Lexus IS250 IS220d GSE20 ALE20 - DIFFERENTIAL

REAR DIFFERENTIAL SIDE GEAR SHAFT OIL SEAL (for 2AD-FHV) - REPLACEMENT

| 1. REMOVE REAR WHEEL |

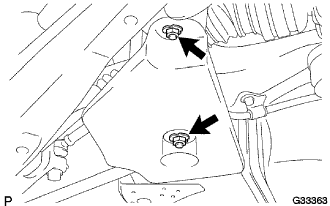

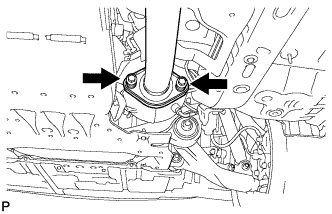

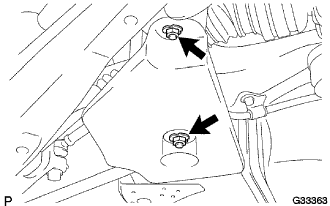

| 2. REMOVE NO. 2 DIFFERENTIAL SUPPORT PROTECTOR |

Remove the 2 nuts and No. 2 differential support protector from the suspension member brace.

| 3. DRAIN DIFFERENTIAL OIL |

Using a hexagon wrench (10 mm), remove the differential filler plug and gasket.

Using a hexagon wrench (10 mm), remove the differential drain plug and gasket, and drain the oil.

Using a hexagon wrench (10 mm), install the differential drain plug and a new gasket.

- Torque:

- 49 N*m{ 500 kgf*cm, 36 ft.*lbf}

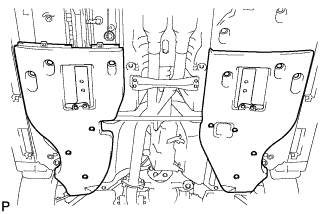

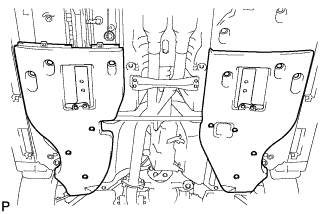

| 4. REMOVE FLOOR UNDER COVER |

Remove the No. 1 floor under cover and No. 2 floor under cover.

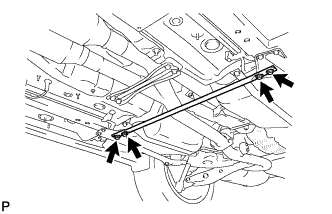

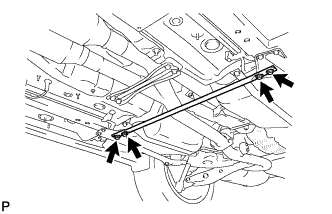

| 5. REMOVE REAR NO. 1 FLOOR PANEL BRACE |

Remove the 4 bolts and rear No. 1 floor panel brace.

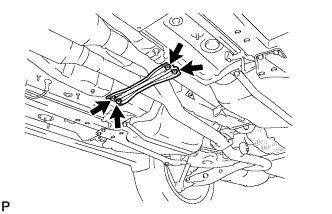

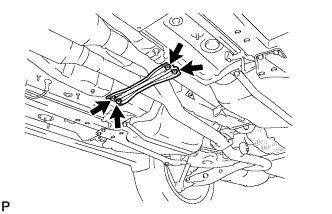

| 6. REMOVE FRONT CENTER FLOOR BRACE |

Remove the 4 bolts and front center floor brace.

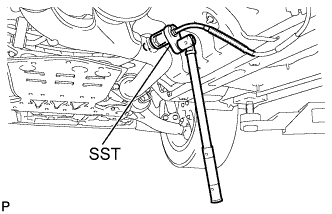

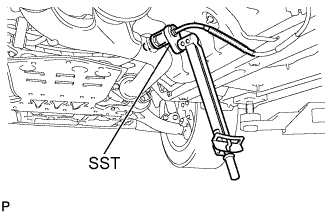

| 7. DISCONNECT AIR FUEL RATIO SENSOR |

Using SST, remove the air fuel ratio sensor.

- SST

- 09224-00010

| 8. REMOVE FRONT EXHAUST PIPE ASSEMBLY |

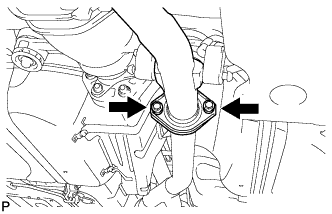

Remove the 2 bolts and 2 compression springs.

