Lexus IS250 IS220d GSE20 ALE20 - PARKING BRAKE

PARKING BRAKE LEVER - INSTALLATION

| 1. INSTALL PARKING BRAKE LEVER SUB-ASSEMBLY |

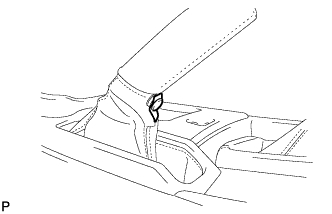

Pass the No. 1 parking brake cable assembly through the parking brake lever and hold the cable with the clip.

Pass the parking brake cable through the lever guide. Temporarily tighten the No. 1 wire adjusting nut and lock nut.

- HINT:

- Fully tighten the No. 1 wire adjusting nut and lock nut when adjusting the parking brake lever free play.

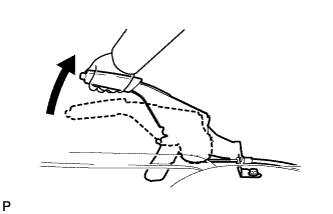

Fully bend the parking brake lever claw.

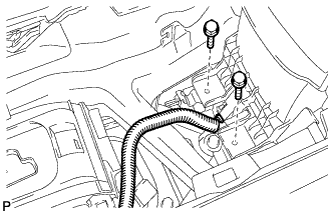

Install the No. 1 parking brake cable assembly through the floor hole.

Install the No. 1 parking brake cable assembly with the 2 bolts.

- Torque:

- 8.0 N*m{ 82 kgf*cm, 71 in.*lbf}

Install the parking brake lever with the 2 bolts.

- Torque:

- 39 N*m{ 400 kgf*cm, 29 ft.*lbf}

Connect the parking brake switch connector.

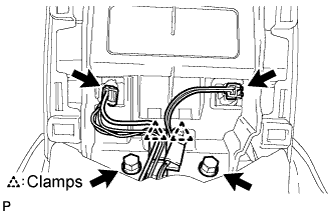

Install the parking brake equalizer to the No. 1 parking brake cable assembly.

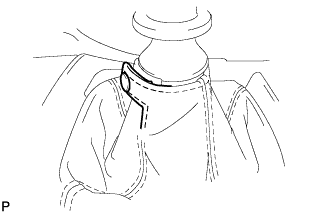

Slide the rubber boot back as shown in the illustration.

Connect the 2 No. 2 parking brake cable assemblies to the parking brake equalizer.

Install the parking brake No. 2 and No. 3 cable assemblies with the 2 bolts.

- Torque:

- 6.0 N*m{ 61 kgf*cm, 53 in.*lbf}

Using needle-nose pliers, install the parking brake return with damper spring.

| 2. INSTALL PROPELLER SHAFT WITH CENTER BEARING ASSEMBLY |

Remove the SST from the transmission.

- SST

- 09325-40010

Insert the yoke of the intermediate shaft into the transmission.

- HINT:

- Be careful not to damage the oil seal.

Install the 2 center support bearing washers and center support bearing. (for automatic transmission)

Install the 2 center support bearing washers, center support bearing and 2 center support bearing dampers. (for manual transmission)

Temporarily tighten the 2 bolts.

Align the matchmarks on the propeller shaft flange and differential companion flange, and connect the shaft with the 4 bolts, washers and nuts.

- Torque:

- 74 N*m{ 750 kgf*cm, 54 ft.*lbf}

Adjust the dimension between the edge surface of the center support bearing and the edge surface of the cushion to 11.5 to 13.5 mm (0.4528 to 0.5315 in.) as shown in illustration.

Check that the center line of the bracket is perpendicular to the shaft axial direction.

Tighten the 2 bolts.

- Torque:

- 49 N*m{ 500 kgf*cm, 36 ft.*lbf}

| 3. INSPECT AND ADJUST NO. 2 AND NO. 3 JOINT ANGLE |

Stabilize the propeller shaft and differential.

Turn the propeller shaft several times by hand to stabilize the center support bearing.

Check both the No. 2 and No. 3 joint angles.

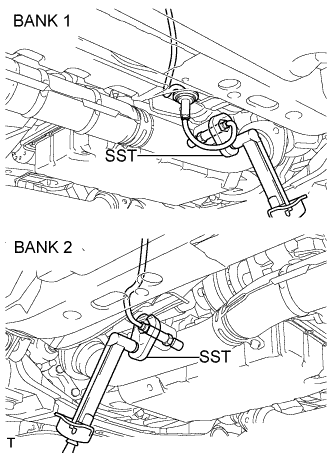

Using SST, measure the installation angle of the intermediate shaft and propeller shaft.

- SST

- 09370-50010

- HINT:

- The SST should be set directly on the bottom of the shaft.

