DTC P2A00 A/F Sensor Circuit Slow Response (Bank 1 Sensor 1)

Check any other dtcs output (in addition to dtc p2a00)

Perform active test using intelligent tester (injection volume)

Perform confirmation driving pattern

Inspect air fuel ratio sensor (heater resistance)

Inspect fuel injector assembly

Check whether dtc output recurs (dtc p2a00)

Perform active test using intelligent tester (control the egr step position)

Confirm whether malfunction has been successfully repaired

Description

| DTC No. | DTC Detection Condition | Trouble Area |

| P2A00 | Calculated value for air fuel ratio sensor response rate deterioration level is less than threshold (2 trip detection logic). |

|

Monitor description

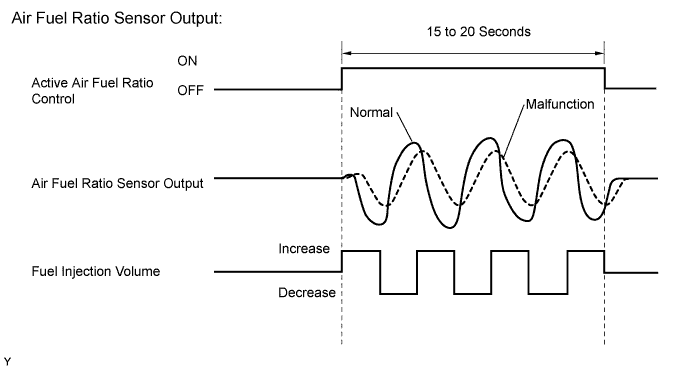

After the engine is warmed up, the ECM performs air fuel ratio feedback control to maintain the air fuel ratio at the stoichiometric level. In addition, active air fuel control is performed for approximately 15 to 20 seconds after preconditions are met in order to measure the air fuel ratio sensor response rate. During active air fuel control, the ECM forcibly increases and decreases the injection volume a certain amount, based on the stoichiometric air fuel ratio learned during normal air fuel ratio control, and measures the air fuel ratio sensor response rate. The ECM receives a signal from the air fuel ratio sensor while performing active air fuel control and uses it to calculate the air fuel ratio sensor response rate deterioration level. If the value for air fuel ratio sensor response rate deterioration level is beyond the threshold, the ECM interprets this as a malfunction and sets the DTC.

Monitor strategy

| Required Sensors/Components (Main) | Air fuel ratio sensor |

| Frequency of Operation | Once per driving cycle |

Typical enabling conditions

| Active air fuel ratio control | Performing |

| Active air fuel ratio control performed when following conditions met | - |

| Auxiliary battery voltage | 11 V or higher |

| Engine coolant temperature | 75°C (167°F) or higher |

| Idling | OFF |

| Engine speed | Less than 4000 rpm |

| Air fuel ratio sensor status | Activated |

| Fuel-cut | OFF |

| Engine load | 10 to 70% |

| Catalyst monitor | Not yet |

| Mass air flow | 6.0 to 12 gm/sec |

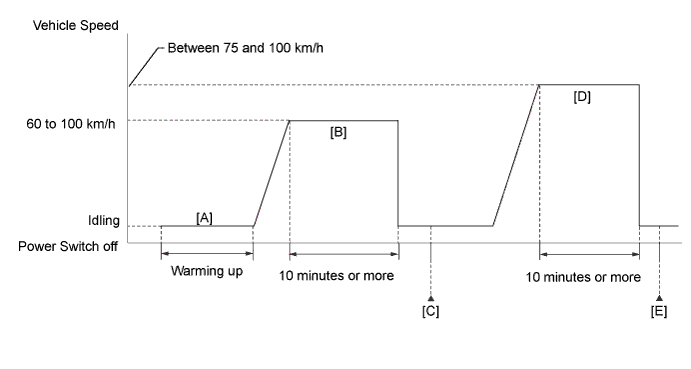

Confirmation driving pattern

HINT:

Performing this confirmation pattern will activate the air fuel ratio sensor response monitor.

- Connect the intelligent tester to the DLC3.

- Turn the power switch on (IG).

- Turn the tester on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC operation).

- Turn the power switch off and wait for at least 30 seconds.

- Turn the power switch on (IG) and turn the tester on.

- Put the engine in inspection mode (maintenance mode) .

- Start the engine and warm it up until the engine coolant temperature is 75°C (167°F) or higher [A].

- Drive the vehicle at approximately 60 to 100 km/h (37 to 62 mph) for 10 minutes or more [B].

CAUTION:

When performing the confirmation driving pattern, obey all speed limits and traffic laws.

- Enter the following menus: Powertrain / Engine and ECT / DTC [C].

- Read the pending DTCs.

HINT:

- If a pending DTC is output, the system is malfunctioning.

