Lexus IS250 IS220d GSE20 ALE20 4GR-FSE ENGINE CONTROL SYSTEM

CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P0014, P0015, P0024 OR P0025)

PERFORM ACTIVE TEST BY INTELLIGENT TESTER (OPERATE OCV)

CHECK WHETHER DTC OUTPUT RECURS (DTC P0014, P0015, P0024 OR P0025)

CHECK VALVE TIMING (CHECK FOR LOOSE AND JUMPED TEETH ON TIMING CHAIN)

INSPECT CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY (OCV FOR EXHAUST CAMSHAFT)

INSPECT OIL CONTROL VALVE FILTER AND PIPE

REPLACE CAMSHAFT TIMING GEAR ASSEMBLY (FOR EXHAUST CAMSHAFT)

CHECK WHETHER DTC OUTPUT RECURS

DTC P0014 Camshaft Position "B" - Timing Over-Advanced or System Performance (Bank 1)

DTC P0015 Camshaft Position "B" - Timing Over-Retarded (Bank 1)

DTC P0024 Camshaft Position "B" - Timing Over-Advanced or System Performance (Bank 2)

DTC P0025 Camshaft Position "B" - Timing Over-Retarded (Bank 2)

DESCRIPTION

- HINT:

- If DTC P0014, P0015, P0024 or P0025 is present, check the VVT (Variable Valve Timing) system.

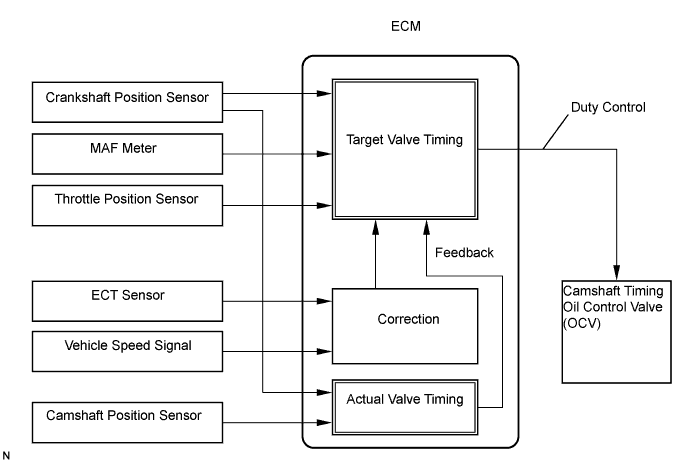

The Variable Valve Timing (VVT) system includes the ECM, OCV and VVT controller. The ECM sends a target duty-cycle control signal to the OCV. This control signal regulates the oil pressure supplied to the VVT controller. Camshaft timing control is performed according to engine operating conditions such as the intake air volume, throttle valve position and engine coolant temperature. The ECM controls the OCV, based on the signals transmitted by several sensors. The VVT controller regulates the exhaust camshaft angle using oil pressure through the OCV. As a result, the relative positions of the camshaft and crankshaft are optimized, the engine torque and fuel economy improve, and the exhaust emissions decrease under overall driving conditions. The ECM detects the actual exhaust valve timing using signals from the camshaft and crankshaft position sensors, and performs feedback control. This is how the target intake valve timing is verified by the ECM.

| DTC No. | DTC Detection Condition | Trouble Area |

| P0014 P0024 | Advanced cam timing: With warm engine and engine speed of between 500 rpm and 4,000 rpm, all conditions (a), (b) and (c) met (2 trip detection logic): (a) Difference between target and actual exhaust valve timing more than 5 °CA (Crankshaft Angle) for 4.5 seconds (b) Current exhaust valve timing fixed (timing changes less than 5°CA in 5 seconds) (c) Variations in VVT controller timing more than 19°CA of maximum delayed timing (advanced) | Valve timing Oil control valve (OCV) for exhaust camshaft (bank 1) OCV filter (bank 1) Exhaust camshaft timing gear assembly ECM |

| P0015 P0025 | Retarded cam timing: With warm engine and engine speed of between 500 rpm and 4,000 rpm, all conditions (a), (b) and (c) met (1 trip detection logic): (a) Difference between target and actual exhaust valve timing more than 5°CA (Crankshaft Angle) for 4.5 seconds (b) Current exhaust valve timing fixed (timing changes less than 5°CA in 5 seconds) (c) Variations in VVT controller timing more than 19°CA or less of maximum delayed timing (retarded) | Valve timing OCV for exhaust camshaft (bank 2) OCV filter (bank 2) Exhaust camshaft timing gear assembly ECM |

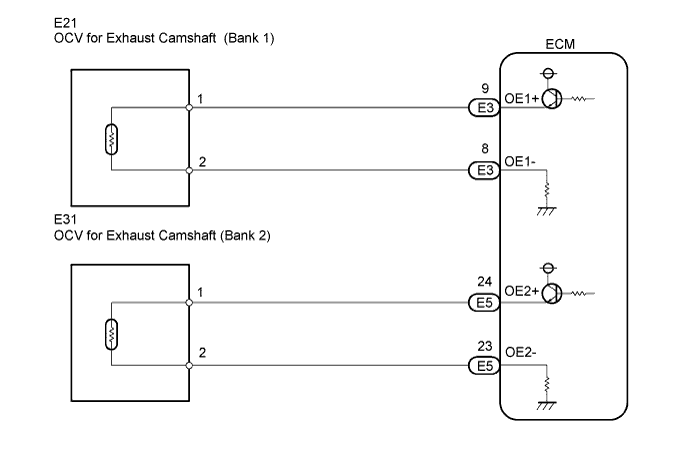

WIRING DIAGRAM

INSPECTION PROCEDURE

- HINT:

| Abnormal bank | Advanced timing over (Valve timing is out of specified range) | Retarded timing over (Valve timing is out of specified range) |

| Bank 1 | P0014 | P0015 |

| Bank 2 | P0024 | P0025 |

| 1.CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P0014, P0015, P0024 OR P0025) |

Connect the intelligent tester to the DLC3.

