Land Cruiser URJ200 URJ202 GRJ200 VDJ200 - 1VD-FTV ENGINE CONTROL

CHECK HARNESS AND CONNECTOR (THROTTLE POSITION SENSOR - ECM)

CHECK ECM TERMINAL VOLTAGE (VC TERMINAL)

REPLACE DIESEL THROTTLE BODY ASSEMBLY

REPAIR OR REPLACE HARNESS OR CONNECTOR

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED

DTC P0122 Throttle / Pedal Position Sensor / Switch "A" Circuit Low Input

DTC P0123 Throttle / Pedal Position Sensor / Switch "A" Circuit High Input

DTC P0222 Throttle / Pedal Position Sensor / Switch "B" Circuit Low Input

DTC P0223 Throttle / Pedal Position Sensor / Switch "B" Circuit High Input

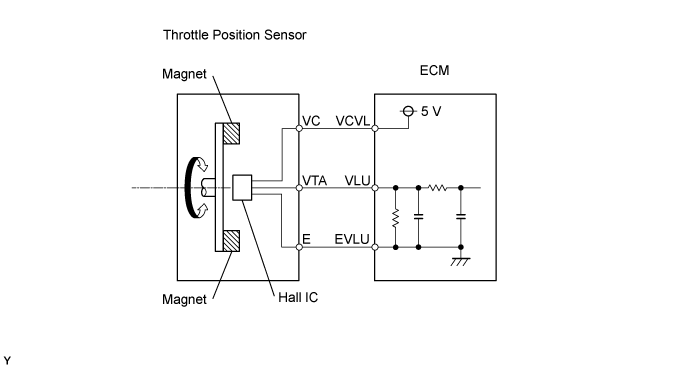

DESCRIPTION

The throttle position sensor is mounted on the diesel throttle body assembly and detects the opening angle of the throttle valve. This sensor is an electronic sensor and uses Hall-effect elements.

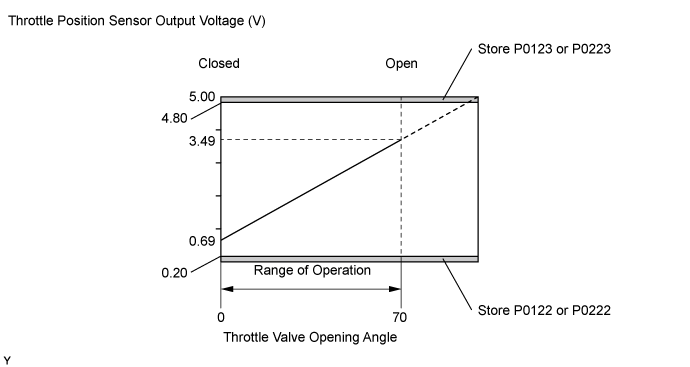

When the throttle valve is fully closed, a voltage of approximately 0.7 V is applied to terminal VLU of the ECM. The voltage applied to terminal VLU of the ECM increases in proportion to the opening angle of the throttle valve and becomes approximately 3.5 to 4.0 V when the throttle valve is fully opened.

The ECM determines the vehicle driving conditions from the signals input to its VLU terminal. The data is one of the pieces of information used for EGR control, etc.

| DTC Detection Drive Pattern | DTC Detection Condition | Trouble Area |

| Engine switch on (IG) for 3 seconds | Throttle position sensor output (VLU, VLU2) is below 0.2 V for 3 seconds. (1 trip detection logic) | Throttle position sensor Open or short in VLU, VLU2 circuit Open in VC circuit ECM |

| DTC Detection Drive Pattern | DTC Detection Condition | Trouble Area |

| Engine switch on (IG) for 3 seconds | Throttle position sensor output (VLU, VLU2) is higher than 4.8 V for 3 seconds. (1 trip detection logic) | Throttle position sensor Open in E2 circuit VC and VLU, VLU2 circuits are short-circuited ECM |

- HINT:

- If DTC P0122, P0123, P0222 and/or P0223 is stored, the following symptoms may appear:

MONITOR DESCRIPTION

When the output voltage of the throttle position sensor deviates from the normal operating range (between 0.2 V and 4.8 V) for more than 3 seconds, the ECM interprets this as a malfunction of the sensor circuit and illuminates the MIL.

