Lexus IS250 IS220d GSE20 ALE20 2AD-FHV ENGINE CONTROL SYSTEM

CHECK HARNESS AND CONNECTOR (IN ENGINE ENGINE COMPARTMENT)

PERFORM CONFIRMATION DRIVING PATTERN

CHECK DTC OUTPUT (RELATING TO ENGINE)

PERFORM ACTIVE TEST BY INTELLIGENT TESTER (FUEL LEAK TEST)

READ VALUE OF INTELLIGENT TESTER (MAP, MAF AND FUEL PRESSURE)

READ VALUE OF INTELLIGENT TESTER (INJECTION FEEDBACK VAL AND INJECTION VOLUME)

CHECK INJECTOR COMPENSATION CODE

CHECK ENGINE MOUNTING INSULATOR

INSPECT DIESEL THROTTLE BODY ASSEMBLY

CHECK INJECTOR ASSEMBLY (IDENTIFY MALFUNCTIONING CYLINDER INJECTOR)

PERFORM ACTIVE TEST BY INTELLIGENT TESTER (FUEL CUT FOR IDENTIFYING MALFUNCTIONING CYLINDER)

PERFORM ACTIVE TEST BY INTELLIGENT TESTER (FUEL CUT FOR IDENTIFYING MALFUNCTION)

CHECK CYLINDER COMPRESSION PRESSURE

CHECK INJECTOR (MALFUNCTIONING CYLINDER'S INJECTOR FOR DEPOSITS)

READ VALUE OF INJECTOR ASSEMBLY (INJECTION FEEDBACK VAL AND INJECTION VOLUME)

CHECK INJECTORS FOR DEPOSITS (EXCEPT FUEL ADDITION INJECTOR)

READ VALUE OF INJECTOR (INJECTION FEEDBACK VAL AND INJECTION VOLUME)

INSPECT COMMON RAIL ASSEMBLY (FUEL PRESSURE SENSOR)

ECD SYSTEM - Rough Idling or Excessive Engine Vibrations

DESCRIPTION

| Malfunction Condition | Main Trouble Areas | Related Trouble Areas |

Rough idling or shuddering due to abnormal combustion Shuddering when vehicle starting due to clutch system malfunctions |

Injector malfunctions Injector sliding malfunction Injector stuck closed Injector stuck open Deposit in injector Injector circuit malfunction Clutch system malfunctions Clutch system (shuddering when starting) |

Injector compensation code Fuel leak Engine mounting insulator Intake air system leakage Intake air system blockage EGR system Throttle valve system Supply pump Pressure limiter Fuel pressure sensor EDU (P0200/97 set simultaneously) Low quality fuel Vehicle modifications Fuel filter air bleed problem Accessory problem (A/C, generator, etc.) ECM |

- HINT:

INSPECTION PROCEDURE

- NOTICE:

- HINT:

| 1.CHECK CLUTCH SYSTEM |

Identify when shuddering occurs.

- Result:

Driving Condition Proceed to When idling A When engaging engine clutch at vehicle start B

(Clutch system shudders)

|

| ||||

|

| ||||

| A | |

| 7.READ VALUE OF INTELLIGENT TESTER (INJECTION FEEDBACK VAL AND INJECTION VOLUME) |

Select the following menu items in order and read the values.

- Standard:

Item Engine Speed* Standard Range Description Injection Feedback Val #1 Idling -3.0 to 3.0 mm3 Value of injector fuel injection volume compensates for differences in combustion condition of cylinders Positive values indicate control which corrects combustion degradationNegative values indicate control which corrects excessive combustion pressureIf problems exist, "Injection Feedback Val" may deviate from the -3.0 and 3.0 mm rangeInjection Feedback Val #2 Idling -3.0 to 3.0 mm3 Injection Feedback Val #3 Idling -3.0 to 3.0 mm3 Injection Feedback Val #4 Idling -3.0 to 3.0 mm3 Injection Volume Idling 3.9 to 7.0 mm3 Fuel injection volume value controlled by ECU Controls NE signal, fuel temperature, engine coolant temperature, intake air temperature, boost pressure, atmospheric pressure, and EGR volume.If problems exist, "Injection Volume" may be outside the standard range

- Result:

Result Proceed to Standard range A Injection Feedback Val #1 to #4 and/or Injection Volume outside standard range B

- HINT:

- *: The A/C switch and all accessory switches should be OFF with a fully warm engine.

|

| ||||

| A | |

| 8.CHECK INJECTOR COMPENSATION CODE |

Read the injector compensation code .

