rear Side:

Install the glow plug wire harness with the nut and screw grommet.

- Torque:

- 4.0 N*m{ 41 kgf*cm, 35 in.*lbf}

w/ DPF:

Connect the 3 connectors.

w/o DPF:

Connect the connector.

Install the engine wire harness protector with the 2 bolts.

Install the 2 ground wires with the 2 bolts.

- Torque:

- 8.4 N*m{ 87 kgf*cm, 74 in.*lbf}

Attach the wire harness clamp.

| 23. INSTALL NO. 4 WATER BY-PASS PIPE |

w/ EGR System:

w/ DPF:

Connect the 3 water hose ends, and temporarily install the No. 4 water by-pass pipe with the 2 bolts and nut.

w/o DPF:

Connect the 4 water hose ends, and temporarily install the No. 4 water by-pass pipe with the 2 bolts and nut.

w/o EGR System:

Connect the 3 water hose ends, and temporarily install the No. 4 water by-pass pipe with the 2 bolts and nut.

First tighten the 2 bolts and then tighten the nut.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

| 24. INSTALL NO. 3 WATER BY-PASS PIPE (w/o Viscous Heater) |

Connect the 2 water hose ends, and install the No. 3 water by-pass pipe with the 2 bolts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

| 25. CONNECT FUEL HOSE |

| 26. INSTALL NO. 1 AIR CLEANER PIPE SUB-ASSEMBLY |

Connect the No. 1 air cleaner pipe to the No. 1 intake air connector pipe.

Install the pipe with the bolt.

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

Tighten the hose clamp.

- Torque:

- 6.3 N*m{ 64 kgf*cm, 56 in.*lbf}

| 27. INSTALL HEATER WATER PIPE SUB-ASSEMBLY (w/ Viscous Heater) |

Connect the 4 water hose ends, and install the water pipe with the 4 bolts.

- Torque:

- 9.8 N*m{ 100 kgf*cm, 87 in.*lbf}

| 28. INSTALL NO. 2 AIR CLEANER PIPE SUB-ASSEMBLY |

Connect the No. 2 air cleaner pipe to the No. 2 intake air connector pipe.

Connect the ventilation hose to the oil separator.

Install the pipe with the bolt.

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

Tighten the hose clamp.

- Torque:

- 6.3 N*m{ 64 kgf*cm, 56 in.*lbf}

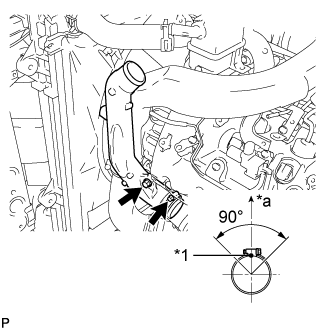

| 29. INSTALL NO. 4 AIR TUBE |

Install the No. 4 air tube with the bolt.

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

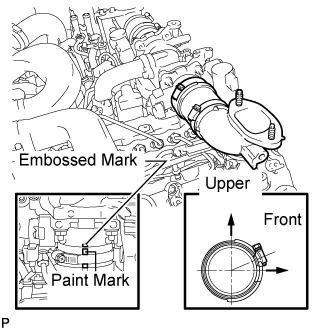

| *1 | Paint Mark |

| *a | Top |

Tighten the hose clamp.

- Torque:

- 6.3 N*m{ 64 kgf*cm, 56 in.*lbf}

- HINT:

- Make sure the direction of the hose clamp is as shown in the illustration.

Install the suction hose with the bolt.

- Torque:

- 9.8 N*m{ 100 kgf*cm, 87 in.*lbf}

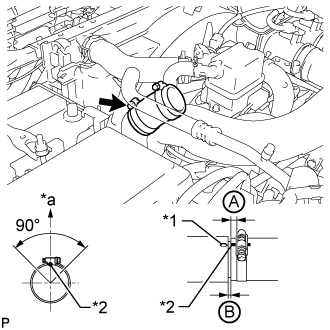

| 30. INSTALL NO. 2 AIR HOSE |

Connect the No. 2 air hose with the hose clamp.

