Meter / Gauge System Oil Pressure Gauge Malfunction

DESCRIPTION

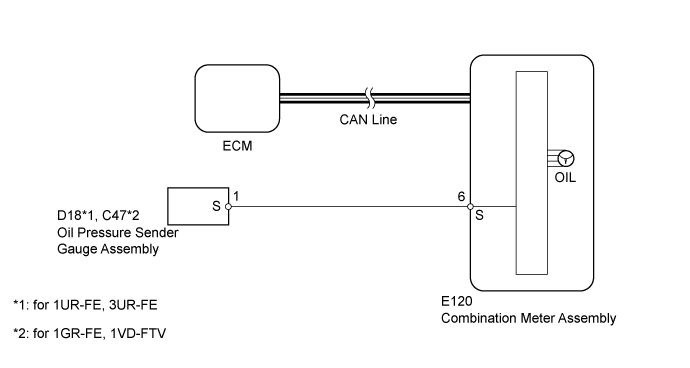

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK CAN COMMUNICATION SYSTEM

PERFORM ACTIVE TEST USING GTS (OIL PRESSURE SENSOR)

INSPECT OIL PRESSURE GAUGE ASSEMBLY (OIL PRESSURE SENSOR)

CHECK HARNESS AND CONNECTOR (COMBINATION METER - OIL PRESSURE SENSOR)

METER / GAUGE SYSTEM - Oil Pressure Gauge Malfunction |

DESCRIPTION

The oil pressure sender detects the oil pressure generated when the engine is started. The combination meter determines that the engine is running when the engine speed is 400 rpm or more, and determines that the engine is cranking when the engine speed is 200 rpm or less. The oil pressure receiver gauge detects and indicates the oil pressure applied to the oil pressure sender.

WIRING DIAGRAM

INSPECTION PROCEDURE

| 1.CHECK CAN COMMUNICATION SYSTEM |

Check for DTCs (Click here).

ResultResult

| Proceed to

|

CAN communication system DTC is not output

| A

|

CAN communication system (for LHD with Central Gateway ECU) DTC is output

| B

|

CAN communication system (for LHD without Central Gateway ECU) DTC is output

| C

|

CAN communication system (for RHD with Central Gateway ECU) DTC is output

| D

|

CAN communication system (for RHD without Central Gateway ECU) DTC is output

| E

|

| 2.PERFORM ACTIVE TEST USING GTS (OIL PRESSURE SENSOR) |

Operate the GTS according to the display and select Active Test (Click here).

Combination MeterTester Display

| Test Part

| Control Range

| Diagnostic Note

|

Oil Pressure Meter Operation

| Oil pressure receiver gauge

| LOW, 1/4, 1/2, 3/4 or HIGH

| Perform the test with the vehicle stopped and engine idling.

|

- OK:

- Needle indication is normal.

| 3.INSPECT OIL PRESSURE GAUGE ASSEMBLY (OIL PRESSURE SENSOR) |

Check that the needle moves in accordance with the engine speed.

- OK:

- Needle is as shown in illustration when engine is stopped.

Needle moves when engine is running.

ResultResult

| Proceed to

|

Oil pressure receiver gauge operates correctly according to engine condition

| A

|

Oil pressure receiver gauge does not operate correctly according to engine condition (for 1GR-FE)

| B

|

Oil pressure receiver gauge does not operate correctly according to engine condition (for 1UR-FE)

| C

|

Oil pressure receiver gauge does not operate correctly according to engine condition (for 3UR-FE)

| D

|

Oil pressure receiver gauge does not operate correctly according to engine condition (for 1VD-FTV)

| E

|

| | REPLACE OIL PRESSURE SENDER GAUGE ASSEMBLY (Click here) |

|

|

| | REPLACE OIL PRESSURE SENDER GAUGE ASSEMBLY (Click here) |

|

|

| | REPLACE OIL PRESSURE SENDER GAUGE ASSEMBLY (Click here) |

|

|

| | REPLACE OIL PRESSURE SENDER GAUGE ASSEMBLY (Click here) |

|

|

| 4.CHECK HARNESS AND CONNECTOR (COMBINATION METER - OIL PRESSURE SENSOR) |

- *1: for 1UR-FE, 3UR-FE

- *2: for 1GR-FE, 1VD-FTV

Disconnect the E120 combination meter assembly connector.

Disconnect the D18*1, C47*2 oil pressure sender gauge assembly connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

E120-6 (S) - D18-1 (S)

| Always

| Below 1 Ω

|

E120-6 (S) - C47-1 (S)

| Always

| Below 1 Ω

|

E120-6 (S) or D18-1 (S) - Body ground

| Always

| 10 kΩ or higher

|

E120-6 (S) or C47-1 (S) - Body ground

| Always

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|