Camshaft -- Installation |

| 1. INSTALL CAMSHAFT BEARING CAP RH |

Apply a light coat of engine oil to the camshaft journals, camshaft housings and bearing caps.

Install the No. 1 and No. 2 camshafts to the camshaft housing.

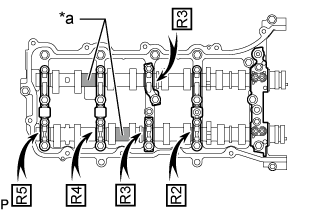

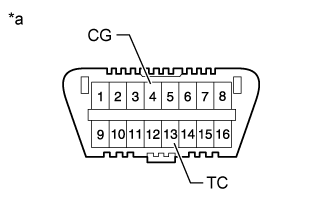

Text in Illustration *a Identification Mark - HINT:

- Check the identification mark stamped on the camshaft.

Item Mark for Intake Side NO. 1 for Exhaust Side NO. 2

|

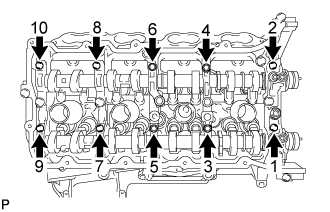

Confirm the marks and numbers on the camshaft bearing caps and place them in their proper positions and directions.

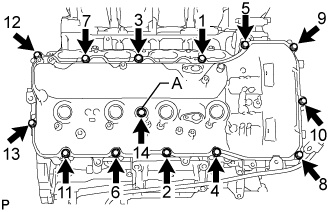

Temporarily install the 10 bolts in the order shown in the illustration.

|

| 2. INSTALL CAMSHAFT HOUSING SUB-ASSEMBLY RH |

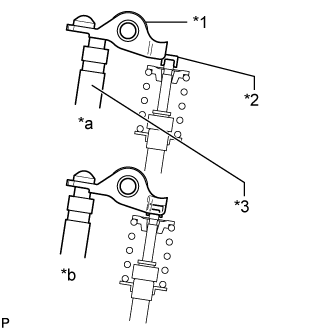

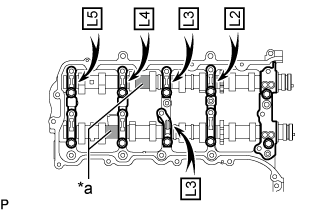

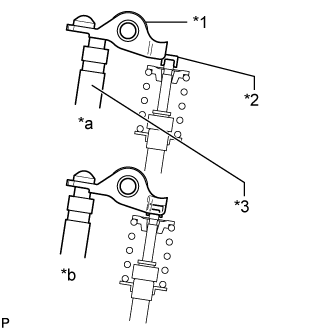

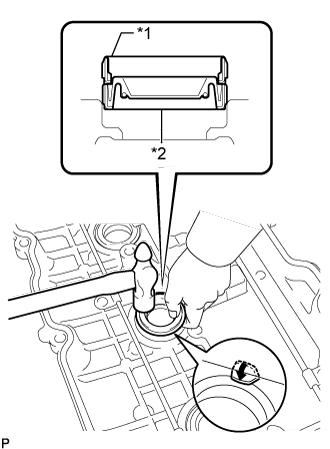

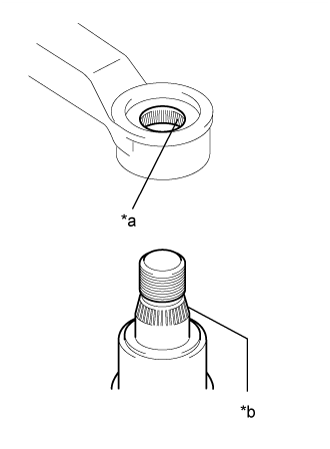

Make sure that the valve rocker arms are installed as shown in the illustration.

Text in Illustration *1 Valve Rocker Arm *2 Valve Stem Cap *3 Valve Lash Adjuster *a INCORRECT *b CORRECT

|

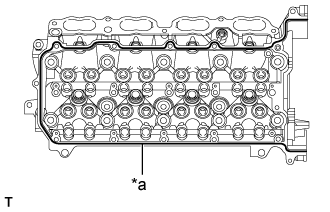

Apply seal packing in a continuous line as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard seal diameter:

- 3.5 to 4.0 mm (0.138 to 0.157 in.)

Text in Illustration *a 3.5 to 4.0 mm - NOTICE:

- Remove any oil from the contact surface.

- Install the camshaft housing within 3 minutes and tighten the bolts within 15 minutes after applying seal packing.

|

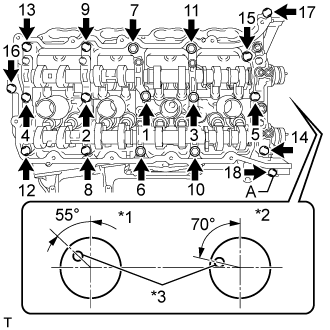

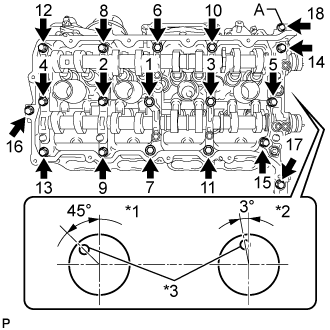

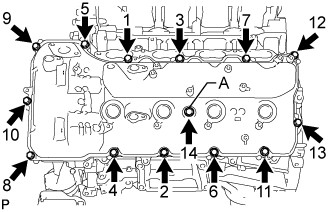

Install the camshaft housing, and install the 18 bolts in the order shown in the illustration.

