Land Cruiser URJ200 URJ202 GRJ200 VDJ200 - 3UR-FE ENGINE MECHANICAL

ENGINE UNIT - REASSEMBLY

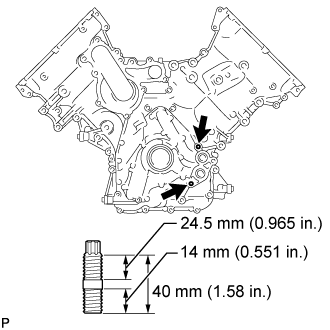

| 1. INSTALL STUD BOLT |

- NOTICE:

- If the stud bolt is deformed or its threads are damaged, replace it.

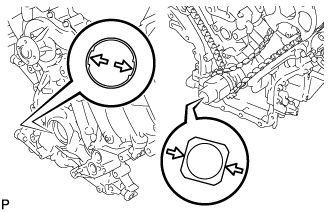

Install the timing chain cover stud bolt.

Using an E10 "TORX" socket wrench, install the 2 stud bolts as shown in the illustration.

- Torque:

- 20 N*m{ 204 kgf*cm, 15 ft.*lbf}

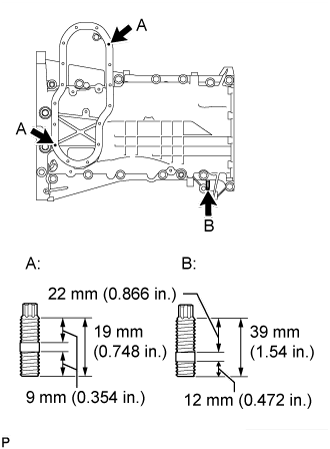

Install the oil pan stud bolt.

Using an E6 and E7 "TORX" socket wrench, install the 3 stud bolts as shown in the illustration.

- Torque:

- for stud bolt A:

- 5.0 N*m{ 51 kgf*cm, 44 in.*lbf}

- for stud bolt B:

- 9.0 N*m{ 92 kgf*cm, 80 in.*lbf}

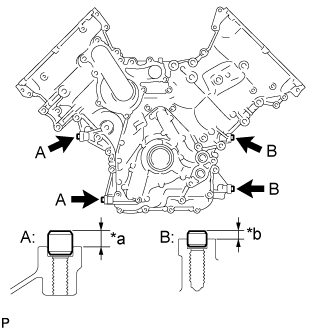

| 2. INSTALL RING PIN |

- NOTICE:

- It is not necessary to remove the ring pin unless it is being replaced.

Using a plastic-faced hammer, tap in new ring pins to the timing chain cover.

- Standard Protrusion:

Item Ring Pin Diameter Specified Condition Ring pin A 13 mm (0.512 in.) 7.5 to 8.5 mm (0.295 to 0.335 in.) Ring pin B 11 mm (0.433 in.) 3.6 to 4.6 mm (0.142 to 0.181 in.)

| *a | 7.5 to 8.5 mm |

| *b | 3.6 to 4.6 mm |

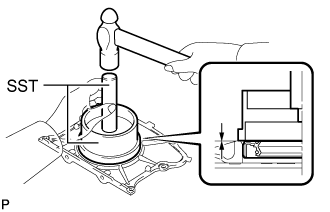

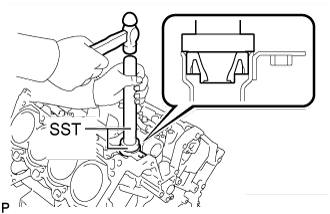

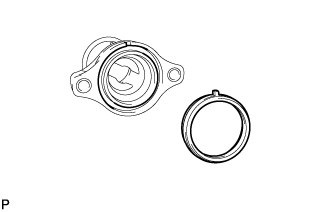

| 3. INSTALL REAR CRANKSHAFT OIL SEAL |

Using SST, tap in a new oil seal until its surface is flush with the oil seal retainer edge.

- SST

- 09223-15030

09950-70010(09951-07100)

- Standard depth:

- 0 to 1.0 mm (0 to 0.0394 in.)

- NOTICE:

| 4. INSTALL OIL DRAIN PIPE SUB-ASSEMBLY |

Apply a light coat of engine oil to a new O-ring.

Install the O-ring to the drain pipe.

Install the oil drain pipe with the bolt.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

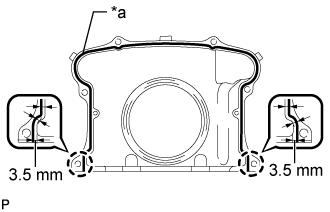

| 5. INSTALL ENGINE REAR OIL SEAL RETAINER |

Apply seal packing in a continuous line as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard Seal diameter:

- 2.0 to 3.0 mm (0.0787 to 0.118 in.)

- Application position from inside edge of retainer:

- 3.5 mm (0.138 in.)

| *a | 2.0 to 3.0 mm |

- NOTICE:

Install the oil seal retainer with the 6 bolts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

- NOTICE:

| 6. INSTALL OIL STRAINER SUB-ASSEMBLY |

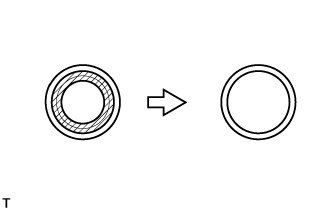

Apply a light coat of engine oil to a new O-ring.

Install the O-ring to the oil strainer.

Install the oil strainer with the 2 bolts.

- Torque:

- 12 N*m{ 122 kgf*cm, 9 ft.*lbf}

- NOTICE:

- Make sure the O-ring is not twisted or damaged.

| 7. INSTALL NO. 1 OIL PAN BAFFLE PLATE |

Install the baffle plate with the 7 bolts.

