Lexus IS250 IS220d GSE20 ALE20 4GR-FSE LUBRICATION

OIL PUMP - INSTALLATION

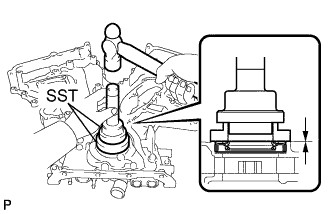

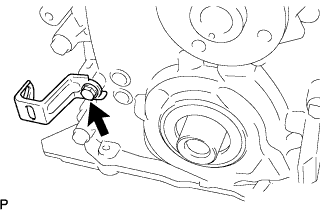

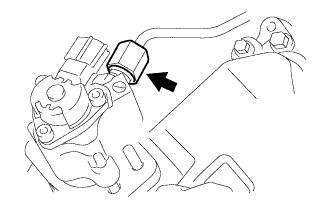

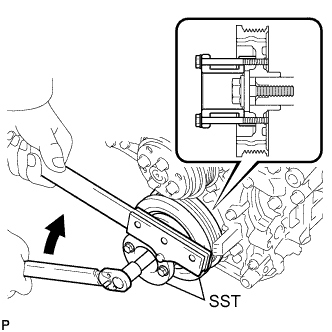

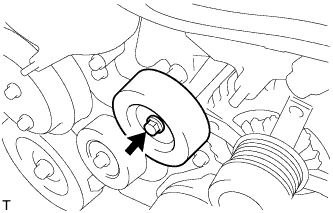

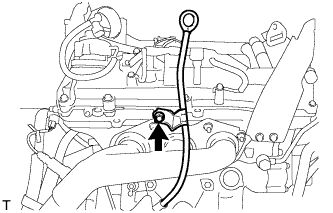

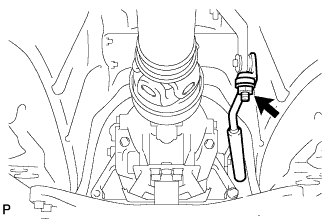

| 1. INSTALL TIMING CHAIN CASE OIL SEAL |

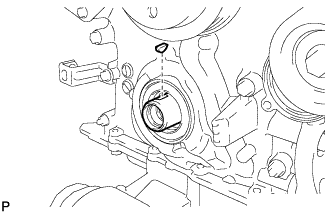

Using SST, tap in a new oil seal until its surface is flush with the timing gear case edge.

- SST

- 09223-22010

09506-35010

- NOTICE:

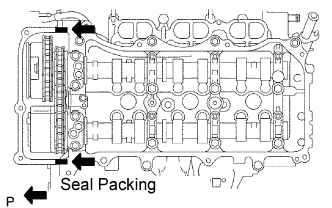

| 2. INSTALL TIMING CHAIN COVER SUB-ASSEMBLY |

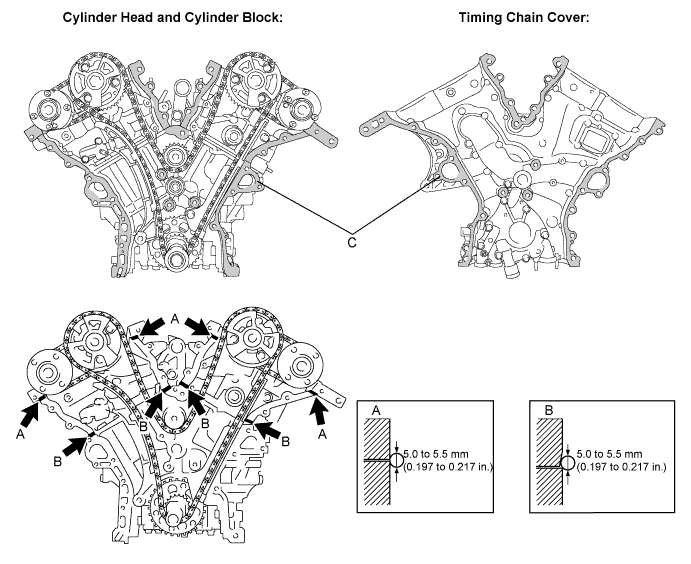

Apply seal packing in a continuous line to the engine unit as shown in the following illustration.

- Seal packing:

- Part No. 08826-00080 or equivalent

- Seal diameter:

- 5.0 to 5.5 mm (0.197 to 0.217 in.)

- NOTICE:

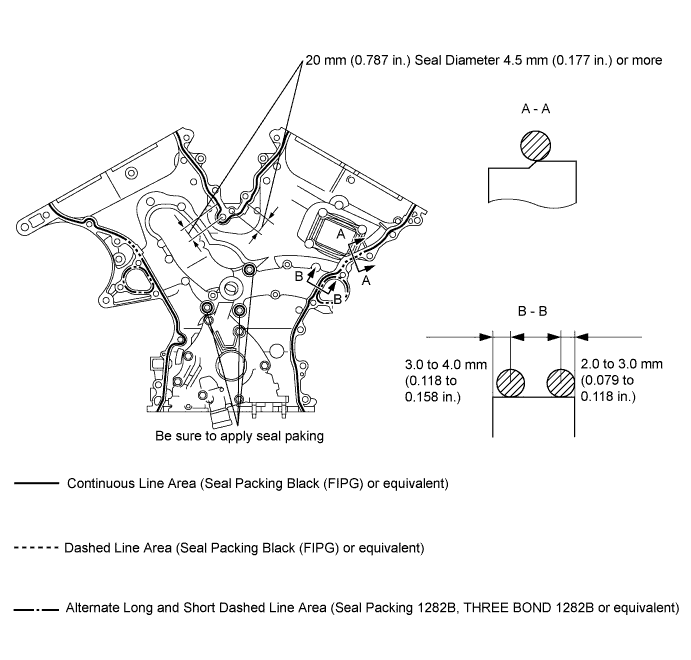

Apply seal packing in a continuous line to the timing chain cover as shown in the following illustration.

- Seal packing:

- 08826-00080 or equivalent

- 08826-00100, THREE BOND 1282B or equivalent

- NOTICE:

- Apply seal packing as follows:

Area Seal Packing Diameter Application Position from Inside Seal Line Continuous Line Area 3.5 to 4.0 mm (0.138 to 0.158 in.) 3.0 to 4.0 mm (0.118 to 0.158 in.) Alternate Long and Dashed Line Area 3.5 to 4.0 mm (0.138 to 0.158 in.) 2.0 to 3.0 mm (0.079 to 0.118 in.) Dashed Line Area 6.0 mm (0.236 in.) -

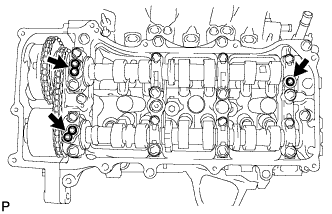

Install a new gasket.

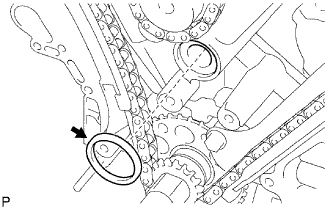

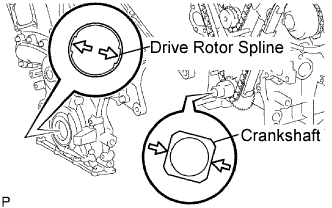

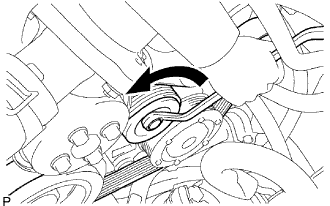

Align the oil pump's drive rotor spline and the crankshaft as shown in the illustration. Install the spline and chain cover to the crankshaft.

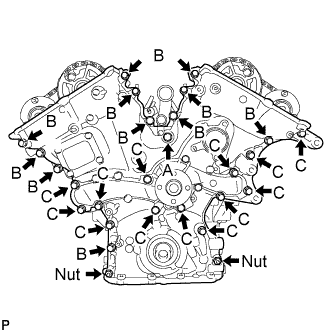

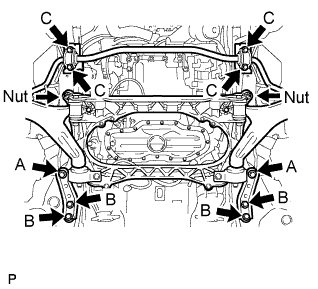

Temporarily tighten the timing chain cover with the 25 bolts and 2 nuts.

- Bolt length:

Item Length Bolt A 50 mm (1.97 in.) Bolt B 25 mm (0.98 in.) Bolt C 55 mm (2.17 in.)

- NOTICE:

- Make sure that there is no oil on the bolt threads.