- Torque:

- for bolt A:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

- except bolt A:

- 30 N*m{306 kgf*cm, 22 ft.*lbf}

Text in Illustration *1 EX *2 IN *3 Knock Pin - NOTICE:

- Do not start the engine for at least 2 hours after the installation.

- Make sure that the knock pin of the camshaft is positioned as shown in the illustration before installing the camshaft housing.

|

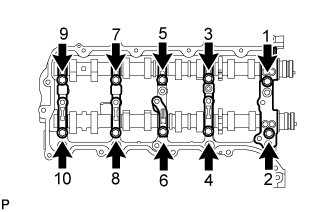

Tighten the 10 bolts in the order shown in the illustration.

- Torque:

- 16 N*m{163 kgf*cm, 12 ft.*lbf}

- NOTICE:

- Thoroughly wipe clean any seal packing.

|

| 3. INSTALL CAMSHAFT BEARING CAP LH |

Apply a light coat of engine oil to the camshaft journals, camshaft housings and bearing caps.

Install the No. 3 and No. 4 camshafts to the camshaft housing.

Text in Illustration *a Identification Mark - HINT:

- Check the identification mark stamped on the camshaft.

Item Mark for Intake Side NO. 3 for Exhaust Side NO. 4

|

Confirm the marks and numbers on the camshaft bearing caps and place them in their proper positions and directions.

Temporarily install the 10 bolts in the order shown in the illustration.

|

| 4. INSTALL CAMSHAFT HOUSING SUB-ASSEMBLY LH |

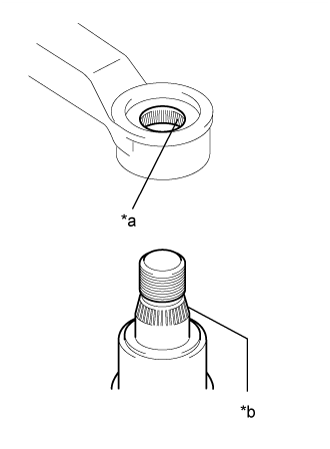

Make sure that the valve rocker arms are installed as shown in the illustration.

Text in Illustration *1 Valve Rocker Arm *2 Valve Stem Cap *3 Valve Lash Adjuster *a INCORRECT *b CORRECT

|

Apply seal packing in a continuous line as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Standard seal diameter:

- 3.5 to 4.0 mm (0.138 to 0.157 in.)

Text in Illustration *a 3.5 to 4.0 mm - NOTICE:

- Remove any oil from the contact surface.

- Install the camshaft housing within 3 minutes and tighten the bolts within 15 minutes after applying seal packing.

|

Install the camshaft housing, and install the 18 bolts in the order shown in the illustration.

- Torque:

- for bolt A:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

- except bolt A:

- 30 N*m{306 kgf*cm, 22 ft.*lbf}

Text in Illustration *1 IN *2 EX *3 Knock Pin - NOTICE:

- Do not start the engine for at least 2 hours after the installation.

- Make sure that the knock pin of the camshaft is positioned as shown in the illustration before installing the camshaft housing.

|

Tighten the 10 bolts in the order shown in the illustration.

- Torque:

- 16 N*m{163 kgf*cm, 12 ft.*lbf}

- NOTICE:

- Thoroughly wipe clean any seal packing.

|

| 5. INSTALL CRANKSHAFT TIMING GEAR KEY |

|

Install the timing gear key.

- HINT:

- The other timing gear key will be installed at a later step.

| 6. SET NO. 1 CYLINDER TO TDC/COMPRESSION |

Temporarily install the crankshaft pulley bolt.

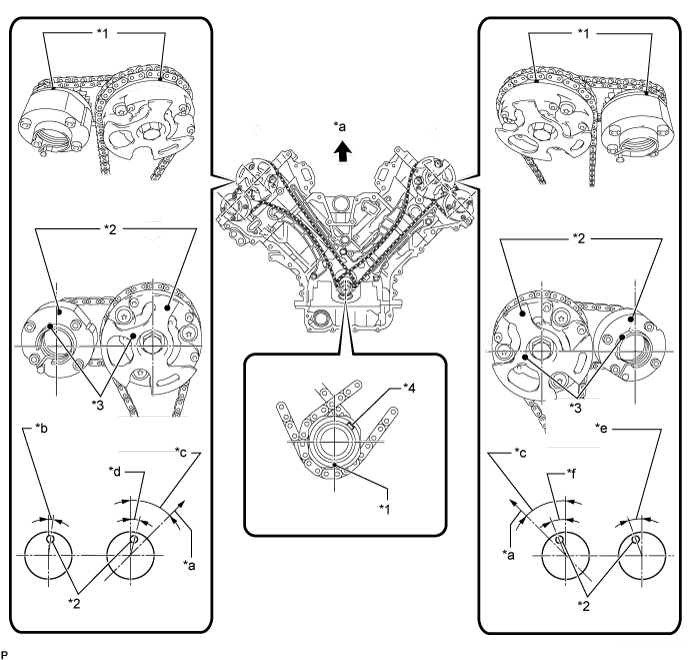

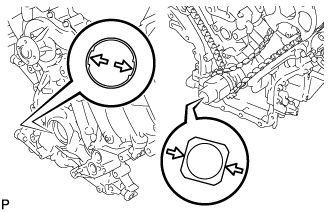

Rotate the crankshaft so that the timing gear key is as shown in the illustration. Then using a wrench, rotate each camshaft so that the timing marks are as shown in the illustration.

- NOTICE:

- When the crankshaft or a camshaft is rotated excessively, the valves and pistons may interfere with each other.

Remove the crankshaft pulley bolt.