- Torque:

- 12 N*m{ 122 kgf*cm, 9 ft.*lbf}

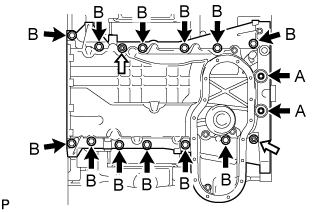

| 8. INSTALL NO. 1 OIL PAN SUB-ASSEMBLY |

Apply seal packing in a continuous line as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard seal diameter:

- 3.0 to 4.0 mm (0.118 to 0.157 in.)

| *a | 3.0 to 4.0 mm |

- NOTICE:

Install the oil pan with the 14 bolts and 2 nuts.

- Torque:

- for bolt A:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

- for bolt B:

- 35 N*m{ 357 kgf*cm, 26 ft.*lbf}

- for nut:

- 35 N*m{ 357 kgf*cm, 26 ft.*lbf}

| Bolt |

| Nut |

- NOTICE:

- Do not start the engine for at least 2 hours after installing.

- Standard Bolt:

Item Length Thread Diameter Bolt A 92 mm (3.62 in.) 6 mm (0.236 in.) Bolt B 30 mm (1.18 in.) 10 mm (0.394 in.)

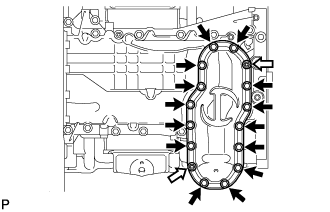

| 9. INSTALL NO. 2 OIL PAN SUB-ASSEMBLY |

Apply seal packing in a continuous line as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard seal diameter:

- 3.0 to 4.0 mm (0.118 to 0.157 in.)

| *a | 3.0 to 4.0 mm |

- NOTICE:

Install the oil pan with the 14 bolts and 2 nuts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

| Bolt |

| Nut |

- NOTICE:

- Do not start the engine for at least 2 hours after installing.

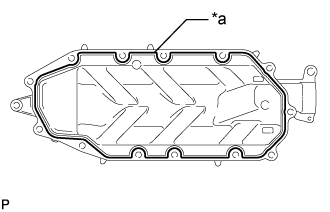

| 10. INSTALL NO. 1 HEAT EXCHANGER COVER |

Apply seal packing in a continuous line as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing 1282B, Three Bond 1282B or equivalent

- Standard seal diameter:

- 3.0 to 4.0 mm (0.118 to 0.157 in.)

| *a | 3.0 to 4.0 mm |

- NOTICE:

Install the heat exchanger cover with the 12 bolts and 2 nuts.

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

| Bolt |

| Nut |

- NOTICE:

- Do not start the engine for at least 2 hours after installing.

- Standard Bolt:

Item Length Thread Diameter Bolt A 20 mm (0.787 in.) 8 mm (0.315 in.) Bolt B 70 mm (2.76 in.) 8 mm (0.315 in.) Bolt C 16 mm (0.630 in.) 6 mm (0.236 in.)

| 11. INSTALL VENTILATION PIPE GASKET |

Using SST, evenly tap in a new ventilation pipe gasket until its surface is flush with the lip of the ventilation pipe.

- SST

- 09950-60010(09951-00360)

09950-70010(09951-07100)

- NOTICE:

| 12. INSTALL CYLINDER BLOCK WATER JACKET SPACER |

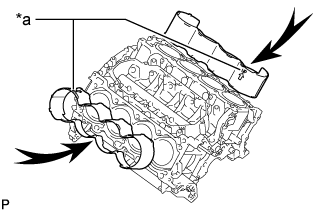

Install the 2 water jacket spacers as shown in the illustration.

| *a | UP Mark |

- HINT:

| 13. INSTALL CYLINDER HEAD SUB-ASSEMBLY RH |

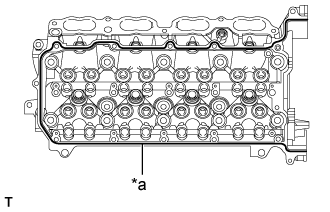

Clean the cylinder block with solvent.

Set the piston of the No. 1 cylinder to slightly ATDC.

Place the cylinder head gasket on the cylinder block surface with the front face of the Lot No. stamp upward.

| *1 | Lot No. |

| *a | Front |

- NOTICE:

Place the cylinder head on the cylinder block.

- NOTICE:

- HINT:

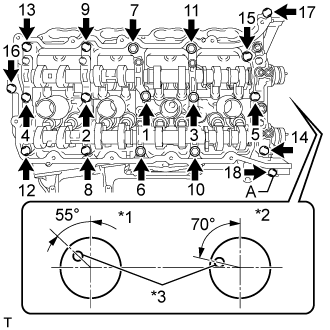

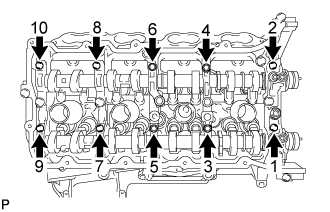

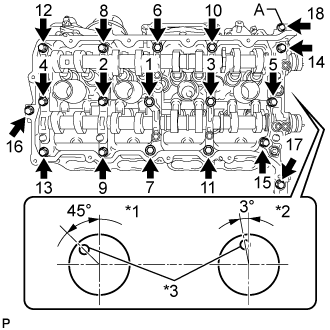

- The cylinder head bolts are tightened in 3 progressive steps.

Apply a light coat of engine oil to the threads and under the heads of the cylinder head bolts.

