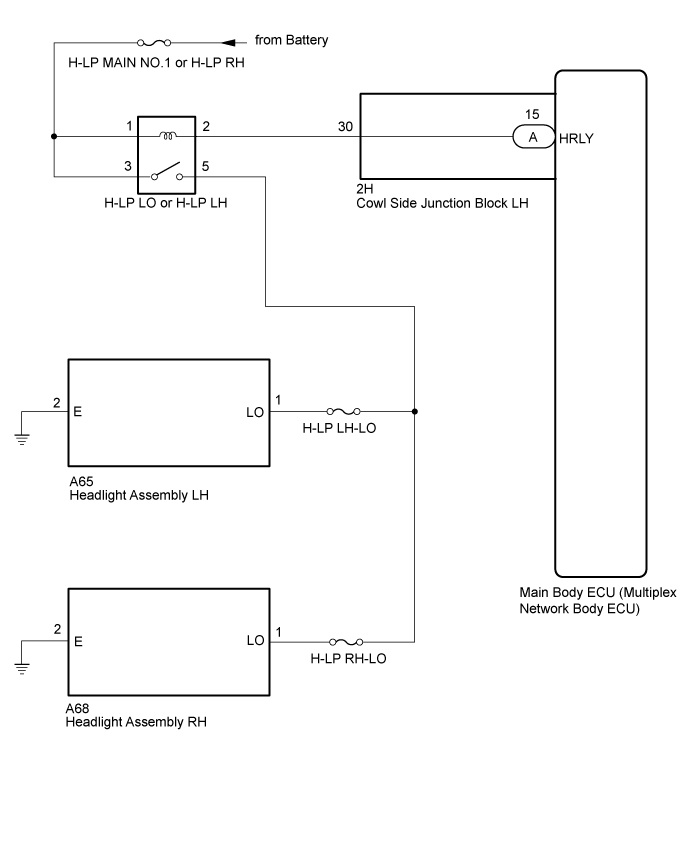

Lighting System Headlight Signal Circuit

DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

PERFORM ACTIVE TEST USING GTS (HEADLIGHT)

INSPECT HEADLIGHT RELAY (H-LP LO OR H-LP LH)

CHECK HARNESS AND CONNECTOR (BATTERY - HEADLIGHT RELAY [H-LP LO OR H-LP LH])

CHECK HARNESS AND CONNECTOR (HEADLIGHT RELAY [H-LP LO OR H-LP LH] - MAIN BODY ECU [MULTIPLEX NETWORK BODY ECU])

INSPECT COWL SIDE JUNCTION BLOCK LH

LIGHTING SYSTEM - Headlight Signal Circuit |

DESCRIPTION

The main body ECU receives a headlight low switch information signal from the light control switch, and illuminates the headlight low beam.

WIRING DIAGRAM

INSPECTION PROCEDURE

- NOTICE:

- Inspect the fuses and bulbs for circuits related to this system before performing the following inspection procedure.

| 1.PERFORM ACTIVE TEST USING GTS (HEADLIGHT) |

Using the GTS, perform the Active Test (Click here).

Main BodyTester Display

| Test Part

| Control Range

| Diagnostic Note

|

Headlight Relay

| Headlight

| ON or OFF

| -

|

- OK:

- Headlight low beam turns on/turns off.

| OK |

|

|

|

| PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE (Click here) |

|

| 2.INSPECT HEADLIGHT RELAY (H-LP LO OR H-LP LH) |

Inspect the headlight relay (Click here).

| | REPLACE HEADLIGHT RELAY (H-LP LO OR H-LP LH) |

|

|

| 3.CHECK HARNESS AND CONNECTOR (BATTERY - HEADLIGHT RELAY [H-LP LO OR H-LP LH]) |

Remove the headlight relay from the engine room relay block, junction block.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

Tester Connection

| Condition

| Specified Condition

|

Headlight relay terminal 1 - Body ground

| Always

| 11 to 14 V

|

Headlight relay terminal 3 - Body ground

|

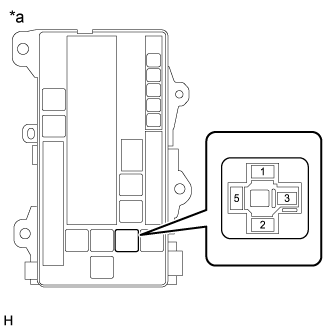

Text in Illustration*a

| Front view of wire harness connector

(to Headlight Relay [H-LP LO or H-LP LH])

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 4.CHECK HARNESS AND CONNECTOR (HEADLIGHT RELAY [H-LP LO OR H-LP LH] - MAIN BODY ECU [MULTIPLEX NETWORK BODY ECU]) |

Remove the headlight relay from the engine room relay block, junction block.

Disconnect the 2H cowl side junction block LH connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

Headlight relay terminal 2 - 2H-30

| Always

| Below 1 Ω

|

Headlight relay terminal 2 - Body ground

| Always

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 5.INSPECT COWL SIDE JUNCTION BLOCK LH |

for LHD:

Remove the cowl side junction block LH (Click here).

Remove the main body ECU (multiplex network body ECU) from the cowl side junction block LH (Click here).

for RHD:

Remove the cowl side junction block LH (Click here).

Remove the main body ECU (multiplex network body ECU) from the cowl side junction block LH (Click here).

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

A-15 (HRLY) - 2H-30

| Always

| Below 1 Ω

|

ResultResult

Result | Proceed to

|

OK (for LHD)

| A

|

NG (for LHD)

| B

|

NG (for RHD)

| C

|

OK (for RHD)

| D

|

| |

|

| |

|

| | REPLACE MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) (Click here) |

|

|

| A |

|

|

|

| REPLACE MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) (Click here) |

|