Text in Illustration *1 IN *2 EX *3 Knock Pin *4 Key *a Toward Ceiling - -

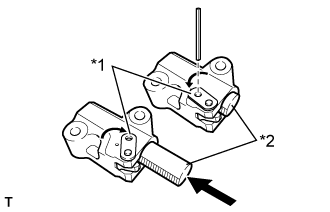

| 7. INSTALL NO. 2 CHAIN TENSIONER ASSEMBLY |

|

Install the chain tensioner with the 2 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

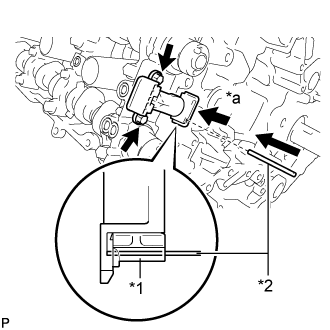

Text in Illustration *1 Plunger *2 Pin *a Push

While raising up the No. 2 chain tensioner, insert a pin of 1.0 mm (0.0394 in.) into the hole to fix it in place.

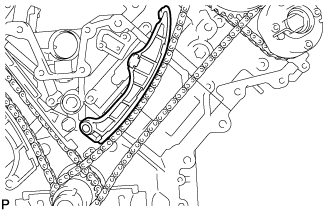

| 8. INSTALL NO. 1 CHAIN SUB-ASSEMBLY RH |

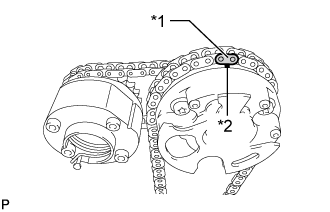

Align the No. 1 chain orange mark plate with the camshaft timing gear timing mark, and attach the chain to the gear as shown in the illustration.

Text in Illustration *1 Mark Plate *2 Timing Mark

|

Align the No. 1 chain orange mark plate with the crankshaft timing sprocket timing mark, and attach the chain to the gear as shown in the illustration.

Text in Illustration *1 Mark Plate *2 Timing Mark

|

Align the No. 2 chain yellow mark plates with the timing marks of the camshaft timing gear assembly and camshaft timing exhaust gear assembly, and attach the No. 2 chain to the gears as shown in the illustration.

Text in Illustration *1 Mark Plate *2 Timing Mark - NOTICE:

- The camshaft timing exhaust gear has 2 grooves. Align the mark plates of the No. 2 chain with the first groove.

- HINT:

- The crankshaft timing sprocket RH and camshaft timing exhaust gear will be installed with the No. 1 and No. 2 chains connected to the gears.

|

Install the crankshaft timing sprocket RH to the crankshaft.

Align and attach the knock pin of the No. 1 camshaft with the pin hole of the camshaft timing gear.

Using the hexagonal portion of the No. 2 camshaft, align and attach the knock pin of the No. 2 camshaft with the pin hole of the camshaft timing exhaust gear.

Remove the pin from the No. 2 chain tensioner.

Using a wrench to hold the hexagonal portion of the No. 1 camshaft, temporarily install the bolt.

Using a wrench to hold the hexagonal portion of the No. 2 camshaft, temporarily install the bolt.

| 9. INSTALL NO. 1 CHAIN VIBRATION DAMPER RH |

Install the vibration damper with the 2 bolts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

| 10. INSTALL NO. 1 CHAIN TENSIONER SLIPPER RH |

- HINT:

- If you cannot install the chain tensioner slipper due to the tension of the chain, use the hexagonal portion of the camshaft to loosen the chain, and then install the chain tensioner slipper.

| 11. INSTALL NO. 1 CHAIN TENSIONER ASSEMBLY RH |

|

Move the stopper plate clockwise to release the lock, and push the plunger deep into the tensioner.

Text in Illustration *1 Stopper Plate *2 Plunger

Move the stopper plate counterclockwise to set the lock, and insert a hexagon wrench into the hole of the stopper plate.

Install the chain tensioner with the 2 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

Remove the hexagon wrench from the chain tensioner.

| 12. INSTALL NO. 3 CHAIN TENSIONER ASSEMBLY |

|

Install the chain tensioner with the 2 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

Text in Illustration *1 Plunger *2 Pin *a Push

While pushing down the No. 2 chain tensioner, insert a pin of 1.0 mm (0.0394 in.) into the hole to fix it in place.

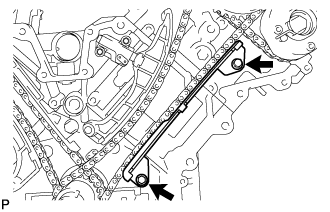

| 13. INSTALL NO. 1 CHAIN SUB-ASSEMBLY LH |

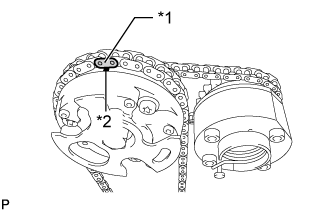

Align the No. 1 chain orange mark plate with the camshaft timing gear timing mark, and attach the chain to the gear as shown in the illustration.

Text in Illustration *1 Mark Plate *2 Timing Mark

|

Align the No. 1 chain orange mark plate with the crankshaft timing sprocket timing mark, and attach the chain to the gear as shown in the illustration.

Text in Illustration *1 Mark Plate *2 Timing Mark

|

Align the No. 2 chain yellow mark plates with the timing marks of the camshaft timing gear assembly and camshaft timing exhaust gear assembly, and attach the No. 2 chain to the gears as shown in the illustration.

Text in Illustration *1 Mark Plate *2 Timing Mark - NOTICE:

- The camshaft timing exhaust gear has 2 grooves. Align the mark plates of the No. 2 chain with the first groove.

- HINT:

- The crankshaft timing sprocket LH and camshaft timing exhaust gear will be installed with the No. 1 and No. 2 chains connected to the gears.

|

Install the crankshaft timing sprocket LH to the crankshaft.