- HINT:

- If the injector compensation code is not correctly registered, it may cause malfunctions .

Check the injector compensation code.

- OK:

- Compensation code of the installed injector is same as the code registered in the ECM.

|

| ||||

| NG | ||

| ||

| 14.CHECK INJECTOR ASSEMBLY (IDENTIFY MALFUNCTIONING CYLINDER INJECTOR) |

Follow the instructions in the table below according to the check result of the intelligent tester.

- HINT:

- This operation is based on the premise that the common rail pressure is normal.

- Standard:

Item Engine Speed* Reference Value Injection Feedback Val #1 to #4 Idling -3.0 to 3.0 mm3 Injection Volume Idling 3.9 to 7.0 mm3

- HINT:

- *: The A/C switch and all accessory switches should be OFF, and the engine should be fully warmed up.

- Result:

Injection Feedback Val #1 to #4 Injection volume Less than 3.9 mm3 Between 3.9 to 7.0 mm3 (Normal) More than 7.0 mm3 3.0 mm3 or more, -3.0 mm3 or less A B B Between -3.0 to 3.0 mm3 - Normal C* Proceed to Inspection Areas Descriptions A Inspect and repair cylinder injector with revised injection volume of less than -3.0 mm3: Perform power balance inspection and identify malfunctioning cylinderReplace malfunctioning cylinder injectorAbnormal value cylinder injector injects excessively large quantity of fuel B Identify malfunctioning cylinders by conducting power balance inspection: Perform power balance inspection to identify malfunctioning cylindersClean malfunctioning cylinder injector, then check and repair itAbnormal value cylinder injector injects excessively large quantity of fuel Fuel injection volume too low due to injector nozzle being blocked by depositsAbnormal value cylinder injector compression decreasesAbnormal value cylinder injector injects excessively large quantity of fuelC Inspect and repair all cylinder injectors:

Clean all cylinder injectors, inspect, and repair themAll cylinder injectors inject excessively small quantity of fuel:

Fuel injection volume too low due to all cylinder injector nozzles being blocked by deposits

- HINT:

- *: When the Injection Volume displayed on the intelligent tester is large despite the Fuel Press and Injection Feedback Val #1 to #4 in the Data List being normal, the injector may be clogged. In this case, there may be deposits inside or outside the tip of the injector.

|

| ||||

|

| ||||

| A | |

| 15.PERFORM ACTIVE TEST BY INTELLIGENT TESTER (FUEL CUT FOR IDENTIFYING MALFUNCTIONING CYLINDER) |

Connect the intelligent tester to the DLC3.

Start the engine and turn the intelligent tester ON.

Enter the following menus: Powertrain / Engine / Active Test / Control the Cylinder #1, #2, #3, and #4 Fuel Cut.

Check the four cylinders in sequence to identify any faulty cylinders by performing the power balance inspection.

- HINT:

| NEXT | ||

| ||

| 16.PERFORM ACTIVE TEST BY INTELLIGENT TESTER (FUEL CUT FOR IDENTIFYING MALFUNCTION) |

Connect the intelligent tester to the DLC3.

Start the engine and turn the intelligent tester ON.

Enter the following menus: Powertrain/ Engine / Active Test / Control the Cylinder #1, #2, #3, and #4 Fuel Cut.

Check the four cylinders in sequence to identify any faulty cylinders by performing the power balance inspection.

- HINT:

| NEXT | |

| 17.CHECK CYLINDER COMPRESSION PRESSURE |

Check the cylinder compression pressure.

