Cylinder Head Gasket -- Installation |

| 1. INSPECT CYLINDER HEAD SET BOLT |

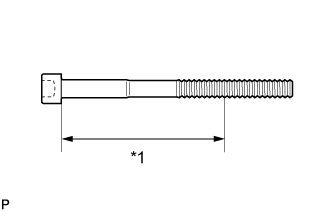

Using a vernier caliper, measure the diameter of the elongated thread at the measuring point.

- Measuring point:

- 94 mm (3.70 in.) for intake side bolt

- 89 mm (3.50 in.) for exhaust side bolt

- Standard diameter:

- 10.85 to 11.00 mm (0.427 to 0.433 in.)

- Minimum diameter:

- 10.6 mm (0.417 in.)

If the diameter is less than the minimum, replace the cylinder head bolt.Text in Illustration *1 Measuring Point - HINT:

- If a visual check reveals no excessively thin areas, check the center of the bolt (see illustration) and find the area that has the smallest diameter.

|

| 2. INSPECT CYLINDER HEAD SUB-ASSEMBLY |

|

Using a precision straightedge and feeler gauge, measure the warpage of the surfaces where the cylinder head contacts the cylinder block and manifold.

- Standard Warpage:

Item Specified Condition Cylinder head lower side 0.05 mm (0.00197 in.) Intake side 0.08 mm (0.00315 in.) Exhaust side 0.05 mm (0.00197 in.)

- Maximum warpage:

- 0.10 mm (0.00394 in.)

If the warpage is more than the maximum, replace the cylinder head.Text in Illustration *A Cylinder Head Lower Side *B Intake Side *C Exhaust Side

Using a dye penetrant, check the intake ports, exhaust ports and cylinder surface for cracks.

If cracked, replace the cylinder head.

| 3. INSTALL CYLINDER HEAD SUB-ASSEMBLY RH |

Clean the cylinder block with solvent.

Set the piston of the No. 1 cylinder to slightly ATDC.

Place the cylinder head gasket on the cylinder block surface with the front face of the Lot No. stamp upward.

Text in Illustration *1 Lot No. *a Front - NOTICE:

- Be careful of the installation direction.

- Make sure that no oil is on the front end (indicated by the arrows) of the cylinder head gasket.

|

Place the cylinder head on the cylinder block.

- NOTICE:

- Ensure that no oil is on the mounting surface of the cylinder head.

- Gently place the cylinder head in order not to damage the gasket with the bottom part of the head.

- HINT:

- The cylinder head bolts are tightened in 3 progressive steps.

Apply a light coat of engine oil to the threads and under the heads of the cylinder head bolts.

Step 1:

Using a 10 mm bi-hexagon wrench, install and uniformly tighten the 10 cylinder head bolts with the plate washers in several steps in the sequence shown in the illustration.

- Torque:

- 36 N*m{367 kgf*cm, 27 ft.*lbf}

|

Step 2:

Mark the front side of each cylinder head bolt head with paint.

Tighten the cylinder head bolts another 90°.

Step 3:

Tighten the cylinder head bolts an additional 90°.

Check that the paint marks are now at a 180° angle to the front.

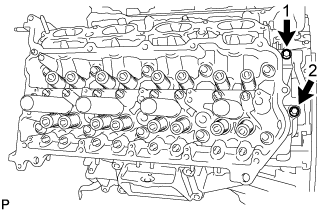

Install and uniformly tighten the 2 bolts in the sequence shown in the illustration.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

|

| 4. INSTALL CYLINDER HEAD SUB-ASSEMBLY LH |

Clean the cylinder block with solvent.

Set the piston of the No. 1 cylinder to slightly ATDC.

Place the cylinder head gasket on the cylinder block surface with the front face of the Lot No. stamp upward.

Text in Illustration *1 Lot No. *a Front - NOTICE:

- Be careful of the installation direction.

- Make sure that no oil is on the front end (indicated by the arrows) of the cylinder head gasket.

|

Place the cylinder head on the cylinder block.

- NOTICE:

- Ensure that no oil is on the mounting surface of the cylinder head.

- Gently place the cylinder head in order not to damage the gasket with the bottom part of the head.

- HINT:

- The cylinder head bolts are tightened in 3 progressive steps.

Apply a light coat of engine oil to the threads and under the heads of the cylinder head bolts.

Step 1:

- HINT:

- The cylinder head bolts are tightened in 3 progressive steps.

Using a 10 mm bi-hexagon wrench, install and uniformly tighten the 10 cylinder head bolts with the plate washers in several steps in the sequence shown in the illustration.

- Torque:

- 36 N*m{367 kgf*cm, 27 ft.*lbf}

|

Step 2:

Mark the front side of each cylinder head bolt head with paint.

Tighten the cylinder head bolts another 90°.

Step 3:

Tighten the cylinder head bolts an additional 90°.

Check that the paint marks are now at a 180° angle to the front.

Install and uniformly tighten the 2 bolts in the sequence shown in the illustration.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

|

| 5. INSTALL VALVE STEM CAP |

Apply a light coat of engine oil to the valve stem caps.

Install the 32 valve stem caps to the cylinder heads.

| 6. INSTALL VALVE LASH ADJUSTER ASSEMBLY |

Inspect the valve lash adjuster before installing it (Click here).

Install the 32 valve lash adjusters to the cylinder heads.

- NOTICE:

- Install the lash adjuster to the same place it was removed from.

| 7. INSTALL NO. 1 VALVE ROCKER ARM SUB-ASSEMBLY |

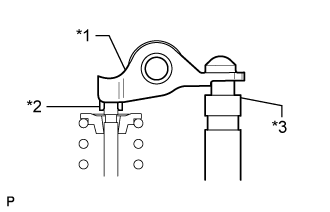

Apply engine oil to the lash adjuster tips and valve stem cap ends.

Install the 32 valve rocker arms as shown in the illustration.

Text in Illustration *1 Valve Rocker Arm *2 Valve Stem Cap *3 Valve Lash Adjuster

|

| 8. INSTALL CAMSHAFT |

| 9. INSTALL EXHAUST MANIFOLD SUB-ASSEMBLY |