DTC P0010 Camshaft Position "A" Actuator Circuit (Bank 1)

-

Perform active test using intelligent tester (operate camshaft timing oil control valve assembly)

-

Check harness and connector (camshaft timing oil control valve assembly - ecm)

Description

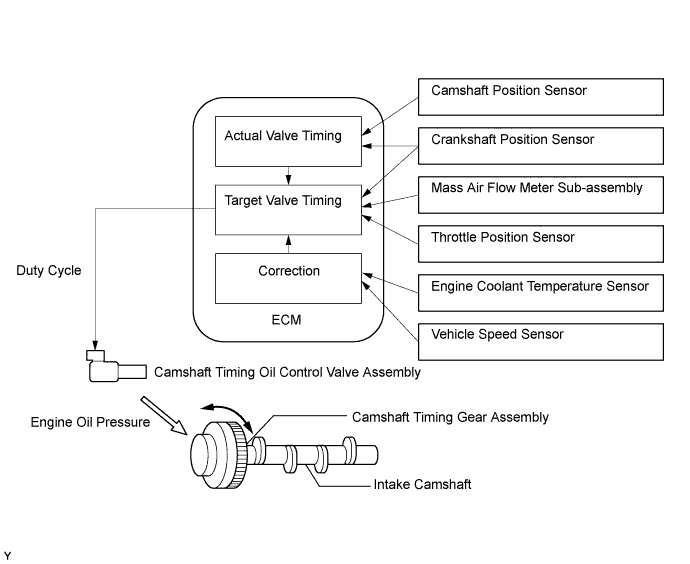

The VVT (variable valve timing) system adjusts the intake valve timing to improve driveability. The engine oil pressure turns the camshaft timing gear assembly to adjust the valve timing.

The camshaft timing oil control valve assembly is a solenoid valve and switches the engine oil line. The valve moves when the ECM applies the 12 V to the solenoid. The ECM changes the energizing time to the solenoid (duty-cycle) in accordance with the camshaft position, crankshaft position, throttle position, etc.

| DTC No. | DTC Detection Condition | Trouble Area |

| P0010 | Open or short in camshaft timing oil control valve assembly circuit (1 trip detection logic). |

|

Monitor description

This DTC is designed to detect open or short circuits in the camshaft timing oil control valve assembly circuit. If the camshaft timing oil control valve assembly duty-cycle is excessively high or low while the power switch to on (IG) or engine running, the ECM will illuminate the MIL and set the DTC.

Confirmation driving pattern

- Turn the power switch on (IG) and wait for 5 seconds or more.

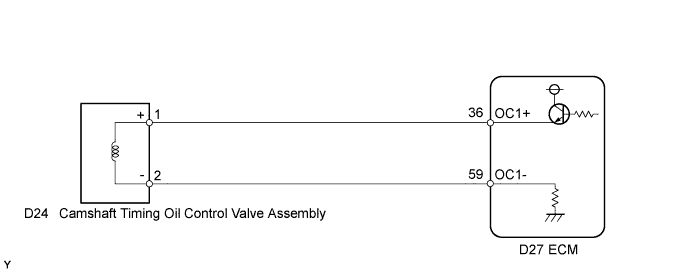

Wiring diagram

Inspection procedure

HINT:

Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air fuel ratio was lean or rich, and other data from the time the malfunction occurred.

| 1.PERFORM ACTIVE TEST USING INTELLIGENT TESTER (OPERATE CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY) |

-

Connect the intelligent tester to the DLC3.

-

Turn the power switch on (IG).

-

Turn the tester on.

-

Put the engine in inspection mode (maintenance mode) .

-

Start the engine.

-

Enter the following menus: Powertrain / Engine and ECT / Active Test / Control the VVT Linear (Bank 1).

-

Check the engine speed while operating the camshaft timing oil control valve assembly using the tester.

OK Tester Operation Specified Condition 0% Normal engine speed 100% Engine idles roughly or stalls HINT:

- If the result is not acceptable, cool the engine (engine coolant temperature is 30°C (86°F) or less) and perform the Active Test again.

- Test not possible with park (P) selected during charge control. Move shift lever to N to perform test.

|

|

||||

| OK | |

|

| 2.INSPECT CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY |

-

Inspect the camshaft timing oil control valve assembly .

|

|

||||

| OK | |

| 3.CHECK HARNESS AND CONNECTOR (CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY - ECM) |

-

Disconnect the camshaft timing oil control valve assembly connector.

-

Disconnect the ECM connector.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance:

Tester Connection Condition Specified Condition D24-1 (+) - D27-36 (OC1+) Always Below 1 ? D24-2 (-) - D27-59 (OC1-) Always Below 1 ? D24-1 (+) or D27-36 (OC1+) - Body ground Always 10 k? or higher D24-2 (-) or D27-59 (OC1-) - Body ground Always 10 k? or higher

|

|

||||

| OK | |

|