- Torque:

- 6.3 N*m{ 64 kgf*cm, 56 in.*lbf}

| *1 | Protrusion |

| *2 | Paint Mark |

| *a | Top |

- HINT:

| 31. INSTALL NO. 3 AIR TUBE |

Install the No. 3 air tube with the bolt.

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

| *1 | Paint Mark |

| *a | Top |

Tighten the hose clamp.

- Torque:

- 6.3 N*m{ 64 kgf*cm, 56 in.*lbf}

- HINT:

- Make sure the direction of the hose clamp is as shown in the illustration.

Install the wire harness bracket with the bolt.

Install the ground wire with the nut, and attach the wire harness clamp.

- Torque:

- 8.4 N*m{ 85 kgf*cm, 74 in.*lbf}

| 32. INSTALL NO. 1 AIR HOSE |

Connect the No. 1 air hose with the hose clamp.

- Torque:

- 6.3 N*m{ 64 kgf*cm, 56 in.*lbf}

| *1 | Protrusion |

| *2 | Paint Mark |

| *a | Top |

- HINT:

| 33. INSTALL INTAKE AIR CONNECTOR |

Connect the intake air connector to the No. 1 and No. 2 air cleaner pipes.

Install the connector with the 2 bolts.

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

Tighten the 2 hose clamps.

- Torque:

- 6.3 N*m{ 64 kgf*cm, 56 in.*lbf}

Attach the 3 wire harness clamps.

w/o Viscous Heater:

Connect the connector to the water temperature sensor.

w/ Viscous Heater:

Connect the 2 connectors to the water temperature sensor and viscous with magnet clutch heater.

| 34. TEMPORARILY INSTALL NO. 1 AIR CLEANER HOSE |

Temporarily install the air cleaner hose to the intake air connector.

| 35. INSTALL AIR CLEANER CAP SUB-ASSEMBLY |

Connect the air cleaner cap to the air cleaner hose, and install the air cleaner cap with the 4 clamps.

Connect the mass air flow meter connector and attach the wire harness clamp to the air cleaner cap.

Attach the wire harness clamp.

Align the protrusion of the air cleaner cap and the concave portion of the air cleaner hose.

Tighten the 2 hose clamps.

- Torque:

- 2.5 N*m{ 25 kgf*cm, 22 in.*lbf}

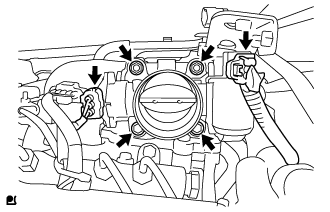

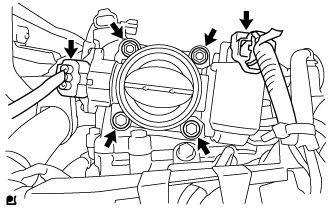

| 36. INSTALL DIESEL THROTTLE BODY ASSEMBLY LH |

Install a new gasket to the intake pipe.

Install the throttle body with the 2 bolts and 2 nuts.

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

Connect the throttle position sensor connector.

Connect the throttle motor connector.

| 37. INSTALL NO. 3 INTERCOOLER SUPPORT BRACKET |

Install the No. 3 intercooler support bracket with the 2 bolts.

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

for Manual Transmission:

Connect the clutch tube to release cylinder 2 way with the bolt.

- Torque:

- 20 N*m{ 204 kgf*cm, 15 ft.*lbf}

Check that the union nut is tightened to the specified torque.

- Torque:

- 15 N*m{ 154 kgf*cm, 11 ft.*lbf}

- HINT:

- Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench ().

| 38. INSTALL NO. 1 GAS FILTER |

Install the No. 1 gas filter.

Connect the hose to the intake pipe.

| 39. INSTALL AIR TUBE SUB-ASSEMBLY LH |

Install the air tube to the throttle body.

Align the embossed mark of the throttle body with the paint mark of the No. 4 air hose.