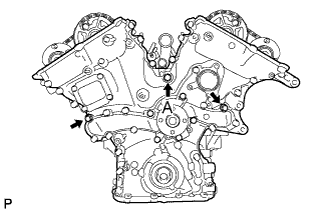

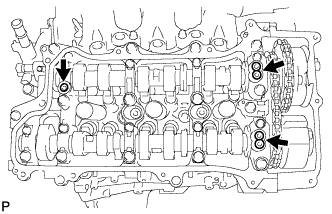

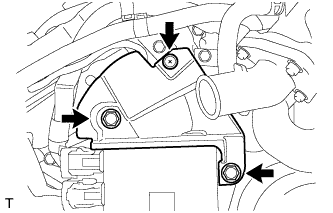

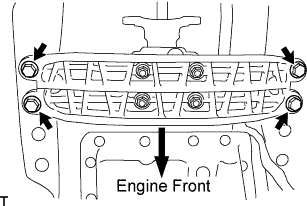

Fully tighten the 3 bolts as shown in the illustration.

- Torque:

- 43 N*m{ 438 kgf*cm, 32 ft.*lbf}for bolt A

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}for bolts except A

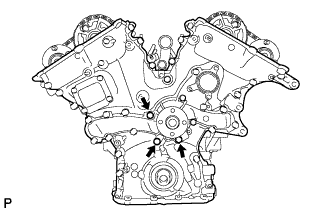

Fully tighten the 3 bolts as shown in the illustration.

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

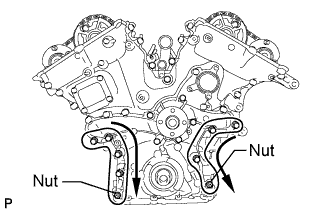

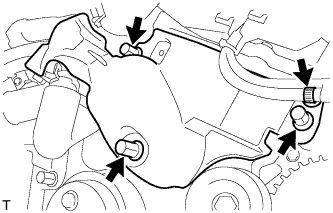

Fully tighten the 7 bolts and 2 nuts as shown in the illustration.

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

- HINT:

- Tighten the bolts and nuts in the order of upper to lower as shown in the illustration.

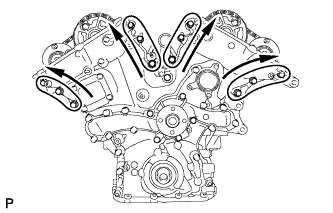

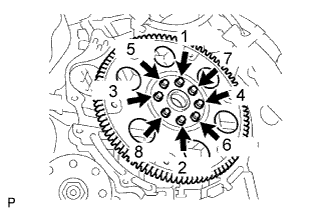

Fully tighten the 12 bolts as shown in the illustration.

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

- HINT:

- Tighten the bolts in the order of lower to upper as shown in the illustration.

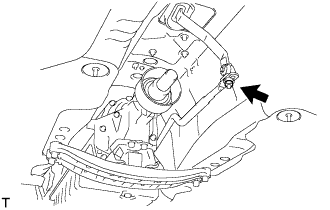

Install the bolt and wiring harness bracket.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

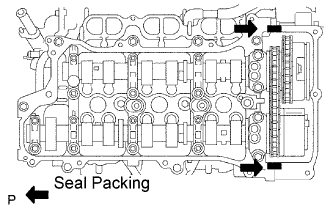

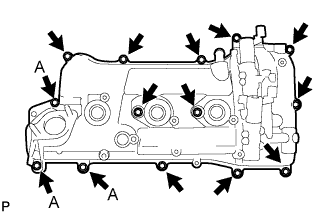

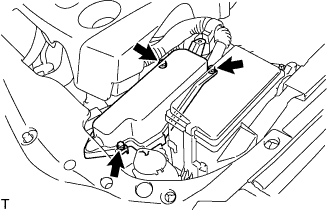

| 3. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY (for Bank 1) |

Apply seal packing as shown in the illustration.

- Seal packing:

- 08826-00080 or equivalent

- NOTICE:

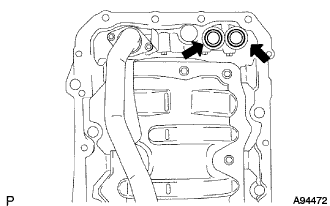

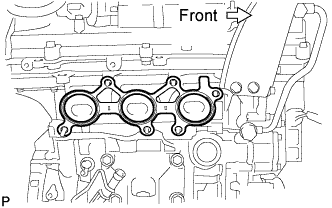

Install 3 new gaskets as shown in the illustration.

Install a new gasket to the head cover.

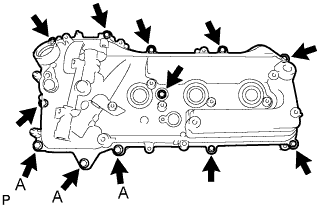

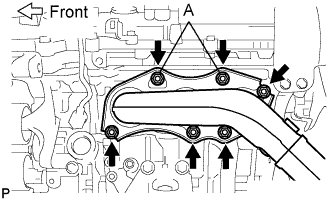

Install a head cover with the 14 bolts.

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}for bolt A

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}for bolts except A

| 4. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY (for Bank 2) |

Apply seal packing as shown in the illustration.

- Seal packing:

- 08826-00080 or equivalent

- NOTICE:

Install 3 new gaskets as shown in the illustration.

Install a new gasket to the head cover.

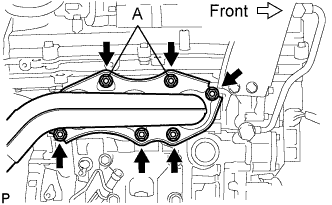

Install the head cover with the 12 bolts.

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}for bolt A

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}for bolts except A

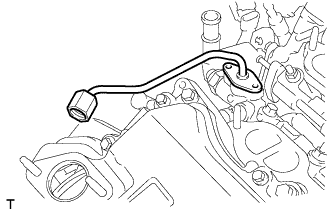

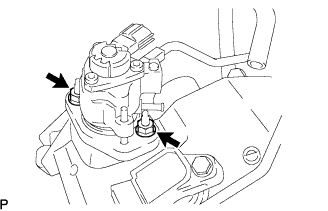

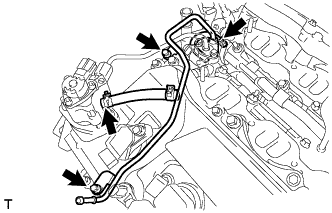

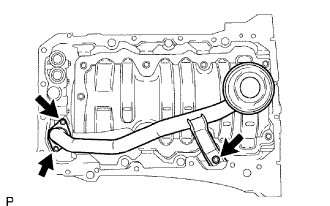

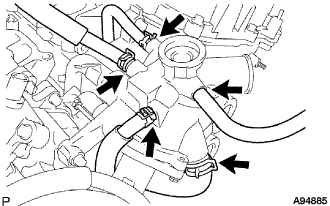

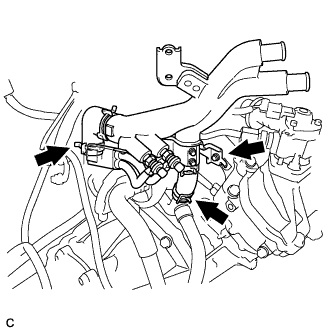

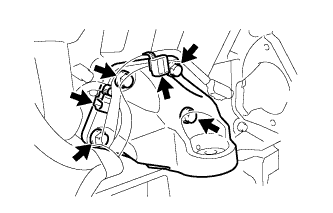

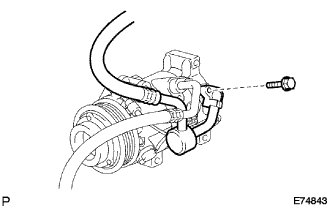

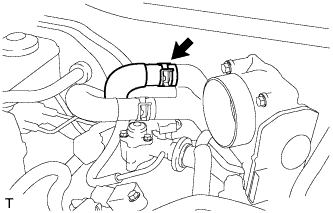

| 5. INSTALL NO. 1 OIL PIPE |

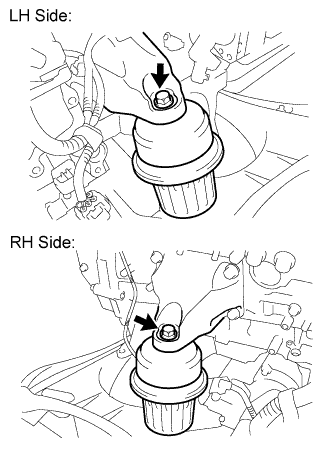

Make sure that there is no foreign matter on the mesh of the oil control valve filter LH.

- NOTICE:

- Do not touch the mesh when installing the oil control valve filter.