- Standard:

- 2,700 kPa (27.5 kgf/cm2, 392 psi)

- Minimum pressure:

- 2,200 kPa (22.4 kgf/cm2, 319 psi)

- Difference between each cylinder:

- 500 kPa (5.1 kgf/cm2, 73 psi)

|

| ||||

| OK | |

| 18.CHECK INJECTOR (MALFUNCTIONING CYLINDER'S INJECTOR FOR DEPOSITS) |

- HINT:

- If an injector is contaminated with deposits, the fuel injection volume deviates from the standard range. This may cause malfunctions.

Check the injector for any deposits.

- Result:

Injector Condition Proceed to Deposits A No deposits B

|

| ||||

| A | |

| 19.CLEAN INJECTOR |

Wipe away deposits from the tips of the injectors.

- HINT:

| NEXT | |

| 20.READ VALUE OF INJECTOR ASSEMBLY (INJECTION FEEDBACK VAL AND INJECTION VOLUME) |

Reinstall the injector to the cylinder head.

Connect the intelligent tester to the DLC3.

Turn the engine switch ON (IG) and turn the intelligent tester ON.

Start the engine and warm it up.

Enter the following menus: Powertrain / Engine / Data List.

Select the following menu items in order and read the values.

- Standard:

Item Engine Speed* Reference Value Injection Feedback Val #1 to #4 Idling -3.0 to 3.0 mm3 Injection Volume Idling 3.9 to 7.0 mm3

- HINT:

- *: The A/C switch and all accessory switches should be OFF, and the engine should be fully warmed up. When the values are outside the standard range, deposits inside the injector may be causing the problem.

- OK:

- Values are within the standard range.

|

| ||||

| OK | ||

| ||

| 21.CHECK INJECTORS FOR DEPOSITS (EXCEPT FUEL ADDITION INJECTOR) |

- HINT:

- If an injector is contaminated with deposits, the fuel injection volume deviates from the standard range. This may cause malfunctions.

Check the injector for any deposits.

- Result:

Injector Condition Proceed to Deposits A No deposits B

|

| ||||

| A | |

| 22.CLEAN INJECTOR |

Wipe away deposits from the tips of the injectors.

- HINT:

| NEXT | |

| 23.READ VALUE OF INJECTOR (INJECTION FEEDBACK VAL AND INJECTION VOLUME) |

Reinstall the injector to the cylinder head.

Connect the intelligent tester to the DLC3.

Turn the engine switch ON (IG) and turn the intelligent tester ON.

Start the engine and warm it up.

Enter the following menus: Powertrain / Engine / Data List.

Select the following menu items in order and read the values.

- Standard:

Item Engine Speed* Reference Value Injection Feedback Val #1 to #4 Idling -3.0 to 3.0 mm3 Injection Volume Idling 3.9 to 7.0 mm3

- HINT:

- *: The A/C switch and all accessory switches should be OFF, and the engine should be fully warmed up. When the values are outside the standard range, deposits inside the injector may be causing the problem.

- OK:

- Values are within the standard range.

|

| ||||

| OK | ||

| ||

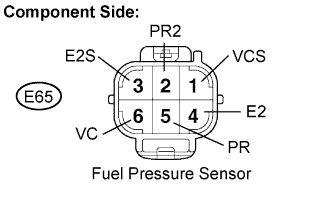

| 24.INSPECT COMMON RAIL ASSEMBLY (FUEL PRESSURE SENSOR) |

Disconnect the E65 fuel sensor connector.

Measure the resistance between each terminal of the fuel pressure sensor connector.

- Standard resistance:

Tester Connection Specified Condition PR (E65-5) - E2 (E65-4) 16.4 kΩ or less PR2 (E65-2) - E2S (E65-3) 16.4 kΩ or less PR (E65-5) - VC (E65-6) 3 kΩ or less PR2 (E65-2) - VCS (E65-1) 3 kΩ or less

Reconnect the fuel pressure sensor connector.

|

| ||||

| OK | |

| 25.INSPECT SUPPLY PUMP ASSEMBLY |

Measure the resistance of the suction control valve terminals.

- Standard resistance:

Condition Specified Condition 20°C (68°F) 1.9 to 2.3 Ω

|

| ||||

| OK | ||

| ||