- If a pending DTC is not output, perform the following procedure.

- Enter the following menus: Powertrain / Engine and ECT / Utility / All Readiness.

- Input the DTC: P2A00.

- Check the DTC judgment result.

Tester Display Description NORMAL - DTC judgment completed

- System normal

ABNORMAL - DTC judgment completed

- System abnormal

INCOMPLETE - DTC judgment not completed

- Perform driving pattern after confirming DTC enabling conditions

UNKNOWN - Unable to perform DTC judgment

- Number of DTCs which do not fulfill DTC preconditions has reached ECU memory limit

HINT:

- If the judgment result shows NORMAL, the system is normal.

- If the judgment result shows ABNORMAL, the system has a malfunction.

- If the judgment result shows INCOMPLETE or UNKNOWN, perform the following procedure.

- Drive the vehicle at a speed between 75 and 100 km/h (47 and 62 mph) for 10 minutes or more [D].

CAUTION:

When performing the confirmation driving pattern, obey all speed limits and traffic laws.

- Check the DTC judgment result [E].

Wiring diagram

Refer to DTC P2195

Inspection procedure

HINT:

- DTC P2A00 may also be set when the air fuel ratio remains rich or lean.

- A low air fuel ratio sensor voltage could be caused by a rich air fuel mixture. Check for conditions that would cause the engine to run rich.

- A high air fuel ratio sensor voltage could be caused by a lean air fuel mixture. Check for conditions that would cause the engine to run lean.

- Sensor 1 refers to the sensor closet to the engine assembly.

- Sensor 2 refers to the sensor farthest away from the engine assembly.

- Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air fuel ratio was lean or rich, and other data from the time the malfunction occurred.

| 1.CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P2A00) |

-

Connect the intelligent tester to the DLC3.

-

Turn the power switch on (IG).

-

Turn the tester on.

-

Enter the following menus: Powertrain / Engine and ECT / DTC.

-

Read the DTCs.

Result Result Proceed to DTC P2A00 is output A DTC P2A00 and other DTCs are output B HINT:

If any DTCs relating to the air fuel ratio sensor (DTCs for the air fuel ratio sensor heater or air fuel ratio sensor admittance) are output, troubleshoot those DTCs first.

|

|

||||

| OK | |

| 2.PERFORM ACTIVE TEST USING INTELLIGENT TESTER (INJECTION VOLUME) |

-

Connect the intelligent tester to the DLC3.

-

Turn the power switch on (IG).

-

Turn the tester on.

-

Put the engine in inspection mode (maintenance mode) .

-

Start the engine.

-

Warm up the engine and run the engine at an engine speed of 2500 rpm for approximately 90 seconds.

-

Enter the following menus: Powertrain / Engine and ECT / Active Test / Control the Injection Volume / All Data / AFS Voltage B1S1 and O2S B1S2.

-

Perform the Control the Injection Volume operation with the engine idling.

-

Monitor the output voltages of the air fuel ratio and heated oxygen sensors (AFS Voltage B1S1 and O2S B1S2) displayed on the tester.

HINT:

- Change the fuel injection volume within the range of - 12.0% to +12.0%. The injection volume can be changed in fine gradations.

- The air fuel ratio sensor has an output delay of a few seconds and the heated oxygen sensor has a maximum output delay of approximately 20 seconds.

- If the sensor output voltage does not change (almost no reaction) while performing the Active Test, the sensor may be malfunctioning.

Standard Tester Display (Sensor) Injection Volume Status Voltage AFS Voltage B1S1 (Air fuel ratio) +12% Rich Below 3.1 V -12% Lean Higher than 3.4 V O2S B1S2 (Heated oxygen) +12% Rich Higher than 0.55 V -12% Lean Below 0.4 V

Lean: During the Control the Injection Volume Active Test, the air fuel ratio sensor output voltage (AFS Voltage) is consistently higher than 3.4 V, and the heated oxygen sensor output voltage (O2S) is consistently below 0.4 V. Rich: During the Control the Injection Volume Active Test, the AFS Voltage is consistently below 3.1 V, and the O2S is consistently higher than 0.55 V. Lean/Rich: During the Control the Injection Volume Active Test, the output voltage of the heated oxygen sensor alternates correctly.Result Status of AFS Voltage B1S1 Status of O2S B1S2 Air Fuel Ratio Condition and Air Fuel Ratio Sensor Condition Proceed to Lean/Rich Lean/Rich Normal A Lean Lean Actual air fuel ratio lean B Rich Rich Actual air fuel ratio rich B Lean Lean/Rich Air fuel ratio sensor malfunction C Rich Lean/Rich Air fuel ratio sensor malfunction C

HINT:

Refer to "Data List / Active Test" [AFS Voltage B1S1, and O2S B1S2] .

|

|

||||

|

|

||||

| OK | |

| 3.PERFORM CONFIRMATION DRIVING PATTERN |

-

Connect the intelligent tester to the DLC3.