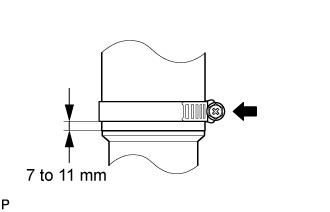

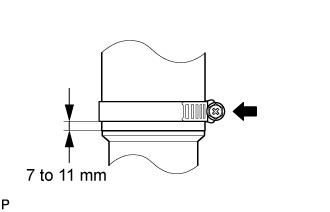

Tighten the hose clamp so that it is 7 to 11 mm (0.276 to 0.433 in.) from the end of the hose as shown in the illustration.

- Torque:

- 6.3 N*m{ 64 kgf*cm, 56 in.*lbf}

| 40. INSTALL DIESEL THROTTLE BODY ASSEMBLY RH |

Install a new gasket to the intake pipe.

Install the throttle body with the 2 bolts and 2 nuts.

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

Connect the throttle position sensor connector.

Connect the throttle motor connector.

| 41. INSTALL AIR TUBE SUB-ASSEMBLY RH |

Install the air tube to the throttle body.

Align the embossed mark of the throttle body with the paint mark of the No. 4 air hose.

Tighten the hose clamp so that it is 7 to 11 mm (0.276 to 0.433 in.) from the end of the hose as shown in the illustration.

- Torque:

- 6.3 N*m{ 64 kgf*cm, 56 in.*lbf}

| 42. INSTALL NO. 2 ENGINE OIL LEVEL DIPSTICK GUIDE |

Apply a light coat of engine oil to a new O-ring.

Install the O-ring to the No. 2 engine oil level dipstick guide.

Install the No. 2 engine oil level dipstick guide with the 2 bolts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

Connect the ventilation hose to the cylinder head cover RH.

Connect the wire harness clamp to the No. 2 engine oil level dipstick guide bracket.

| 43. CONNECT WATER HOSE SUB-ASSEMBLY |

| 44. INSTALL INTERCOOLER ASSEMBLY |

()

| 45. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

- NOTICE:

- When disconnecting the cable, some systems need to be initialized after the cable is reconnected ().

Connect the cables to the negative (-) main battery and sub-battery terminals.

| 46. REGISTER INJECTOR COMPENSATION CODE |

()

| 47. ADD ENGINE COOLANT |

Remove the engine air bleed cap.

Connect a clear hose to the engine air bleed pipe.

Using a wrench, remove the vent plug.

Fill the radiator with TOYOTA SLLC to the radiator reservoir filler neck.

- HINT:

- Pour TOYOTA SLLC until it spills out of the engine air bleed pipe.

- Standard Capacity (for Automatic Transmission):

Item Specified Condition Front heater only 14.8 liters (15.6 US qts, 13.0 Imp. qts) Front heater and rear heater 17.6 liters (18.6 US qts, 15.5 Imp. qts) Front heater with viscous heater 15.2 liters (16.1 US qts, 13.4 Imp. qts) Front heater and rear heater with viscous heater 18.0 liters (19.0 US qts, 15.4 Imp. qts)

- Standard capacity (for Manual Transmission):

- 15.4 liters (16.3 US qts, 13.5 Imp. qts)

- NOTICE:

- Do not substitute plain water for engine coolant.

- HINT:

- TOYOTA vehicles are filled with TOYOTA SLLC at the factory. In order to avoid damage to the engine cooling system and other technical problems, only use TOYOTA SLLC or similar high quality ethylene glycol based non-silicate, non-amine, non-nitrite, non-borate coolant with long-life hybrid organic acid technology (coolant with long-life hybrid organic acid technology consists of a combination of low phosphates and organic acids).

Install the vent plug.

- Torque:

- 2.0 N*m{ 20 kgf*cm, 18 in.*lbf}

- NOTICE:

- Do not tighten the plug to 5.0 N*m (51 kgf*cm, 44 in.*lbf) or more, as the plug will be damaged.