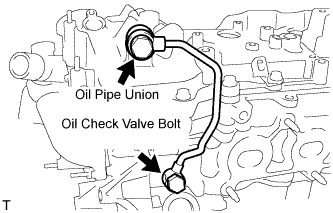

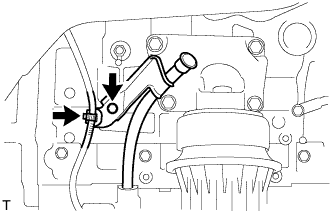

Install the oil control valve filter LH to the oil pipe union. Install new gaskets and temporarily install the oil pipe (on the head cover side).

Install a new gasket and temporarily install the oil pipe (on the cylinder head side) with the oil check valve bolt.

Tighten the oil pipe union (on the head cover side).

- Torque:

- 60 N*m{ 612 kgf*cm, 44 ft.*lbf}

Tighten the oil check valve bolt (on the cylinder head side).

- Torque:

- 60 N*m{ 612 kgf*cm, 44 ft.*lbf}

- NOTICE:

- If the link that connects the gaskets is broken, remove the connecting link by using nippers or similar tools.

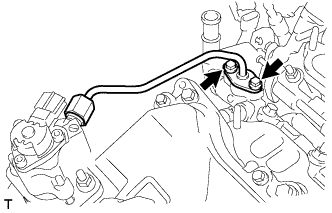

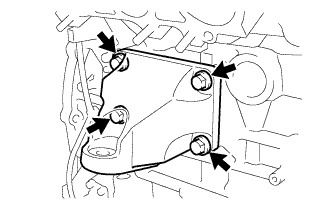

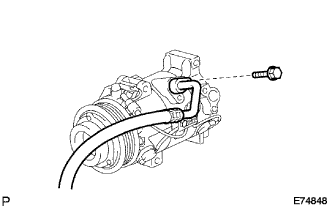

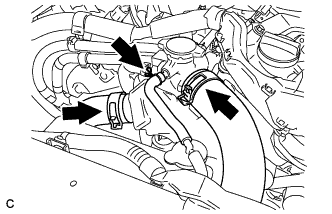

| 6. INSTALL NO. 2 OIL PIPE |

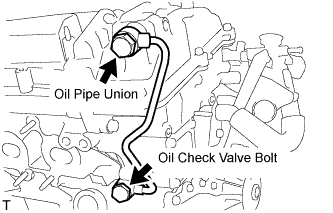

Make sure that there is no foreign matter on the mesh of the oil control valve filter RH.

- NOTICE:

- Do not touch the mesh when installing the oil control valve filter.

Install the oil control valve filter RH to the oil pipe union. Install new gaskets and temporarily install the oil pipe (on the head cover side).

Install a new gasket and temporarily install the oil pipe (on the cylinder head side) with the oil check valve bolt.

Tighten the oil pipe union (on the head cover side).

- Torque:

- 60 N*m{ 612 kgf*cm, 44 ft.*lbf}

Tighten the oil check valve bolt (on the cylinder head side).

- Torque:

- 60 N*m{ 612 kgf*cm, 44 ft.*lbf}

- NOTICE:

- If the link that connects the gaskets is broken, remove the connecting link by using nippers or similar tools.

| 7. INSTALL IGNITION COIL ASSEMBLY |

Install the 6 ignition coils with the 6 bolts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

| 8. INSTALL NO. 2 FUEL PIPE |

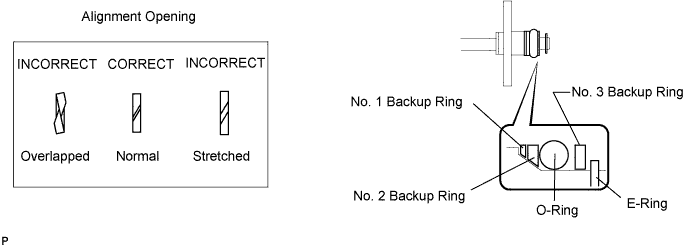

Install a new O-ring, new backup rings (No. 1 and No. 2) and new E-ring to the fuel injector as shown in the illustration.

- NOTICE:

Apply gasoline to the O-ring and connect the fuel pipe to the delivery pipe.

- NOTICE:

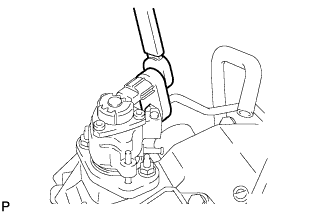

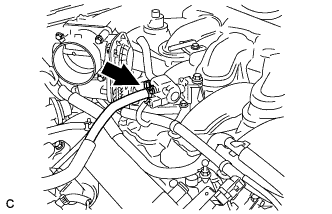

| 9. INSTALL FUEL PUMP ASSEMBLY |

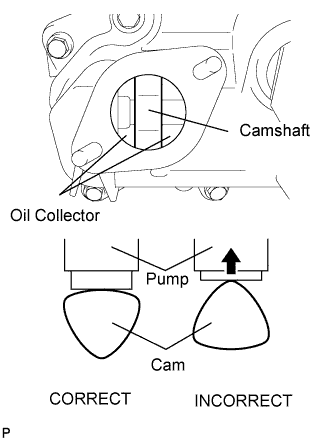

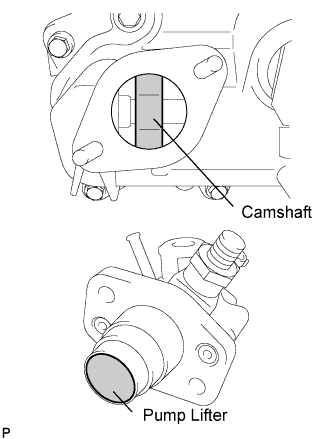

Turn the crankshaft until the flat of the cam is facing the cylinder head cover's fuel pump attachment hole, as shown in the illustration.

- HINT:

- When installing the fuel pump by following the procedure described above: By not using the crankshaft pointed side to push up the pump activation surface, it is easier to install the fuel pump and No. 2 fuel pipe later.

Pour 30 cc of engine oil through the cylinder head cover's fuel pump attachment hole into the cylinder head oil collector.

Apply a coat of engine oil to the pump activation cam and pump lifter part.

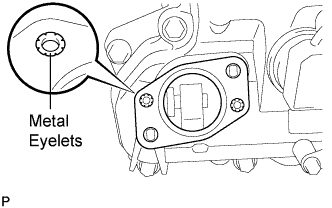

Install a new fuel pump insulator to the cylinder head cover. Then pass the 2 stud bolts through the holes of the fuel pump and set them on the insulator.

- NOTICE:

- Install the insulator so that the open sides of the metal eyelets are facing outward, as shown in the illustration.

Temporarily install the No.2 fuel pipe sub-assembly to the fuel pump assembly.

- NOTICE:

- Be careful not to damage the sealing surface of the fuel pipe when temporarily installing the fuel pipe.

Install the 2 nuts and tighten them in several passes.

- Torque:

- 25 N*m{ 255 kgf*cm, 18 ft.*lbf}

Connect the fuel hose.

| 10. CONNECT NO. 2 FUEL PIPE |

Install the No. 2 fuel pipe to the delivery pipe with the 2 bolts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

Using a 19 mm union nut wrench, connect the fuel pipe.

- Torque:

- 30 N*m{ 306 kgf*cm, 22 ft.*lbf}

- HINT:

- The torque shown above should be used for tightening without using union nut wrench. When the union nut wrench is used for tightening, the torque should be calculated based on the length of the union nut wrench .

Connect the connector to the fuel pump.

| 11. INSTALL NO. 1 FUEL PIPE |

Install the fuel pipe with the 2 bolts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

Connect the 2 fuel hoses.

| 12. INSTALL FUEL PRESSURE PULSATION DAMPER ASSEMBLY |

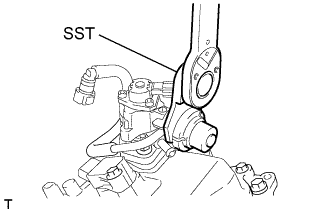

Using SST, install a new gasket and the fuel pulsation damper to the fuel pump.

- Torque:

- 40 N*m{ 408 kgf*cm, 28 ft.*lbf}

- HINT:

- The torque shown above should be used for tightening without using SST. When the SST is used for tightening, the torque should be calculated based on the length of the SST .

