Ignition system Lexus

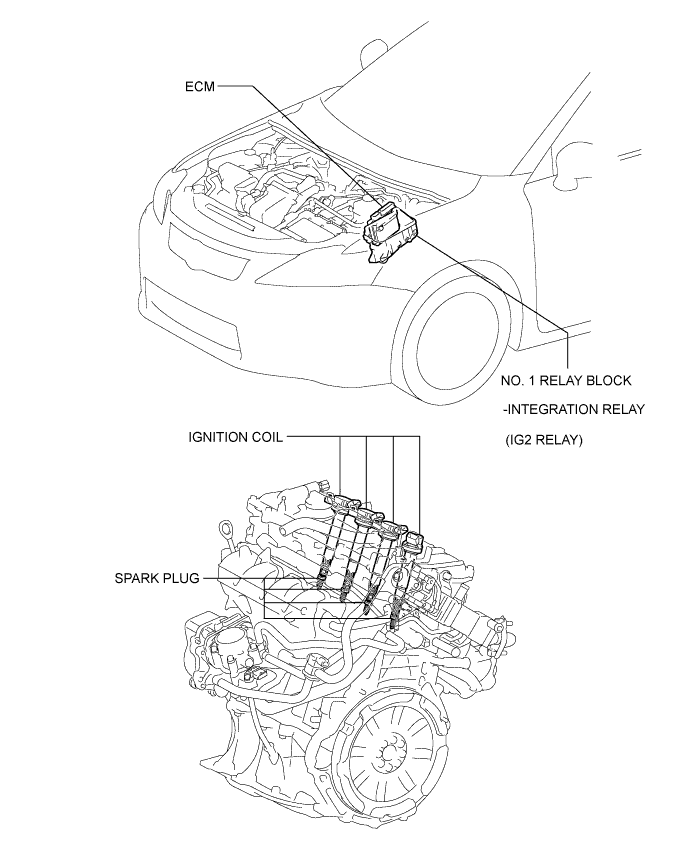

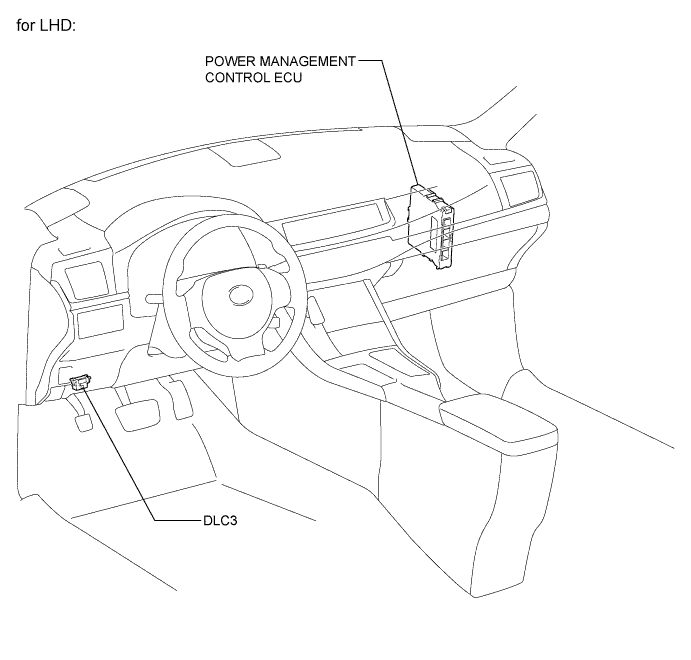

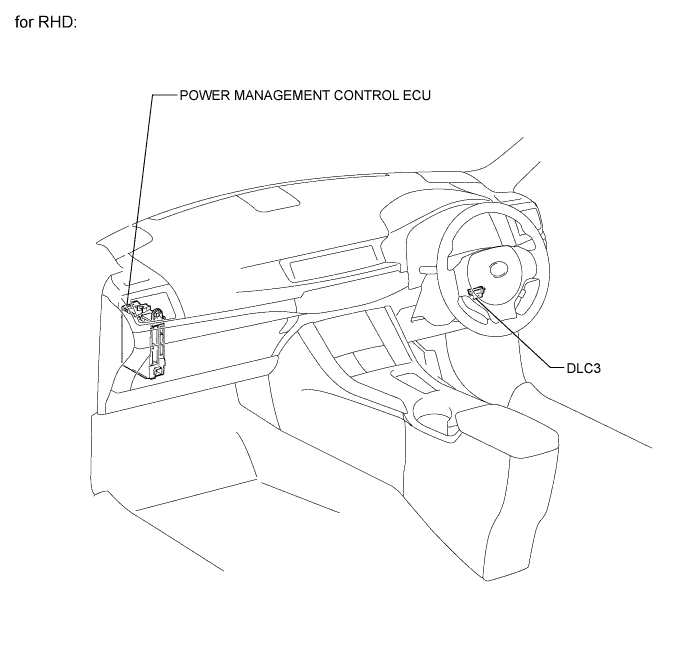

Parts location

Ignition system lexus

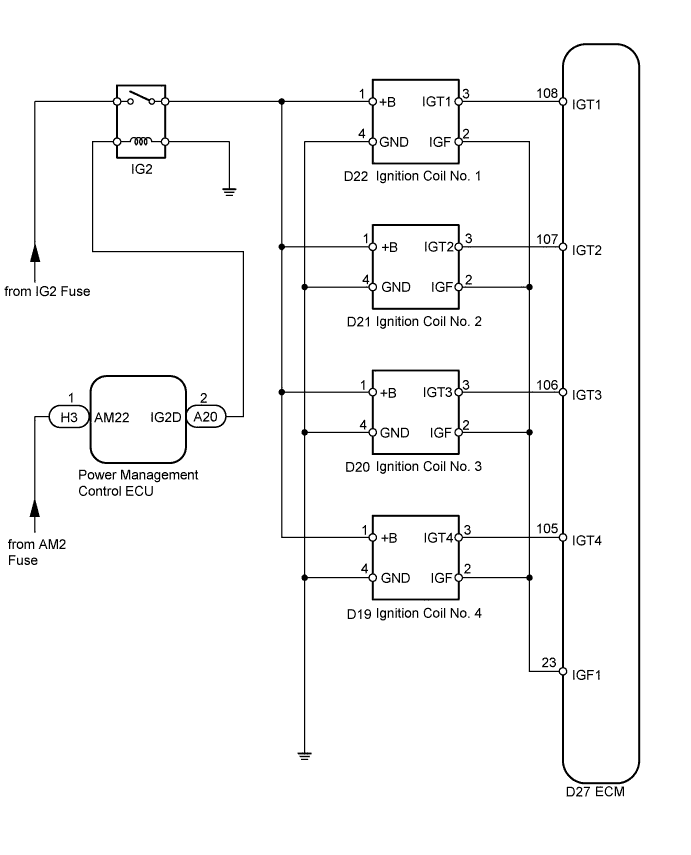

System diagram

Ignition system lexus

On-vehicle inspection

| 1. CHECK IGNITION COIL ASSEMBLY AND PERFORM SPARK TEST |

-

Check for DTCs .

NOTICE:

If any DTC is present, perform troubleshooting in accordance with the procedure for that DTC.

-

Check that spark occurs.

-

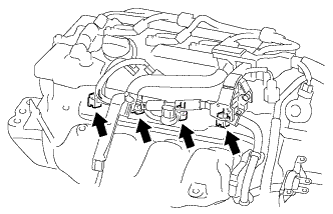

Remove the ignition coils and spark plugs .

-

Disconnect the 4 fuel injector connectors.

-

Set the vehicle to inspection mode (Step 3) .

-

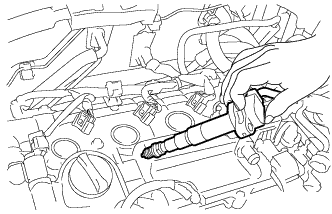

Install the spark plug into the ignition coil, and then connect the ignition coil connector. (Step 4)

-

Ground the spark plug. (Step 5)

-

Check that spark occurs while the engine is being cranked. (Step 6)

HINT:

Repeat steps 3 to 6 for each spark plug and ignition coil.

NOTICE:

- Ground the spark plugs when checking them.

- Replace any ignition coils that have been subjected to any physical impacts.

- Do not crank the engine for more than 2 seconds.

-

-

Perform the following spark test procedure.