WIRING DIAGRAM

INSPECTION PROCEDURE

- NOTICE:

- HINT:

- Read freeze frame data using the GTS. Freeze frame data records the engine condition when malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, and other data from the time the malfunction occurred.

| 1.CHECK HARNESS AND CONNECTOR (THROTTLE POSITION SENSOR - ECM) |

Disconnect the throttle position sensor connector.

Disconnect the ECM connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

for LHD Tester Connection Condition Specified Condition C83-1 (VC) - C45-110 (VCVL) Always Below 1 Ω C83-3 (VTA) - C45-64 (VLU) Always Below 1 Ω C83-2 (E2) - C45-87 (EVLU) Always Below 1 Ω C84-1 (VC) - C45-110 (VCVL) Always Below 1 Ω C84-3 (VTA2) - C45-65 (VLU2) Always Below 1 Ω C84-2 (E2) - C45-87 (EVLU) Always Below 1 Ω C83-1 (VC) or C45-110 (VCVL) - Body ground Always 10 kΩ or higher C83-3 (VTA) or C45-64 (VLU) - Body ground Always 10 kΩ or higher C84-1 (VC) or C45-110 (VCVL) - Body ground Always 10 kΩ or higher C84-3 (VTA2) or C45-65 (VLU2) - Body ground Always 10 kΩ or higher

- Standard Resistance:

for RHD Tester Connection Condition Specified Condition C83-1 (VC) - C46-110 (VCVL) Always Below 1 Ω C83-3 (VTA) - C46-64 (VLU) Always Below 1 Ω C83-2 (E2) - C46-87 (EVLU) Always Below 1 Ω C84-1 (VC) - C46-110 (VCVL) Always Below 1 Ω C84-3 (VTA2) - C46-65 (VLU2) Always Below 1 Ω C84-2 (E2) - C46-87 (EVLU) Always Below 1 Ω C83-1 (VC) or C46-110 (VCVL) - Body ground Always 10 kΩ or higher C83-3 (VTA) or C46-64 (VLU) - Body ground Always 10 kΩ or higher C84-1 (VC) or C46-110 (VCVL) - Body ground Always 10 kΩ or higher C84-3 (VTA2) or C46-65 (VLU2) - Body ground Always 10 kΩ or higher

Reconnect the throttle position sensor connector.

Reconnect the ECM connector.

|

| ||||

| OK | |

| 2.CHECK ECM TERMINAL VOLTAGE (VC TERMINAL) |

Disconnect the throttle position sensor connector.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

Tester Connection Switch Condition Specified Condition C83-1 (VC) - C83-2 (E2) Engine switch on (IG) 4.5 to 5.5 V C84-1 (VC) - C84-2 (E2) Engine switch on (IG) 4.5 to 5.5 V

| *A | for Bank 1 |

| *B | for Bank 2 |

| *a | Front view of wire harness connector (to Throttle Position Sensor) |

Reconnect the throttle position sensor connector.

|

| ||||

| OK | |

| 3.REPLACE DIESEL THROTTLE BODY ASSEMBLY |

When DTC P0122 or P0123 is output:

When DTC P0222 or P0223 is output:

| NEXT | |

| 4.READ VALUE USING GTS |

Connect the GTS to the DLC3.

Turn the engine switch on (IG) and turn the GTS on.

Clear the DTCs ().

Enter the following menus: Engine and ECT / Data List / Actual Throttle position, Actual Throttle position #2.

Check the movement of the throttle valve when idling the engine after starting it from engine switch on (IG).

- OK:

Condition GTS Display Engine switch on (IG) 95 to 105% Idling 5 to 15%

|

| ||||

| OK | ||

| ||

| 5.REPLACE ECM |

Replace the ECM ().

|

| ||||

| 6.REPAIR OR REPLACE HARNESS OR CONNECTOR |

Repair or replace the harness or connector.

| NEXT | |

| 7.CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED |

Connect the GTS to the DLC3.

Clear the DTCs ().

Turn the engine switch off.

Turn the engine switch on (IG) for 3 seconds.

Enter the following menus: Engine and ECT / Trouble Codes.

Confirm that the DTC is not output again.

| NEXT | ||

| ||