Disconnect the clear hose from the engine air bleed pipe.

Install the engine air bleed cap when coolant comes out.

Install the radiator reservoir cap.

Start the engine.

- NOTICE:

- Immediately after starting the engine, if the radiator reservoir does not have any coolant, perform the following: 1) stop the engine, 2) wait until the coolant has cooled down, and 3) add coolant until the coolant is filled to the FULL line.

Maintain an engine speed of 3000 rpm for approximately 10 minutes so that the thermostat opens and air bleeding is performed.

- CAUTION:

- NOTICE:

- HINT:

- The thermostat opening timing can be confirmed by pressing the No. 2 radiator hose by hand, and checking when the engine coolant starts to flow inside the hose.

Stop the engine, and wait until the engine coolant cools down to ambient temperature.

- CAUTION:

- Do not remove the radiator reservoir cap while the engine and radiator are still hot. Pressurized, hot engine coolant and steam may be released and cause serious burns.

Check that the coolant level is between the FULL and LOW lines.

If the coolant level is above the FULL line, drain coolant so that the coolant level is between the FULL and LOW lines.

| 48. INSPECT FOR COOLANT LEAK |

- CAUTION:

- Do not remove the radiator reservoir cap while the engine and radiator are still hot. Pressurized, hot engine coolant and steam may be released and cause serious burns.

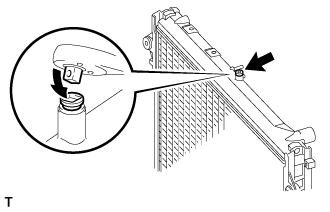

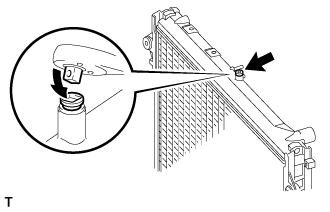

Fill the radiator with coolant and attach a radiator cap tester to the radiator reservoir.

Warm up the engine.

Using the radiator cap tester, increase the pressure inside the radiator to 123 kPa (1.3 kgf/cm2, 17.8 psi), and check that the pressure does not drop.

If the pressure drops, check the hoses, radiator and water pump for leaks.

If no external leaks are found, check the cylinder block and cylinder head.

| 49. INSPECT FOR FUEL LEAK |

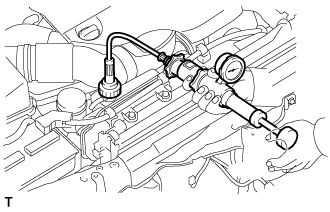

Perform Active Test.

Connect the intelligent tester to the DLC3.

Turn the ignition switch to ON.

Start the engine.

Turn the intelligent tester ON.

Enter the following menus: Powertrain / Engine and ECT / Active Test.

Perform the Active Test.

| Tester Display | Test Detail | Control Range | Diagnostic Note |

| Test the Fuel Leak | Pressurizes fuel inside common rail and checks for fuel leaks | Stop/Start | The fuel inside the common rail is pressurized to the specified value and the engine speed increases to 2000 rpm when Start is selected. The above conditions are preserved while Start is selected. |

| 50. INSPECT FOR OIL LEAK |

Warm up the engine and check for an engine oil leak.

| 51. INSTALL UPPER RADIATOR SUPPORT SEAL |

Install the upper radiator support seal with the 7 clips.

| 52. INSTALL NO. 1 ENGINE UNDER COVER SUB-ASSEMBLY |

Install the No. 1 engine under cover with the 10 bolts.

- Torque:

- 29 N*m{ 296 kgf*cm, 21 ft.*lbf}

| 53. INSTALL FRONT FENDER SPLASH SHIELD SUB-ASSEMBLY RH |

Install the front fender splash shield RH with the clip, and then install the 3 bolts and 2 screws.

| 54. INSTALL FRONT FENDER SPLASH SHIELD SUB-ASSEMBLY LH |

Install the front fender splash shield LH with the clip, and then install the 3 bolts and screw.