Align and attach the knock pin of the No. 3 camshaft with the pin hole of the camshaft timing gear.

Using the hexagonal portion of the No. 4 camshaft, align and attach the knock pin of the No. 4 camshaft with the pin hole of the camshaft timing exhaust gear.

- NOTICE:

- Because the timing mark positions of the gears may shift due to looseness of the No. 1 chain, use the hexagonal portion of the camshaft to hold the No. 3 camshaft in place until the No. 1 chain tensioner is installed.

Remove the pin from the No. 3 chain tensioner.

Using a wrench to hold the hexagonal portion of the No. 3 camshaft, temporarily install the bolt.

Using a wrench to hold the hexagonal portion of the No. 4 camshaft, temporarily install the bolt.

| 14. INSTALL NO. 1 CHAIN TENSIONER SLIPPER LH |

|

- HINT:

- If you cannot install the chain tensioner slipper due to the tension of the chain, use the hexagonal portion of the camshaft to loosen the chain, and install the chain tensioner slipper.

| 15. INSTALL NO. 1 CHAIN TENSIONER ASSEMBLY LH |

|

Move the stopper plate clockwise to release the lock, and push the plunger deep into the tensioner.

Text in Illustration *1 Stopper Plate *2 Plunger

Move the stopper plate counterclockwise to set the lock, and insert a hexagon wrench into the hole of the stopper plate.

Install a new gasket and the chain tensioner with the 2 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

| 16. INSTALL NO. 1 CHAIN VIBRATION DAMPER LH |

|

Install the vibration damper with the 2 bolts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

Remove the hexagon wrench from the No. 1 chain tensioner.

| 17. TIGHTEN CAMSHAFT TIMING GEAR ASSEMBLY |

for Bank 1:

Using a wrench, hold the hexagonal portion of the No. 3 camshaft.

Text in Illustration *a Hold

Turn Tighten the bolt of the camshaft timing gear.

- Torque:

- 100 N*m{1020 kgf*cm, 74 ft.*lbf}

Using a wrench to hold the hexagonal portion of the No. 4 camshaft, tighten the bolt of the camshaft timing exhaust gear.

- Torque:

- 100 N*m{1020 kgf*cm, 74 ft.*lbf}

Text in Illustration *a Hold

Turn

|

for Bank 2:

Using a wrench, hold the hexagonal portion of the No. 1 camshaft.

Text in Illustration *a Hold

Turn Tighten the bolt of the camshaft timing gear.

- Torque:

- 100 N*m{1020 kgf*cm, 74 ft.*lbf}

Using a wrench to hold the hexagonal portion of the No. 2 camshaft, tighten the bolt of the camshaft timing exhaust gear.

- Torque:

- 100 N*m{1020 kgf*cm, 74 ft.*lbf}

Text in Illustration *a Hold

Turn

|

| 18. CHECK NO. 1 CYLINDER TO TDC/COMPRESSION |

Temporarily install the crankshaft pulley bolt.

Rotate the crankshaft clockwise, and check that the timing marks on the crankshaft timing sprocket and camshaft timing gears are as shown in the illustration.

Remove the crankshaft pulley bolt.

Text in Illustration *1 Timing Mark *2 Timing Mark Position *3 Knock Pin Position *4 Key *a Toward Ceiling *b Approximately 2° *c Approximately 45° *d Approximately 16° *e Approximately 18° *f Approximately 32°

| 19. INSTALL WATER INLET PIPE |

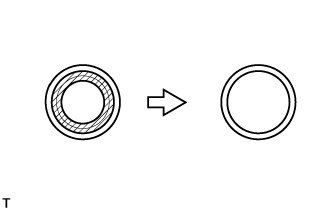

Apply soapy water to 2 new O-rings and install them to the inlet pipe.

Install the inlet pipe to the No. 1 heat exchanger cover.

| 20. INSTALL TIMING CHAIN COVER SUB-ASSEMBLY |

Apply a light coat of engine oil to a new oil pump gasket.

Install the oil pump gasket.

Apply a light coat of engine oil to a new O-ring.

Install the O-ring.

Apply seal packing in a continuous line to the timing chain cover as shown in the following illustration.

Text in Illustration *1 Continuous line area *2 Dashed line area *3 Diagonal line area - - - Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- Apply Seal Packing as Follows:

Area Seal Packing Diameter Application Position from Inside Edge of Cover Continuous Line Area 3.0 to 4.0 mm (0.118 to 0.157 in.) 2.5 mm (0.0984 in.) Dashed Line Area 6.4 mm (0.252 in.) or more, or within OK area shown in illustration 7.0 mm (0.276 in.) Diagonal Line Area 3.0 to 4.0 mm (0.118 to 0.157 in.) 5.5 mm (0.217 in.)

Text in Illustration *1 Seal Packing Thickness mm (in.) *2 Seal Packing Width mm (in.) *3 Seal Packing Thickness *4 Seal Packing Width *5 OK Area

- NOTICE:

- When the contact surfaces are wet, wipe them with an oil-free cloth before applying seal packing.

- Install the chain cover within 3 minutes and tighten the bolts within 10 minutes after applying seal packing.

Align the oil pump drive rotor spline and crankshaft as shown in the illustration. Install the spline and chain cover to the crankshaft.

|

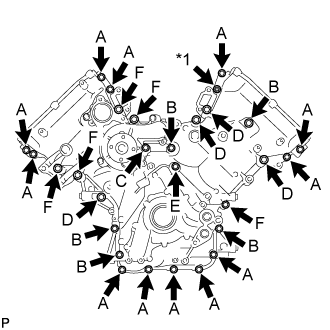

Temporarily install the timing chain cover with the 28 bolts and nut.