Remove the 2 bolts, 2 compression springs, front exhaust pipe assembly and 2 gaskets.

| 9. REMOVE TAIL EXHAUST PIPE ASSEMBLY |

Remove the tail exhaust pipe assembly.

| 10. REMOVE PROPELLER SHAFT WITH CENTER BEARING ASSEMBLY |

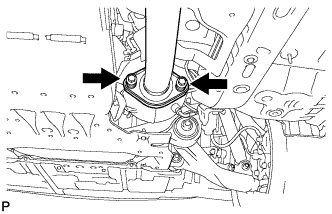

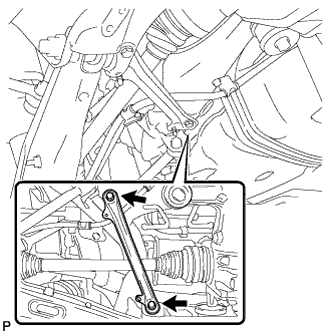

| 11. REMOVE REAR SUSPENSION MEMBER BRACE LH |

Remove the 2 bolts and rear suspension member brace LH.

| 12. SEPARATE NO. 3 PARKING BRAKE CABLE ASSEMBLY |

Remove the 3 bolts and disengage the 2 clamps and No. 3 parking brake cable assembly LH.

Separate the No. 3 parking brake cable assembly LH from the parking brake equalizer.

| 13. SEPARATE REAR STABILIZER LINK ASSEMBLY LH |

Remove the bolt and nut, and separate the load sensing valve sensor bracket and stabilizer link assembly.

| 14. REMOVE REAR AXLE SHAFT NUT |

Using SST and a hammer, release the staked part of the axle shaft nut.

- SST

- 09930-00010

- NOTICE:

- Release the staked part of the nut completely, otherwise the threads of the drive shaft may be damaged.

While depressing the brake pedal, remove the axle shaft nut.

| 15. SEPARATE REAR DISC BRAKE CALIPER ASSEMBLY |

Remove the 2 bolts, and disconnect the rear disc brake caliper assembly.

- NOTICE:

- Use wire or equivalent to prevent the brake caliper from hanging down by the flexible hose.

Remove the No.1 caliper plates from the brake caliper.

| 16. SEPARATE REAR SPEED SENSOR |

Remove the 2 bolts, and separate the speed sensor from the axle carrier.

- NOTICE:

| 17. SEPARATE NO. 2 REAR UPPER CONTROL ARM ASSEMBLY |

Remove the nut from the No. 2 upper control arm assembly rear.

Using SST, separate the No. 2 upper control arm assembly rear from the rear axle carrier sub-assembly.

- SST

- 09628-00011

- NOTICE:

| 18. SEPARATE NO. 1 REAR UPPER CONTROL ARM ASSEMBLY |

Jack up the rear axle assembly so that the bolt on the No. 1 upper control arm assembly rear can be removed.

- HINT:

- Place a wooden block between the jack and rear axle carrier to prevent damage to the rear axle carrier.

Remove the bolt, washer and nut, and separate the No. 1 upper control arm assembly rear from the rear axle carrier sub-assembly.

| 19. SEPARATE NO. 1 REAR SUSPENSION ARM ASSEMBLY |

Remove the bolt and nut, and separate the No. 1 rear suspension arm assembly from the rear axle carrier sub-assembly.

- NOTICE:

- Turn the bolt while holding the nut.

| 20. SEPARATE NO. 2 REAR SUSPENSION ARM ASSEMBLY |

Remove the bolt and nut, and separate the No. 2 rear suspension arm assembly from the rear axle carrier sub-assembly.

- NOTICE:

- Turn the bolt while holding the nut.

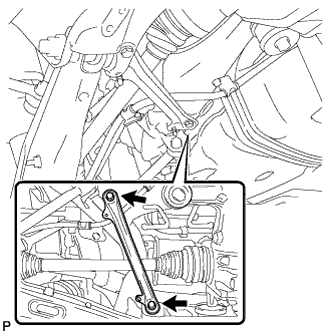

| 21. SEPARATE TOE CONTROL LINK SUB-ASSEMBLY |

Remove the nut from the toe control link sub-assembly.

Using SST, separate the toe control link sub-assembly from the rear axle carrier sub-assembly.

