PRECAUTION

DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

REMOVE ENGINE ASSEMBLY

REMOVE NO. 1 INTAKE AIR CONNECTOR PIPE

REMOVE GENERATOR ASSEMBLY

DISCONNECT NO. 1 OUTLET TURBO OIL HOSE

REMOVE NO. 1 ENGINE OIL LEVEL DIPSTICK GUIDE

DISCONNECT NO. 2 OUTLET TURBO OIL HOSE

DISCONNECT NO. 2 INLET TURBO OIL PIPE SUB-ASSEMBLY

REMOVE STIFFENER INSULATOR RH (w/ Intercooler)

DISCONNECT NO. 1 OIL COOLER HOSE

DISCONNECT NO. 2 OIL COOLER HOSE

REMOVE V-RIBBED BELT TENSIONER ASSEMBLY

REMOVE CRANKSHAFT PULLEY

REMOVE TIMING GEAR COVER SPACER (w/ Intercooler)

REMOVE OIL FILTER ELEMENT

REMOVE OIL FILTER BRACKET SUB-ASSEMBLY

REMOVE ENGINE OIL LEVEL SENSOR

REMOVE NO. 2 OIL PAN SUB-ASSEMBLY

REMOVE OIL STRAINER SUB-ASSEMBLY

REMOVE NO. 1 OIL PAN SUB-ASSEMBLY

REMOVE REAR ENGINE OIL SEAL RETAINER

REMOVE REAR CRANKSHAFT OIL SEAL

REMOVE SCAVENGING PUMP ASSEMBLY

Scavenging Pump -- Removal |

- NOTICE:

- When replacing an injector (including interchanging injectors between cylinders) or common rail, replace the corresponding injection pipes with new ones.

- w/DPF

When fuel lines are disconnected, air may enter the fuel lines, leading to engine starting trouble. Therefore, perform forced regeneration and bleed the air from the fuel lines.

- NOTICE:

- After turning the ignition switch off, waiting time may be required before disconnecting the cable from the battery terminal. Therefore, make sure to read the disconnecting the cable from the battery terminal notice before proceeding with work (Click here).

| 2. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL |

- CAUTION:

- Wait at least 90 seconds after disconnecting the cable from the negative (-) battery terminal to disable the SRS system.

- NOTICE:

- When disconnecting the cable, some systems need to be initialized after the cable is reconnected (Click here).

Disconnect the cables from the negative (-) main battery and sub-battery terminals.

| 3. REMOVE ENGINE ASSEMBLY |

Remove the engine assembly from the vehicle (Click here).

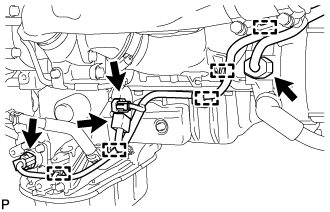

| 4. REMOVE NO. 1 INTAKE AIR CONNECTOR PIPE |

Disconnect the 4 connectors.

Using a clip remover, detach the 5 wire harness clamps.

Loosen the hose clamp, and remove the bolt and No. 1 intake air connector pipe.

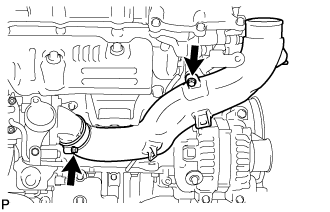

| 5. REMOVE GENERATOR ASSEMBLY |

Remove the nut and bolt, and disconnect the generator positive (+) cable.

Remove the 3 bolts, 2 nuts and generator.

| 6. DISCONNECT NO. 1 OUTLET TURBO OIL HOSE |

| 7. REMOVE NO. 1 ENGINE OIL LEVEL DIPSTICK GUIDE |

Remove the 2 bolts and No. 1 engine oil level dipstick guide.

| 8. DISCONNECT NO. 2 OUTLET TURBO OIL HOSE |

| 9. DISCONNECT NO. 2 INLET TURBO OIL PIPE SUB-ASSEMBLY |

Remove the union bolt and gasket, and disconnect the No. 2 inlet turbo oil pipe.

| 10. REMOVE STIFFENER INSULATOR RH (w/ Intercooler) |

Remove the 2 bolts and stiffener insulator RH.

