Land Cruiser URJ200 URJ202 GRJ200 VDJ200 - 1UR-FE INTAKE / EXHAUST

EXHAUST MANIFOLD - INSTALLATION

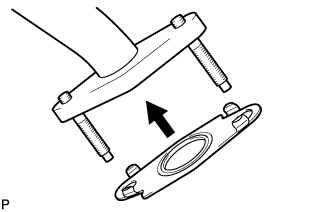

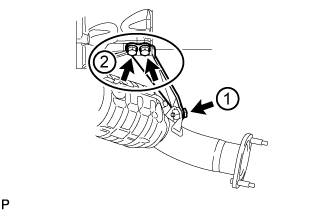

| 1. INSTALL AIR FUEL RATIO SENSOR (for Bank 1 Sensor 1) |

Temporarily install the air fuel ratio sensor to the exhaust manifold LH by hand.

Using SST, tighten the air fuel ratio sensor.

- SST

- 09224-00010

- Torque:

- without SST:

- 44 N*m{ 449 kgf*cm, 32 ft.*lbf}

- with SST:

- 40 N*m{ 408 kgf*cm, 30 ft.*lbf}

| *1 | Fulcrum Length |

- HINT:

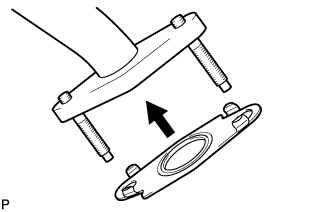

| 2. INSTALL AIR FUEL RATIO SENSOR (for Bank 2 Sensor 1) |

Temporarily install the air fuel ratio sensor to the exhaust manifold RH by hand.

Using SST, tighten the air fuel ratio sensor.

- SST

- 09224-00010

- Torque:

- without SST:

- 44 N*m{ 449 kgf*cm, 32 ft.*lbf}

- with SST:

- 40 N*m{ 408 kgf*cm, 30 ft.*lbf}

| *1 | Fulcrum Length |

- HINT:

| 3. INSTALL EXHAUST MANIFOLD ASSEMBLY RH |

w/ Secondary Air Injection System:

Install a new gasket to the No. 3 air tube.

- HINT:

- Install the gasket with the claws of the gasket facing the tube.

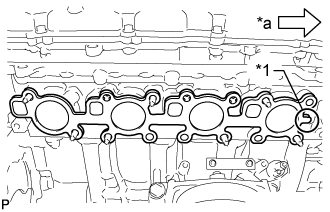

Install a new gasket to the cylinder head.

| *1 | Tab |

| *a | Front |

- HINT:

- Install the gasket with the gasket tab facing toward the front of the engine.

w/ Secondary Air Injection System:

Install the exhaust manifold to the cylinder head with the 7 new nuts labeled A.

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

Install the exhaust manifold to the No. 3 air tube with the 2 nuts labeled B.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

w/o Secondary Air Injection System:

Install the exhaust manifold with 7 new nuts.

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

Connect the air fuel ratio sensor connector and attach the wire harness clamp.

| 4. INSTALL NO. 1 EXHAUST MANIFOLD HEAT INSULATOR |

Install the heat insulator with 3 new bolts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

| 5. INSTALL ENGINE OIL LEVEL DIPSTICK GUIDE |

Apply engine oil to a new O-ring, and then install the O-ring to the engine oil level dipstick guide.

Install the engine oil level dipstick guide with the bolt.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

Attach the engine wire clamp.

Install the engine oil level dipstick.

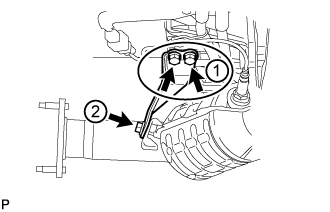

| 6. INSTALL MANIFOLD STAY |

Temporarily install the manifold stay with the 3 bolts.

Tighten the 3 bolts in the sequence shown in the illustration.

- Torque:

- 40 N*m{ 408 kgf*cm, 30 ft.*lbf}

| 7. INSTALL EXHAUST MANIFOLD ASSEMBLY LH |

w/ Secondary Air Injection System:

Install a new gasket to the No. 4 air tube.

- HINT:

- Install the gasket with the claws of the gasket facing the tube.

