Land Cruiser URJ200 URJ202 GRJ200 VDJ200 - 1GR-FE ENGINE MECHANICAL

ENGINE UNIT - INSTALLATION

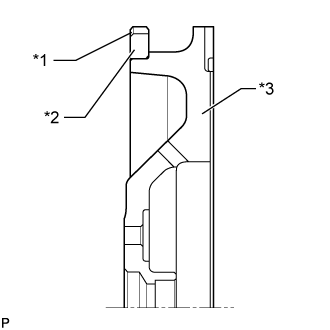

| 1. INSTALL FLYWHEEL RING GEAR (for Manual Transmission) |

Using a torch, heat the ring gear evenly to approximately 200°C (392°F).

| *1 | Chamfer |

| *2 | Ring Gear |

| *3 | Flywheel |

- NOTICE:

- Be careful not to overheat the ring gear.

Using a brass bar, tap the ring gear onto the flywheel with its chamfered gear teeth facing the block.

- NOTICE:

- After installing, allow the ring gear to cool before handling.

| 2. INSTALL FRONT NO. 1 ENGINE MOUNTING BRACKET RH |

Install the front No. 1 engine mounting bracket RH with the 4 bolts.

- Torque:

- 43 N*m{ 438 kgf*cm, 32 ft.*lbf}

| 3. INSTALL FRONT NO. 1 ENGINE MOUNTING BRACKET LH |

Install the front No. 1 engine mounting bracket LH with the 3 bolts.

- Torque:

- 43 N*m{ 438 kgf*cm, 32 ft.*lbf}

| 4. INSTALL ENGINE OIL LEVEL DIPSTICK GUIDE |

Install a new O-ring to the engine oil level dipstick guide.

| *1 | New O-Ring |

Apply a light coat of engine oil to the O-ring.

Push the engine oil level dipstick guide end into the guide hole.

Install the engine oil level dipstick guide with the bolt.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

Install the engine oil level dipstick.

| 5. INSTALL V-RIBBED BELT TENSIONER ASSEMBLY |

Temporarily install the V-ribbed belt tensioner with the 5 bolts.

- Standard Bolt:

Item Length A 70 mm (2.76 in.) B 33 mm (1.30 in.)

| Bolt A |

| Bolt B |

Tighten bolts 1 and 2 in numerical order.

- Torque:

- 36 N*m{ 367 kgf*cm, 27 ft.*lbf}

Tighten the other bolts.

- Torque:

- 36 N*m{ 367 kgf*cm, 27 ft.*lbf}

| 6. INSTALL NO. 2 IDLER PULLEY SUB-ASSEMBLY |

Install the 2 No. 2 idler pulleys with the 2 bolts.

- Torque:

- 54 N*m{ 551 kgf*cm, 40 ft.*lbf}

| 7. INSTALL NO. 1 IDLER PULLEY SUB-ASSEMBLY |

Install the No. 1 idler pulley with the bolt.

- Torque:

- 54 N*m{ 551 kgf*cm, 40 ft.*lbf}

| *1 | DOUBLE |

- HINT:

- "DOUBLE" is marked on the No. 1 idler pulley to distinguish it from the No. 2 idler pulley.

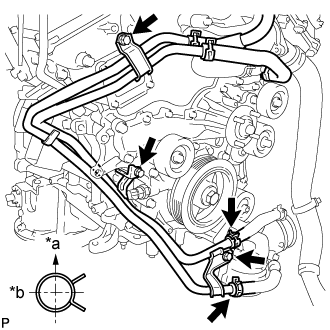

| 8. INSTALL WATER BY-PASS PIPE SUB-ASSEMBLY |

Install the water by-pass pipe with the 3 bolts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

Connect the 2 hoses.

| *a | Upward |

| *b | Rearward |

- HINT:

- The direction of the hose clamp is indicated in the illustration.

| 9. INSTALL INTAKE MANIFOLD |

Set a new gasket on each cylinder head.

- NOTICE:

Set the intake manifold on the cylinder heads.

Install and uniformly tighten the 6 bolts and 4 nuts in several passes.

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

- HINT:

- Tighten the inner installation bolts of the intake manifold before tightening the outer bolts.

| 10. INSTALL FUEL INJECTOR ASSEMBLY |

Install a new insulator to each fuel injector.

| *1 | New Insulator |

| *2 | New O-Ring |

Apply a light coat of spindle oil or gasoline to new O-rings and install one to each fuel injector.

Install the 6 injectors.

While turning each fuel injector left and right, install it to the fuel delivery pipe.

| *1 | Connector |

| Outward |

| Turn |

| Push |

Position the fuel injectors with the connectors facing outward.

| 11. INSTALL FUEL DELIVERY PIPE SUB-ASSEMBLY |

Place the fuel delivery pipe together with the 6 fuel injectors on the intake manifold.

Temporarily install the 4 bolts, which are used to hold the fuel delivery pipe in place, to the intake manifold.

Check that the fuel injectors rotate smoothly.

| *1 | Turn |

If the fuel injectors do not rotate smoothly, replace the O-ring of any injector that does not rotate smoothly.

Position the fuel injectors with the connectors facing outward.

Tighten the 4 bolts.

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

Connect the 6 fuel injector connectors.

| 12. INSTALL FUEL PIPE SUB-ASSEMBLY |

Install the No. 1 fuel pipe and No. 2 fuel pipe with the 2 bolts.

- Torque:

- 9.0 N*m{ 92 kgf*cm, 80 in.*lbf}

Connect the 2 fuel pipes ().

| 13. INSTALL IGNITION COIL ASSEMBLY |

Install the 6 ignition coils with the 6 bolts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

Connect the 6 ignition coil connectors.

| 14. INSTALL NO. 2 EMISSION CONTROL VALVE SET (w/ Secondary Air Injection System) |

Install the No. 2 emission control valve set with the 3 nuts.

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

Align the paint mark with the rib and connect the No. 1 air hose.

| *1 | Paint Mark |

| *2 | Rib |

| *a | Top |

| *b | LH Side |

- HINT:

- Make sure the direction of the hose clamp is as shown in the illustration.

Connect the No. 2 emission control valve set connector.

| 15. INSTALL NO. 1 EMISSION CONTROL VALVE SET (w/ Secondary Air Injection System) |

Install the No. 1 emission control valve set with the 3 nuts.

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

Align the paint mark with the rib and connect the No. 1 air hose.

| *1 | Rib |

| *2 | Paint Mark |

| *a | RH Side |

| *b | Top |

- HINT:

- Make sure the direction of the hose clamp is as shown in the illustration.

Connect the No. 1 emission control valve set connector.

| 16. INSTALL HEATER WATER HOSE ASSEMBLY |

Install the heater water hose assembly and connect the 2 hoses with the 2 bolts.

- Torque:

- 9.8 N*m{ 100 kgf*cm, 87 in.*lbf}

| 17. INSTALL ENGINE WIRE |