Step 1:

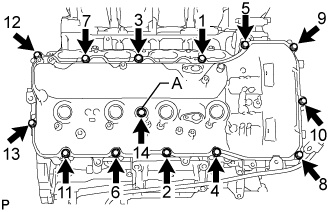

Using a 10 mm bi-hexagon wrench, install and uniformly tighten the 10 cylinder head bolts with the plate washers in several steps in the sequence shown in the illustration.

- Torque:

- 36 N*m{ 367 kgf*cm, 27 ft.*lbf}

Step 2:

Mark the front side of each cylinder head bolt head with paint.

Tighten the cylinder head bolts another 90°.

Step 3:

Tighten the cylinder head bolts an additional 90°.

Check that the paint marks are now at a 180° angle to the front.

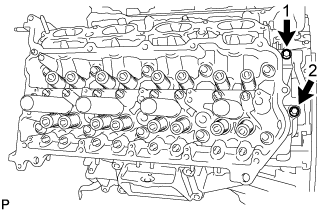

Install and uniformly tighten the 2 bolts in the sequence shown in the illustration.

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

| 14. INSTALL CYLINDER HEAD SUB-ASSEMBLY LH |

Clean the cylinder block with solvent.

Set the piston of the No. 1 cylinder to slightly ATDC.

Place the cylinder head gasket on the cylinder block surface with the front face of the Lot No. stamp upward.

| *1 | Lot No. |

| *a | Front |

- NOTICE:

Place the cylinder head on the cylinder block.

- NOTICE:

- HINT:

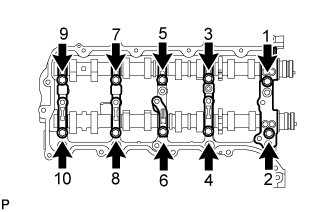

- The cylinder head bolts are tightened in 3 progressive steps.

Apply a light coat of engine oil to the threads and under the heads of the cylinder head bolts.

Step 1:

- HINT:

- The cylinder head bolts are tightened in 3 progressive steps.

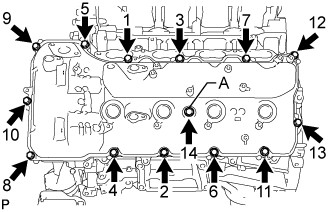

Using a 10 mm bi-hexagon wrench, install and uniformly tighten the 10 cylinder head bolts with the plate washers in several steps in the sequence shown in the illustration.

- Torque:

- 36 N*m{ 367 kgf*cm, 27 ft.*lbf}

Step 2:

Mark the front side of each cylinder head bolt head with paint.

Tighten the cylinder head bolts another 90°.

Step 3:

Tighten the cylinder head bolts an additional 90°.

Check that the paint marks are now at a 180° angle to the front.

Install and uniformly tighten the 2 bolts in the sequence shown in the illustration.

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

| 15. INSTALL VALVE STEM CAP |

Apply a light coat of engine oil to the valve stem caps.

Install the 32 valve stem caps to the cylinder heads.

| 16. INSTALL VALVE LASH ADJUSTER ASSEMBLY |

Inspect the valve lash adjuster before installing it ().

Install the 32 valve lash adjusters to the cylinder heads.

- NOTICE:

- Install the lash adjuster to the same place it was removed from.

| 17. INSTALL NO. 1 VALVE ROCKER ARM SUB-ASSEMBLY |

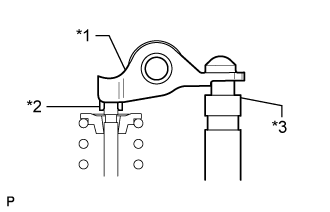

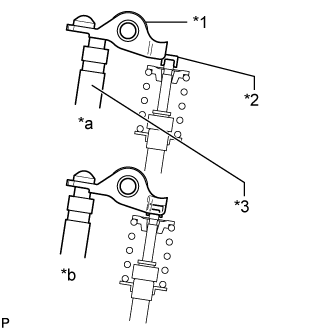

Apply engine oil to the lash adjuster tips and valve stem cap ends.

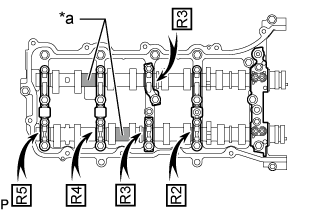

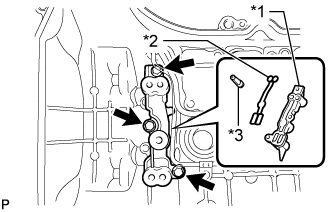

Install the 32 valve rocker arms as shown in the illustration.

| *1 | Valve Rocker Arm |

| *2 | Valve Stem Cap |

| *3 | Valve Lash Adjuster |

| 18. INSTALL CAMSHAFT BEARING CAP RH |

Apply a light coat of engine oil to the camshaft journals, camshaft housings and bearing caps.

Install the No. 1 and No. 2 camshafts to the camshaft housing.

| *a | Identification Mark |

- HINT:

- Check the identification mark stamped on the camshaft.

| Item | Mark |

| for Intake Side | NO. 1 |

| for Exhaust Side | NO. 2 |

Confirm the marks and numbers on the camshaft bearing caps and place them in their proper positions and directions.