-

Check that the ignition coil connector is securely connected.

Result:

Result Action NG Connect securely OK Go to next step -

Perform a spark test.

- Replace the ignition coil with a known good one.

- Set the vehicle to inspection mode .

- Perform the spark test again.

Result:

Result Action NG Go to next step OK Replace ignition coil -

Perform a spark test.

- Replace the spark plug with a known good one.

- Set the vehicle to inspection mode .

- Perform the spark test again.

Result:

Result Action NG Go to next step OK Replace the spark plug -

Check the power supply.

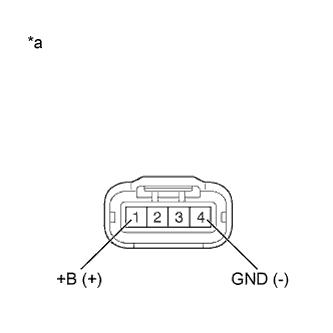

Text in Illustration *a Front view of wire harness connector (to Ignition Coil) - Turn the power switch on (IG).

- Measure the voltage according to the value(s) in the table below.

Standard Voltage:

Tester Connection Condition Specified Condition 1 (+B) - 4 (GND) Power switch on (IG) 11 to 14 V Result:

Result Action NG Check wiring between auxiliary battery and ignition coil and check ground circuit OK Replace the ECM

-

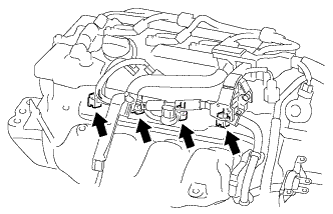

Connect the 4 fuel injector connectors.

-

Install the ignition coils and spark plugs .

-

| 2. INSPECT SPARK PLUG |

-

Check the electrode.

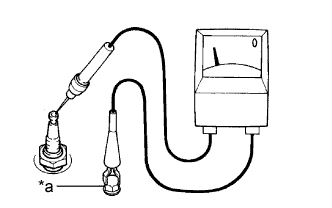

Text in Illustration *a Ground -

Using a megohmmeter, measure the resistance.

Standard Resistance:

10 M? or more

If the result is 10 M? or less, clean the plug and measure the resistance again.HINT:

If a megohmmeter is not available, perform the following simple inspection instead.

-

-

Alternative inspection method:

-

Quickly accelerate the engine to approximately 2500 rpm 5 times.

-

Remove each spark plug.

-

Visually check the spark plug. If the electrode is dry, the spark plug is functioning properly. If the electrode is damp, proceed to the next step.

-

-

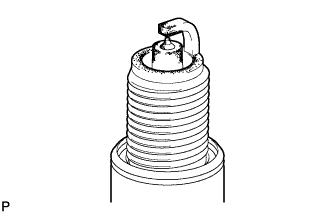

Check the spark plug for any damage to its threads and insulator. If there is any damage, replace the spark plug.

Recommended Spark Plug Manufacturer Spark Plug Type DENSO SC20HR11

-

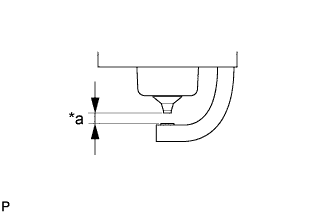

Check the spark plug electrode gap.

Text in Illustration *a Spark Plug Electrode Gap Maximum Electrode Gap for Used Spark Plug:

If the gap is greater than the maximum, replace the spark plug.Electrode Gap 1.3 mm (0.0512 in.) Electrode Gap for New Spark Plug:

Electrode Gap 1.0 to 1.1 mm (0.0394 to 0.0433 in.)

-

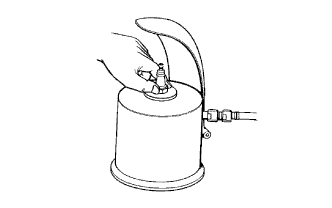

Clean the spark plugs. If the electrode has traces of wet carbon, clean the electrode with a spark plug cleaner and then dry it.

Standard air pressure:

588 kPa (6.0 kgf/cm2, 85 psi)

Standard duration:

20 seconds or less.

HINT:

Only use the spark plug cleaner when the electrode is free of oil. If the electrode has traces of oil, use gasoline to clean off the oil before using the spark plug cleaner.