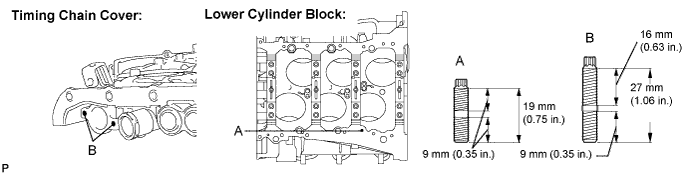

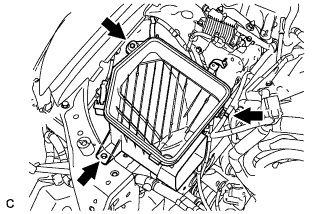

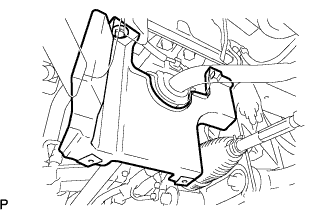

| 13. INSTALL OIL STRAINER SUB-ASSEMBLY |

Using an E6 "torx" socket, install the stud bolts as shown in the illustration.

- Torque:

- 4.0 N*m{ 41 kgf*cm, 35 in.*lbf}

Install the baffle plate with the 8 bolts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

- HINT:

- Temporarily tighten the 8 bolts. Fully tighten 2 bolts A as shown in the illustration before tightening the other bolts.

Install a new gasket and the oil strainer with the 3 nuts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

Install 2 new O-rings.

| 14. INSTALL OIL PAN SUB-ASSEMBLY |

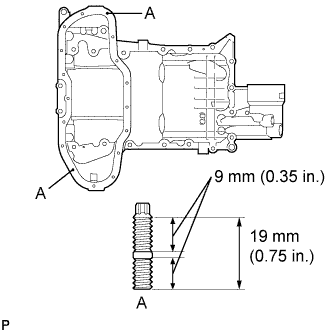

When replacing a stud bolt, install it by using an E6 "torx" socket wrench.

- Torque:

- 4.0 N*m{ 41 kgf*cm, 35 in.*lbf}

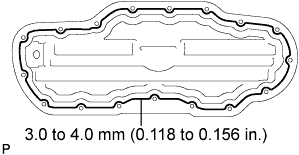

Apply seal packing in a continuous line as shown in the illustration.

- Seal packing:

- Part No. 08826-00080 or equivalent

- Seal diameter:

- 3.0 to 4.0 mm (0.118 to 0.156 in.)

- NOTICE:

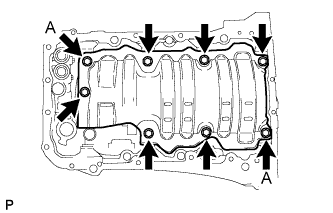

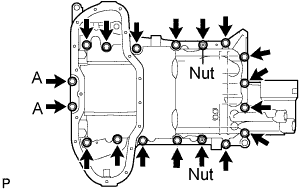

Install the oil pan with the 16 bolts and 2 nuts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}for bolt A

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}for bolts except A

| 15. INSTALL NO. 2 OIL PAN SUB-ASSEMBLY |

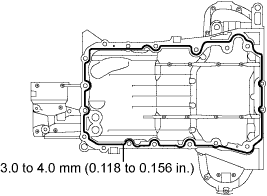

Apply seal packing in a continuous line as shown in the illustration.

- Seal packing:

- Part No. 08826-00080 or equivalent

- Seal diameter:

- 3.0 to 4.0 mm (0.118 to 0.156 in.)

- NOTICE:

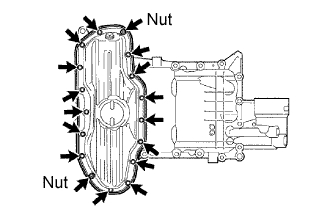

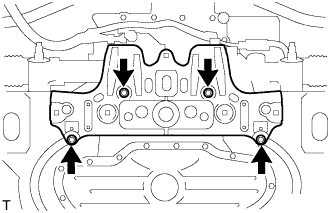

Install the oil pan with the 15 bolts and 2 nuts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

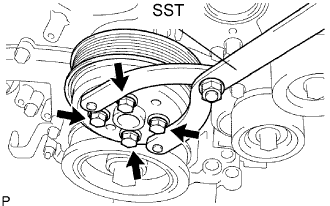

| 16. INSTALL CRANKSHAFT PULLEY |

Install the pulley set key to the key groove.

Align the pulley set key with the key groove of the pulley, and slide on the pulley.

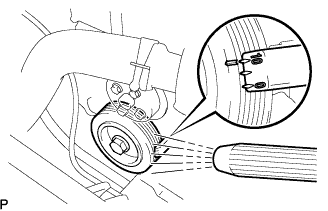

Using SST, install the crankshaft pulley bolt.

- SST

- 09213-70011(09213-70020)

09330-00021

- Torque:

- 250 N*m{ 2,550 kgf*cm, 184 ft.*lbf}

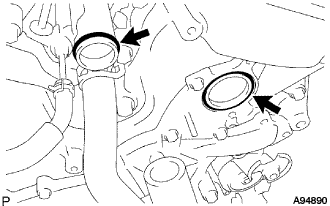

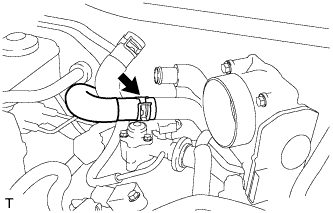

| 17. INSTALL WATER INLET |

Install a new water inlet housing gasket No.1 and water outlet pipe O-ring.

Install the water inlet with the 4 bolts and nut.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

- NOTICE:

- Be careful not to allow the O-ring to get caught between parts.

Connect the 5 hoses.

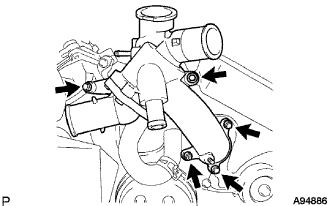

| 18. INSTALL WATER HOSE JOINT |

Connect the 2 hoses, and install the bolt and water hose joint.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

| 19. INSTALL NO. 2 SURGE TANK STAY |

Install the bolt and No. 2 surge tank stay.

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

| 20. INSTALL INTAKE AIR SURGE TANK ASSEMBLY |

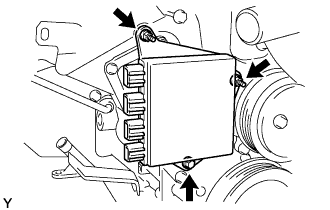

| 21. INSTALL INJECTOR DRIVER |

Install the injector driver with the bolt and 2 nuts.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

| 22. INSTALL ENGINE WIRE |

Install the engine wire to the engine assembly.

| 23. INSTALL WATER PUMP PULLEY |

Temporarily install the pulley with the 4 bolts.

Using SST, hold the pulley and tighten the 4 bolts.

- SST

- 09960-10010(09962-01000,09963-00700)

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

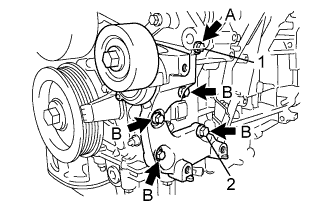

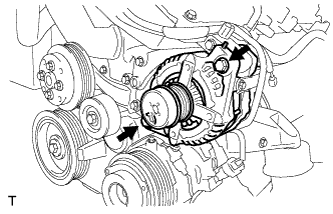

| 24. INSTALL V-RIBBED BELT TENSIONER ASSEMBLY |

Temporarily install the V-ribbed belt tensioner with the 5 bolts.

- Each bolt length is as follows:

Mark Specified Length A 70 mm (2.76 in.) B 35 mm (1.38 in.)

Install the V-ribbed belt tensioner by tightening the bolt 1 and bolt 2 in the order shown in the illustration.

- Torque:

- 43 N*m{ 439 kgf*cm, 32 ft.*lbf}

Tighten the other bolts.

- Torque:

- 43 N*m{ 439 kgf*cm, 32 ft.*lbf}

| 25. INSTALL ENGINE MOUNTING BRACKET LH |

Install the mounting bracket with the 4 bolts.

- Torque:

- 43 N*m{ 439 kgf*cm, 32 ft.*lbf}

Connect the 2 clamps.

| 26. INSTALL ENGINE MOUNTING BRACKET RH |

Install the mounting bracket with the 4 bolts.

- Torque:

- 43 N*m{ 439 kgf*cm, 32 ft.*lbf}

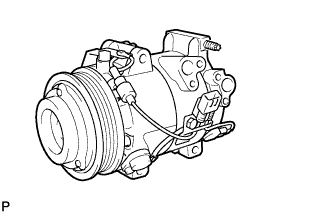

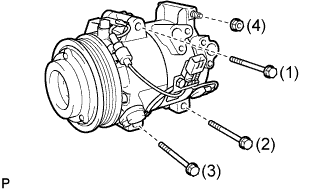

| 27. CONNECT COOLER COMPRESSOR ASSEMBLY |

Temporarily install the compressor and magnetic clutch onto the stud bolt.

Install the compressor and magnetic clutch with the 3 bolts and nut.

