Lexus IS250 IS220d GSE20 ALE20 2AD-FHV EMISSION CONTROL

EXHAUST MANIFOLD CONVERTER - INSTALLATION

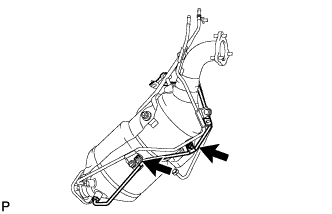

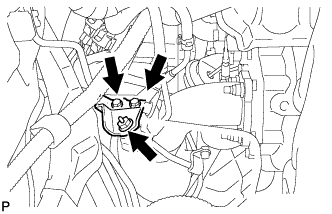

| 1. INSTALL NO. 1 MANIFOLD CONVERTER INSULATOR |

Install the No. 1 manifold converter insulator with the 3 bolts and nut.

- Torque:

- 25 N*m{ 255 kgf*cm, 18 ft.*lbf}

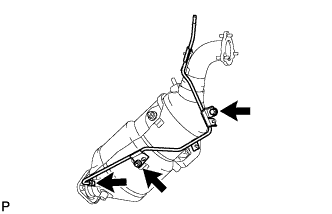

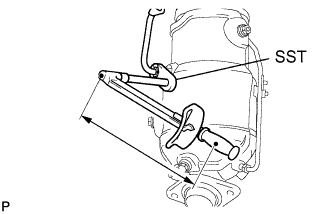

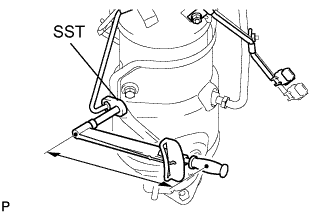

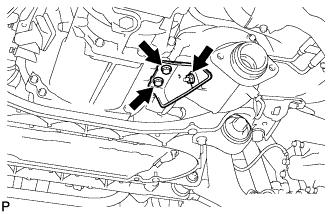

| 2. INSTALL NO. 2 VACUUM PIPE |

Temporarily install the No. 2 vacuum pipe with the bolt and nut.

Tighten the bolt and nut.

- Torque:

- 18 N*m{ 184 kgf*cm, 13 ft.*lbf}

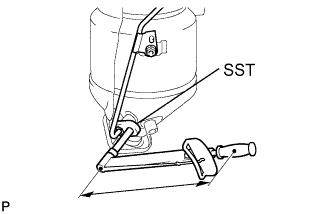

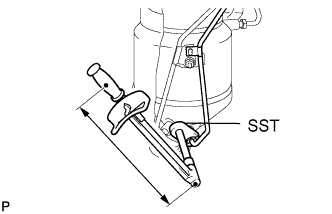

Using SST, tighten the nut of the No. 2 vacuum pipe.

- SST

- 09023-38401

- Torque:

- 30 N*m{ 306 kgf*cm, 22 ft.*lbf}

- HINT:

- Use a torque wrench with a fulcrum length of 30 cm (11.81 in.).

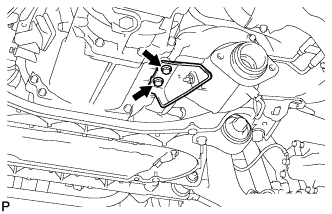

| 3. INSTALL NO. 1 VACUUM PIPE |

Temporarily install the No. 1 vacuum pipe with the nut.

Tighten the nut.

- Torque:

- 18 N*m{ 184 kgf*cm, 13 ft.*lbf}

Using SST, tighten the nut of the No. 1 vacuum pipe.

- SST

- 09023-38401

- Torque:

- 30 N*m{ 306 kgf*cm, 22 ft.*lbf}

- HINT:

- Use a torque wrench with a fulcrum length of 30 cm (11.81 in.).

