DTC P0016 Crankshaft Position - Camshaft Position Correlation (Bank 1 Sensor A)

Description

The ECM optimizes the valve timing by using the VVT (Variable Valve Timing) system to control the intake camshaft. The VVT system includes the ECM, the camshaft timing oil control valve assembly and the camshaft timing gear assembly. The ECM sends a target duty-cycle control signal to the camshaft timing oil control valve assembly.

This control signal regulates the oil pressure supplied to the camshaft timing gear assembly. The camshaft timing gear assembly can advance or retard the intake camshaft.

| DTC No. | Detection Condition | Trouble Area |

| P0016 | Deviation in crankshaft position sensor signal and camshaft position sensor signal (2 trip detection logic). |

|

Monitor description

To monitor the correlation of the intake camshaft position and crankshaft position, the ECM checks the VVT learning value while the engine is idling. The VVT learning value is calibrated based on the camshaft position and crankshaft position. The intake valve timing is set to the most retarded angle while the engine is idling. If the VVT learning value is out of specified range in consecutive driving cycles, the ECM illuminates the MIL and sets the DTC P0016.

This DTC indicates that the intake camshaft has been installed toward the crankshaft at an incorrect angle, caused by factors such as the timing chain having jumped a tooth.

This monitor begins to run after the engine has idled for 5 minutes.

Monitor strategy

| Required Sensors/Components (Main) | Camshaft timing gear assembly |

| Required Sensors/Components (Related) | Camshaft position sensor Crankshaft position sensor |

| Frequency of Operation | Continuous |

Typical enabling conditions

| Engine speed | 900 to 1100 rpm |

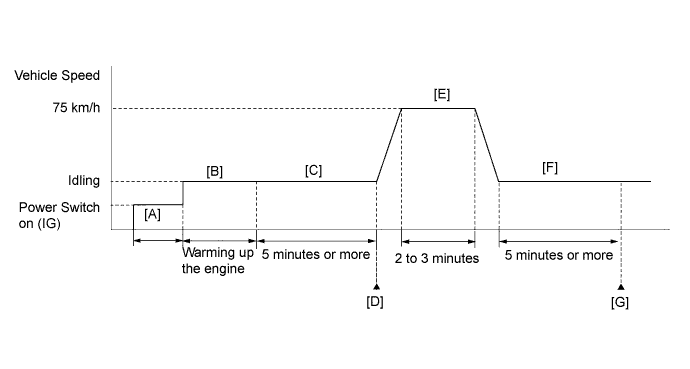

Confirmation driving pattern

- Connect the intelligent tester to the DLC3.

- Turn the power switch on (IG) and turn the tester on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC operation).

- Turn the power switch off and wait for 30 seconds.

- Turn the power switch on (IG) and turn the tester on [A].

- Put the engine in inspection mode (maintenance mode) .

- Start the engine and warm it up until the engine coolant temperature reaches 75°C (167°F) or higher [B].

- Idle the engine for 5 minutes or more [C].

- Enter the following menus: Powertrain / Engine and ECT / DTC / Pending.

- Read the pending DTC [D].

HINT:

- If a pending DTC is output, the system is malfunctioning.

- If a pending DTC is not output, perform the following procedure.

- Enter the following menus: Powertrain / Engine and ECT / Utility / All Readiness.

- Input the DTC: P0016.

- Check the DTC judgment result.

Tester Display Description NORMAL - DTC judgment completed

- System normal

ABNORMAL - DTC judgment completed

- System abnormal

INCOMPLETE - DTC judgment not completed

- Perform driving pattern after confirming DTC enabling conditions

UNKNOWN - Unable to perform DTC judgment

- Number of DTCs which do not fulfill DTC preconditions has reached ECU memory limit

HINT:

- If the judgment result shows NORMAL, the system is normal.

- If the judgment result shows ABNORMAL, the system has a malfunction.

- If the judgment result shows INCOMPLETE or UNKNOWN, perform steps [E] through [G].

- Drive the vehicle at 75 km/h (47 mph) for 2 to 3 minutes [E].

CAUTION:

When performing the confirmation driving pattern, obey all speed limits and traffic laws.

- Idle the engine for 5 minutes or more [F].

- Check the DTC judgment result [G].

HINT:

- If the judgment result shows NORMAL, the system is normal.

- If the judgment result shows ABNORMAL, the system has a malfunction.

Inspection procedure

HINT:

- DTC P0016 may be set when foreign objects in the engine oil are caught in some parts of the system. The DTC will remain set even if the system returns to normal after a short time. Foreign objects are filtered out by the oil filter.

- Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air fuel ratio was lean or rich, and other data from the time the malfunction occurred.

| 1.CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P0016) |

-

Connect the intelligent tester to the DLC3.

-

Turn the power switch on (IG).

-

Turn the tester on.

-

Enter the following menus: Powertrain / Engine and ECT / DTC.

-

Read the DTCs.

Result Result Proceed to DTC P0016 is output A DTC P0016 and other DTCs are output B HINT:

If any DTCs other than P0016 are output, troubleshoot those DTCs first.

|

|

||||

| OK | |

| 2.PERFORM ACTIVE TEST USING INTELLIGENT TESTER (OPERATE CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY) |

-

Connect the intelligent tester to the DLC3.

-

Turn the power switch on (IG).

-

Turn the tester on.

-

Put the engine in inspection mode (maintenance mode) .

-

Start the engine.

-

Enter the following menus: Powertrain / Engine and ECT / Active Test / Control the VVT Linear (Bank 1).

-

Check the engine speed while operating the camshaft timing oil control valve assembly using the tester.

OK Tester Operation Specified Condition 0% Normal engine speed 100% Engine idles roughly or stalls HINT:

- If the result is not acceptable, cool the engine (engine coolant temperature is 30°C (86°F) or less) and perform the Active Test again.

- Test not possible with park (P) selected during charge control. Move shift lever to N to perform test.

|

|

||||

| OK | |

| 3.CHECK WHETHER DTC OUTPUT RECURS (DTC P0016) |

-

Connect the intelligent tester to the DLC3.

-

Turn the power switch on (IG).

-

Turn the tester on.

-

Clear the DTCs .

-

Drive the vehicle in accordance with the driving pattern described in the Confirmation Driving Pattern.

-

Enter the following menus: Powertrain / Engine and ECT / DTC.

-

Read the DTCs.

Result Result Proceed to DTC is not output A DTC P0016 is output B HINT:

DTC P0016 may be set when foreign objects in the engine oil are caught in some parts of the system. The DTC will remain set even if the system returns to normal after a short time. Foreign objects are filtered out by the oil filter.

|

|

||||

| A | |

|

| 4.INSPECT CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY |

-

Inspect the camshaft timing oil control valve assembly .

|

|

||||

| OK | |

| 5.INSPECT CAMSHAFT TIMING GEAR ASSEMBLY |

-

Inspect the camshaft timing gear assembly .

|

|

||||

| OK | |

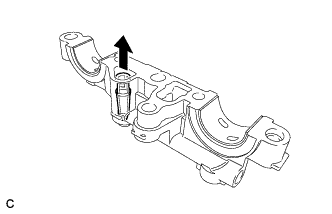

| 6.INSPECT OIL CONTROL VALVE FILTER |

-

Remove the oil control valve filter .

-

Check that the filter is not clogged.

OK:

Filter is not clogged.

|

|

||||

| OK | |

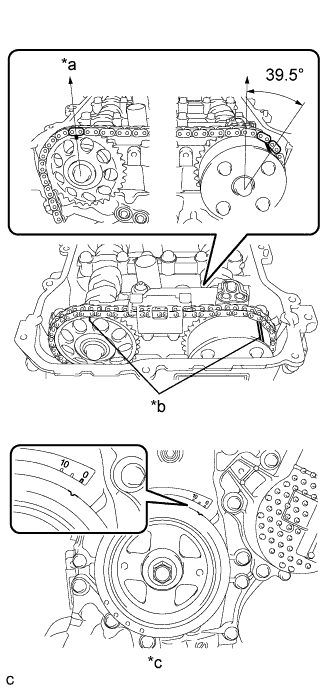

| 7.ADJUST VALVE TIMING |

HINT:

There are no marks on the cylinder head to match-up for the purpose of checking valve timing. Valve timing can only be inspected by lining up the colored plates on the timing chain with the marks on the pulleys. It may be necessary to remove and reinstall the chain to match-up the alignment marks .

| *a | Top |

| *b | Alignment Mark |

| *c | No. 1 Cylinder at TDC Compression |

| NEXT | |

| 8.CHECK WHETHER DTC OUTPUT RECURS (DTC P0016) |

-

Connect the intelligent tester to the DLC3.

-

Turn the power switch on (IG).

-

Turn the tester on.

-

Clear the DTCs .

-

Drive the vehicle in accordance with the driving pattern described in the Confirmation Driving Pattern.

-

Enter the following menus: Powertrain / Engine and ECT / DTC / Pending.

-

Read the pending DTCs.

Result Result Proceed to DTC is not output A DTC P0016 is output B

|

|

||||

| A | |

|