- Torque:

- 25 N*m{ 255 kgf*cm, 18 ft.*lbf}

- NOTICE:

- Tighten the bolts in the order shown in the illustration to install the compressor and magnetic clutch.

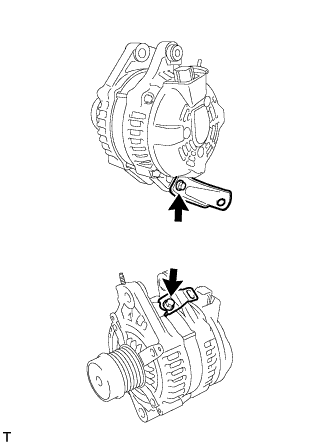

| 28. INSTALL GENERATOR ASSEMBLY |

Install the 2 generator brackets with the 2 bolts.

- Torque:

- 20 N*m{ 204 kgf*cm, 15 ft.*lbf}

Install the generator assembly with the 2 bolts.

- Torque:

- 43 N*m{ 438 kgf*cm, 32 ft.*lbf}

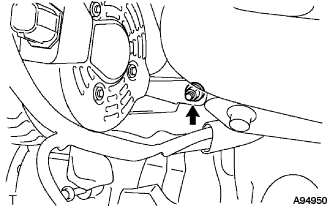

Install the bracket with the nut.

- Torque:

- 20 N*m{ 204 kgf*cm, 15 ft.*lbf}

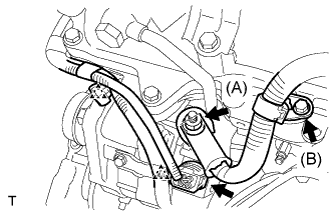

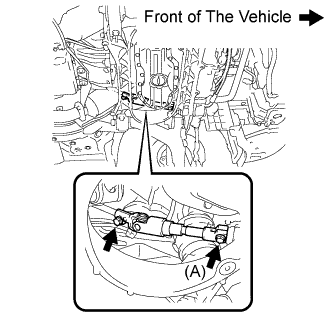

Install the generator wire to terminal B with the nut (A).

- Torque:

- 9.8 N*m{ 100 kgf*cm, 87 in.*lbf}

Install the terminal cap.

Install the clamp bracket with the bolt (B).

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

Attach the 2 clamps, and connect the generator connector to the generator.

| 29. INSTALL NO. 2 IDLER PULLEY SUB-ASSEMBLY |

Install the plate and idler pulley with the bolt.

- Torque:

- 43 N*m{ 439 kgf*cm, 32 ft.*lbf}

| 30. INSTALL NO. 1 ENGINE COVER |

Install the No. 1 engine cover with the 3 clips.

| 31. INSTALL NO. 2 ENGINE COVER |

Install the No. 2 engine cover with the 3 clips.

Connect the clamp.

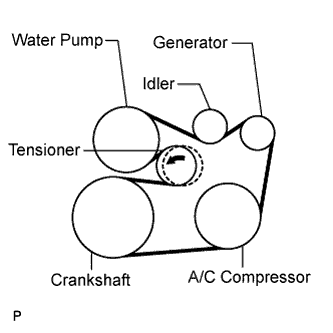

| 32. INSTALL V-RIBBED BELT |

Install the V-ribbed belt.

While turning the belt tensioner counterclockwise, remove the bar.

- NOTICE:

If it is difficult to install the V-ribbed belt, perform the following procedure.

Put the V-ribbed belt on every part except the tensioner pulley as shown in the illustration.

While releasing the belt tension by turning the belt tensioner counterclockwise, put the V-ribbed belt on the tensioner pulley.

- NOTICE:

| 33. INSTALL ENGINE HANGERS |

- Torque:

- 33 N*m{ 336 kgf*cm, 24 ft.*lbf}

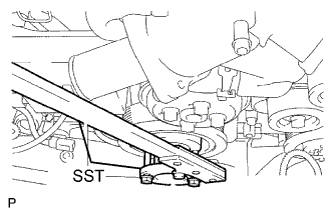

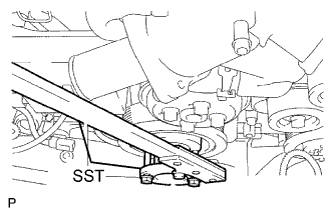

| 34. INSTALL FLYWHEEL SUB-ASSEMBLY (for Manual Transmission) |

Hold the crankshaft with SST.

- SST

- 09213-70011(09213-70020)

09330-00021

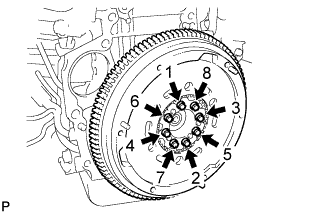

Using several steps, install and tighten 8 new bolts uniformly in the sequence shown in the illustration.

- Torque:

- 73 N*m{ 741 kgf*cm, 54 ft.*lbf}

- NOTICE:

| 35. INSTALL DRIVE PLATE AND RING GEAR SUB-ASSEMBLY (for Automatic Transmission) |

Using SST, hold the crankshaft.

- SST

- 09213-70011(09213-70020)

09330-00021

Apply adhesive to 2 or 3 threads of the mounting bolts ends.

- Adhesive:

- Part No. 08833-00070, THREE BOND 1324 or equivalent

Install the front spacer, drive plate and rear spacer on the crankshaft.

Install and tighten the 8 mounting bolts uniformly in several steps.

- Torque:

- 83 N*m{ 846 kgf*cm, 61 ft.*lbf}

- NOTICE:

- Do not start the engine for at least 1 hour after installing.

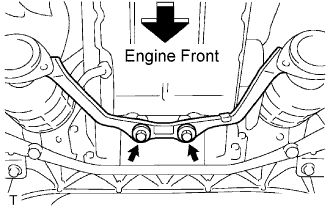

| 36. INSTALL FRONT SUSPENSION CROSSMEMBER SUB-ASSEMBLY |

Install the front suspension crossmember sub-assembly with the 2 bolts.

- Torque:

- 35 N*m{ 357 kgf*cm, 26 ft.*lbf}

| 37. INSTALL MANUAL TRANSMISSION UNIT ASSEMBLY (for Manual Transmission) |

| 38. INSTALL AUTOMATIC TRANSMISSION ASSEMBLY (for Automatic Transmission) |

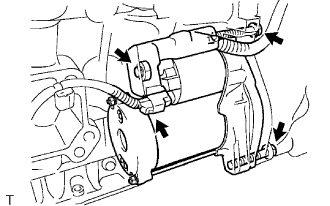

| 39. INSTALL STARTER ASSEMBLY |

Install the starter with the 2 bolts.

- Torque:

- 58 N*m{ 591 kgf*cm, 43 ft.*lbf}

Connect the wire harness to terminal 30 and install the nut, and then attach the terminal cap.

- Torque:

- 9.8 N*m{ 100 kgf*cm, 87 in.*lbf}

Connect the terminal 50 connector to the starter assembly.

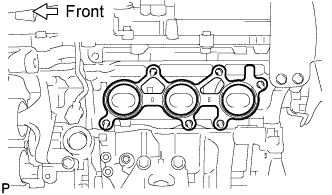

| 40. INSTALL EXHAUST MANIFOLD SUB-ASSEMBLY LH |

Install a new gasket as shown in the illustration.

Install the exhaust manifold with 6 new nuts.

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

- NOTICE:

| 41. INSTALL EXHAUST MANIFOLD SUB-ASSEMBLY RH |

Install a new gasket as shown in the illustration.

Install the exhaust manifold with 6 new nuts.

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

- NOTICE:

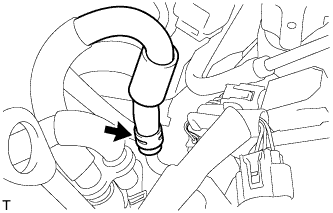

| 42. INSTALL OIL DIPSTICK GUIDE SUB-ASSEMBLY |

Install a new O-ring to the oil dipstick guide.

Apply a light coat of engine oil to the O-ring.

Push in the oil dipstick guide end into the guide hole.

Install the No. 1 oil dipstick guide with the bolt.

- Torque:

- 10 N*m{ 102 kgf*cm, 7 ft.*lbf}

Connect the clamp.

Install the No. 2 oil dipstick guide with the bolt.

- Torque:

- 21 N*m{ 214 kgf*cm, 15 ft.*lbf}

Install the oil dipstick.

| 43. INSTALL ENGINE AND TRANSMISSION ASSEMBLY |

Set the engine lifter.

Operate the engine lifter, then install the engine to the vehicle.

Install the engine and transmission assembly with crossmember with the 12 bolts.

