Exhaust Manifold -- Installation |

| 1. INSTALL AIR FUEL RATIO SENSOR (for Bank 2 Sensor 1) |

Using SST, install the air fuel ratio sensor.

- SST

- 09224-00010

- Torque:

- without SST:

- 44 N*m{449 kgf*cm, 32 ft.*lbf}

- with SST:

- 40 N*m{408 kgf*cm, 30 ft.*lbf}

Text in Illustration *1 Fulcrum Length - HINT:

- Use a torque wrench with a fulcrum length of 300 mm (11.8 in.). When using a torque wrench with a fulcrum length that is not 300 mm (11.8 in.), calculate the torque specification for the torque wrench and SST based on the "without SST" torque specification (Click here).

- Make sure SST and the wrench are connected in a straight line.

|

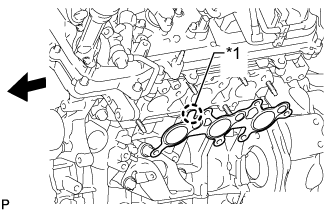

| 2. INSTALL EXHAUST MANIFOLD SUB-ASSEMBLY LH |

Install a new gasket to the cylinder head.

Text in Illustration *1 Protrusion

Front - NOTICE:

- Be careful of the installation direction.

|

Temporarily install the manifold with 6 new nuts.

Tighten the 6 nuts in the sequence shown in the illustration.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

Text in Illustration *A w/ Secondary Air Injection System *B w/o Secondary Air Injection System

|

Connect the air fuel ratio sensor connector.

| 3. INSTALL NO. 2 EXHAUST MANIFOLD HEAT INSULATOR |

Install the heat insulator with the 3 bolts.

- Torque:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

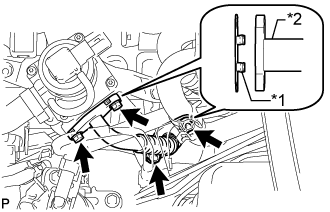

| 4. INSTALL NO. 2 AIR TUBE (w/ Secondary Air Injection System) |

Install 2 new gaskets.

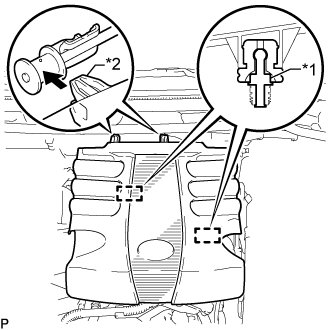

Text in Illustration *1 Claw *2 No. 2 Air Tube - NOTICE:

- Make sure the gasket's claws are not caught between the No. 2 emission control valve set and No. 2 air tube.

|

Install the No. 2 air tube with the 2 bolts and 2 nuts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

| 5. INSTALL NO. 2 MANIFOLD STAY |

Install the No. 2 manifold stay with the 3 bolts.

- Torque:

- 40 N*m{408 kgf*cm, 30 ft.*lbf}

| 6. INSTALL AIR FUEL RATIO SENSOR (for Bank 1 Sensor 1) |

Using SST, install the air fuel ratio sensor.

- SST

- 09224-00010

- Torque:

- without SST:

- 44 N*m{449 kgf*cm, 32 ft.*lbf}

- with SST:

- 40 N*m{408 kgf*cm, 30 ft.*lbf}

Text in Illustration *1 Fulcrum Length - HINT:

- Use a torque wrench with a fulcrum length of 300 mm (11.8 in.). When using a torque wrench with a fulcrum length that is not 300 mm (11.8 in.), calculate the torque specification for the torque wrench and SST based on the "without SST" torque specification (Click here).

- Make sure SST and the wrench are connected in a straight line.

|

| 7. INSTALL EXHAUST MANIFOLD SUB-ASSEMBLY RH |

Install a new gasket to the cylinder head.

Text in Illustration *1 Protrusion

Front - NOTICE:

- Be careful of the installation direction.

|

Temporarily install the manifold with 6 new nuts.

Tighten the 6 nuts in the sequence shown in the illustration.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

Text in Illustration *A w/ Secondary Air Injection System *B w/o Secondary Air Injection System

|

Connect the air fuel ratio sensor connector.

| 8. INSTALL NO. 1 EXHAUST MANIFOLD HEAT INSULATOR |

Install the heat insulator with the 3 bolts.

