DESCRIPTION

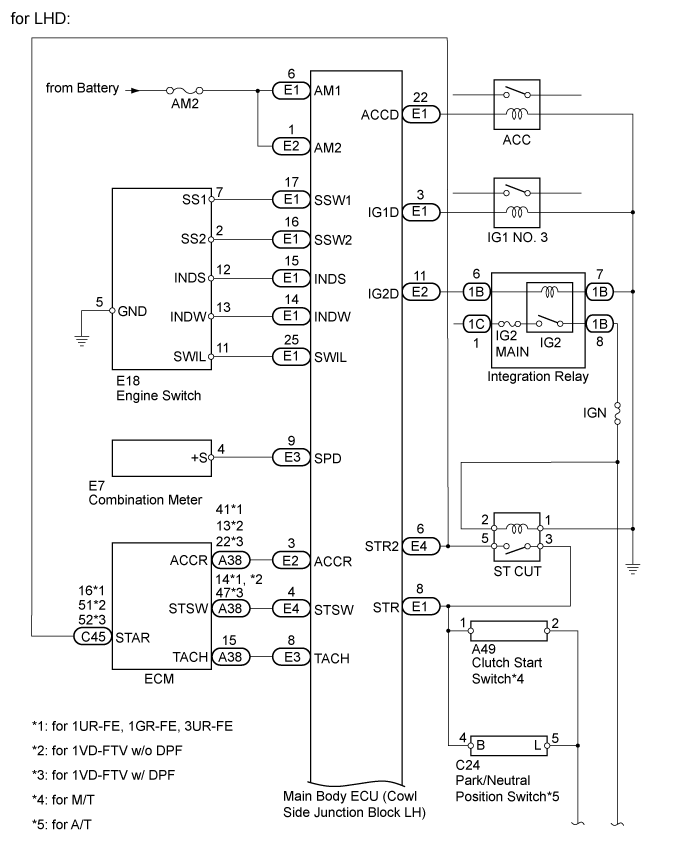

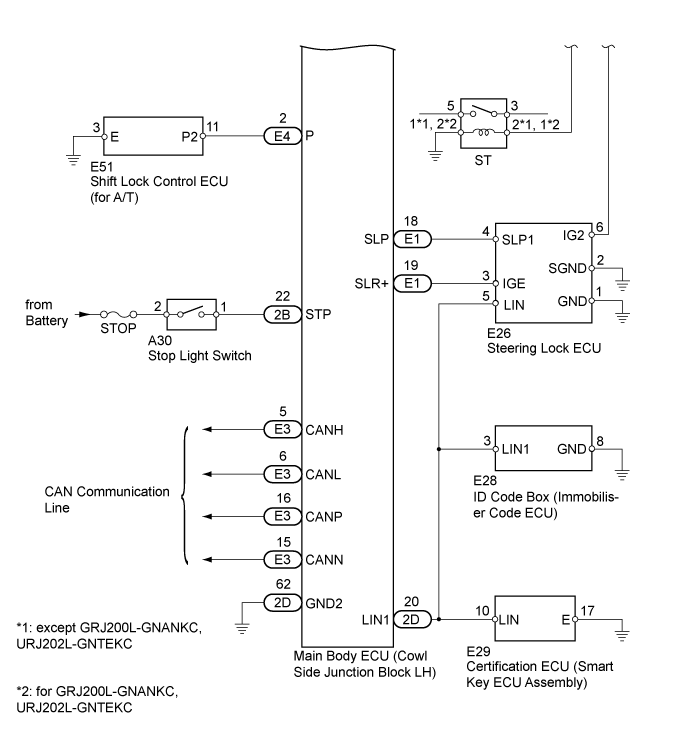

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK ENGINE SWITCH (SWITCH CONDITION)

CHECK WHETHER DTC OUTPUT RECURS

CHECK CRANKING FUNCTION

READ VALUE USING INTELLIGENT TESTER (L CODE)

READ VALUE USING INTELLIGENT TESTER (ENGINE START CONDITION)

READ VALUE USING INTELLIGENT TESTER (S CODE)

REPLACE ID CODE BOX (IMMOBILISER CODE ECU)

READ VALUE USING INTELLIGENT TESTER (PARK/NEUTRAL POSITION SWITCH OR CLUTCH START SWITCH)