- Torque:

- 167 N*m{ 1,700 kgf*cm, 123 ft.*lbf}for Nut

- 204 N*m{ 2,080 kgf*cm, 150 ft.*lbf}for bolt A

- 50 N*m{ 510 kgf*cm, 37 ft.*lbf}for bolt B

- 49 N*m{ 500 kgf*cm, 36 ft.*lbf}for bolt C

Install the engine rear mounting member with the 4 bolts.

- Torque:

- 26 N*m{ 265 kgf*cm, 19 ft.*lbf}

| 44. CONNECT FLOOR SHIFT GEAR SHIFTING ROD SUB-ASSEMBLY |

Temporarily tighten the floor shift gear shifting rod sub-assembly with the nut.

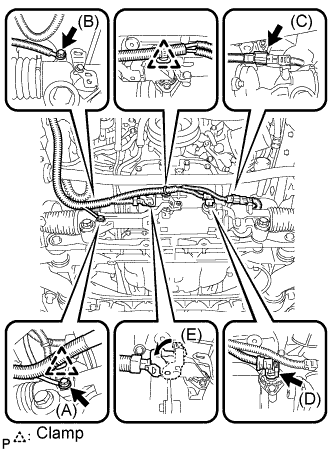

| 45. CONNECT POWER STEERING LINK WIRE HARNESS |

Install the power steering earth wire to the power steering link assembly with bolt (B).

- Torque:

- 13 N*m{ 130 kgf*cm, 10 ft.*lbf}

Connect the wire harness connector (E) to the power steering link assembly and securely lock the connector.

Connect the 2 wire harness connectors (C) and (D) to the power steering link assembly.

Install the 2 wire harness clamps to the power steering link assembly.

Connect the earth wire to the bracket with bolt (A).

- Torque:

- 5.0 N*m{ 51 kgf*cm, 44 in.*lbf}

| 46. INSTALL EXHAUST PIPE NO.1 SUPPORT BRACKET SUB-ASSEMBLY (for Automatic Transmission) |

Install the exhaust pipe No. 1 support bracket sub-assembly with the 2 bolts.

- Torque:

- 43 N*m{ 438 kgf*cm, 32 ft.*lbf}

| 47. INSTALL FRONT LOWER BALL JOINT ASSEMBLY LH |

Install the front lower ball joint with the 2 bolts.

- Torque:

- 120 N*m{ 1,224 kgf*cm, 89 ft.*lbf}

| 48. INSTALL FRONT LOWER BALL JOINT ASSEMBLY RH |

- HINT:

- Install the RH side following the same procedures as for the LH side.

| 49. INSTALL FRONT SHOCK ABSORBER ASSEMBLY LH |

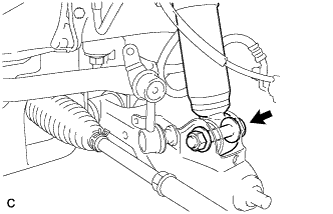

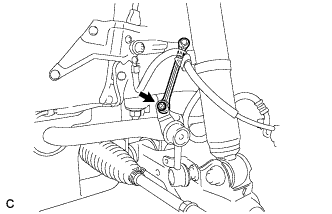

Install the bolt on the lower side of the front shock absorber while holding the nut.

- Torque:

- 157 N*m{ 1,600 kgf*cm, 116 ft.*lbf}

| 50. INSTALL FRONT SHOCK ABSORBER ASSEMBLY RH |

- HINT:

- Install the RH side following the same procedures as for the LH side.

| 51. CONNECT HEIGHT CONTROL SENSOR LINK |

Connect the height control sensor link and install it with the nut.

- Torque:

- 5.4 N*m{ 55 kgf*cm, 48 in.*lbf}

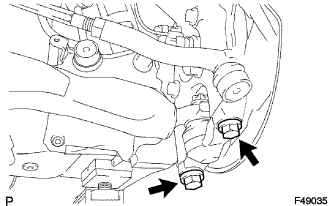

| 52. INSTALL STEERING SLIDING WITH SHAFT YOKE SUB-ASSEMBLY |

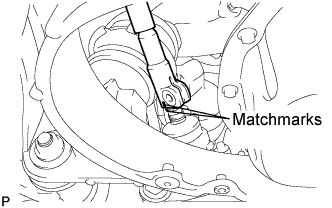

Align the matchmarks on the steering sliding yoke sub-assembly and the power steering gear assembly.

Install bolt (A) and tighten the 2 bolts.

- Torque:

- 35 N*m{ 360 kgf*cm, 26 ft.*lbf}

| 53. INSTALL FRONT LOWER SUSPENSION MEMBER PROTECTOR |

Install the protector with the 4 bolts.

- Torque:

- 8.0 N*m{ 82 kgf*cm, 71 in.*lbf}

| 54. CONNECT NO. 3 FUEL HOSE |

Connect the No. 3 fuel hose and clamp.

| 55. CONNECT FUEL MAIN TUBE |

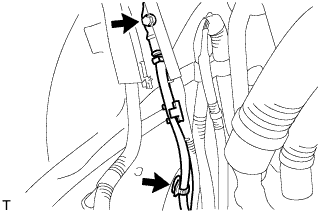

| 56. CONNECT ENGINE WIRE |

Install the bolt, clamp and engine wire No. 3.

- Torque:

- 8.5 N*m{ 87 kgf*cm, 75 in.*lbf}

Connect the ground cable and install it with the bolt.

- Torque:

- 13 N*m{ 133 kgf*cm, 10 ft.*lbf}

Connect the connector and install the 4 clamps to the body.

Connect the wire to the engine room No. 1 junction block. Then, install it with the nut.

- Torque:

- 12 N*m{ 124 kgf*cm, 9 ft.*lbf}

Install the engine room No. 1 relay block cover.

Connect the battery positive (+) cable and install it with the nut.

- Torque:

- 13 N*m{ 133 kgf*cm, 10 ft.*lbf}

Connect the ECM connectors.

Connect the connector holder.

| 57. INSTALL ECM COVER |

Install the ECM cover with the 3 bolts.

- Torque:

- 5.5 N*m{ 56 kgf*cm, 49 in.*lbf}

- NOTICE:

- Make sure that the wire harness does not get caught between the parts.

| 58. CONNECT DISCHARGE HOSE SUB-ASSEMBLY |

Remove the attached vinyl tape from the hose.

Apply sufficient compressor oil (ND-OIL 8) to a new O-ring and the fitting surface of the compressor and magnetic clutch.

- Compressor oil:

- ND-OIL 8 or equivalent

Install the O-ring onto the discharge hose sub-assembly.

Install the discharge hose sub-assembly onto the compressor and magnetic clutch with the bolt.

- Torque:

- 9.8 N*m{ 100 kgf*cm, 87 in.*lbf}

| 59. CONNECT NO. 1 COOLER REFRIGERANT SUCTION HOSE |

Remove the attached vinyl tape from the hose.

Apply sufficient compressor oil to a new O-ring and the fitting surface of the compressor and magnetic clutch.

- Compressor oil:

- ND-OIL 8 or equivalent

Install the O-ring onto the No.1 cooler refrigerant suction hose.

Install the No. 1 cooler refrigerant suction hose onto the compressor and magnetic clutch with the bolt.

- Torque:

- 9.8 N*m{ 100 kgf*cm, 87 in.*lbf}

| 60. CONNECT INLET HEATER WATER HOSE |

Connect the inlet heater water hose.

| 61. CONNECT OUTLET HEATER WATER HOSE |

Connect the outlet heater water hose.

| 62. CONNECT INLET RADIATOR HOSE |

Install the clamp and connect the inlet radiator hose.

| 63. CONNECT OUTLET RADIATOR HOSE |

Install the clamp and connect the outlet radiator hose.

| 64. CONNECT RADIATOR RESERVOIR TANK HOSE |

Install the clamp and connect the reservoir tank hose.

| 65. CONNECT NO. 2 FUEL VAPOR FEED HOSE |

Install the clamp and connect the No. 2 fuel vapor feed hose.

| 66. CONNECT UNION TO CHECK VALVE HOSE |

Connect the hose to the surge tank.

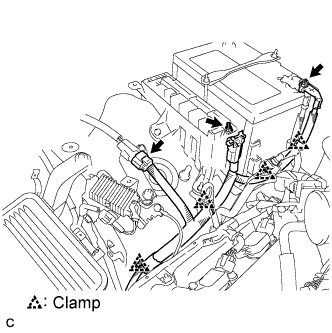

| 67. INSTALL AIR CLEANER CASE SUB-ASSEMBLY |

Install the air cleaner case, clamp and 2 bolts.