- Torque:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

| 9. CONNECT NO. 2 STEERING INTERMEDIATE SHAFT SUB-ASSEMBLY |

- for Manual Tilt and Manual Telescopic Steering Column: (Click here)

- for Power Tilt and Power Telescopic Steering Column: (Click here)

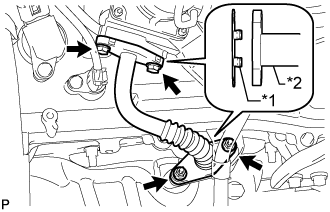

| 10. INSTALL AIR TUBE (w/ Secondary Air Injection System) |

Install 2 new gaskets.

Text in Illustration *1 Claw *2 Air Tube - NOTICE:

- Make sure the gasket's claws are not caught between the No. 1 emission control valve set and air tube.

|

Install the air tube with the 2 bolts and 2 nuts.

- Torque:

- 10 N*m{102 kgf*cm, 7 in.*lbf}

| 11. INSTALL MANIFOLD STAY |

Install the manifold stay with the 3 bolts.

- Torque:

- 40 N*m{408 kgf*cm, 30 ft.*lbf}

| 12. INSTALL FRONT EXHAUST PIPE ASSEMBLY |

| 13. INSTALL NO. 2 ENGINE UNDER COVER |

Install the No. 2 engine under cover with the 2 bolts.

- Torque:

- 29 N*m{296 kgf*cm, 21 ft.*lbf}

| 14. INSTALL NO. 1 ENGINE UNDER COVER SUB-ASSEMBLY |

Install the No. 1 engine under cover with the 10 bolts.

- Torque:

- 29 N*m{296 kgf*cm, 21 ft.*lbf}

| 15. INSTALL FRONT FENDER SPLASH SHIELD SUB-ASSEMBLY RH |

Push in the clip to install the front fender splash shield sub-assembly RH.

Install the 3 bolts and 2 screws.

| 16. INSTALL FRONT FENDER SPLASH SHIELD SUB-ASSEMBLY LH |

Push in the clip to install the front fender splash shield sub-assembly LH.

Install the 3 bolts and screw.

| 17. INSTALL AIR CLEANER CASE SUB-ASSEMBLY |

Install the air cleaner case with the 3 bolts.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

Install the air cleaner filter element.

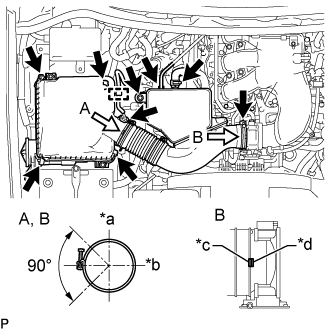

| 18. INSTALL AIR CLEANER CAP AND HOSE |

Install the air cleaner cap and hose.

Text in Illustration *a Top *b Front *c Protrusion (Hose) *d Protrusion (Throttle body) Install the air cleaner cap and hose with the bolt and fasten the 4 hook clamps.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

Tighten the clamp.

- Torque:

- 2.5 N*m{25 kgf*cm, 22 in.*lbf}

Attach the 4 clamps and connect the No. 2 PCV hose, vacuum hose and mass air flow meter connector.

- HINT:

- The direction of the hose clamp is indicated in the illustration.

|

| 19. INSTALL V-BANK COVER |

Attach the 2 V-bank cover hooks to the bracket. Then align the 2 V-bank cover grommets with the 2 pins and press down on the V-bank cover to attach the pins.

Text in Illustration *1 Pin *2 Hook

|

| 20. INSPECT FOR EXHAUST GAS LEAK |

- If gas is leaking, tighten the areas necessary to stop the leak. Replace damaged parts as necessary.

| 21. INSTALL FRONT FENDER APRON TRIM PACKING B |

w/ KDSS:

Install the front fender apron trim packing B with the 3 clips.

w/o KDSS:

Install the front fender apron trim packing B with the 4 clips.

| 22. INSTALL FRONT FENDER APRON TRIM PACKING A |

Install the front fender apron trim packing A with the 3 clips.

| 23. INSTALL FRONT FENDER APRON TRIM PACKING D |

Install the front fender apron trim packing D with the 4 clips.

| 24. INSTALL FRONT FENDER APRON TRIM PACKING C |

Install the front fender apron trim packing C with the 4 clips.