Двигатель -- Проверка Без Снятия С Автомобиля |

| 1. INSPECT INJECTION TIMING |

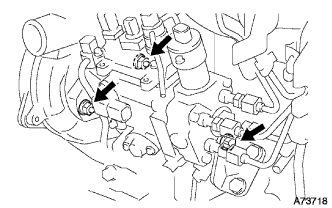

Using a mirror, check that the matchmarks of the injection pump flange and timing belt case are aligned.

Text in Illustration *1 Matchmark

|

| 2. ADJUST INJECTION TIMING |

Loosen the following nuts and bolts.

The bolt holding the injection pump to the injection pump stay.

The 2 nuts holding the injection pump to the timing belt case.

|

Align the matchmark by slightly tilting the injection pump.

Tighten the following nuts and bolts.

The 2 nuts holding the injection pump to the timing belt case.

- Момент затяжки:

- 21 N*m{209 kgf*cm, 15 ft.*lbf}

The bolt holding the injection pump to the injection pump stay.

- Момент затяжки:

- 26 N*m{265 kgf*cm, 19 ft.*lbf}

| 3. INSPECT ENGINE IDLE SPEED |

Warm up the engine.

When using the intelligent tester:

Connect the intelligent tester to the DLC3.

- Idle speed:

- 720 to 820 rpm

- ПРИМЕЧАНИЕ:

- Turn all the electrical systems and the A/C off.

- When checking the idling speed, the shift lever should be in neutral.

- УКАЗАНИЕ:

- Refer to the intelligent tester operator's manual for further details.

When not using an intelligent tester:

Using SST, connect the tachometer test probe to terminal 9 (TAC) of the DLC3.

- SST

- 09843-18030

- Standard idle speed:

- 720 to 820 rpm

Text in Illustration *a Front View of DLC3 - ПРИМЕЧАНИЕ:

- Turn all the electrical systems and the A/C off.

- When checking the idling speed, the shift lever should be in neutral.

- Confirm the terminal number before connecting them. Connecting the wrong terminal can be damage the engine.

|

| 4. INSPECT MAXIMUM ENGINE SPEED |

Start the engine.

Fully depress the accelerator pedal.

Check the maximum speed.

- Maximum engine speed:

- 4850 to 4950 rpm

| 5. INSPECT COMPRESSION |

- УКАЗАНИЕ:

- If there is a lack of power, excessive oil consumption or poor fuel economy is suspected. Measure the compression pressure.

Warm up and stop the engine.

Remove the glow plugs.

Disconnect the spill control valve connector.

Check the cylinder compression pressure.

Install SST (attachment) to the glow plug hole.

- SST

- 09992-00026(09992-00121)

- Момент затяжки:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

Connect SST (compression gauge) to SST (attachment).

- SST

- 09992-00026(09992-00121,09992-00211)

Fully open the throttle valve, and start the engine.

While cranking the engine, measure the compression pressure.

- ПРИМЕЧАНИЕ:

- This measurement must be done as quickly as possible.

- УКАЗАНИЕ:

- Always use a fully charged battery to obtain an engine speed of 250 rpm or more.

Repeat the steps above for each cylinder.

- Standard compression pressure:

- 3138 kPa (32.0 kgf/cm2, 455 psi) or higher

- Minimum pressure:

- 1961 kPa (20.0 kgf/cm2, 284 psi)

- Difference between each cylinder:

- 490 kPa (5.0 kgf/cm2, 71 psi) or less

- УКАЗАНИЕ:

- If adding oil helps the compression, the piston rings and/or cylinder bore may be worn or damaged.

- If the pressure stays low, a valve may be stuck or the seating may be improper, or there may be leakage past the gasket.

Remove SST.

Reinstall the glow plugs.

Reconnect the spill control valve connector.