- Standard Bolt:

Item Length Thread Diameter Bolt A 25 mm (0.984 in.) 8 mm (0.315 in.) Bolt B 55 mm (2.17 in.) 8 mm (0.315 in.) Bolt C 70 mm (2.76 in.) 8 mm (0.315 in.) Bolt D 35 mm (1.38 in.) 10 mm (0.394 in.) Bolt E 55 mm (2.17 in.) 10 mm (0.394 in.) Bolt F 80 mm (3.15 in.) 10 mm (0.394 in.)

Text in Illustration *1 Nut - NOTICE:

- Make sure that there is no oil on the bolt threads.

|

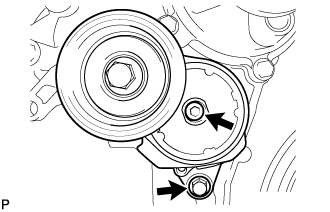

Tighten the 3 bolts in several steps in the sequence shown in the illustration.

- Torque:

- 47 N*m{479 kgf*cm, 35 ft.*lbf}

|

Temporarily install the fluid coupling bracket with the 4 bolts.

- Standard Bolt:

Item Length Thread Diameter Bolt A 70 mm (2.76 in.) 8 mm (0.315 in.) Bolt B 80 mm (3.15 in.) 10 mm (0.394 in.)

|

Temporarily install the belt tensioner with the standard bolt and 6 mm hexagon wrench bolt.

|

Tighten the 8 bolts labeled 4 to 11 in several steps in the sequence shown in the illustration.

- Torque:

- 47 N*m{479 kgf*cm, 35 ft.*lbf}

|

Tighten the 23 bolts and nut labeled 12 to 35 in several steps in the sequence shown in the illustration.

- Torque:

- 23 N*m{235 kgf*cm, 17 ft.*lbf}

- NOTICE:

- Do not start the engine for at least 2 hours after installing.

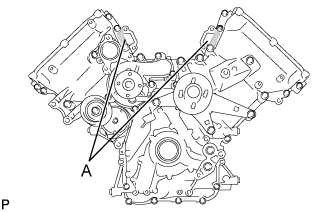

After the installation, if the seal packing has seeped out at the areas labeled A shown in the illustration, wipe it off.

|

| 21. INSTALL SPARK PLUG TUBE GASKET |

Using a cutter knife, cut off the seal part of the removed gasket.

Text in Illustration

Area to cut off

|

Using the removed gasket and a hammer, tap in a new gasket until it stops.

Text in Illustration *1 Removed Gasket *2 New Gasket - HINT:

- If the removed gasket does not fit on the new one, correct the removed one with pliers.

|

Apply a light coat of MP grease to the lip of the gasket.

Return the 4 ventilation baffle plate claws to the original positions.

| 22. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY LH |

Install 5 new gaskets to the camshaft bearing caps (No. 2, No. 3).

Install a new gasket to the cylinder head cover.

- NOTICE:

- Remove any oil from the contact surface.

Apply seal packing as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

Text in Illustration

Seal Packing - NOTICE:

- Remove any oil from the contact surface.

- Install the cylinder head cover within 3 minutes and tighten the bolts within 15 minutes after applying seal packing.

|

Install the cylinder head cover and a new seal washer with the 14 bolts in the order shown in the illustration.

- Torque:

- for bolt A:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

- except bolt A:

- 12 N*m{122 kgf*cm, 9 ft.*lbf}

- NOTICE:

- Do not start the engine for at least 2 hours after the installation.

|

| 23. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY RH |

Install 5 new gaskets to the camshaft bearing caps. (No. 1, No. 3).

Install a new gasket to the cylinder head cover.

- NOTICE:

- Remove any oil from the contact surface.

Apply seal packing as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

Text in Illustration

Seal Packing - NOTICE:

- Remove any oil from the contact surface.

- Install the cylinder head cover within 3 minutes and tighten the bolts within 15 minutes after applying seal packing.

|

Install the cylinder head cover and a new seal washer with the 14 bolts in the order shown in the illustration.

- Torque:

- for bolt A:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

- except bolt A:

- 12 N*m{122 kgf*cm, 9 ft.*lbf}

- NOTICE:

- Do not start the engine for at least 2 hours after the installation.

|

Install the noise filter to the cylinder head cover with the bolt.

- Torque:

- 7.0 N*m{71 kgf*cm, 62 in.*lbf}

| 24. INSTALL IGNITION COIL ASSEMBLY |

Install the 8 ignition coils with the 8 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

| 25. INSTALL CRANKSHAFT TIMING GEAR KEY |

|

Install the timing gear key.

- HINT:

- The other timing gear key will be installed at a later step.

| 26. INSTALL CRANKSHAFT PULLEY |

Align the pulley set key with the key groove of the pulley, and slide on the pulley.

|

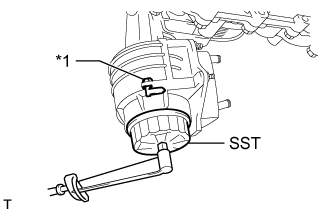

Using SST, install the pulley set bolt.

- SST

- 09213-70011

09330-00021

- Torque:

- 300 N*m{3059 kgf*cm, 221 ft.*lbf}

Text in Illustration *a Hold

Turn

| 27. CONNECT WIRE HARNESS CLAMP BRACKET |

Connect the bracket to the timing chain cover with the bolt.

- Torque:

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}

| 28. INSTALL NO. 1 IDLER PULLEY SUB-ASSEMBLY |

Install the idler pulley with the bolt.