- SST

- 09628-00011

- NOTICE:

| 22. REMOVE REAR AXLE ASSEMBLY |

Using a plastic hammer, separate the drive shaft from the rear axle assembly.

- NOTICE:

| 23. REMOVE REAR DRIVE SHAFT ASSEMBLY |

Using SST, remove the rear drive shaft assembly.

- SST

- 09520-01010

09520-24010(09520-32040)

- NOTICE:

| 24. REMOVE REAR DIFFERENTIAL SIDE GEAR SHAFT OIL SEAL |

Using SST, remove the oil seal.

- SST

- 09308-10010

| 25. INSTALL REAR DIFFERENTIAL SIDE GEAR SHAFT OIL SEAL |

Using SST and a hammer, install a new oil seal.

- SST

- 09223-15030

09950-70010(09951-07200)

- Oil seal installation depth:

- -0.5 to 0.5 mm (-0.020 to 0.020 in.)

Apply MP grease to the oil seal lip.

| 26. INSTALL REAR DRIVE SHAFT ASSEMBLY |

Coat the spline of the inboard joint shaft assembly with gear oil.

Set the shaft snap ring with the opening side facing down.

Align the shaft splines and install the drive shaft assembly with a brass bar and hammer.

- NOTICE:

- HINT:

- It is possible to determine if the inboard joint shaft is properly engaged (the shaft is in contact with the pinion shaft, and the snap ring is engaged in the pinion gear) based on the sound or feeling when the shaft is driven in.

Install the rear drive shaft assembly to the rear axle carrier.

- NOTICE:

- Be careful not to damage the drive shaft boot.

| 27. INSTALL REAR AXLE ASSEMBLY |

Install the rear drive shaft assembly and rear axle assembly.

| 28. INSTALL NO. 2 REAR UPPER CONTROL ARM ASSEMBLY |

Install the No. 2 rear upper control arm assembly to the rear axle carrier sub-assembly with a new nut.

- Torque:

- 70 N*m{ 714 kgf*cm, 52 ft.*lbf}

| 29. TEMPORARILY TIGHTEN NO. 1 REAR UPPER CONTROL ARM ASSEMBLY |

Temporarily tighten the No. 1 rear upper control arm assembly to the rear axle carrier sub-assembly with the bolt, washer and nut.

- HINT:

- Install the bolt from the rear side of the vehicle and lightly tighten the bolt.

| 30. TEMPORARILY TIGHTEN NO. 1 REAR SUSPENSION ARM ASSEMBLY |

Temporarily tighten the No. 1 rear suspension arm assembly to the rear axle carrier sub-assembly with the bolt and nut.

- HINT:

- Install the bolt from the rear side of the vehicle and lightly tighten the bolt.

| 31. TEMPORARILY TIGHTEN NO. 2 REAR SUSPENSION ARM ASSEMBLY |

Temporarily tighten the No. 2 rear suspension arm assembly to the rear axle carrier sub-assembly with the bolt and nut.

- HINT:

- Install the bolt from the rear side of the vehicle and lightly tighten the bolt.

| 32. INSTALL TOE CONTROL LINK SUB-ASSEMBLY |

Install the toe control link sub-assembly to the rear axle carrier sub-assembly with a new nut.

- Torque:

- 70 N*m{ 714 kgf*cm, 52 ft.*lbf}

| 33. INSTALL REAR STABILIZER LINK ASSEMBLY LH |

Install the stabilizer link assembly and the load sensing valve sensor bracket to the No. 2 rear suspension arm assembly with the bolt and nut.

- Torque:

- 27 N*m{ 275 kgf*cm, 20 ft.*lbf}

| 34. INSTALL REAR SPEED SENSOR |

Install the speed sensor to the rear axle carrier with the 2 bolts.

- Torque:

- Bolt (A):

- 8.5 N*m{ 87 kgf*cm, 75 in.*lbf}

- Bolt (B):

- 6.0 N*m{ 61 kgf*cm, 53 in.*lbf}

- NOTICE:

| 35. INSTALL REAR DISC BRAKE CALIPER ASSEMBLY |

Install the rear disc brake caliper assembly and No. 1 caliper plates with the 2 bolts.

- Torque:

- 54 N*m{ 551 kgf*cm, 40 ft.*lbf}

- NOTICE:

| 36. INSTALL REAR AXLE SHAFT NUT |

Using a chisel and a hammer, stake the axle shaft nut.

| 37. STABILIZE SUSPENSION |

Install the rear wheels.