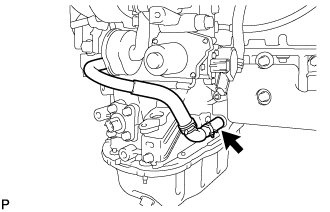

| 11. DISCONNECT NO. 1 OIL COOLER HOSE |

| 12. DISCONNECT NO. 2 OIL COOLER HOSE |

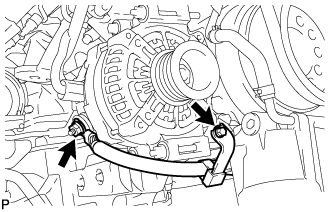

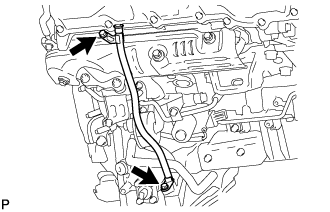

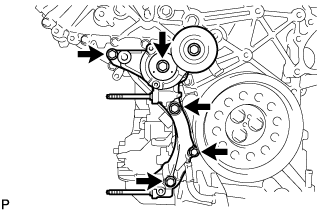

| 13. REMOVE V-RIBBED BELT TENSIONER ASSEMBLY |

Remove the 3 bolts and V-ribbed belt tensioner bracket.

Remove the bolt and No. 1 idler pulley.

Remove the 5 bolts and V-ribbed belt tensioner.

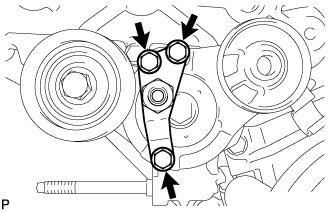

| 14. REMOVE CRANKSHAFT PULLEY |

- NOTICE:

- This procedure is intended for removal/installation of the crankshaft pulley only. Do not use this procedure for removal/installation of the flywheel or the drive plate and ring gear.

Text in Illustration*1

| Service Hole

|

*2

| Protrusion

|

Install the 2 bolts to the bolt holes of the crankshaft rear side.

Using a bar, turn the crankshaft until the crankshaft pulley service hole is a little to the left of bottom dead center.

Install a 14 mm x 1.5 pitch service bolt with a length of 70 mm or more to the crankshaft pulley service hole, and hold the crankshaft using the timing chain cover protrusion.

Remove the 3 bolts and crankshaft pulley.

- NOTICE:

- If the crankshaft pulley cannot be removed, temporarily install a bolt to the crankshaft so that the pulley does not fall, and lightly tap the outer edge of the mass damper with a plastic-faced hammer to remove the pulley. Do not tap the pulley V-ribbed belt ribs, as the crankshaft may be damaged.

| 15. REMOVE TIMING GEAR COVER SPACER (w/ Intercooler) |

Remove the 2 bolts and timing gear cover spacer.

| 16. REMOVE OIL FILTER ELEMENT |

Clean the inside of the oil filter cap, its threads and its O-ring groove.

Apply a small amount of engine oil to a new O-ring and install it to the oil filter cap.

Set a new oil filter element in the oil filter cap.

Remove any dirt or foreign matter from the installation surface of the engine.

Apply a small amount of engine oil to the O-ring again and temporarily install the oil filter cap by hand.

Using SST, tighten the oil filter cap.

- SST

- 09228-06501

- Torque:

- 25 N*m{255 kgf*cm, 18 ft.*lbf}

- NOTICE:

- Make sure that the oil filter is installed securely as shown in the illustration.

- Be careful that the O-ring does not get caught between any surrounding parts.

Install the No. 2 engine under cover seal to the No. 2 engine under cover with the 2 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

| 17. REMOVE OIL FILTER BRACKET SUB-ASSEMBLY |

Disconnect the 2 wire harness clamps.

Remove the 3 bolts, 2 nuts and oil filter bracket.

Remove the 2 O-rings.

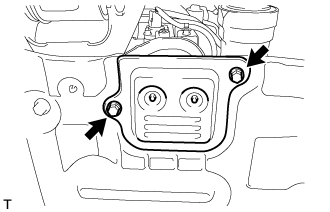

| 18. REMOVE ENGINE OIL LEVEL SENSOR |

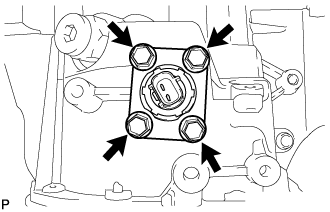

Remove the 4 bolts and engine oil level sensor.