Turn the engine switch on (IG) and turn the tester ON.

Enter the following menus: Power train / Engine / DTC.

Read DTCs.

- Result:

Display (DTC output) Proceed to P0014, P0015, P0024 or P0025 A P0014, P0015, P0024 or P0025 and other DTCs B

- HINT:

- If any DTCs other than P0014, P0015, P0024 or P0025 are output, troubleshoot those DTCs first.

|

| ||||

| OK | |

| 3.CHECK WHETHER DTC OUTPUT RECURS (DTC P0014, P0015, P0024 OR P0025) |

Connect the intelligent tester to the DLC3.

Turn the engine switch on (IG) and turn the tester ON.

Clear DTCs .

Start the engine and warm it up.

Switch the ECM from normal mode to check mode using the tester .

Drive the vehicle for more than 10 minutes.

Read DTCs using the tester.

- OK:

- No DTC output.

|

| ||||

| OK | ||

| ||

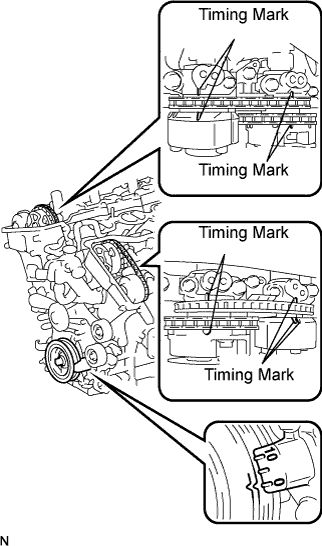

| 4.CHECK VALVE TIMING (CHECK FOR LOOSE AND JUMPED TEETH ON TIMING CHAIN) |

Remove the cylinder head covers RH and LH.

Turn the crankshaft pulley, and align its groove with the timing mark "0" of the timing chain cover.

Check that the timing marks of the camshaft timing gears are aligned with the timing marks of the bearing cap as shown in the illustration.

If not, turn the crankshaft 1 revolution (360°), then align the marks as above.

- OK:

- Timing marks on crankshaft timing gears are aligned as shown in the illustration.

Reinstall the cylinder head covers.

|

| ||||

| OK | |

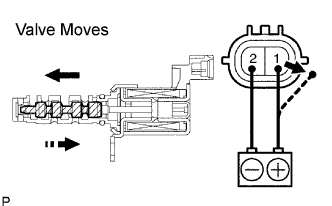

| 5.INSPECT CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY (OCV FOR EXHAUST CAMSHAFT) |

Remove the OCV.

Measure the resistance between the terminals of the OCV.

- Standard resistance:

- 6.9 to 7.9 Ω at 20°C (68°F)

Apply the positive battery voltage to terminal 1 and negative battery voltage to terminals 2. Check the valve operation.

- OK:

- Valve moves quickly.

Reinstall the OCV.

|

| ||||

| OK | |

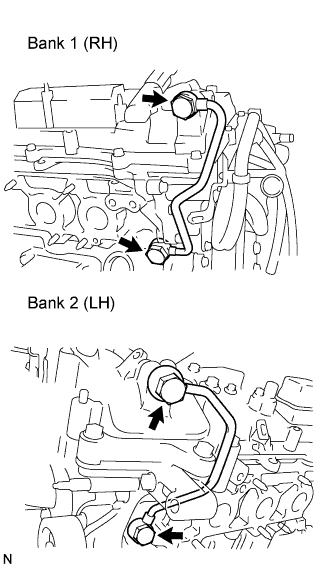

| 6.INSPECT OIL CONTROL VALVE FILTER AND PIPE |

Remove the oil pipe No. 1 or No. 2.

Remove the oil control valve filter.

Check that the filter and pipe are not clogged.

- OK:

- Filter is not clogged.

|

| ||||

| OK | |

| 7.REPLACE CAMSHAFT TIMING GEAR ASSEMBLY (FOR EXHAUST CAMSHAFT) |

| NEXT | |

| 8.CHECK WHETHER DTC OUTPUT RECURS |

Clear the DTCs.

Operate the intelligent tester, or disconnect the EFI and ETCS fuses more than 60 sec. to erase the codes.

Start the engine and warm up the engine.

Switch the ECM from normal mode to check mode using the intelligent tester .

Drive the vehicle for more than 10 minutes or more.

Read output DTCs using the intelligent tester.

- OK:

- No DTC output.

- HINT:

- DTC P0014, P0015, P0024 or P0025 is output when foreign objects in engine oil are caught in some parts of the system. These codes will stay registered even if the system returns to normal after a short time. These foreign objects are then captured by the oil, thus eliminating the source of the problem.

|

| ||||

| NG | ||

| ||