Lower the vehicle to the ground. Bounce the vehicle up and down at the corners to stabilize the rear suspension.

Remove the rear wheels.

Jack up the axle carrier, with a wooden block placed between the jack and axle carrier, to apply a load to the suspension so that the rear drive shaft assembly becomes level.

| 38. FULLY TIGHTEN NO. 1 REAR UPPER CONTROL ARM ASSEMBLY |

Fully tighten the No. 1 rear upper control arm assembly with the nut.

- Torque:

- 161 N*m{ 1,642 kgf*cm, 119 ft.*lbf}

| 39. FULLY TIGHTEN NO. 1 REAR SUSPENSION ARM ASSEMBLY |

Fully tighten the No. 1 rear suspension arm assembly with the bolt and nut.

- Torque:

- 95 N*m{ 969 kgf*cm, 70 ft.*lbf}

- NOTICE:

- Turn the bolt while holding the nut.

| 40. FULLY TIGHTEN NO. 2 REAR SUSPENSION ARM ASSEMBLY |

Fully tighten the No. 2 rear suspension arm assembly with the bolt and nut.

- Torque:

- 161 N*m{ 1,642 kgf*cm, 119 ft.*lbf}

- NOTICE:

- Turn the bolt while holding the nut.

| 41. INSTALL NO. 3 PARKING BRAKE CABLE ASSEMBLY |

Connect the No. 3 parking brake cable assembly to the parking brake equalizer.

Install the No. 3 parking brake cable assembly to the body with the 3 bolts and 2 clamps.

- Torque:

- Bolt (A):

- 6.0 N*m{ 61 kgf*cm, 53 in.*lbf}

- Bolt (B):

- 19 N*m{ 194 kgf*cm, 14 ft.*lbf}

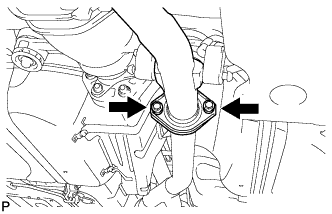

| 42. INSTALL REAR SUSPENSION MEMBER BRACE LH |

Install the rear suspension member brace LH with the 2 bolts.

- Torque:

- 50 N*m{ 510 kgf*cm, 37 ft.*lbf}

| 43. INSTALL PROPELLER SHAFT WITH CENTER BEARING ASSEMBLY |

| 44. INSTALL TAIL EXHAUST PIPE ASSEMBLY |

Install the tail exhaust pipe assembly with the 4 exhaust pipe supports.

| 45. INSTALL FRONT EXHAUST PIPE ASSEMBLY |

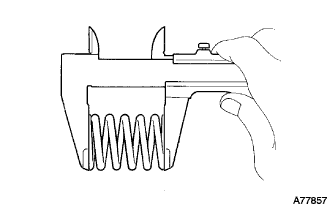

Using vernier calipers, measure the free length of the compression springs.

- Minimum length:

- 38.5 mm (1.516 in.)

If the free length is less than the minimum, replace the compression spring.

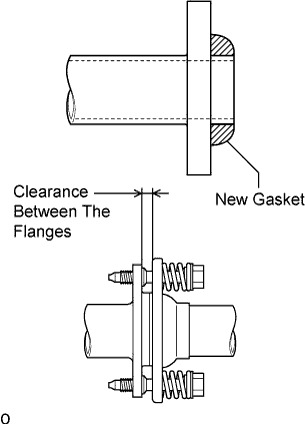

Fully insert 2 new gaskets to the exhaust manifold converter and front exhaust pipe assembly by hand.

- NOTICE:

- HINT:

- Using a plastic hammer, uniformly strike the gasket so that the gasket and front exhaust pipe are properly fit.

Install the front exhaust pipe assembly.

Install the 2 bolts and 2 compression springs.

- Torque:

- 43 N*m{ 439 kgf*cm, 32 ft.*lbf}

- NOTICE:

- After installation, check that the clearance is almost the same at any point between the flanges of the tail exhaust pipe assembly and front exhaust pipe assembly.

Install the 2 bolts and 2 compression springs.

- Torque:

- 43 N*m{ 439 kgf*cm, 32 ft.*lbf}

- NOTICE:

- After installation, check that the clearance is almost the same at any point between the flanges of the exhaust manifold converter and front exhaust pipe assembly.