- Torque:

- 43 N*m{438 kgf*cm, 32 ft.*lbf}

| 29. INSTALL WATER PUMP PULLEY |

Temporarily install the pulley with the 4 bolts.

|

Using SST, hold the pulley and tighten the 4 bolts.

- SST

- 09960-10010(09962-01000,09963-01000)

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

| 30. INSTALL WATER INLET HOUSING |

Install a new gasket to the timing chain cover.

|

Install the water inlet with the 3 bolts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

Text in Illustration *1 Gasket

| 31. INSTALL NO. 1 ENGINE COVER |

| 32. INSTALL NO. 2 ENGINE COVER |

| 33. INSTALL FRONT WATER BY-PASS JOINT |

Install 2 new gaskets and the water by-pass joint with the 4 nuts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

Connect the No. 2 water by-pass hose to the water by-pass joint.

| 34. INSTALL WATER BY-PASS PIPE SUB-ASSEMBLY |

Connect the 2 hoses.

Install the water by-pass pipe with the 2 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

| 35. INSTALL NO. 1 WATER BY-PASS HOSE |

Install the No. 1 water by-pass hose by connecting the hose to the water inlet housing and front water by-pass joint.

| 36. INSTALL GENERATOR ASSEMBLY |

Install the stud bolt.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

Install the generator assembly with the 3 bolts and nut.

- Torque:

- 43 N*m{438 kgf*cm, 32 ft.*lbf}

Connect the harness bracket to the generator assembly with the bolt.

- Torque:

- 31 N*m{316 kgf*cm, 23 ft.*lbf}

Connect the generator wire with the nut.

- Torque:

- 9.8 N*m{100 kgf*cm, 87 in.*lbf}

Close the terminal cap.

Connect the generator connector.

| 37. CONNECT OIL COOLER PIPE ASSEMBLY |

Connect the oil cooler pipe with the 2 bolts.

- Torque:

- 14 N*m{143 kgf*cm, 10 ft.*lbf}

| 38. CONNECT VANE PUMP ASSEMBLY |

|

- HINT:

- Before performing the following procedures, move the spacer until the vane pump can be installed.

| *1 | Spacer |

Connect the vane pump to the timing chain cover with the 2 bolts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

| 39. INSTALL INTAKE MANIFOLD |

Place 2 new gaskets on the intake manifold.

Text in Illustration *1 Gasket

|

Place the intake manifold on the cylinder head.

Install and uniformly tighten the 8 bolts and 2 nuts in several steps.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

Install the wire bracket to the intake manifold with the bolt.

- Torque:

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}

Connect the 3 wire clamps to the 3 wire brackets.

Install the No. 3 engine cover.

Install the No. 1 engine cover sub-assembly.

Connect the purge VSV connector.

Connect the purge line hose to the purge VSV.

Connect the vacuum switching valve connector (for ACIS).

Connect the No. 1 ventilation hose.

Connect the 2 water by-pass hoses.

Connect the throttle body connector.

Connect the ventilation hose to the ventilation pipe of the cylinder head cover LH and RH.

| 40. INSTALL OIL FILTER BRACKET |

Apply a light coat of engine oil to 2 new O-rings.

Install the 2 O-rings to the timing chain cover.

Install the oil filter bracket with the 2 nuts and 2 bolts.

- Torque:

- 35 N*m{357 kgf*cm, 26 ft.*lbf}

| 41. INSTALL NO. 1 OIL COOLER BRACKET |

Connect the ground wire to the cylinder block.

Install the oil cooler bracket with the 2 nuts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

| 42. INSTALL NO. 2 WATER BY-PASS PIPE SUB-ASSEMBLY |

Connect the 4 hoses.

Install the water by-pass pipe with the 3 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

| 43. INSTALL OIL PRESSURE SENDER GAUGE ASSEMBLY |

Apply adhesive to 2 or 3 threads of the oil pressure sender gauge.

- Adhesive:

- Toyota Genuine Adhesive 1344, Three Bond 1344 or equivalent

- NOTICE:

- Do not allow adhesive to contact the oil hole.

Text in Illustration *1 Oil Hole

Install the oil pressure sender gauge.

- Torque:

- 15 N*m{153 kgf*cm, 11 ft.*lbf}

- NOTICE:

- Do not start the engine within 1 hour after installation.

Connect the sender gauge connector.

| 44. INSTALL ENGINE OIL LEVEL DIPSTICK GUIDE |

Apply a light coat of engine oil to a new O-ring.

Install the O-ring to the guide.

Install the dipstick guide with the bolt.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

Install the dipstick.

Connect the wire harness clamp.

| 45. INSTALL OIL FILTER ELEMENT |

Clean the inside of the oil filter cap, its threads and its O-ring groove.

Apply a small amount of engine oil to a new O-ring and install it to the oil filter cap.

Set a new oil filter element to the oil filter cap.

Remove any dirt or foreign matter from the installation surface of the engine.

Apply a small amount of engine oil to the O-ring again and temporarily install the oil filter cap.

- NOTICE:

- Do not remove the oil filter bracket clip.

Using SST, tighten the oil filter cap.

- SST

- 09228-06501

- Torque:

- 25 N*m{255 kgf*cm, 18 ft.*lbf}

Text in Illustration *1 Oil Filter Bracket Clip - NOTICE:

- When tightening the oil filter cap, do not remove the oil filter bracket clip.

- Make sure that the oil filter is installed securely as shown in the illustration.

- Be careful that the O-ring does not get caught between any surrounding parts.

|

Apply a small amount of engine oil to a new drain plug O-ring, and install it to the oil filter cap.

Text in Illustration *1 O-Ring - NOTICE:

- Before installing the O-ring, remove any dirt or foreign matter from the installation surface of the oil filter cap.

|

Install the oil filter drain plug.