Install a new gasket to the cylinder head.

| *1 | Tab |

| *a | Front |

- HINT:

- Install the gasket with the gasket tab facing toward the rear of the engine.

w/ Secondary Air Injection System:

Install the exhaust manifold to the cylinder head with the 7 new nuts labeled A.

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

Install the exhaust manifold to the No. 4 air tube with the 2 nuts labeled B.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

w/o Secondary Air Injection System:

Install the exhaust manifold with 7 new nuts.

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

Connect the air fuel ratio sensor connector and attach the wire harness clamp.

| 8. INSTALL NO. 2 EXHAUST MANIFOLD HEAT INSULATOR |

Install the heat insulator with 3 new bolts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

| 9. INSTALL NO. 2 MANIFOLD STAY |

Temporarily install the manifold stay with the 3 bolts.

Tighten the 3 bolts in the sequence shown in the illustration.

- Torque:

- 40 N*m{ 408 kgf*cm, 30 ft.*lbf}

| 10. INSTALL PROPELLER SHAFT HEAT INSULATOR |

Install the propeller shaft heat insulator with the 2 bolts.

- Torque:

- 16 N*m{ 160 kgf*cm, 12 ft.*lbf}

| 11. INSTALL FRONT PROPELLER SHAFT ASSEMBLY |

()

| 12. INSTALL FRONT EXHAUST PIPE ASSEMBLY |

()

| 13. INSPECT FOR EXHAUST GAS LEAK |

If gas is leaking, tighten the areas necessary to stop the leak. Replace damaged parts as necessary.

| 14. INSTALL FRONT FENDER APRON TRIM PACKING C |

Install the front fender apron trim packing C with the 4 clips.

| 15. INSTALL FRONT FENDER APRON TRIM PACKING A |

Install the front fender apron trim packing A with the 3 clips.

| 16. INSTALL FRONT FENDER APRON TRIM PACKING D |

Install the front fender apron trim packing D with the 4 clips.

| 17. INSTALL FRONT FENDER APRON TRIM PACKING B |

w/ KDSS

Install the front fender apron trim packing B with the 3 clips.

w/o KDSS

Install the front fender apron trim packing B with the 4 clips.

| 18. INSTALL NO. 2 ENGINE UNDER COVER |

Install the No. 2 engine under cover with the 2 bolts.

- Torque:

- 29 N*m{ 296 kgf*cm, 21 ft.*lbf}

| 19. INSTALL NO. 1 ENGINE UNDER COVER SUB-ASSEMBLY |

Install the No. 1 engine under cover sub-assembly with the 10 bolts.

- Torque:

- 29 N*m{ 296 kgf*cm, 21 ft.*lbf}

| 20. INSTALL FRONT FENDER SPLASH SHIELD SUB-ASSEMBLY RH |

Push in the clip to install the front fender splash shield sub-assembly RH.

Install the 3 bolts and 2 screws.

| 21. INSTALL FRONT FENDER SPLASH SHIELD SUB-ASSEMBLY LH |

Push in the clip to install the front fender splash shield sub-assembly LH.

Install the 3 bolts and screw.

| 22. INSTALL AIR CLEANER AND HOSE |

Install the air cleaner and hose with the 3 bolts, and then tighten the hose clamp.

- Torque:

- for bolt:

- 5.0 N*m{ 51 kgf*cm, 44 in.*lbf}

- for hose clamp:

- 2.5 N*m{ 25 kgf*cm, 22 in.*lbf}

Attach the clamp and connect the mass air flow meter connector.

Connect the No. 2 PCV hose and No. 1 air hose.

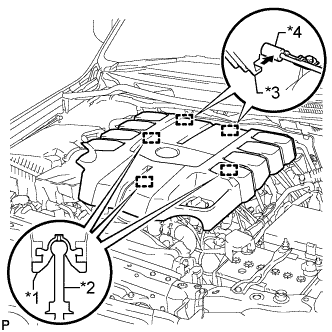

| 23. INSTALL V-BANK COVER SUB-ASSEMBLY |

Attach the 2 V-bank cover hooks to the bracket. Then align the 3 V-bank cover grommets with the 3 pins, and press down on the V-bank cover to attach the pins.

| *1 | Grommet |

| *2 | Pin |

| *3 | Hook |

| *4 | Bracket |