-

Turn the power switch on (IG).

-

Turn the tester on.

-

Clear the DTCs .

-

Turn the power switch off and wait for at least 30 seconds.

-

Drive the vehicle in accordance with the driving pattern described in Confirmation Driving Pattern.

-

Enter the following menus: Powertrain / Engine and ECT / Utility / All Readiness.

-

Input the DTC: P2A00.

-

Check the DTC judgment result.

Result Result Proceed to NORMAL (DTC is not output) A ABNORMAL (DTC P2A00 is output) B

|

|

||||

| A | |

|

| 4.INSPECT AIR FUEL RATIO SENSOR (HEATER RESISTANCE) |

-

Inspect the air fuel ratio sensor .

|

|

||||

| OK | |

| 5.CHECK INTAKE SYSTEM |

-

Check the intake system for vacuum leaks .

OK:

No leaks in intake system.

|

|

||||

| OK | |

| 6.CHECK FUEL PRESSURE |

-

Check fuel pressure .

|

|

||||

| OK | |

| 7.INSPECT FUEL INJECTOR ASSEMBLY |

-

Inspect the fuel injector assembly .

|

|

||||

| OK | |

| 8.REPLACE AIR FUEL RATIO SENSOR |

-

Replace the air fuel ratio sensor .

| NEXT | |

| 9.CHECK WHETHER DTC OUTPUT RECURS (DTC P2A00) |

-

Connect the intelligent tester to the DLC3.

-

Turn the power switch on (IG).

-

Turn the tester on.

-

Clear the DTCs .

-

Turn the power switch off and wait for at least 30 seconds.

-

Drive the vehicle in accordance with the driving pattern described in Confirmation Driving Pattern.

-

Enter the following menus: Powertrain / Engine and ECT / Utility / All Readiness.

-

Input the DTC: P2A00.

-

Check the DTC judgment result.

Result Result Proceed to ABNORMAL (DTC P2A00 is output) A NORMAL (DTC is not output) B

|

|

||||

| OK | |

| 10.PERFORM ACTIVE TEST USING INTELLIGENT TESTER (CONTROL THE EGR STEP POSITION) |

-

Connect the intelligent tester to the DLC3.

-

Turn the power switch on (IG).

-

Turn the tester on.

-

Put the engine in inspection mode (maintenance mode) .

-

Start the engine and warm it up until the engine coolant temperature reaches 75°C (167°F) or higher.

HINT:

The A/C switch and all accessory switches should be off.

-

Enter the following menus: Powertrain / Engine and ECT / Active Test / Control the EGR Step Position / Data List / All Data / Throttle Idle Position and MAP.

-

Confirm that the Throttle Idle Position is ON and check the engine idling condition and MAP values in the Data List while performing the Active Test.

HINT:

- Do not leave the EGR valve open for 10 seconds or more during the Active Test.

- Be sure to return the EGR valve to step 0 when the Active Test is completed.

- Do not open the EGR valve 30 steps or more during the Active Test.

OK:

MAP and idling condition change in response to EGR step position when Throttle Idle Position is ON in Data List.

Standard:

- EGR Step Position (Active Test) 0 Steps 0 to 30 Steps Idling condition Steady idling Idling changes from steady to rough idling or stalls MAP (Data List) MAP value is 20 to 40 kPa (150 to 300 mmHg) (EGR valve is fully closed) MAP value is at least +10 kPa (75 mmHg) higher than when EGR valve is fully closed HINT:

During Active Test, if the idling condition does not change in response to EGR step position, then there is probably a malfunction in the EGR valve.

Result Result Proceed to Outside of standard range A Within standard range B

|

|

||||

| OK | |

| 11.INSPECT EGR VALVE ASSEMBLY |

-

Remove the EGR valve assembly .

-

Check if the EGR valve is stuck open.

OK:

EGR valve is tightly closed.

|

|

||||

| OK | |

| 12.REPLACE ECM |

-

Replace the ECM .

| NEXT | |

| 13.CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED |

-

Connect the intelligent tester to the DLC3.

-

Turn the power switch on (IG).

-

Turn the tester on.

-

Clear the DTCs .

-

Turn the power switch off and wait for 30 seconds.

-

Drive the vehicle in accordance with the driving pattern described in the Confirmation Driving Pattern.

-

Enter the following menus: Powertrain / Engine and ECT / Utility / All Readiness.

-

Input the DTC: P2A00.

-

Check the DTC judgment result is NORMAL.

| NEXT | |

|

| 14.INSPECT FUEL PUMP |

-

Inspect the fuel pump .

|

|

||||

| OK | |

|