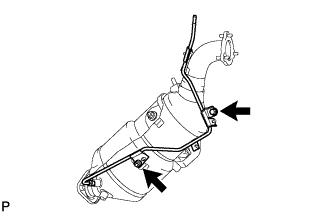

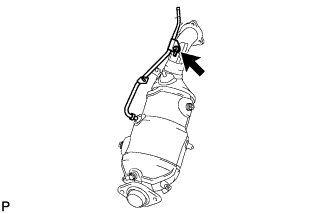

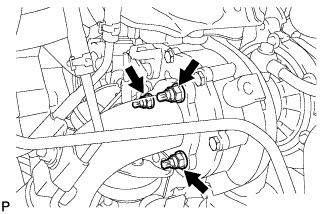

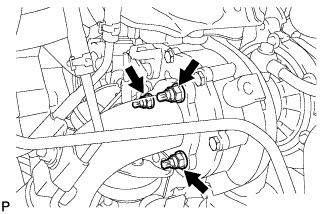

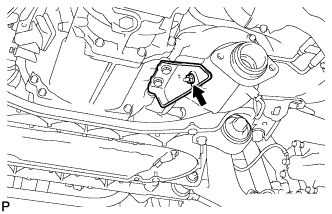

| 4. INSTALL EXHAUST GAS TEMPERATURE SENSOR (LOWER) |

Temporarily install the exhaust gas temperature sensor (lower) with the 2 nuts.

Tighten the 2 nuts.

- Torque:

- 6.4 N*m{ 65 kgf*cm, 57 in.*lbf}

Using SST, tighten the nut of the exhaust gas temperature sensor (lower).

- SST

- 09023-38401

- Torque:

- 30 N*m{ 306 kgf*cm, 22 ft.*lbf}

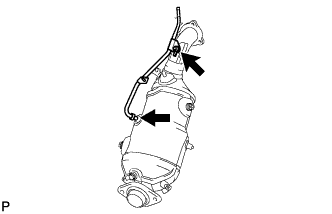

| 5. INSTALL EXHAUST GAS TEMPERATURE SENSOR (UPPER) |

Temporarily install the exhaust gas temperature sensor (upper).

Tighten the 3 nuts.

- Torque:

- 6.4 N*m{ 65 kgf*cm, 57 in.*lbf}

Using SST, tighten the nut of the exhaust gas temperature sensor (upper).

- SST

- 09023-38401

- Torque:

- 30 N*m{ 306 kgf*cm, 22 ft.*lbf}

- HINT:

- Use a torque wrench with a fulcrum length of 30 cm (11.81 in.).

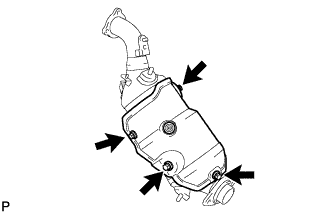

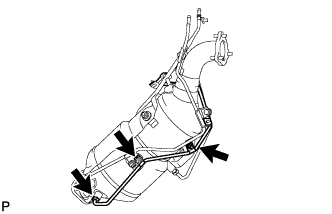

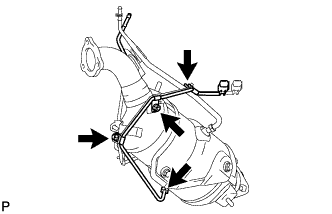

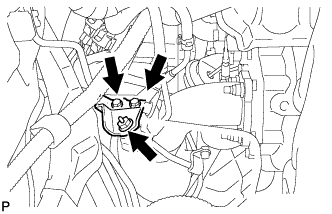

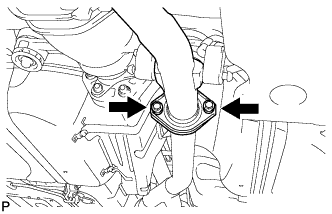

| 6. INSTALL EXHAUST MANIFOLD CONVERTER SUB-ASSEMBLY |

Temporarily install the No. 1 manifold stay.

Temporarily install a new turbine outlet elbow gasket and exhaust manifold converter with the 3 nuts.

Temporarily install the 2 bolts and nut.

Tighten the 3 nuts (Pushing the manifold converter against the No. 1 manifold stay).

- Torque:

- 25 N*m{ 255 kgf*cm, 18 ft.*lbf}

Tighten the 2 bolts and nut.

- Torque:

- 56 N*m{ 571 kgf*cm, 41 ft.*lbf}

Temporarily install the No. 2 exhaust manifold stay with the 2 bolts and nut.