READ VALUE USING INTELLIGENT TESTER (SHIFT LOCK CONTROL ECU)

READ VALUE USING INTELLIGENT TESTER (STOP LIGHT SWITCH)

CHECK STEERING LOCK

CHECK MAIN BODY ECU

CHECK HARNESS AND CONNECTOR (MAIN BODY ECU - SHIFT LOCK CONTROL ECU AND BODY GROUND)

INSPECT SHIFT LOCK CONTROL ECU

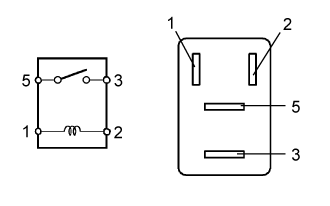

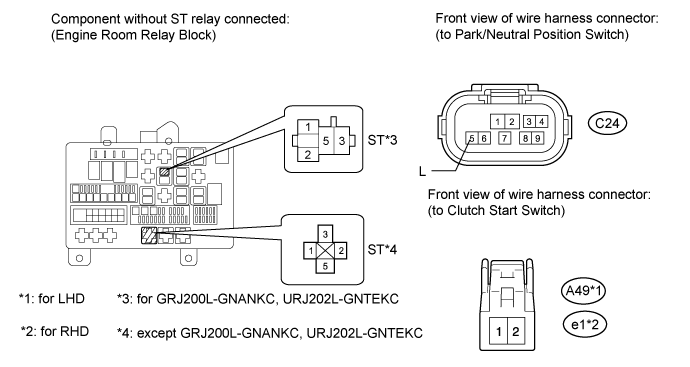

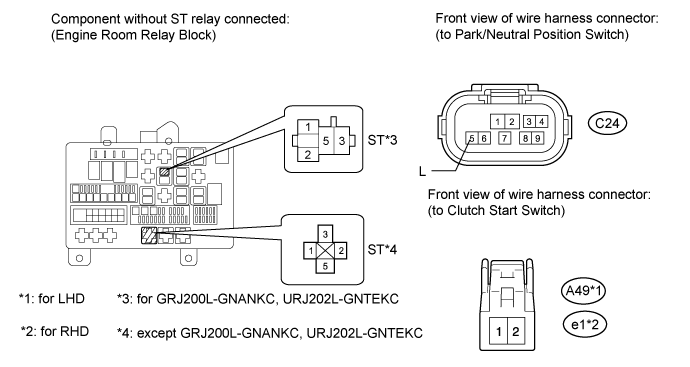

INSPECT STARTER RELAY (ST)

INSPECT PARK/NEUTRAL POSITION SWITCH

INSPECT CLUTCH START SWITCH

CHECK HARNESS AND CONNECTOR (MAIN BODY ECU - PARK/NEUTRAL POSITION SWITCH OR CLUTCH START SWITCH AND BODY GROUND)

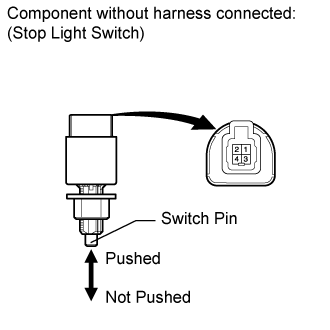

CHECK HARNESS AND CONNECTOR (PARK/NEUTRAL POSITION SWITCH OR CLUTCH START SWITCH - STARTER RELAY AND BODY GROUND)

INSPECT FUSE (STOP)

INSPECT STOP LIGHT SWITCH

CHECK HARNESS AND CONNECTOR (MAIN BODY ECU - STOP LIGHT SWITCH AND BODY GROUND)

REPLACE STEERING LOCK ACTUATOR ASSEMBLY (STEERING LOCK ECU)

REPLACE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY)

ENTRY AND START SYSTEM (for Start Function) - Engine does not Start |

DESCRIPTION

| ENGINE START SYSTEM OPERATION |

When the engine switch is pressed with the brake pedal depressed and the shift lever in P (for A/T) or the clutch pedal depressed (for M/T), the main body ECU determines that it is an engine start request.

The certification ECU (smart key ECU assembly) and other ECUs perform key verification via the LIN communication line. The engine switch indicator light illuminates in green.

The main body ECU activates the IG1 No. 3 relay, ACC relay and integration relay (IG2 relay).

The certification ECU (smart key ECU assembly) outputs a steering unlock signal. The signal is sent to the steering lock ECU via the LIN communication line.

The main body ECU sends an engine start request signal to the ECM.

The main body ECU deactivates the ACC relay until the ECU detects an engine start.

The ECU reactivates the ACC relay and turns off the engine switch indicator light.

Symbols of Main Body ECU

| Signals

|

SSW1/SSW2

| Engine switch on (ACC, IG) signal

|

IG1D

| IG1 No. 3 relay operation signal

|

ACCD

| ACC relay operation signal

|

IG2D

| Integration relay (IG2 relay) operation signal

|

STP

| Stop light switch signal

|

P (for A/T)

| Shift lock signal

|

TACH

| Engine start detection signal

|

STSW

| Starter activation request signal

|

ACCR

| ACC cut request signal

|

WIRING DIAGRAM

INSPECTION PROCEDURE

| 1.CHECK ENGINE SWITCH (SWITCH CONDITION) |

Check the power source mode change.

When the key is inside the vehicle and the shift lever is in P (for A/T), check that pressing the engine switch causes the power source mode to change as follows:

- OK:

- off → on (ACC) → on (IG) → off

| | GO TO ENTRY AND START SYSTEM (FOR START FUNCTION) (POWER SOURCE MODE DOES NOT CHANGE) (Click here) |

|

|

| 2.CHECK WHETHER DTC OUTPUT RECURS |

Clear the DTCs (Click here).

Check whether the trouble recurs 5 seconds after the engine switch is turned on (IG).

Check whether DTCs for the main body ECU or certification ECU (smart key ECU assembly) are output.

ResultResult

| Proceed to

|

No DTC output

| A

|

Main body ECU

Entry and start system (for start function)

| B

|

Certification ECU (Smart key ECU assembly)

Steering lock system

| C

|

Certification ECU (Smart key ECU assembly)

Engine immobiliser system

| D

|

| | GO TO ENTRY AND START SYSTEM (FOR START FUNCTION) (DIAGNOSTIC TROUBLE CODE CHART) (Click here) |

|

|

| | GO TO STEERING LOCK SYSTEM (DIAGNOSTIC TROUBLE CODE CHART) (Click here) |

|

|

| | GO TO ENGINE IMMOBILISER SYSTEM (DIAGNOSTIC TROUBLE CODE CHART) (Click here) |

|

|

| 3.CHECK CRANKING FUNCTION |

Check the engine cranking function.

for A/T:

When there is fuel in the fuel tank, the key is inside the vehicle and the shift lever is in P, check that depressing the brake pedal and pressing the engine switch cranks the engine.

for M/T:

When there is fuel in the fuel tank and the key is inside the vehicle, check that depressing the clutch pedal and pressing the engine switch cranks the engine.

- OK:

- Engine cranks.

| 4.READ VALUE USING INTELLIGENT TESTER (L CODE) |

Use the Data List to check if L code certification is functioning properly.

Entry&StartTester Display

| Measurement Item/Range

| Normal Condition

| Diagnostic Note

|

L Code Check

| L code certification result/NG or OK

| OK: L code certification result is normal

NG: L code certification result is abnormal

| -

|

- OK:

- OK is displayed on the intelligent tester.

| 5.READ VALUE USING INTELLIGENT TESTER (ENGINE START CONDITION) |

Use the Data List to check if the engine start is functioning properly.

Entry&StartTester Display

| Measurement Item/Range

| Normal Condition

| Diagnostic Note

|

Engine Start Condition

| Engine start condition by certification ECU (smart key ECU assembly)/OK or NG

| OK: Engine start is permitted

NG: Engine start is prohibited

| -

|

- OK:

- OK is displayed on the intelligent tester.

| 6.READ VALUE USING INTELLIGENT TESTER (S CODE) |

Use the Data List to check if S code certification is functioning properly.

Entry&StartTester Display

| Measurement Item/Range

| Normal Condition

| Diagnostic Note

|

S Code Check

| S code certification result/NG or OK

| OK: S code certification result is normal

NG: S code certification result is abnormal

| -

|

- OK:

- OK is displayed on the intelligent tester.

| 7.REPLACE ID CODE BOX (IMMOBILISER CODE ECU) |

Replace the ID code box (immobiliser code ECU).

Register the recognition code (ECU code).

Check that the engine starts.

ResultResult

| Proceed to

|

Engine starts

| A

|

Engine does not start (for 1GR-FE)

| B

|

Engine does not start (for 1UR-FE)

| C

|

Engine does not start (for 3UR-FE)

| D

|

Engine does not start (for 1VD-FTV)

| E

|

| 8.READ VALUE USING INTELLIGENT TESTER (PARK/NEUTRAL POSITION SWITCH OR CLUTCH START SWITCH) |

Use the Data List to check if the park/neutral position switch (for A/T) or clutch start switch (for M/T) is functioning properly.

Main BodyTester Display

| Measurement Item/Range

| Normal Condition

| Diagnostic Note

|

Neutral SW/ Clutch SW

| Park/neutral position switch (A/T), clutch start switch (M/T)/ON or OFF

| ON: Shift lever in P or N (A/T), clutch pedal depressed (M/T)

OFF: Shift lever not in P or N (A/T), clutch pedal released (M/T)

| -

|

ResultResult

| Proceed to

|

for A/T:

ON (shift lever in P or N) and OFF (shift lever not in P or N) displayed on the intelligent tester.

| A

|

for M/T:

ON (clutch pedal depressed) and OFF (clutch pedal released) displayed on the intelligent tester.

| B

|

for A/T:

ON (shift lever in P or N) and OFF (shift lever not in P or N) not displayed on the intelligent tester.

for M/T:

ON (clutch pedal depressed) and OFF (clutch pedal released) not displayed on the intelligent tester.

| C

|

| 9.READ VALUE USING INTELLIGENT TESTER (SHIFT LOCK CONTROL ECU) |

Use the Data List to check if the shift position signal is functioning properly.

Main BodyTester Display

| Measurement Item/Range

| Normal Condition

| Diagnostic Note

|

Shift P Signal

| Shift P position signal/ON or OFF

| ON: Shift lever in P

OFF: Shift lever not in P

| -

|

- OK:

- ON (shift lever in P) and OFF (shift lever not in P) are displayed on the intelligent tester.

| 10.READ VALUE USING INTELLIGENT TESTER (STOP LIGHT SWITCH) |

Use the Data List to check if the stop light switch is functioning properly.

Main BodyTester Display

| Measurement Item/Range

| Normal Condition

| Diagnostic Note

|

Stop Light SW

| Stop light switch/ON or OFF

| ON: Brake pedal is depressed

OFF: Brake pedal is released

| -

|

- OK:

- ON (brake pedal is depressed) and OFF (brake pedal is released) are displayed on the intelligent tester.

Check if the steering lock is released when turning the engine switch on (ACC).

- OK:

- The steering lock is released.

| | GO TO STEERING LOCK SYSTEM (HOW TO PROCEED WITH TROUBLESHOOTING) (Click here) |

|

|

Measure the voltage according to the value(s) in the table below.

- HINT:

- The voltage is generated at terminal STSW for 0.3 seconds when the engine cranks.

- Standard Voltage:

Tester Connection

| Condition

| Specified Condition

|

E4-4 (STSW) - Body ground

| for A/T:

Brake pedal depressed, engine switch depressed

for M/T:

Clutch pedal depressed, engine switch depressed

| 11 to 14 V

|

ResultResult

| Proceed to

|

Outside specified range

| A

|

Within specified range (for 1GR-FE)

| B

|

Within specified range (for 1UR-FE)

| C

|

Within specified range (for 3UR-FE)

| D

|

Within specified range (for 1VD-FTV)

| E

|

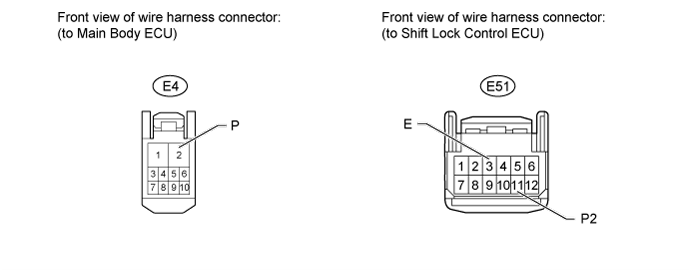

| 13.CHECK HARNESS AND CONNECTOR (MAIN BODY ECU - SHIFT LOCK CONTROL ECU AND BODY GROUND) |

Disconnect the E4 main body ECU connector.