Temporarily install the 10 bolts in the order shown in the illustration.

| 19. INSTALL CAMSHAFT HOUSING SUB-ASSEMBLY RH |

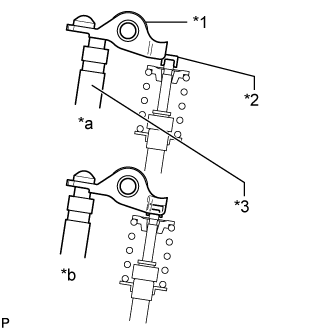

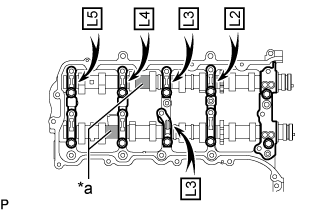

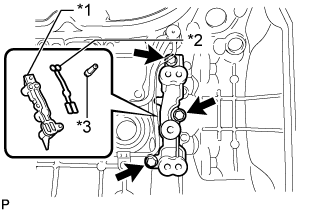

Make sure that the valve rocker arms are installed as shown in the illustration.

| *1 | Valve Rocker Arm |

| *2 | Valve Stem Cap |

| *3 | Valve Lash Adjuster |

| *a | INCORRECT |

| *b | CORRECT |

Apply seal packing in a continuous line as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard seal diameter:

- 3.5 to 4.0 mm (0.138 to 0.157 in.)

| *a | 3.5 to 4.0 mm |

- NOTICE:

Install the camshaft housing, and install the 18 bolts in the order shown in the illustration.

- Torque:

- for bolt A:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

- except bolt A:

- 30 N*m{ 306 kgf*cm, 22 ft.*lbf}

| *1 | EX |

| *2 | IN |

| *3 | Knock Pin |

- NOTICE:

Tighten the 10 bolts in the order shown in the illustration.

- Torque:

- 16 N*m{ 163 kgf*cm, 12 ft.*lbf}

- NOTICE:

- Thoroughly wipe clean any seal packing.

| 20. INSTALL CAMSHAFT BEARING CAP LH |

Apply a light coat of engine oil to the camshaft journals, camshaft housings and bearing caps.

Install the No. 3 and No. 4 camshafts to the camshaft housing.

| *a | Identification Mark |

- HINT:

- Check the identification mark stamped on the camshaft.

| Item | Mark |

| for Intake Side | NO. 3 |

| for Exhaust Side | NO. 4 |

Confirm the marks and numbers on the camshaft bearing caps and place them in their proper positions and directions.

Temporarily install the 10 bolts in the order shown in the illustration.

| 21. INSTALL CAMSHAFT HOUSING SUB-ASSEMBLY LH |

Make sure that the valve rocker arms are installed as shown in the illustration.

| *1 | Valve Rocker Arm |

| *2 | Valve Stem Cap |

| *3 | Valve Lash Adjuster |

| *a | INCORRECT |

| *b | CORRECT |

Apply seal packing in a continuous line as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard seal diameter:

- 3.5 to 4.0 mm (0.138 to 0.157 in.)

| *a | 3.5 to 4.0 mm |

- NOTICE:

Install the camshaft housing, and install the 18 bolts in the order shown in the illustration.

- Torque:

- for bolt A:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

- except bolt A:

- 30 N*m{ 306 kgf*cm, 22 ft.*lbf}

| *1 | IN |

| *2 | EX |

| *3 | Knock Pin |

- NOTICE:

Tighten the 10 bolts in the order shown in the illustration.

- Torque:

- 16 N*m{ 163 kgf*cm, 12 ft.*lbf}

- NOTICE:

- Thoroughly wipe clean any seal packing.

| 22. INSTALL CRANKSHAFT TIMING GEAR KEY |

Install the timing gear key.

- HINT:

- The other timing gear key will be installed at a later step.

| 23. SET NO. 1 CYLINDER TO TDC/COMPRESSION |

Temporarily install the crankshaft pulley bolt.

Rotate the crankshaft so that the timing gear key is as shown in the illustration. Then using a wrench, rotate each camshaft so that the timing marks are as shown in the illustration.

- NOTICE:

- When the crankshaft or a camshaft is rotated excessively, the valves and pistons may interfere with each other.

Remove the crankshaft pulley bolt.

| *1 | IN | *2 | EX |

| *3 | Knock Pin | *4 | Key |

| *a | Toward Ceiling | - | - |

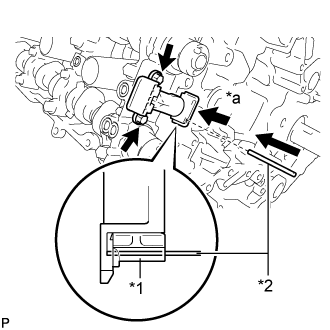

| 24. INSTALL NO. 2 CHAIN TENSIONER ASSEMBLY |

Install the chain tensioner with the 2 bolts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

| *1 | Plunger |

| *2 | Pin |

| *a | Push |

While raising up the No. 2 chain tensioner, insert a pin of 1.0 mm (0.0394 in.) into the hole to fix it in place.

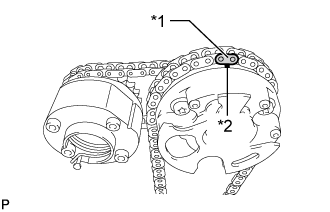

| 25. INSTALL NO. 1 CHAIN SUB-ASSEMBLY RH |

Align the No. 1 chain orange mark plate with the camshaft timing gear timing mark, and attach the chain to the gear as shown in the illustration.

| *1 | Mark Plate |

| *2 | Timing Mark |

Align the No. 1 chain orange mark plate with the crankshaft timing sprocket timing mark, and attach the chain to the gear as shown in the illustration.

| *1 | Mark Plate |

| *2 | Timing Mark |

Align the No. 2 chain yellow mark plates with the timing marks of the camshaft timing gear assembly and camshaft timing exhaust gear assembly, and attach the No. 2 chain to the gears as shown in the illustration.

| *1 | Mark Plate |

| *2 | Timing Mark |

- NOTICE:

- The camshaft timing exhaust gear has 2 grooves. Align the mark plates of the No. 2 chain with the first groove.