- Torque:

- 5.0 N*m{ 51 kgf*cm, 44 in.*lbf}

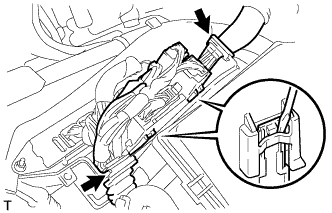

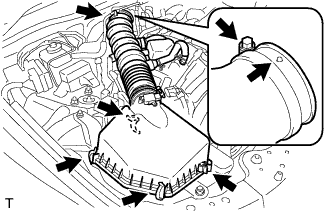

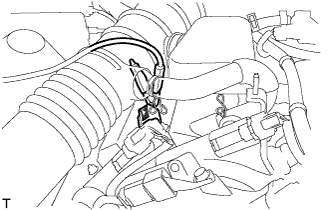

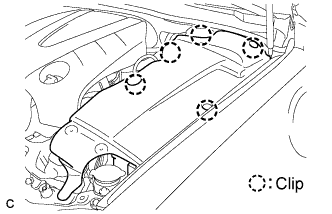

| 68. INSTALL AIR CLEANER CAP WITH AIR CLEANER HOSE |

Install the air cleaner cap with air cleaner hose assembly with the 4 clamps and hose clamp.

- HINT:

- Be sure to install the air cleaner assembly so that the screw part of the hose clamp is as shown in the illustration.

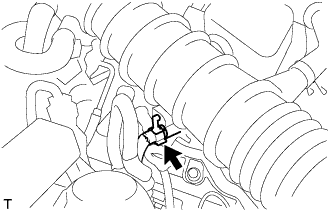

Install the VSV hose to the air cleaner hose.

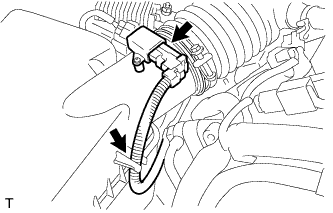

Connect the MAF meter connector and clamp to the air cleaner.

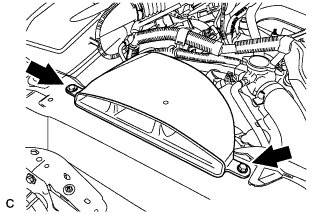

| 69. INSTALL NO. 1 INLET AIR CLEANER |

Install the inlet air cleaner with the bolt.

- Torque:

- 5.0 N*m{ 51 kgf*cm, 44 in.*lbf}

| 70. INSTALL PROPELLER SHAFT WITH CENTER BEARING ASSEMBLY |

| 71. INSTALL FRONT EXHAUST PIPE ASSEMBLY |

| 72. ADD ENGINE OIL |

Add new oil.

- Specification:

Item Capacity Drain and refill with oil filter change 6.3 liters (6.7 US qts, 5.5 Imp. qts) Drain and refill without oil filter change 5.9 liters (6.2 US qts, 5.2 Imp. qts) Dry fill 7.2 liters (7.6 US qts, 6.3 Imp. qts)

Install the oil filter cap.

| 73. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

- Torque:

- 5.4 N*m{ 55 kgf*cm, 48 in.*lbf}

| 74. ADD ENGINE COOLANT |

Tighten all the plugs and fill the radiator with TOYOTA Super Long Life Coolant (SLLC).

- Torque:

- 13 N*m{ 130 kgf*cm, 9 ft.*lbf}for cylinder block drain cock plug

Add engine coolant.

- Specified capacity:

- 9.1 liters (9.6 US qts, 8.0 lmp. qts)

- HINT:

Slowly pour coolant into the radiator reservoir until it reaches the FULL line.

Press the inlet and outlet radiator hoses several times by hand, and then check the level of the coolant.

If the coolant level is low, add coolant.

Install the radiator cap and reservoir cap.

Bleed air from the cooling system.

- NOTICE:

- Before starting the engine to warm up the engine, turn the A/C switch OFF.

Warm up the engine until the thermostat opens. While the thermostat is open, circulate the coolant for several minutes.

- HINT:

- The thermostat open timing can be confirmed by pressing the inlet radiator hose by hand, and checking when the engine coolant starts to flow inside the hose.

- NOTICE:

- When pressing the radiator hoses:

Maintain the engine speed at 2,000 to 2,500 rpm.

Press the inlet and outlet radiator hoses several times by hand to bleed air.

- NOTICE:

- When pressing the radiator hoses:

Stop the engine, and wait until the engine coolant cools down to ambient temperature.

- NOTICE:

- Do not remove the radiator cap while the engine and radiator are still hot. Pressurized, hot engine coolant and steam may be released and cause serious burns.

Check the coolant level in the radiator reservoir.

If the coolant level is low, add SLLC to the radiator reservoir FULL line.

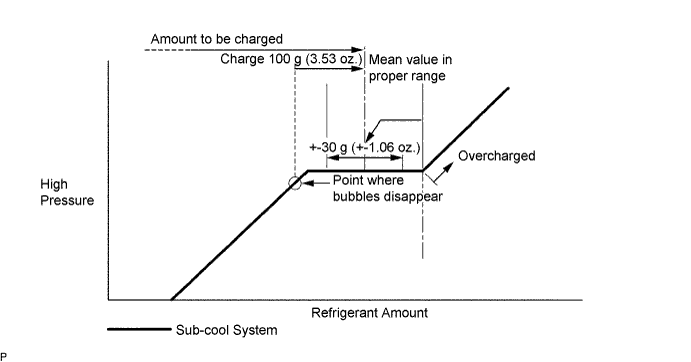

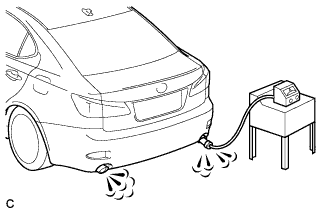

| 75. CHARGE REFRIGERANT |

Perform vacuum purging using a vacuum pump.

Charge refrigerant HFC-134a (R134a).

- Standard:

- 430 +- 30 g (15.17 +- 1.06 oz.)

- SST

- 07110-58060(07117-58060,07117-58070,07117-58080,07117-58090,07117-78050,07117-88060,07117-88070,07117-88080)

- NOTICE:

| 76. CHECK FOR FUEL LEAKS |

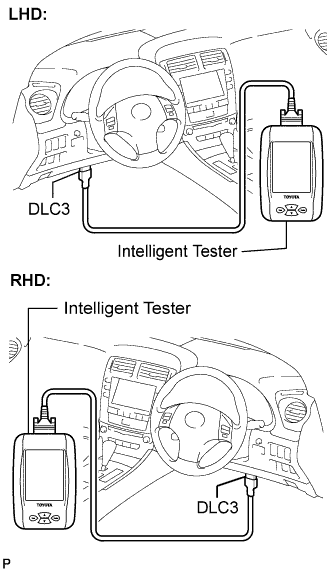

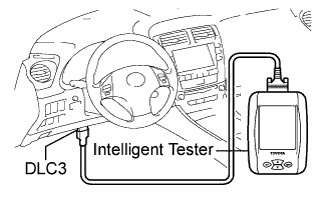

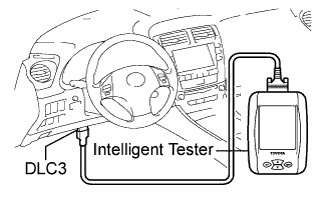

Connect the intelligent tester to the DLC3.

Turn the engine switch on (IG).

- NOTICE:

- Do not start the engine.

Push the intelligent tester main switch ON.

Select the following menus: Powertrain / Engine / Active Test / Control the Fuel Pump /Speed.

Check the fuel pump operation.

Check for pressure in the fuel inlet tube from the fuel line. Check that sound of fuel flowing in the fuel tank can be heard.

If no sound can be heard, check the integration relay, fuel pump, ECM and wiring connector.

Check for fuel leaks.

Check that there are no fuel leaks anywhere on the system after performing maintenance.

If there is a fuel leak, repair or replace parts as necessary.

| 77. CHECK FOR ENGINE COOLANT LEAKS |

- NOTICE:

- Before performing each inspection, turn the A/C switch OFF.

- CAUTION:

- Do not remove the radiator cap while the engine and radiator are still hot. Pressurized, hot engine coolant and steam may be released and cause serious burns.

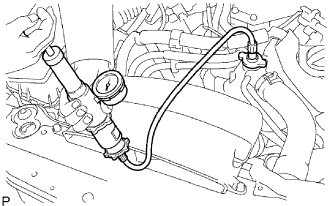

Fill the radiator with coolant and attach a radiator cap tester.

Warm up the engine.

Using a radiator cap tester, increase the pressure inside the radiator to 118 kPa (1.2 kgf*cm2, 17 psi), and check that the pressure does not drop.

