Exhaust Pipe -- Installation |

| 1. INSTALL FRONT EXHAUST PIPE ASSEMBLY |

Install a new gasket and the front exhaust pipe to the exhaust manifold with the 2 nuts.

- Torque:

- 54 N*m{554 kgf*cm, 40 ft.*lbf}

| 2. INSTALL FRONT NO. 2 EXHAUST PIPE ASSEMBLY |

Install a new gasket and the front No. 2 exhaust pipe to the exhaust manifold LH with the 2 nuts.

- Torque:

- 54 N*m{554 kgf*cm, 40 ft.*lbf}

| 3. INSTALL CENTER EXHAUST PIPE ASSEMBLY |

Install 2 new gaskets to the center exhaust pipe.

Connect the center exhaust pipe to the 3 exhaust pipe supports.

Install the center exhaust pipe with the 4 bolts.

- Torque:

- 48 N*m{489 kgf*cm, 35 ft.*lbf}

| 4. INSTALL EXHAUST PIPE DAMPER |

Install the exhaust pipe damper and No. 4 exhaust pipe upper protector with the 2 bolts.

- Torque:

- 19 N*m{194 kgf*cm, 14 ft.*lbf}

| 5. INSTALL TAILPIPE ASSEMBLY |

Install a new gasket to the center exhaust pipe.

Install the tailpipe to the 2 exhaust pipe supports.

Install a new clamp.

- Torque:

- 32 N*m{326 kgf*cm, 24 ft.*lbf}

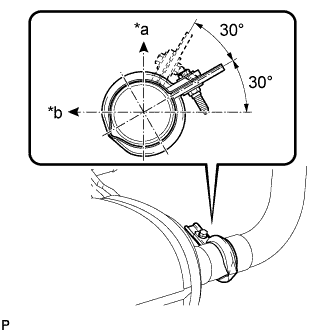

Text in Illustration *a Top *b LH Side - HINT:

- Install the clamp within the angle range shown in the illustration.

|

| 6. INSTALL HEATED OXYGEN SENSOR (for Bank 1 Sensor 2) |

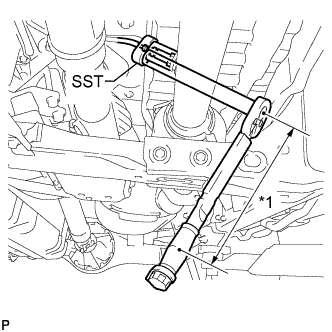

Temporarily install the sensor to the front No. 2 exhaust pipe by hand.

Using SST, tighten the heated oxygen sensor.

- SST

- 09224-00010

- Torque:

- without SST:

- 44 N*m{449 kgf*cm, 32 ft.*lbf}

- with SST:

- 40 N*m{408 kgf*cm, 30 ft.*lbf}

Text in Illustration *1 Fulcrum Length - HINT:

- Use a torque wrench with a fulcrum length of 300 mm (11.8 in.). When using a torque wrench with a fulcrum length that is not 300 mm (11.8 in.), calculate the torque specification for the torque wrench and SST based on the "without SST" torque specification (Click here).

- Make sure SST and the wrench are connected in a straight line.

|

Connect the heated oxygen sensor connector.

| 7. INSTALL HEATED OXYGEN SENSOR (for Bank 2 Sensor 2) |

Temporarily install the sensor to the front exhaust pipe by hand.

Using SST, tighten the heated oxygen sensor.

- SST

- 09224-00010

- Torque:

- without SST:

- 44 N*m{449 kgf*cm, 32 ft.*lbf}

- with SST:

- 40 N*m{408 kgf*cm, 30 ft.*lbf}

Text in Illustration *1 Fulcrum Length - HINT:

- Use a torque wrench with a fulcrum length of 300 mm (11.8 in.). When using a torque wrench with a fulcrum length that is not 300 mm (11.8 in.), calculate the torque specification for the torque wrench and SST based on the "without SST" torque specification (Click here).

- Make sure SST and the wrench are connected in a straight line.

|

Attach the clamp and connect the heated oxygen sensor connector.

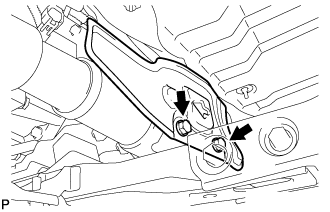

| 8. INSTALL PROPELLER SHAFT HEAT INSULATOR |

Install the insulator with the 2 bolts.

- Torque:

- 16 N*m{160 kgf*cm, 12 ft.*lbf}

|

| 9. INSPECT FOR EXHAUST GAS LEAK |