- HINT:

- The crankshaft timing sprocket RH and camshaft timing exhaust gear will be installed with the No. 1 and No. 2 chains connected to the gears.

Install the crankshaft timing sprocket RH to the crankshaft.

Align and attach the knock pin of the No. 1 camshaft with the pin hole of the camshaft timing gear.

Using the hexagonal portion of the No. 2 camshaft, align and attach the knock pin of the No. 2 camshaft with the pin hole of the camshaft timing exhaust gear.

Remove the pin from the No. 2 chain tensioner.

Using a wrench to hold the hexagonal portion of the No. 1 camshaft, temporarily install the bolt.

Using a wrench to hold the hexagonal portion of the No. 2 camshaft, temporarily install the bolt.

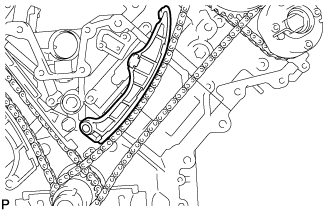

| 26. INSTALL NO. 1 CHAIN VIBRATION DAMPER RH |

Install the vibration damper with the 2 bolts.

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

| 27. INSTALL NO. 1 CHAIN TENSIONER SLIPPER RH |

- HINT:

- If you cannot install the chain tensioner slipper due to the tension of the chain, use the hexagonal portion of the camshaft to loosen the chain, and then install the chain tensioner slipper.

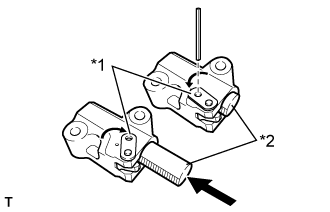

| 28. INSTALL NO. 1 CHAIN TENSIONER ASSEMBLY RH |

Move the stopper plate clockwise to release the lock, and push the plunger deep into the tensioner.

| *1 | Stopper Plate |

| *2 | Plunger |

Move the stopper plate counterclockwise to set the lock, and insert a hexagon wrench into the hole of the stopper plate.

Install the chain tensioner with the 2 bolts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

Remove the hexagon wrench from the chain tensioner.

| 29. INSTALL NO. 3 CHAIN TENSIONER ASSEMBLY |

Install the chain tensioner with the 2 bolts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

| *1 | Plunger |

| *2 | Pin |

| *a | Push |

While pushing down the No. 2 chain tensioner, insert a pin of 1.0 mm (0.0394 in.) into the hole to fix it in place.

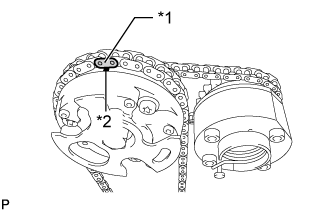

| 30. INSTALL NO. 1 CHAIN SUB-ASSEMBLY LH |

Align the No. 1 chain orange mark plate with the camshaft timing gear timing mark, and attach the chain to the gear as shown in the illustration.

| *1 | Mark Plate |

| *2 | Timing Mark |

Align the No. 1 chain orange mark plate with the crankshaft timing sprocket timing mark, and attach the chain to the gear as shown in the illustration.

| *1 | Mark Plate |

| *2 | Timing Mark |

Align the No. 2 chain yellow mark plates with the timing marks of the camshaft timing gear assembly and camshaft timing exhaust gear assembly, and attach the No. 2 chain to the gears as shown in the illustration.

| *1 | Mark Plate |

| *2 | Timing Mark |

- NOTICE:

- The camshaft timing exhaust gear has 2 grooves. Align the mark plates of the No. 2 chain with the first groove.

- HINT:

- The crankshaft timing sprocket LH and camshaft timing exhaust gear will be installed with the No. 1 and No. 2 chains connected to the gears.

Install the crankshaft timing sprocket LH to the crankshaft.

Align and attach the knock pin of the No. 3 camshaft with the pin hole of the camshaft timing gear.

Using the hexagonal portion of the No. 4 camshaft, align and attach the knock pin of the No. 4 camshaft with the pin hole of the camshaft timing exhaust gear.

- NOTICE:

- Because the timing mark positions of the gears may shift due to looseness of the No. 1 chain, use the hexagonal portion of the camshaft to hold the No. 3 camshaft in place until the No. 1 chain tensioner is installed.

Remove the pin from the No. 3 chain tensioner.

Using a wrench to hold the hexagonal portion of the No. 3 camshaft, temporarily install the bolt.

Using a wrench to hold the hexagonal portion of the No. 4 camshaft, temporarily install the bolt.

| 31. INSTALL NO. 1 CHAIN TENSIONER SLIPPER LH |

- HINT:

- If you cannot install the chain tensioner slipper due to the tension of the chain, use the hexagonal portion of the camshaft to loosen the chain, and install the chain tensioner slipper.

| 32. INSTALL NO. 1 CHAIN TENSIONER ASSEMBLY LH |

Move the stopper plate clockwise to release the lock, and push the plunger deep into the tensioner.

| *1 | Stopper Plate |

| *2 | Plunger |

Move the stopper plate counterclockwise to set the lock, and insert a hexagon wrench into the hole of the stopper plate.

Install a new gasket and the chain tensioner with the 2 bolts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

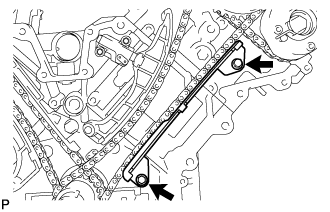

| 33. INSTALL NO. 1 CHAIN VIBRATION DAMPER LH |

Install the vibration damper with the 2 bolts.