Remove the gasket.

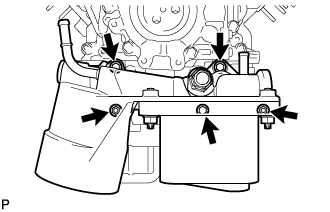

| 19. REMOVE NO. 2 OIL PAN SUB-ASSEMBLY |

Remove the 10 bolts and 2 nuts.

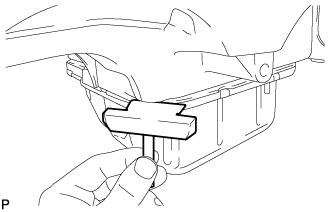

Insert the blade of an oil pan seal cutter between the oil pans. Cut through the applied sealer and remove the No. 2 oil pan.

- NOTICE:

- Be careful not to damage the contact surfaces of the No. 1 and No. 2 oil pans.

| 20. REMOVE OIL STRAINER SUB-ASSEMBLY |

Remove the 2 bolts and oil strainer.

Remove the O-ring from the oil strainer.

| 21. REMOVE NO. 1 OIL PAN SUB-ASSEMBLY |

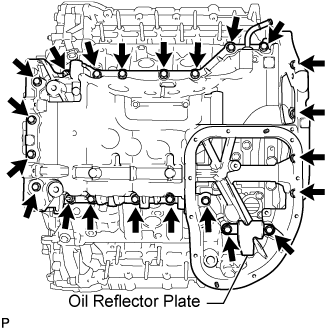

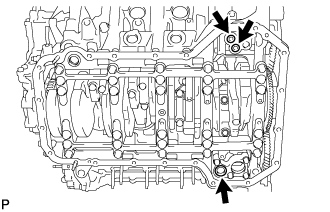

Remove the 20 bolts, 2 nuts and oil reflector plate.

- NOTICE:

- If the oil reflector plate is deformed, replace it.

- HINT:

- Be sure to clean the bolts and stud bolts, and check the threads for cracks or other damage.

Remove the No. 1 oil pan by prying between the No. 1 oil pan and cylinder block with a screwdriver.

- NOTICE:

- Be careful not to damage the contact surfaces of the cylinder block and oil pan.

- HINT:

- Tape the screwdriver tip before use.

Remove the 3 O-rings.

Remove the cylinder block oil hole gasket.

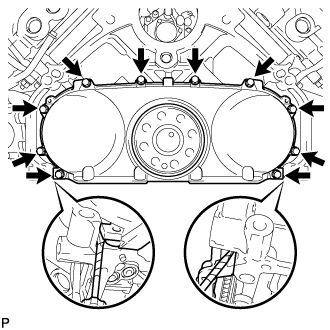

| 22. REMOVE REAR ENGINE OIL SEAL RETAINER |

Remove the 10 bolts.

Remove the oil seal retainer by prying between the oil seal retainer and cylinder block with a screwdriver.

- HINT:

- Tape the screwdriver tip before use.

| 23. REMOVE REAR CRANKSHAFT OIL SEAL |

Place the oil seal retainer on wooden blocks.

Using a screwdriver and hammer, tap out the oil seal.

- HINT:

- Tape the screwdriver tip before use.

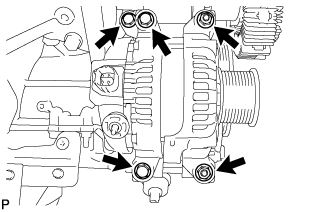

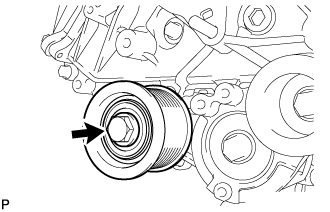

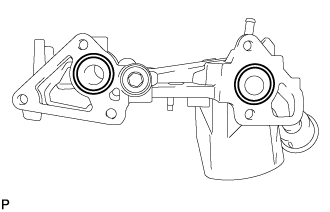

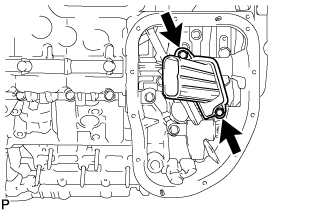

| 24. REMOVE SCAVENGING PUMP ASSEMBLY |

Remove the 4 bolts and scavenging pump.