1. REMOVE OIL PRESSURE SENSOR

-

Using a 24 mm deep socket wrench, remove the oil pressure sensor.

2. REMOVE ENGINE COOLANT TEMPERATURE SENSOR

-

Remove the engine coolant temperature sensor and gasket.

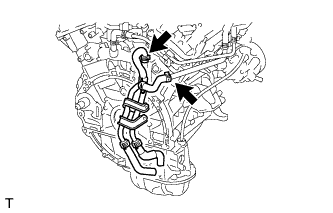

3. DISCONNECT NO. 1 WATER BY-PASS PIPE (for Automatic Transmission)

-

Disconnect the 2 water by-pass pipe hoses and remove the pipe.

4. DISCONNECT WATER HOSE SUB-ASSEMBLY (for Automatic Transmission)

-

Remove the 2 bolts and disconnect the water hose.

5. DISCONNECT WATER HOSE SUB-ASSEMBLY (for Manual Transmission)

-

Remove the 2 bolts and disconnect the water hose.

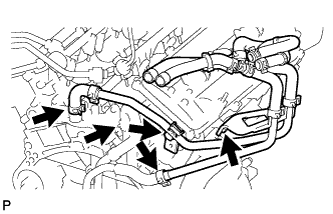

6. REMOVE FUEL DELIVERY PIPE SUB-ASSEMBLY

-

Disconnect the 6 fuel injector connectors.

-

Remove the 6 bolts and fuel delivery pipe together with the 6 fuel injectors.

NOTICE:

Be careful not to drop the injectors when removing the fuel delivery pipe.

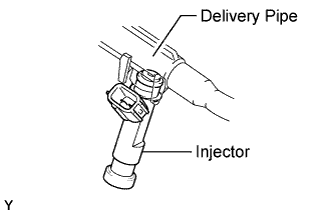

7. REMOVE FUEL INJECTOR

-

Pull the 6 fuel injectors from the fuel delivery pipe.

-

Remove the O-ring and injector vibration insulator from each fuel injector.

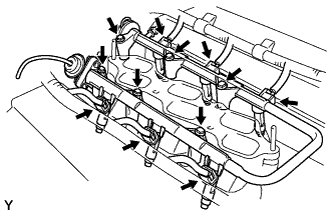

8. REMOVE INTAKE MANIFOLD

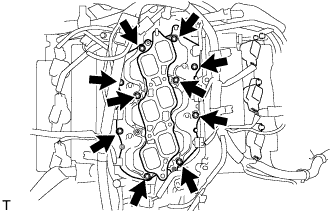

-

Remove the 10 bolts, intake manifold and 2 gaskets.

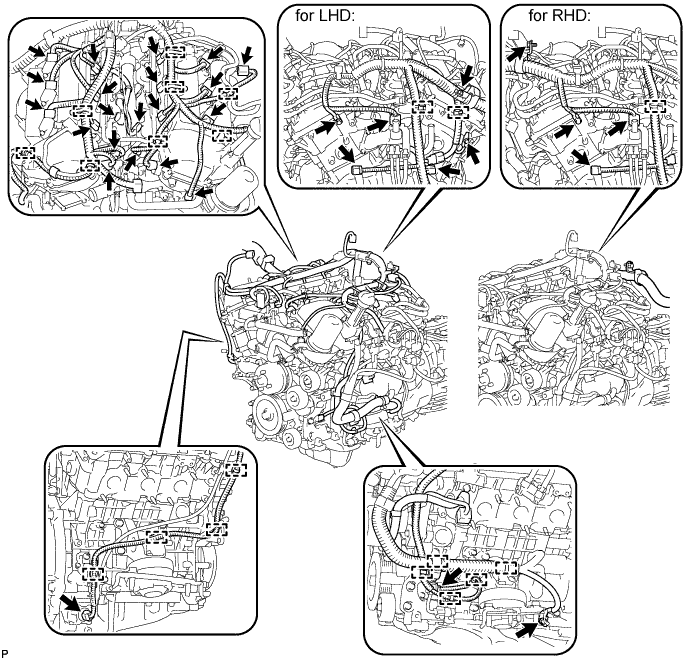

9. REMOVE ENGINE WIRE

10. REMOVE IGNITION COIL ASSEMBLY

-

Remove the 6 bolts and 6 ignition coils.