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

Remove the hexagon wrench from the No. 1 chain tensioner.

| 34. TIGHTEN CAMSHAFT TIMING GEAR |

for Bank 1:

Using a wrench, hold the hexagonal portion of the No. 3 camshaft.

| *a | Hold |

| Turn |

Tighten the bolt of the camshaft timing gear.

- Torque:

- 100 N*m{ 1020 kgf*cm, 74 ft.*lbf}

Using a wrench to hold the hexagonal portion of the No. 4 camshaft, tighten the bolt of the camshaft timing exhaust gear.

- Torque:

- 100 N*m{ 1020 kgf*cm, 74 ft.*lbf}

| *a | Hold |

| Turn |

for Bank 2:

Using a wrench, hold the hexagonal portion of the No. 1 camshaft.

| *a | Hold |

| Turn |

Tighten the bolt of the camshaft timing gear.

- Torque:

- 100 N*m{ 1020 kgf*cm, 74 ft.*lbf}

Using a wrench to hold the hexagonal portion of the No. 2 camshaft, tighten the bolt of the camshaft timing exhaust gear.

- Torque:

- 100 N*m{ 1020 kgf*cm, 74 ft.*lbf}

| *a | Hold |

| Turn |

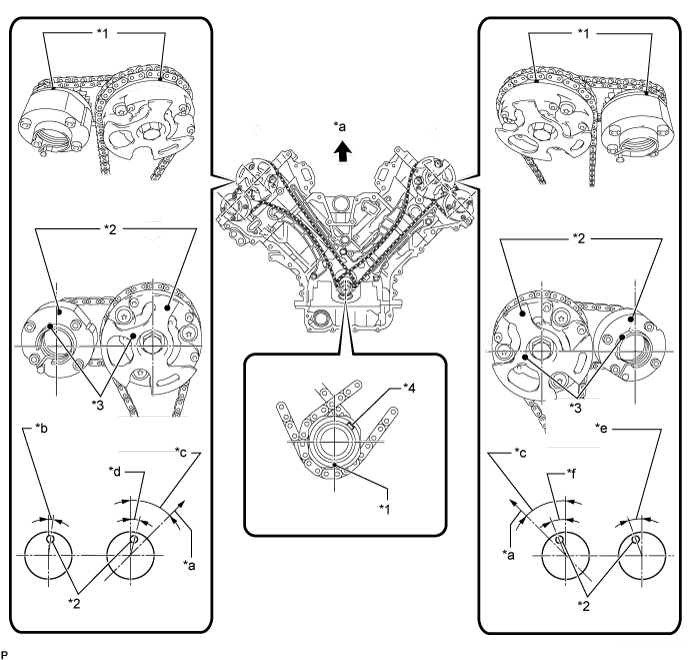

| 35. CHECK NO. 1 CYLINDER TO TDC/COMPRESSION |

Temporarily install the crankshaft pulley bolt.

Rotate the crankshaft clockwise, and check that the timing marks on the crankshaft timing sprocket and camshaft timing gears are as shown in the illustration.

Remove the crankshaft pulley bolt.

| *1 | Timing Mark | *2 | Timing Mark Position |

| *3 | Knock Pin Position | *4 | Key |

| *a | Toward Ceiling | *b | Approximately 2° |

| *c | Approximately 45° | *d | Approximately 16° |

| *e | Approximately 18° | *f | Approximately 32° |

| 36. INSTALL WATER INLET PIPE |

Apply soapy water to 2 new O-rings and install them to the inlet pipe.

Install the inlet pipe to the No. 1 heat exchanger cover.

| 37. INSTALL TIMING CHAIN COVER SUB-ASSEMBLY |

Apply a light coat of engine oil to a new oil pump gasket.

Install the oil pump gasket.

Apply a light coat of engine oil to a new O-ring.

Install the O-ring.

Apply seal packing in a continuous line to the timing chain cover as shown in the following illustration.

| *1 | Continuous line area | *2 | Dashed line area |

| *3 | Diagonal line area | - | - |

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Apply Seal Packing as Follows:

Area Seal Packing Diameter Application Position from Inside Edge of Cover Continuous Line Area 3.0 to 4.0 mm (0.118 to 0.157 in.) 2.5 mm (0.0984 in.) Dashed Line Area 6.4 mm (0.252 in.) or more, or within OK area shown in illustration 7.0 mm (0.276 in.) Diagonal Line Area 3.0 to 4.0 mm (0.118 to 0.157 in.) 5.5 mm (0.217 in.)

| *1 | Seal Packing Thickness mm (in.) |

| *2 | Seal Packing Width mm (in.) |

| *3 | Seal Packing Thickness |

| *4 | Seal Packing Width |

| *5 | OK Area |

- NOTICE:

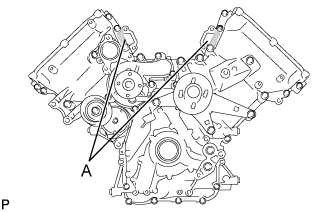

Align the oil pump drive rotor spline and crankshaft as shown in the illustration. Install the spline and chain cover to the crankshaft.

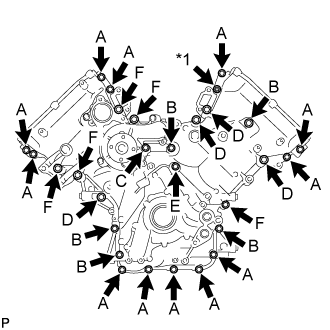

Temporarily install the timing chain cover with the 28 bolts and nut.