Using SST, measure the installation angle of the differential.

- SST

- 09370-50010

- HINT:

- Measure the installation angle by placing the SST in the positions shown in the illustration.

Calculate the No. 2 joint angle.

- No. 2 joint angle:

- A - B = -1°13' to -0°13'

- A:

- Intermediate shaft installation angle

- B:

- Propeller shaft installation angle

Calculate the No. 3 joint angle.

- No. 3 joint angle:

- B - C = 1°30' to 2°30'

- B:

- Propeller shaft installation angle

- C:

- Differential installation angle

- HINT:

- If the measured angle is not within the specified range, adjust it with the center support bearing washers.

Adjust the No. 2 joint angle .

Select the center support bearing washers for adjustment.

| Thickness mm (in) |

| 2 (0.078) |

| 4.5 (0.1772) |

| 6.5 (0.2559) |

| 9.0 (0.3543) |

| 11 (0.4331) |

| Thickness mm (in) |

| 2 (0.078) |

| 4.5 (0.1772) |

| 6.5 (0.2559) |

| 9.0 (0.3543) |

| 11 (0.4331) |

| 13.5 (0.5315) |

- NOTICE:

- The 2 washers should be the same thickness.

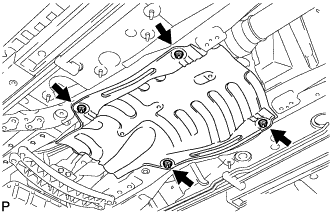

| 4. INSTALL OUTSIDE AIR GUIDE PLATE |

Install the air guide plate outside RH with the 4 nuts.

- Torque:

- 5.4 N*m{ 55 kgf*cm, 48 in.*lbf}

| 5. INSTALL NO. 1 FRONT FLOOR HEAT INSULATOR |

Install the No. 1 heat insulator with the 4 nuts.

- Torque:

- 5.4 N*m{ 55 kgf*cm, 48 in.*lbf}

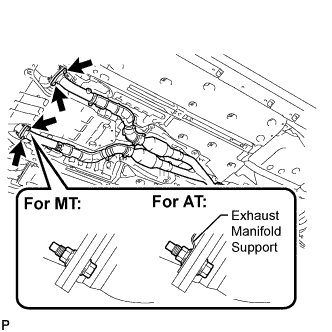

| 6. INSTALL FRONT EXHAUST PIPE ASSEMBLY |

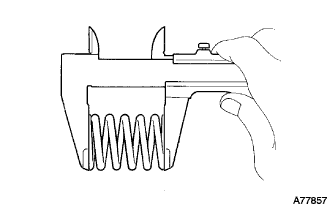

Using a vernier caliper, measure the free length of the compression springs.

- Minimum length:

- 38.5 mm (1.516 in.)

If the free length is less than the minimum, replace the compression spring.

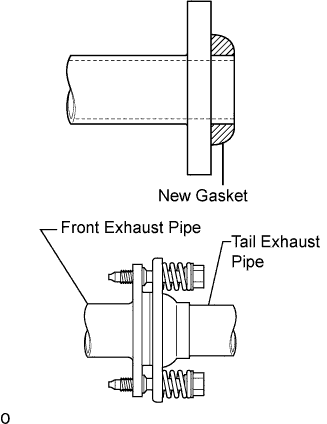

Install a new gasket to the rear end of the front exhaust pipe.

- NOTICE:

- HINT:

- Using a plastic hammer, uniformly strike the gasket so that the gasket and front exhaust pipe are properly fit.

Install 3 new gaskets and front exhaust pipe assembly.

- CAUTION:

- Do not reuse the gaskets.

Install the 2 bolts and 2 compression springs.

- Torque:

- 43 N*m{ 438 kgf*cm, 32 ft.*lbf}

Install 4 new nuts and 4 bolts.

- Torque:

- 62 N*m{ 632 kgf*cm, 46 ft.*lbf}

- NOTICE:

- Do not reuse the nuts.

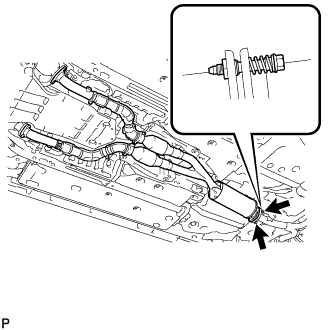

| 7. INSTALL OXYGEN SENSOR |

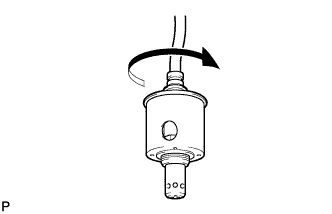

Before installing the heated oxygen sensors, twist the sensor wires counterclockwise 4 turns.

Using the SST, install the heated oxygen sensors to the front exhaust pipe.