11. REMOVE V-RIBBED BELT TENSIONER ASSEMBLY

-

Remove the 5 bolts and V-ribbed belt tensioner.

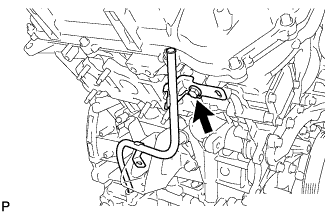

12. REMOVE ENGINE OIL LEVEL DIPSTICK GUIDE

-

Remove the bolt and dipstick guide.

-

Remove the O-ring from the dipstick guide.

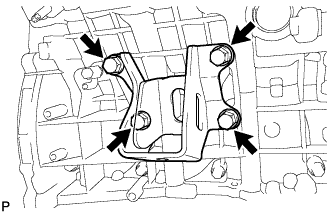

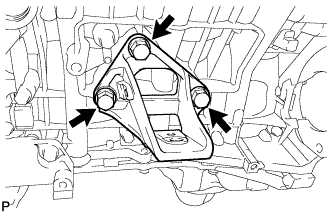

13. REMOVE FRONT NO. 1 ENGINE MOUNTING BRACKET RH

-

Remove the 4 bolts and front No. 1 engine mounting bracket RH.

14. REMOVE FRONT NO. 1 ENGINE MOUNTING BRACKET LH

-

Remove the 3 bolts and front No. 1 engine mounting bracket LH.

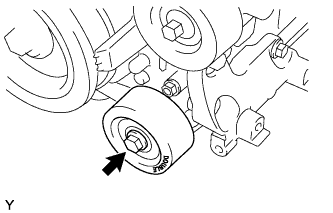

15. REMOVE NO. 1 IDLER PULLEY SUB-ASSEMBLY

-

Remove the bolt and No. 1 idler pulley.

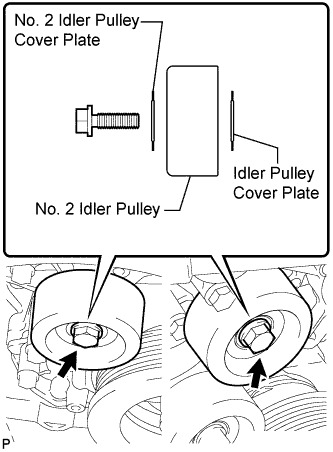

16. REMOVE NO. 2 IDLER PULLEY SUB-ASSEMBLY

-

w/ Pulley Cover Plate: Remove the 2 bolts, 2 No. 2 idler pulley cover plate, 2 idler pulley and 2 idler pulley cover plate.

-

w/o Pulley Cover Plate: Remove the 2 bolts and 2 No. 2 idler pulleys.

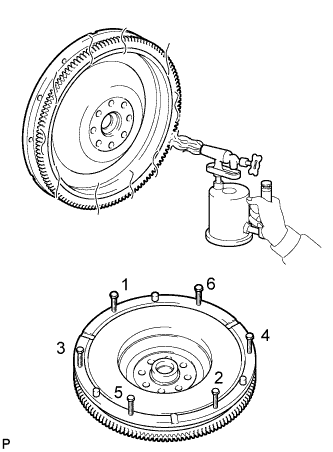

17. REMOVE FLYWHEEL RING GEAR (for Manual Transmission)

HINT:

If the flywheel ring gear is deformed or the gears are damaged, replace it.

CAUTION:

Wear protective gloves. Hot ares on the flywheel ring gear may injure your hands.

-

Using a torch, heat the ring gear evenly to approximately 200°C (392°F).

-

Temporarily install 6 bolts (8 mm x 1.25 pitch) with a length of 70 mm or more to the flywheel.

-

Uniformly tighten the 6 bolts in the order shown in the illustration.

-

Remove the ring gear from the flywheel.