- Standard Bolt:

Item Length Thread Diameter Bolt A 25 mm (0.984 in.) 8 mm (0.315 in.) Bolt B 55 mm (2.17 in.) 8 mm (0.315 in.) Bolt C 70 mm (2.76 in.) 8 mm (0.315 in.) Bolt D 35 mm (1.38 in.) 10 mm (0.394 in.) Bolt E 55 mm (2.17 in.) 10 mm (0.394 in.) Bolt F 80 mm (3.15 in.) 10 mm (0.394 in.)

| *1 | Nut |

- NOTICE:

- Make sure that there is no oil on the bolt threads.

Tighten the 3 bolts in several steps in the sequence shown in the illustration.

- Torque:

- 47 N*m{ 479 kgf*cm, 35 ft.*lbf}

Temporarily install the fluid coupling bracket with the 4 bolts.

- Standard Bolt:

Item Length Thread Diameter Bolt A 70 mm (2.76 in.) 8 mm (0.315 in.) Bolt B 80 mm (3.15 in.) 10 mm (0.394 in.)

Temporarily install the belt tensioner with the standard bolt and 6 mm hexagon wrench bolt.

Tighten the 8 bolts labeled 4 to 11 in several steps in the sequence shown in the illustration.

- Torque:

- 47 N*m{ 479 kgf*cm, 35 ft.*lbf}

Tighten the 23 bolts and nut labeled 12 to 35 in several steps in the sequence shown in the illustration.

- Torque:

- 23 N*m{ 235 kgf*cm, 17 ft.*lbf}

- NOTICE:

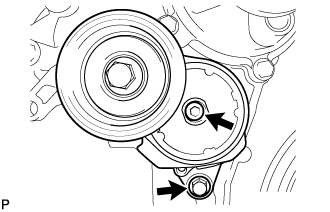

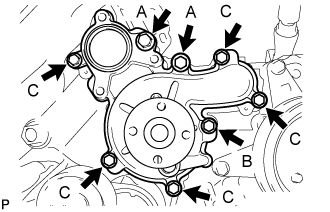

| 38. INSTALL WATER PUMP ASSEMBLY |

Install a new gasket and the water pump with the 8 bolts shown in the illustration.

- Torque:

- for bolt A:

- 47 N*m{ 479 kgf*cm, 35 ft.*lbf}

- for bolt B:

- 23 N*m{ 235 kgf*cm, 17 ft.*lbf}

- for bolt C:

- 20 N*m{ 204 kgf*cm, 15 ft.*lbf}

- Standard Bolt:

Item Length Thread Diameter Bolt A 80 mm (3.15 in.) 10 mm (0.394 in.) Bolt B 70 mm (2.76 in.) 8 mm (0.315 in.) Bolt C 25 mm (0.984 in.) 8 mm (0.315 in.)

| 39. INSTALL FRONT CRANKSHAFT OIL SEAL |

Apply MP grease to the lip of a new oil seal.

Using SST and a hammer, tap in the oil seal to a depth between 0 and 1.0 mm (0 and 0.0394 in.) from the timing chain cover edge.

- SST

- 09223-22010

09506-35010

- NOTICE:

| 40. INSTALL CRANKSHAFT TIMING GEAR KEY |

Install the crankshaft timing gear key.

| 41. INSTALL CRANKSHAFT PULLEY |

Align the pulley set key with the key groove of the pulley, and slide on the pulley.

Using SST, install the pulley set bolt.

- SST

- 09213-70011

09330-00021

- Torque:

- 300 N*m{ 3059 kgf*cm, 221 ft.*lbf}

| *a | Hold |

| Turn |

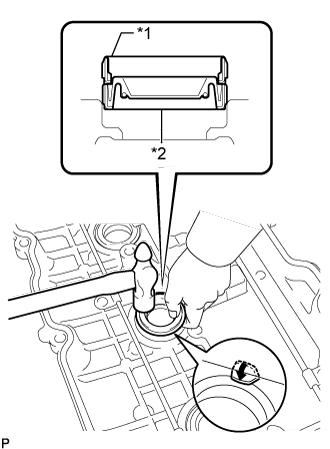

| 42. INSTALL SPARK PLUG TUBE GASKET |

Using a cutter knife, cut off the seal part of the removed gasket.

| Area to cut off |

Using the removed gasket and a hammer, tap in a new gasket until it stops.

| *1 | Removed Gasket |

| *2 | New Gasket |

- HINT:

- If the removed gasket does not fit on the new one, correct the removed one with pliers.

Apply a light coat of MP grease to the lip of the gasket.

Return the 4 ventilation baffle plate claws to the original positions.

| 43. INSTALL OIL CONTROL VALVE FILTER |

LH:

Install the filter in the cylinder head.

| *1 | Cylinder Head Cover Spacer |

| *2 | Gasket |

| *3 | Filter |

Install a new gasket and the cylinder head cover spacer with the 3 bolts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

RH:

Install the filter in the cylinder head.

| *1 | Cylinder Head Cover Spacer |

| *2 | Gasket |

| *3 | Filter |

Install a new gasket and the cylinder head cover spacer with the 3 bolts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

| 44. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY RH |

Install 5 new gaskets to the camshaft bearing caps. (No. 1, No. 3).

Install a new gasket to the cylinder head cover.

- NOTICE:

- Remove any oil from the contact surface.

Apply seal packing as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

| Seal Packing |

- NOTICE:

Install the cylinder head cover and a new seal washer with the 14 bolts in the order shown in the illustration.