Tighten the 2 bolts (Pushing the No. 2 exhaust manifold stay against the manual transmission).

- Torque:

- 56 N*m{ 571 kgf*cm, 41 ft.*lbf}

Tighten the nut.

- Torque:

- 56 N*m{ 571 kgf*cm, 41 ft.*lbf}

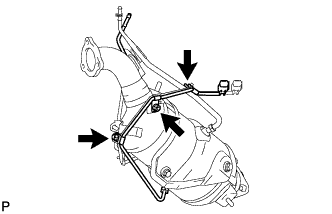

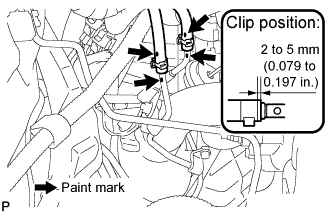

Using pliers, slide the clip to install the No. 1 and No. 2 vacuum transmitting hose assembly.

- HINT:

- Make sure that the paint marks on the No. 1 and No. 2 vacuum transmitting hose assemblies and No. 1 and No. 2 vacuum pipes are aligned.

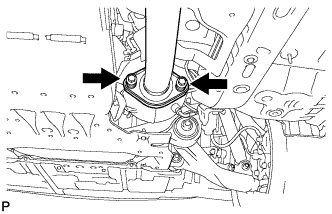

| 7. INSTALL FRONT EXHAUST PIPE ASSEMBLY |

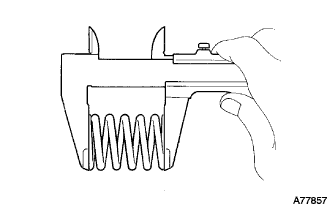

Using vernier calipers, measure the free length of the compression springs.

- Minimum length:

- 38.5 mm (1.516 in.)

If the free length is less than the minimum, replace the compression spring.

Fully insert 2 new gaskets to the exhaust manifold converter and front exhaust pipe assembly by hand.

- NOTICE:

- HINT:

- Using a plastic hammer, uniformly strike the gasket so that the gasket and front exhaust pipe are properly fit.

Install the front exhaust pipe assembly.

Install the 2 bolts and 2 compression springs.

- Torque:

- 43 N*m{ 439 kgf*cm, 32 ft.*lbf}

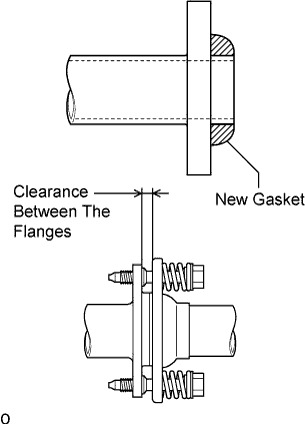

- NOTICE:

- After installation, check that the clearance is almost the same at any point between the flanges of the tail exhaust pipe assembly and front exhaust pipe assembly.

Install the 2 bolts and 2 compression springs.

- Torque:

- 43 N*m{ 439 kgf*cm, 32 ft.*lbf}

- NOTICE:

- After installation, check that the clearance is almost the same at any point between the flanges of the exhaust manifold converter and front exhaust pipe assembly.

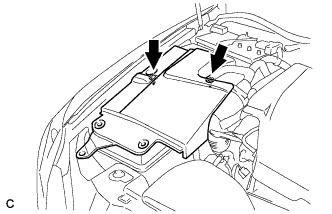

| 8. INSTALL BATTERY TRAY |

| 9. INSTALL POWER STEERING ECU ASSEMBLY |

- HINT:

| 10. INSTALL ENGINE ROOM SIDE COVER RH |

Install the side cover with the 2 clips.

| 11. INSTALL COOL AIR INTAKE DUCT SEAL |

Install the intake duct seal with the 11 clips.

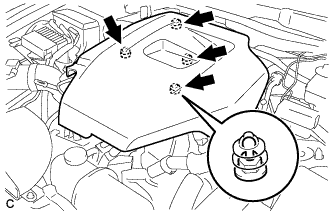

| 12. INSTALL NO. 1 ENGINE COVER |

Install the No. 1 engine cover.

| 13. PERFORM INITIALIZATION |

- HINT: