Wiper And Washer System (W/ Rain Sensor) Washer Nozzle Heater Circuit

DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK NO. 2 MULTIPLEX NETWORK BODY ECU

INSPECT WASHER NOZZLE HEATER ASSEMBLY

CHECK HARNESS AND CONNECTOR (WASHER NOZZLE HEATER ASSEMBLY - COWL SIDE JUNCTION BLOCK RH AND BODY GROUND)

CHECK HARNESS AND CONNECTOR (COWL SIDE JUNCTION BLOCK RH - BATTERY)

CHECK COWL SIDE JUNCTION BLOCK RH

CHECK HARNESS AND CONNECTOR (NO. 2 MULTIPLEX NETWORK BODY ECU - COWL SIDE JUNCTION BLOCK RH)

CHECK HARNESS AND CONNECTOR (COWL SIDE JUNCTION BLOCK RH - BATTERY)

INSPECT COWL SIDE JUNCTION BLOCK RH

WIPER AND WASHER SYSTEM (w/ Rain Sensor) - Washer Nozzle Heater Circuit |

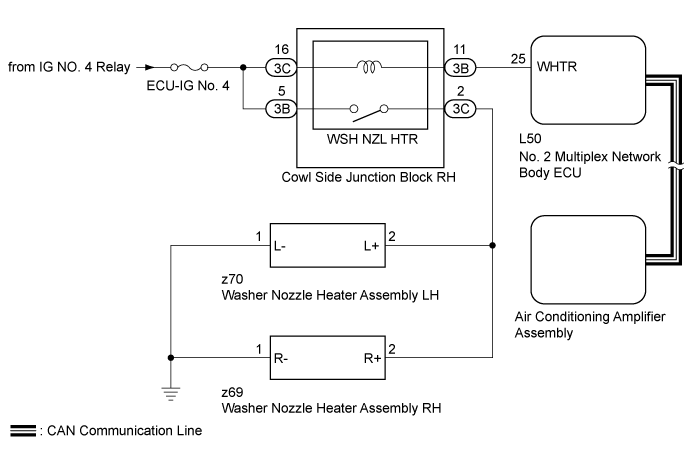

DESCRIPTION

The No. 2 multiplex network body ECU receives ambient air temperature information from the air conditioning amplifier assembly via CAN communication.The washer nozzle heater assembly controls the No. 2 multiplex network body ECU and operates the washer nozzle heater assembly according to the ambient temperature.

WIRING DIAGRAM

INSPECTION PROCEDURE

- NOTICE:

- Inspect the fuses for circuits related to this system before performing the following inspection procedure.

- Since the wiper and washer system has functions that use CAN communication, first confirm that there is no malfunction in the CAN communication system with the How to Proceed with Troubleshooting procedure (Click here).

- Since the wiper and washer system has functions that use the air conditioning system, first confirm that there is no malfunction in the air conditioning system with the How to Proceed with Troubleshooting procedure (Click here).

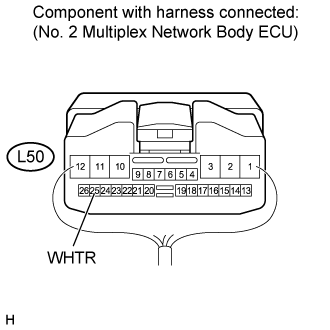

| 1.CHECK NO. 2 MULTIPLEX NETWORK BODY ECU |

Using the intelligent tester, enter the following menus: Body / Body No. 4 / Active Test.

Select "Front Washer Nozzle Heater", and perform the Active Test.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

Tester Connection

| Condition

| Specified Condition

|

L50-25 (WHTR) - Body ground

| - Engine switch on (IG)

- Active Test is not performed

| 11 to 14 V

|

L50-25 (WHTR) - Body ground

| - Engine switch on (IG)

- Active Test is performed

| Below 1 V

|

| 2.INSPECT WASHER NOZZLE HEATER ASSEMBLY |

for LH:

Remove the washer nozzle heater assembly LH (Click here).

Inspect the washer nozzle heater assembly LH (Click here).

for RH:

Remove the washer nozzle heater assembly RH (Click here).

Inspect the washer nozzle heater assembly RH (Click here).

ResultResult

| Proceed to

|

OK

| A

|

NG (for LH)

| B

|

NG (for RH)

| C

|

| | REPLACE WASHER NOZZLE HEATER ASSEMBLY LH (Click here) |

|

|

| | REPLACE WASHER NOZZLE HEATER ASSEMBLY RH (Click here) |

|

|

| 3.CHECK HARNESS AND CONNECTOR (WASHER NOZZLE HEATER ASSEMBLY - COWL SIDE JUNCTION BLOCK RH AND BODY GROUND) |

Disconnect the z70 washer nozzle heater assembly LH connector.

Disconnect the z69 washer nozzle heater assembly RH connector.

Disconnect the 3C cowl side junction block RH connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

z70-2 (L+) - 3C-2

| Always

| Below 1 Ω

|

z69-2 (R+) - 3C-2

| Always

| Below 1 Ω

|

z70-1 (L-) - Body ground

| Always

| Below 1 Ω

|

z69-1 (R-) - Body ground

| Always

| Below 1 Ω

|

z70-2 (L+) or 3C-2 - Body ground

| Always

| 10 kΩ or higher

|

z69-2 (R+) or 3C-2 - Body ground

| Always

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

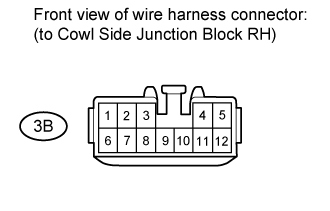

| 4.CHECK HARNESS AND CONNECTOR (COWL SIDE JUNCTION BLOCK RH - BATTERY) |

Disconnect the 3B cowl side junction block RH connector.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

Tester Connection

| Switch Condition

| Specified Condition

|

3B-5 - Body ground

| Engine switch on (IG)

| 11 to 14 V

|

3B-5 - Body ground

| Engine switch off

| Below 1 V

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 5.CHECK COWL SIDE JUNCTION BLOCK RH |

Remove the cowl side junction block RH.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

3B-5 - 3C-2

| Battery voltage applied between terminals 3C-16 and 3B-11

| Below 1 Ω

|

3B-5 - 3C-2

| Battery voltage not applied between terminals 3C-16 and 3B-11

| 10 kΩ or higher

|

ResultResult

| Proceed to

|

OK (w/ Sliding Roof System)

| A

|

OK (w/o Sliding Roof System)

| B

|

NG

| C

|

| | REPLACE NO. 2 MULTIPLEX NETWORK BODY ECU (Click here) |

|

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| A |

|

|

|

| REPLACE NO. 2 MULTIPLEX NETWORK BODY ECU (Click here) |

|

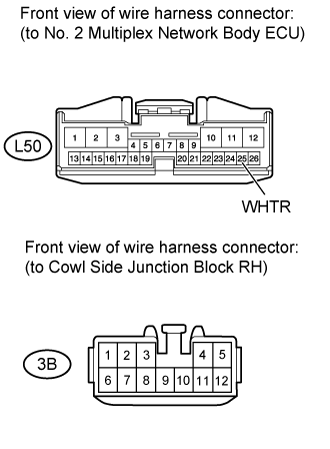

| 6.CHECK HARNESS AND CONNECTOR (NO. 2 MULTIPLEX NETWORK BODY ECU - COWL SIDE JUNCTION BLOCK RH) |

Disconnect the L50 No. 2 multiplex network body ECU connector.

Disconnect the 3B cowl side junction block RH connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

L50-25 (WHTR) - 3B-11

| Always

| Below 1 Ω

|

L50-25 (WHTR) or 3B-11 - Body ground

| Always

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 7.CHECK HARNESS AND CONNECTOR (COWL SIDE JUNCTION BLOCK RH - BATTERY) |

Disconnect the 3C cowl side junction block RH connector.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

Tester Connection

| Switch Condition

| Specified Condition

|

3C-16 - Body ground

| Engine switch on (IG)

| 11 to 14 V

|

3C-16 - Body ground

| Engine switch off

| Below 1 V

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 8.INSPECT COWL SIDE JUNCTION BLOCK RH |

Remove the cowl side junction block RH.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

3B-5 - 3C-2

| Battery voltage applied between terminals 3C-16 and 3B-11

| Below 1 Ω

|

3B-5 - 3C-2

| Battery voltage not applied between terminals 3C-16 and 3B-11

| 10 kΩ or higher

|

ResultResult

| Proceed to

|

OK (w/ Sliding Roof System)

| A

|

OK (w/o Sliding Roof System)

| B

|

NG

| C

|

| | REPLACE NO. 2 MULTIPLEX NETWORK BODY ECU (Click here) |

|

|

| | REPLACE COWL SIDE JUNCTION BLOCK RH |

|

|

| A |

|

|

|

| REPLACE NO. 2 MULTIPLEX NETWORK BODY ECU (Click here) |

|