- SST

- 09224-00010

- Torque:

- 44 N*m{ 449 kgf*cm, 33 ft.*lbf}

After installing the sensors, check that the sensor wires are not twisted.

If the sensor wires are twisted, reinstall them.

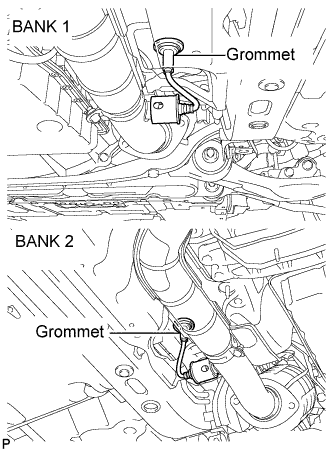

Install the grommets of the heated oxygen sensors.

| 8. INSTALL FRONT CENTER FLOOR BRACE |

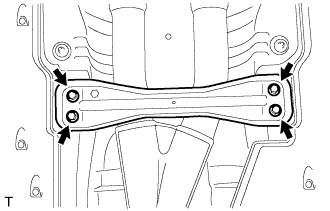

Install the front center floor brace with the 4 bolts.

- Torque:

- 7.4 N*m{ 75 kgf*cm, 65 in.*lbf}

| 9. INSTALL NO. 1 REAR FLOOR PANEL BRACE |

Install the rear No. 1 floor panel brace with the 4 bolts.

- Torque:

- 19 N*m{ 194 kgf*cm, 14 ft.*lbf}

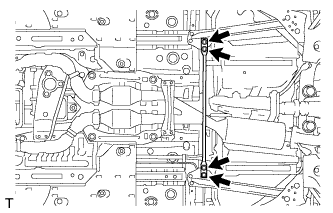

| 10. INSTALL FRONT FLOOR REAR UPPER SUB PANEL SUB-ASSEMBLY |

Install the front floor rear upper sub panel with the 4 bolts.

- Torque:

- 18 N*m{ 184 kgf*cm, 13 ft.*lbf}

Engage the 6 clamps.

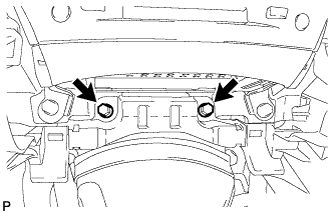

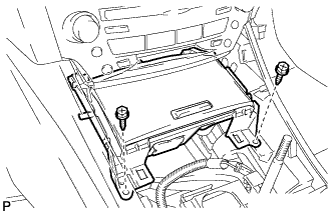

| 11. INSTALL CENTER AIRBAG SENSOR ASSEMBLY |

Check that the engine switch is off.

Check that the battery negative (-) terminal is disconnected.

- NOTICE:

- After disconnecting the negative battery terminal, wait for at least 90 seconds before starting the operation.

Install the center airbag sensor assembly with the nut and 2 bolts.

- Torque:

- 17.5 N*m{ 179 kgf*cm, 13 ft.*lbf}

- NOTICE:

Check that there is no looseness in the installation parts of the center airbag sensor assembly.

Connect the holder (with connectors).

Check that the water-proof sheet is properly set.

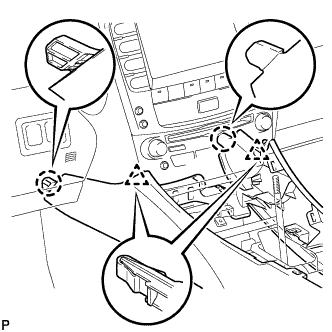

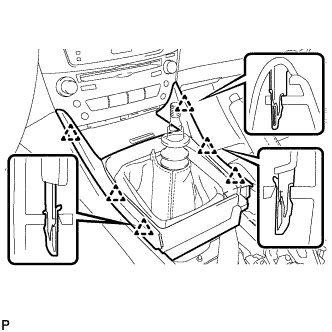

| 12. INSTALL CONSOLE BOX |

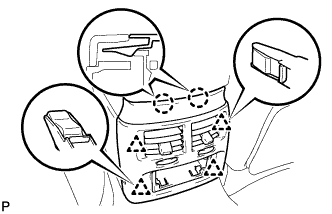

Engage the 2 claws and 2 clips.

Install the 2 bolts <C-.

Install the 2 bolts <C-.

Connect the connector.

Connect the connectors.

Engage the 2 clamps.

Install the 2 bolts <C-.

| 13. INSTALL CONSOLE BOX REGISTER ASSEMBLY |

Engage the 2 claws and 4 clips, and then install the console box register assembly.