- Torque:

- 13 N*m{127 kgf*cm, 9 ft.*lbf}

- NOTICE:

- Be careful that the O-ring does not get caught between any surrounding parts.

Install the No. 2 engine under cover seal with the 2 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

| 46. CONNECT NO. 2 FUEL TUBE SUB-ASSEMBLY |

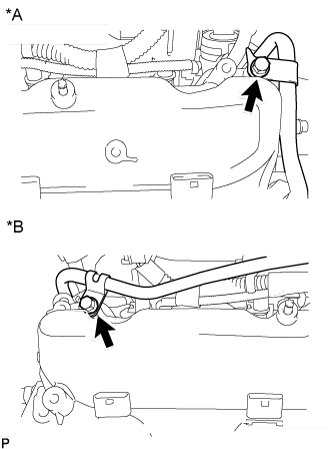

Connect the fuel tube with the 2 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

Text in Illustration *A LH Side *B RH Side

|

| 47. CONNECT COOLER COMPRESSOR ASSEMBLY |

Install the cooler compressor with the stud bolt.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

|

Install the 3 bolts and nut.

- Torque:

- 25 N*m{250 kgf*cm, 18 ft.*lbf}

- NOTICE:

- Tighten the bolts and nut in the order shown in the illustration to install the cooler compressor.

| 48. CONNECT WATER PIPE AND HOSE SUB-ASSEMBLY |

Connect the water pipe and hose to the cylinder head cover with the 2 bolts.

- Torque:

- 18 N*m{184 kgf*cm, 13 ft.*lbf}

Connect the 3 hoses.

| 49. CONNECT ENGINE WIRE |

Connect the 2 clamps and power steering oil pressure switch connector.

Engine Room RH Side:

Connect the 6 clamps.

Connect the throttle position sensor and throttle control motor connector.

Connect the ground wire with the bolt.

- Torque:

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}

Connect the noise filter connector.

Connect the 2 VVT sensor connectors.

Connect the injector connector.

Connect the 4 ignition coil connectors.

Connect the 2 camshaft timing oil control valve connectors.

Engine Room LH Side:

Connect the cooler compressor connector.

Connect the 3 clamps.

Connect the camshaft position sensor connector.

Connect the 2 camshaft timing oil control valve connectors.

Connect the engine coolant temperature sensor connector.

Connect the 4 clamps.

Connect the ground wire with the bolt.

- Torque:

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}

Connect the noise filter connector.

Connect the 2 VVT sensor connectors.

Connect the 4 ignition coil connectors.

Connect the injector connector.

Connect the 2 connectors and 2 clips to the engine room junction block.

Install the engine room relay block cover.

| 50. INSTALL RADIATOR ASSEMBLY |

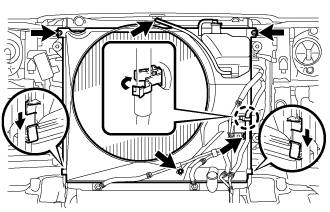

Set the radiator bracket hooks to the radiator support holes.

|

Install the radiator with the 4 bolts.

- Torque:

- 18 N*m{184 kgf*cm, 13 ft.*lbf}

Connect the 2 oil cooler hoses.

| 51. INSTALL FAN SHROUD |

Install the fan pulley.

Place the shroud together with the coupling fan between the radiator and engine.

- NOTICE:

- Be careful not to damage the radiator core.

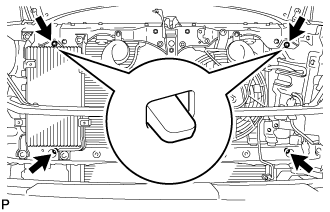

Temporarily install the fluid coupling fan to the fluid coupling bracket with the 4 nuts. Tighten the nuts as much as possible by hand.

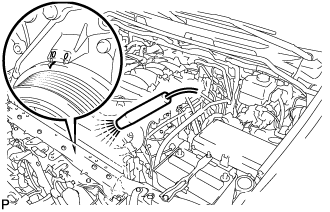

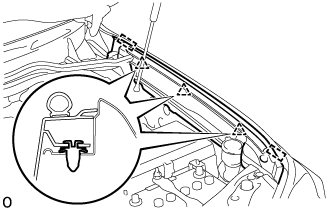

Attach the claws of the shroud to the radiator as shown in the illustration.

|

Install the shroud with the 2 bolts.

- Torque:

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}

Connect the oil cooler tube to the fan shroud with the 2 bolts.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

Pass the hose through the flexible hose clamp and close the clamp as shown in the illustration.

Connect the reservoir hose to the upper radiator tank.

Install the fan and generator V belt (Click here).

Tighten the 4 nuts of the fluid coupling fan.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

| 52. INSTALL NO. 2 RADIATOR HOSE |

| 53. INSTALL NO. 1 RADIATOR HOSE |

| 54. INSTALL AIR CLEANER ASSEMBLY |

Install the air cleaner with the 3 bolts.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

| 55. INSTALL AIR CLEANER HOSE ASSEMBLY |

Install the air cleaner hose so that the protrusion of the air cleaner cap aligns with the groove of the hose as shown in the illustration.

Text in Illustration *1 Groove *2 Protrusion

|

Tighten the 2 clamps.

- Torque:

- 2.5 N*m{25 kgf*cm, 22 in.*lbf}

Connect the vacuum hose.

Connect the No. 2 ventilation hose.

| 56. INSTALL V-BANK COVER SUB-ASSEMBLY |

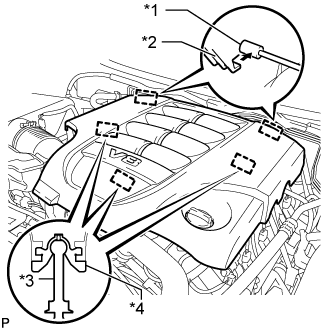

Attach the 2 V-bank cover hooks to the bracket. Then align the 3 V-bank cover grommets with the 3 pins, and press down on the V-bank cover to attach the pins.