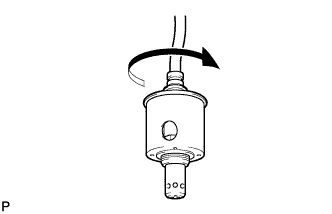

| 46. INSTALL AIR FUEL RATIO SENSOR |

Before installing the air fuel ratio sensor, twist the sensor wire counterclockwise 4 turns.

Using SST, install the air fuel ratio sensor to the front exhaust pipe.

- SST

- 09224-00010

- Torque:

- 44 N*m{ 449 kgf*cm, 33 ft.*lbf}

| 47. INSTALL FRONT CENTER FLOOR BRACE |

Install the front center floor brace with the 4 bolts.

- Torque:

- 7.4 N*m{ 75 kgf*cm, 65 in.*lbf}

| 48. INSTALL REAR NO. 1 FLOOR PANEL BRACE |

Install the rear No. 1 floor panel brace with the 4 bolts.

- Torque:

- 19 N*m{ 195 kgf*cm, 14 ft.*lbf}

| 49. INSTALL FLOOR UNDER COVER |

Install the No. 1 floor under cover and No. 2 floor under cover.

| 50. ADD DIFFERENTIAL OIL |

Using a hexagon wrench (10 mm), remove the differential filler plug and gasket.

Add oil.

- Capacity:

- 1.30 to 1.40 litter (1.37 to 1.48 US qts, 1.14 to 1.23 lmp. qts)

- Oil grade:

- Toyota genuine differential synthetic gear oil API GL-5 SAE 75W-85 or equivalent

- Torque:

- 49 N*m{ 500 kgf*cm, 36 ft.*lbf}

- NOTICE:

- After replacing the oil, drive the vehicle and recheck the oil level.

Check the oil level.

Using a hexagon wrench (10 mm), install the differential filler plug with a new gasket.

| 51. INSPECT DIFFERENTIAL OIL |

Stop the vehicle on a level place.

Using a hexagon wrench (10 mm), remove the differential filler plug and gasket.

Check that the oil surface is within 5 mm (0.20 in.) of the lowest position of the inner surface of the differential filler plug opening.

- NOTICE:

Check for oil leakage if the oil level is low.

Using a hexagon wrench (10 mm), install the differential filler plug and a new gasket.

- Torque:

- 49 N*m{ 500 kgf*cm, 36 ft.*lbf}

| 52. INSTALL NO. 2 DIFFERENTIAL SUPPORT PROTECTOR |

Install the No. 2 differential support protector to the rear suspension member brace with the 2 nuts.

- Torque:

- 5.4 N*m{ 55 kgf*cm, 48 in.*lbf}

| 53. INSTALL REAR WHEEL |

- Torque:

- 103 N*m{ 1,050 kgf*cm, 76 ft.*lbf}

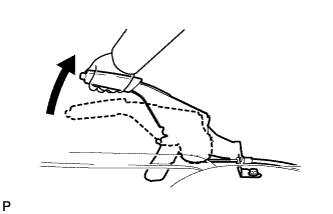

| 54. INSPECT PARKING BRAKE LEVER TRAVEL |

Pull firmly on the parking brake lever.

Release the parking brake lock, and return the parking brake lever to its off position.

Slowly pull the parking brake lever all the way up, and count the number of clicks.

- Parking brake lever travel:

- 4 to 6 notches at 200 N (20 kgf, 45 lbf)

| 55. ADJUST PARKING BRAKE LEVER TRAVEL |

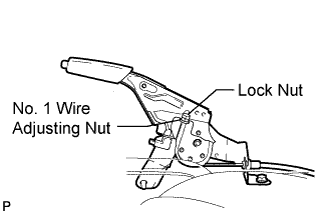

Depress the parking brake lever. Hold the No. 1 wire adjusting nut using a wrench and loosen the lock nut.

Release the parking brake lever.

Turn the No. 1 wire adjusting nut until the parking brake lever travel meets the above specification.

Hold the No. 1 wire adjusting nut using a wrench or equivalent tool and tighten the lock nut.

- Torque:

- 6.0 N*m{ 61 kgf*cm, 53 in.*lbf}

Count the number of clicks after depressing and releasing the parking brake lever 3 or 4 times.

Check whether the parking brake drags or not.

When operating the parking brake lever, check that the parking brake indicator light comes on.

| 56. CHECK FOR EXHAUST GAS LEAKAGE |

| 57. INSPECT AND ADJUST REAR WHEEL ALIGNMENT |

| 58. CHECK ABS SPEED SENSOR SIGNAL |

(with VDIM: )

(without VDIM: )