Install the rear ash receptacle assembly.

| 14. INSTALL FRONT ASH RECEPTACLE SUB-ASSEMBLY |

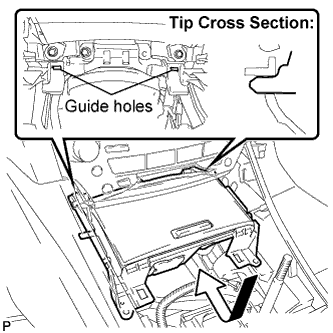

Connect the connectors.

Insert the protruding parts of the front ash receptacle sub-assembly into the 2 guide holes as shown in the illustration.

Install the front ash receptacle sub-assembly with the 2 screws <F-.

| 15. INSTALL FRONT CONSOLE PANEL SUB-ASSEMBLY |

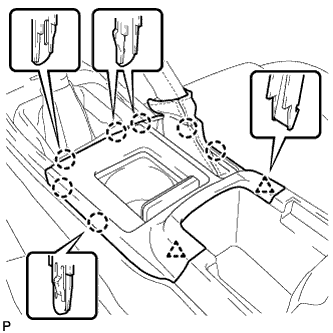

Engage the 6 clips.

Close the snap.

| 16. INSTALL REAR CONSOLE PANEL SUB-ASSEMBLY |

Engage the 7 claws and 2 clips.

Close the snap.

| 17. INSTALL SHIFT LEVER KNOB SUB-ASSEMBLY |

Turn the shift knob clockwise and install the shift lever knob sub-assembly.

| 18. INSTALL FRONT DOOR OPENING TRIM COVER LH |

Engage the 4 claws and install the front door opening trim cover LH.

| 19. INSTALL CENTER PILLAR GARNISH LOWER LH |

Engage the 5 clips and 3 claws, and install the lower center pillar garnish LH.

| 20. INSTALL REAR DOOR SCUFF PLATE LH |

Engage the 2 clips.

Engage the 5 claws and install the rear door scuff plate LH.

| 21. INSTALL FRONT DOOR SCUFF PLATE LH (w/o Illumination) |

Engage the 4 clips.

Engage the 7 claws, and install the front door scuff plate LH.

| 22. INSTALL FRONT DOOR SCUFF PLATE LH (w/ Illumination) |

Connect the connector.

Engage the 4 clips.

Engage the 7 claws, and install the front door scuff plate LH.

| 23. INSTALL FRONT SEAT OUTER BELT ASSEMBLY |

- HINT:

- .

| 24. INSTALL REAR SEAT CUSHION ASSEMBLY |

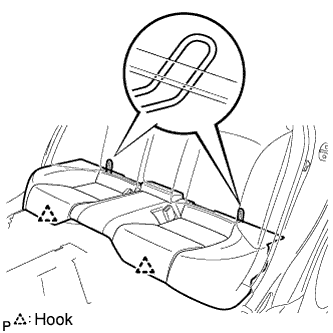

Attach the 2 rear hooks of the seat cushion to the seatback.

Attach the 2 front hooks of the seat cushion to the vehicle body.

Confirm that the seat cushion is firmly installed.

- NOTICE:

- When installing the seat cushion, make sure the seat belt buckle is not under the seat cushion.

| 25. INSTALL FRONT SEAT ASSEMBLY (for Power Seat) |

- HINT:

| 26. INSTALL FRONT SEAT ASSEMBLY (for Manual Seat) |

- HINT:

| 27. INSPECT PARKING BRAKE LEVER TRAVEL |

Pull firmly on the parking brake lever.

Release the parking brake lock, and return the parking brake lever to its off position.

Slowly pull the parking brake lever all the way up, and count the number of clicks.

- Parking brake lever travel:

- 4 to 6 notches at 200 N (20 kgf, 45 lbf)

| 28. ADJUST PARKING BRAKE LEVER TRAVEL |

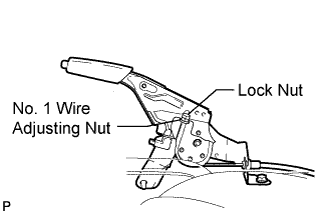

Depress the parking brake lever. Hold the No. 1 wire adjusting nut using a wrench and loosen the lock nut.

Release the parking brake lever.

Turn the No. 1 wire adjusting nut until the parking brake lever travel meets the above specification.

Hold the No. 1 wire adjusting nut using a wrench or equivalent tool and tighten the lock nut.

- Torque:

- 6.0 N*m{ 61 kgf*cm, 53 in.*lbf}

Count the number of clicks after depressing and releasing the parking brake lever 3 or 4 times.

Check whether the parking brake drags or not.

When operating the parking brake lever, check that the parking brake indicator light comes on.

| 29. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

- Torque:

- 5.4 N*m{ 55 kgf*cm, 48 in.*lbf}

| 30. PERFORM INITIALIZATION |

- HINT:

| 31. INSPECT SRS WARNING LIGHT |

- HINT:

- .