Disconnect the E51 shift lock control ECU connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

E4-2 (P) - E51-11 (P2)

| Always

| Below 1 Ω

|

E51-3 (E) - Body ground

| Always

| Below 1 Ω

|

E4-2 (P) or E51-11 (P2) - Body ground

| Always

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

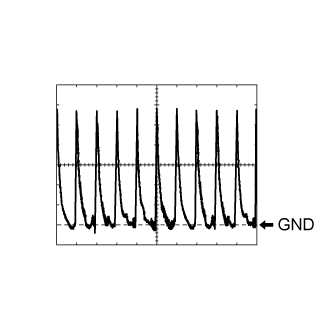

| 14.INSPECT SHIFT LOCK CONTROL ECU |

Check the signal waveform according to the condition(s) in the table below.

ReferenceTerminal No. (Symbol)

| Tool Setting

| Condition

|

E51-11 (P2) - E51-3 (E)

| 2 V/DIV., 20 msec./DIV.

| Shift lever in P

|

- OK:

- The waveform is similar to that shown in the illustration.

ResultResult

| Proceed to

|

OK

| A

|

NG

| for 1GR-FE

| B

|

for 1VD-FTV, 3UR-FE, 1UR-FE

| C

|

| 15.INSPECT STARTER RELAY (ST) |

expect GRJ200L-GNANKC, URJ202L-GNTEKC:

Remove the ST relay from the engine room relay block.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

3 - 5

| Battery voltage not applied to terminals 1 and 2

| 10 kΩ or higher

|

3 - 5

| Battery voltage applied to terminals 1 and 2

| Below 1 Ω

|

for GRJ200L-GNANKC, URJ202L-GNTEKC:

Remove the ST relay from the engine room relay block.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

3 - 5

| Battery voltage not applied to terminals 1 and 2

| 10 kΩ or higher

|

3 - 5

| Battery voltage applied to terminals 1 and 2

| Below 1 Ω

|

ResultResult

| Proceed to

|

Within specified range (for A/T)

| A

|

Within specified range (for M/T)

| B

|

Outside specified range

| C

|

| 16.INSPECT PARK/NEUTRAL POSITION SWITCH |

Disconnect the C24 park/neutral position switch connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

4 (B) - 5 (L)

| P

| Below 1 Ω

|

4 (B) - 5 (L)

| N

| Below 1 Ω

|

4 (B) - 5 (L)

| Not in P or N

| 10 kΩ or higher

|

ResultResult

| Proceed to

|

Outside specified range (for A750F)

| A

|

Outside specified range (for AB60F)

| B

|

Within specified range

| C

|

| 17.INSPECT CLUTCH START SWITCH |

Disconnect the A49 (for LHD) or e1 (for RHD) clutch start switch connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

1 - 2

| Clutch start switch pin pushed

| Below 1 Ω

|

1 - 2

| Clutch start switch pin not pushed

| 10 kΩ or higher

|

| 18.CHECK HARNESS AND CONNECTOR (MAIN BODY ECU - PARK/NEUTRAL POSITION SWITCH OR CLUTCH START SWITCH AND BODY GROUND) |

Measure the resistance according to the value(s) in the table below.

- Standard Resistance (for A/T):

Tester Connection

| Condition

| Specified Condition

|

E1-8 (STR) - C24-4 (B)

| Always

| Below 1 Ω

|

E1-8 (STR) or C24-4 (B) - Body ground

| Always

| 10 kΩ or higher

|

- Standard Resistance (for M/T):

Tester Connection

| Condition

| Specified Condition

|

for LHD:

E1-8 (STR) - A49-1

| Always

| Below 1 Ω

|

for LHD:

E1-8 (STR) or A49-1 - Body ground

| Always

| 10 kΩ or higher

|

for RHD:

E1-8 (STR) - e1-1

| Always

| Below 1 Ω

|

for RHD:

E1-8 (STR) or e1-1 - Body ground

| Always

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 19.CHECK HARNESS AND CONNECTOR (PARK/NEUTRAL POSITION SWITCH OR CLUTCH START SWITCH - STARTER RELAY AND BODY GROUND) |

Measure the resistance according to the value(s) in the table below.

- Standard Resistance (for A/T):

Tester Connection

| Condition

| Specified Condition

|

C24-5 (L) - Relay block ST relay terminal 1*1

C24-5 (L) - Relay block ST relay terminal 2*2

| Always

| Below 1 Ω

|

C24-5 (L) or Relay block ST relay terminal 1 - Body ground*1

C24-5 (L) or Relay block ST relay terminal 2 - Body ground*2

| Always

| 10 kΩ or higher

|

Relay block ST relay terminal 2 - Body ground*1

Relay block ST relay terminal 1- Body ground*2

| Always

| Below 1 Ω

|

- HINT:

- *1: for GRJ200L-GNANKC, URJ202L-GNTEKC

- *2: except GRJ200L-GNANKC, URJ202L-GNTEKC

- Standard Resistance (for M/T):

Tester Connection

| Condition

| Specified Condition

|

for LHD:

A49-2 - Relay block ST relay terminal 1*1

A49-2 - Relay block ST relay terminal 2*2

| Always

| Below 1 Ω

|

for LHD:

A49-2 or Relay block ST relay terminal 1 - Body ground*1

A49-2 or Relay block ST relay terminal 2 - Body ground*2

| Always

| 10 kΩ or higher

|

for RHD:

e1-2 - Relay block ST relay terminal 1*1

e1-2 - Relay block ST relay terminal 2*2

| Always

| Below 1 Ω

|

for RHD:

e1-2 or Relay block ST relay terminal 1 - Body ground*1

e1-2 or Relay block ST relay terminal 2 - Body ground*2

| Always

| 10 kΩ or higher

|

Relay block ST relay terminal 2 - Body ground*1

Relay block ST relay terminal 1 - Body ground*2

| Always

| Below 1 Ω

|

- HINT:

- *1: for GRJ200L-GNANKC, URJ202L-GNTEKC

- *2: except GRJ200L-GNANKC, URJ202L-GNTEKC

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

Remove the STOP fuse from the engine room relay block.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

STOP fuse

| Always

| Below 1 Ω

|

| 21.INSPECT STOP LIGHT SWITCH |

Disconnect the A30 stop light switch connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Switch Condition

| Specified Condition

|

1 - 2

| Stop light switch pin not pushed

| Below 1 Ω

|

3 - 4

| Stop light switch pin pushed

| Below 1 Ω

|

1 - 2

| Stop light switch pin pushed

| 10 kΩ or higher

|

3 - 4

| Stop light switch pin not pushed

| 10 kΩ or higher

|

| 22.CHECK HARNESS AND CONNECTOR (MAIN BODY ECU - STOP LIGHT SWITCH AND BODY GROUND) |

Disconnect the 2B main body ECU connector.

Disconnect the A30 stop light switch connector.

Measure the voltage and resistance according to the value(s) in the table below.

- Standard Voltage:

Tester Connection

| Condition

| Specified Condition

|

A30-2 - Body ground

| Always

| 11 to 14 V

|

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

2B-22 (STP) - A30-1

| Always

| Below 1 Ω

|

2B-22 (STP) or A30-1 - Body ground

| Always

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 23.REPLACE STEERING LOCK ACTUATOR ASSEMBLY (STEERING LOCK ECU) |

Replace the steering lock actuator assembly (steering lock ECU).

- HINT:

- For Power tilt and telescopic, use the following procedures Click here

- For Manual tilt and telescopic, use the following procedures Click here

Register the recognition code (ECU code).

Check that the engine starts.

- OK:

- Engine starts.

| | REPLACE ID CODE BOX (IMMOBILISER CODE ECU) |

|

|

| 24.REPLACE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

Replace the certification ECU (smart key ECU assembly).

Register the recognition code (ECU code).

Check that the engine starts.

- OK:

- Engine starts.

| | REPLACE ID CODE BOX (IMMOBILISER CODE ECU) |

|

|