If the pressure drops, check the hoses, radiator and water pump for leaks. If no external leaks are found, check the heater core, cylinder block and cylinder head.

| 78. CHECK FOR ENGINE OIL LEAKS |

| 79. CHECK FOR EXHAUST GAS LEAKS |

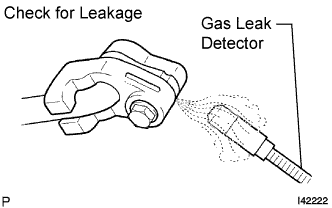

| 80. CHECK FOR LEAKAGE OF REFRIGERANT |

After recharging the refrigerant gas, check for refrigerant gas leakage using a halogen leak detector.

Perform the operation under the following conditions:

Using a gas leak detector, check the refrigerant line for leakage.

If a gas leak is not detected on the drain hose, remove the blower motor control (blower resistor) from the cooling unit. Insert the gas leak detector sensor into the unit and perform the test.

Disconnect the connector and leave the pressure switch on for approximately 20 minutes. Bring the gas leak detector close to the pressure switch and perform the test.

| 81. INSTALL FRONT WHEEL |

- Torque:

- 103 N*m{ 1,050 kgf*cm, 76 ft.*lbf}

| 82. PLACE FRONT WHEELS FACING STRAIGHT AHEAD |

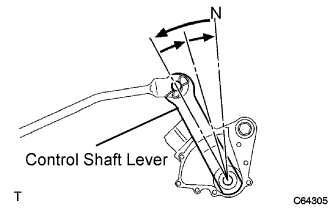

| 83. ADJUST SHIFT LEVER POSITION |

Remove the nut and disconnect the shifting rod.

Turn the control shaft lever of the park/neutral position switch counterclockwise until it stops, and turn it clockwise 2 notches to set it to the N position.

Move the shift lever to the N position and tighten the nut while lightly pushing the lever toward the R position.

- NOTICE:

- Do not push the shift lever too hard.

After adjustment, check that the shift lever moves smoothly and the shift lever and gear operate correctly.

| 84. CHECK SHIFT LEVER POSITION |

When shifting from the P to R position with the engine switch on (IG) and the brake pedal depressed, make sure that the shift lever moves smoothly and moves correctly into the position.

Start the engine and make sure that the vehicle moves forward when shifting from the N to D position and moves rearward when shifting to the R position.

If operation cannot be done as specified, inspect the park/neutral position switch assembly and check the shift lever assembly installation condition.

| 85. CHECK AND ADJUST FRONT WHEEL ALIGNMENT |

| 86. CHECK IGNITION TIMING |

Warm up the engine and stop the engine.

- NOTICE:

- A warmed up engine should have an engine coolant temperature of over 80°C (176°F), have an engine oil temperature of 60°C (140°F), and the engine rpm should be stabilized.

When using the intelligent tester:

Connect the intelligent tester to the DLC3.

Start the engine and idle it.

Push the intelligent tester main switch ON.

Enter the following items: Powertrain / Engine and ECT / Data list / IGN Advance.

- Ignition timing:

- 5 to 15° BTDC at idle

- HINT:

- Refer to the intelligent tester operator's manual for further details.

When not using the intelligent tester:

Remove the V-bank cover sub-assembly.

Connect the tester probe of a timing light to the wire of the ignition connector for No. 1 cylinder.

- NOTICE:

- Use a timing light which can detect the primary current.

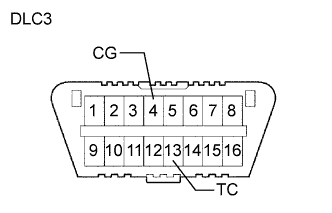

Using SST, connect terminals TC and CG of the DLC3.

- SST

- 09843-18040

- NOTICE:

Using a timing light, check the ignition timing.

- Ignition timing:

- 8 to 12 BTDC at idle

Remove the SST from the DLC3.

Check the ignition timing.

- Ignition timing:

- 5 to 15° BTDC at idle

Check that the ignition timing advances immediately when the engine speed is increased.

Disconnect the timing light from the engine.

Install the V-bank cover sub-assembly.

| 87. CHECK ENGINE IDLE SPEED |

Warm up and stop the engine.

- NOTICE:

- A warmed up engine should have an engine coolant temperature of over 80°C (176°F) and an engine oil temperature of 60°C (140°F), and the engine rpm should be stabilized.

When using the intelligent tester:

Connect the intelligent tester to the DLC3.

- NOTICE:

- Switch off all accessories and A/C before connecting the intelligent tester.

Race the engine speed at 2,500 rpm for approx. 90 seconds.

Push the intelligent tester main switch ON.

Enter the following items: powertrain / Engine and ECT / Data list / Engine SPD.

- Idle speed:

- 650 to 750 rpm

- NOTICE:

- When checking the idle speed, the transmission should be in the neutral.

- HINT:

- Refer to the intelligent tester operator's manual for further details.

If the idle speed is not as specified, check the air intake system.

Disconnect the intelligent tester from the DLC3.

When not using the intelligent tester:

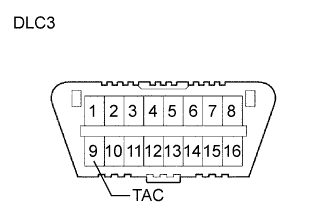

Using SST, connect the tachometer probe to terminal TAC of the DLC3.

- SST

- 09843-18040

- NOTICE:

- Confirm the terminal numbers before connecting them. Connecting the wrong terminals can damage the engine.

Race the engine speed at 2,500 rpm for approx. 90 seconds.

Check the idle speed.

- Idle speed (Transmission neutral position):

- 650 to 750 rpm

If the speed is not as specified, check the air intake system.

Disconnect the tachometer from the DLC3.

| 88. CHECK CO/HC |

- HINT:

- This check for determining whether or not the idle CO / HC complies with regulations.

Start the engine.

Keep the engine speed at 2,500 rpm for approx. 180 seconds.

Insert the CO / HC meter testing probe at least 40 cm (1.3 ft) into the tailpipe during idling.

Immediately check CO / HC concentration at idle and / or 2,500 rpm.

- HINT:

Check the A/F sensor and heated oxygen sensor operation.

See the table below for possible causes, then inspect and correct the applicable causes if necessary.

| CO | HC | Symptom | Causes |

| Normal | High | Rough idle | 1 .Faulty ignitions Incorrect timing Fouled, shorted or improperly gapped plugs 2. Leaky intake and exhaust valves 3. Leaky cylinder |

| Low | High | Rough idle (Fluctuating HC reading) | 1. Vacuum leaks PCV hose Intake manifold Throttle body 2. Lean mixture causing misfire |

| High | High | Rough idle (Black smoke from exhaust) | 1. Restricted air filter 2. Faulty fuel SFI system Faulty pressure Defective ECT sensor Faulty ECM Faulty injector Faulty throttle position sensor Faulty MAF sensor |

| 89. CHECK ENGINE OIL LEVEL |

Warm up the engine, stop the engine and wait 5 minutes. The oil level should be between the dipstick's low level mark and full level mark.

If low, check for leakage and add oil up to the full level mark.

- NOTICE:

- Do not fill with engine oil above the full level mark.

| 90. INSTALL ENGINE UNDER COVER REAR LH |

Install the engine under cover rear LH with the bolt.

| 91. INSTALL ENGINE UNDER COVER REAR RH |

- HINT:

- Install the RH side following the same procedures as for the LH side.

| 92. INSTALL NO. 2 ENGINE UNDER COVER |

| 93. INSTALL ENGINE UNDER COVER |

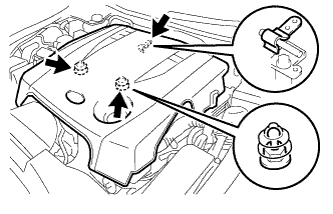

| 94. INSTALL V-BANK COVER SUB-ASSEMBLY |

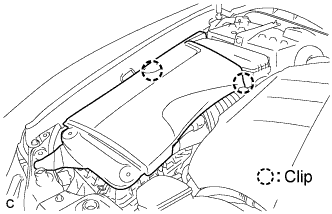

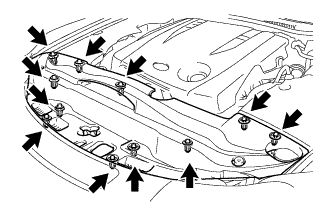

Engage the 2 clips on the front of the cover, and then engage the clip on the rear to install the V-bank cover.

- NOTICE:

| 95. INSTALL ENGINE ROOM SIDE COVER LH |

Install the side cover with the 5 clips.

| 96. INSTALL ENGINE ROOM COVER SIDE RH |

Install the side cover with the 2 clips.

| 97. INSTALL COOL AIR INTAKE DUCT SEAL |

Install the intake duct seal with the 11 clips.

| 98. PERFORM INITIALIZATION |

Perform initialization .

- NOTICE:

- Certain systems need to be initialized after reconnecting the cable to the negative (-) battery terminal.