- Torque:

- for bolt A:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

- except bolt A:

- 12 N*m{ 122 kgf*cm, 9 ft.*lbf}

- NOTICE:

- Do not start the engine for at least 2 hours after the installation.

Install the noise filter to the cylinder head cover with the bolt.

- Torque:

- 7.0 N*m{ 71 kgf*cm, 62 in.*lbf}

| 45. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY LH |

Install 5 new gaskets to the camshaft bearing caps (No. 2, No. 3).

Install a new gasket to the cylinder head cover.

- NOTICE:

- Remove any oil from the contact surface.

Apply seal packing as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

| Seal Packing |

- NOTICE:

Install the cylinder head cover and a new seal washer with the 14 bolts in the order shown in the illustration.

- Torque:

- for bolt A:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

- except bolt A:

- 12 N*m{ 122 kgf*cm, 9 ft.*lbf}

- NOTICE:

- Do not start the engine for at least 2 hours after the installation.

| 46. INSTALL NO. 1 IDLER PULLEY SUB-ASSEMBLY |

Install the idler pulley with the bolt.

- Torque:

- 43 N*m{ 438 kgf*cm, 32 ft.*lbf}

| 47. INSTALL WATER PUMP PULLEY |

Temporarily install the pulley with the 4 bolts.

Using SST, hold the pulley and tighten the 4 bolts.

- SST

- 09960-10010(09962-01000,09963-01000)

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

| 48. INSTALL CAMSHAFT OIL CONTROL VALVE ASSEMBLY |

for Bank 1:

Apply a light coat of engine oil to 2 new O-rings.

Install the 2 O-rings to the 2 oil control valves.

Install the 2 oil control valves with the 2 bolts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

for Bank 2:

Apply a light coat of engine oil to 2 new O-rings.

Install the 2 O-rings to the 2 oil control valves.

Install the 2 oil control valves with the 2 bolts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

| 49. INSTALL ENGINE OIL LEVEL SENSOR |

Install a new gasket and the oil level sensor with the 4 bolts.

- Torque:

- 7.0 N*m{ 71 kgf*cm, 62 in.*lbf}

Connect the oil level sensor connector.

| 50. INSTALL CRANKSHAFT POSITION SENSOR |

Install the crankshaft position sensor with the bolt.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

| 51. INSTALL CRANK POSITION SENSOR PROTECTOR |

Install the sensor protector with the 2 bolts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

| 52. INSTALL CAMSHAFT POSITION SENSOR |

Install the camshaft position sensor with the bolt.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

| 53. INSTALL VVT SENSOR |

for Bank 1:

Install the 2 VVT sensors with the 2 bolts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

for Bank 2:

Install the 2 VVT sensors with the 2 bolts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

| 54. INSTALL SPARK PLUG |

Using a 16 mm plug wrench, install the 8 spark plugs.

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

| 55. INSTALL OIL FILLER CAP HOUSING |

Align the protrusion of a new gasket with the cutout of the oil filler cap housing, and install the gasket to the housing.

Install the cap housing with the 2 bolts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

| 56. INSTALL OIL FILLER CAP SUB-ASSEMBLY |

| 57. INSTALL OIL FILTER BRACKET |

Apply a light coat of engine oil to 2 new O-rings.

Install the 2 O-rings to the timing chain cover.

Install the oil filter bracket with the 2 nuts and 2 bolts.

- Torque:

- 35 N*m{ 357 kgf*cm, 26 ft.*lbf}

| 58. INSTALL NO. 1 OIL COOLER BRACKET |

Connect the ground wire to the cylinder block.

Install the oil cooler bracket with the 2 nuts.

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

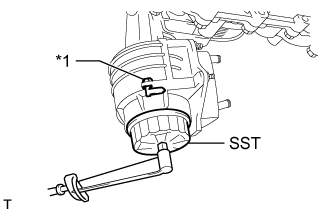

| 59. INSTALL OIL FILTER ELEMENT |

Clean the inside of the oil filter cap, its threads and its O-ring groove.

Apply a small amount of engine oil to a new O-ring and install it to the oil filter cap.

Set a new oil filter element to the oil filter cap.

Remove any dirt or foreign matter from the installation surface of the engine.

Apply a small amount of engine oil to the O-ring again and temporarily install the oil filter cap.

- NOTICE:

- Do not remove the oil filter bracket clip.

Using SST, tighten the oil filter cap.

- SST

- 09228-06501

- Torque:

- 25 N*m{ 255 kgf*cm, 18 ft.*lbf}

| *1 | Oil Filter Bracket Clip |

- NOTICE:

Apply a small amount of engine oil to a new drain plug O-ring, and install it to the oil filter cap.

| *1 | O-Ring |

- NOTICE:

- Before installing the O-ring, remove any dirt or foreign matter from the installation surface of the oil filter cap.

Install the oil filter drain plug.

- Torque:

- 13 N*m{ 127 kgf*cm, 9 ft.*lbf}

- NOTICE:

- Be careful that the O-ring does not get caught between any surrounding parts.

Install the No. 2 engine under cover seal with the 2 bolts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

| 60. INSTALL OIL PRESSURE SENDER GAUGE ASSEMBLY |

Apply adhesive to 2 or 3 threads of the oil pressure sender gauge.

- Adhesive:

- Toyota Genuine Adhesive 1344, Three Bond 1344 or equivalent

- NOTICE:

- Do not allow adhesive to contact the oil hole.

| *1 | Oil Hole |

Install the oil pressure sender gauge.

- Torque:

- 15 N*m{ 153 kgf*cm, 11 ft.*lbf}

- NOTICE:

- Do not start the engine within 1 hour after installation.

Connect the sender gauge connector.