Text in Illustration *1 Bracket *2 Hook *3 Pin *4 Grommet

|

| 57. ADD ENGINE OIL |

Add fresh oil and install the oil filler cap.

- Standard Oil Grade:

Oil Grade Oil Viscosity (SAE) API grade SL "Energy-Conserving", SM "Energy-Conserving", SN "Resource-Conserving" or ILSAC multigrade engine oil 5W-30

10W-30API grade SL, SM or SN multigrade engine oil 15W-40

20W-50

- Standard Oil Capacity:

Item Specified Condition Drain and refill without oil filter change 7.1 liters (7.5 US qts, 6.2 Imp. qts) Drain and refill with oil filter change 7.5 liters (7.9 US qts, 6.6 Imp. qts) Dry fill 9.3 liters (9.8 US qts, 8.2 Imp. qts)

| 58. ADD ENGINE COOLANT |

Add engine coolant.

- Standard Capacity:

Item Specified Condition with rear heater 16.2 liters (17.1 US qts, 14.3 Imp. qts) without rear heater 13.4 liters (14.2 US qts, 11.8 Imp. qts)

- NOTICE:

- Do not substitute plain water for engine coolant.

- HINT:

- TOYOTA vehicles are filled with TOYOTA SLLC at the factory. In order to avoid damage to the engine cooling system and other technical problems, only use TOYOTA SLLC or similar high quality ethylene glycol based non-silicate, non-amine, non-nitrite, non-borate coolant with long-life hybrid organic acid technology (coolant with long-life hybrid organic acid technology consists of a combination of low phosphates and organic acids).

Slowly pour coolant into the radiator reservoir until it reaches the F line.

Install the reservoir cap.

Press the No. 1 and No. 2 radiator hoses several times by hand, and then check the coolant level. If the coolant level is low, add coolant.

Install the radiator cap.

Start the engine and warm it up until the thermostat opens.

- HINT:

- The thermostat opening timing can be confirmed by pressing the radiator inlet hose by hand, and checking when the engine coolant starts to flow inside the hose.

Maintain the engine speed at 2000 to 2500 rpm.

- NOTICE:

- Make sure that the radiator reservoir still has some coolant in it.

- Pay attention to the needle of the water temperature meter. Make sure that the needle does not show an abnormally high temperature.

- If there is not enough coolant, the engine may burn out or overheat.

- Immediately after starting the engine, if the radiator reservoir does not have any coolant, perform the following: 1) stop the engine, 2) wait until the coolant has cooled down, and 3) add coolant until the coolant is filled to the F line.

- Run the engine at 2000 rpm until the coolant level has stabilized.

Press the No. 1 and No. 2 radiator hoses several times by hand to bleed air.

- CAUTION:

- Wear protective gloves.

- Be careful as the radiator hoses are hot.

- Keep your hands away from the fan.

Stop the engine, and wait until the engine coolant cools down to ambient temperature.

- CAUTION:

- Do not remove the radiator cap while the engine and radiator are still hot. Pressurized, hot engine coolant and steam may be released and cause serious burns.

Check that the coolant level is between the F and L lines.

If the coolant level is below the L line, repeat all of the procedures above.

If the coolant level is above the F line, drain coolant so that the coolant level is between the F and L lines.

| 59. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

- NOTICE:

- When disconnecting the cable, some systems need to be initialized after the cable is reconnected (Click here).

| 60. INSPECT FOR OIL LEAK |

Start the engine. Make sure that there are no oil leaks from the area that was worked on.

| 61. INSPECT FOR COOLANT LEAK |

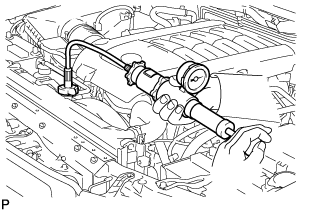

|

- CAUTION:

- Do not remove the radiator cap while the engine and radiator are still hot. Pressurized, hot engine coolant and steam may be released and cause serious burns.

Fill the radiator with coolant and attach a radiator cap tester.

Warm up the engine.

Using the radiator cap tester, increase the pressure inside the radiator to 123 kPa (1.3 kgf/cm2, 18 psi), and check that the pressure does not drop.

If the pressure drops, check the hoses, radiator and water pump for leaks. If no external leaks are found, check the heater core, cylinder block and head.

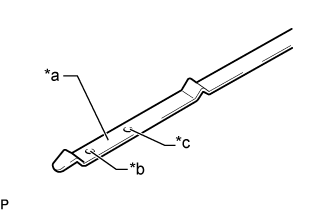

| 62. INSPECT ENGINE OIL LEVEL |

Warm up the engine. Then stop the engine and wait for 5 minutes.

Check that the engine oil level is between the dipstick low level mark and full level mark.

If the level is low, check for leakage and add oil up to the full level mark.Text in Illustration *a Measuring Surface *b Low Level Mark *c Full Level Mark - NOTICE:

- Do not fill engine oil above the full level mark.

- HINT:

- A certain amount of engine oil will be consumed while driving. In the following situations, oil consumption may increase, and engine oil may need to be refilled in between oil maintenance intervals.

- When the engine is new, for example directly after purchasing the vehicle or after replacing the engine.

- If low quality oil or oil of an inappropriate viscosity is used.

- When driving at high engine speed or with a heavy load, (when towing, or), when driving while accelerating or decelerating frequently.

- When leaving the idling for a long time, or when driving frequently through heavy traffic.

- When judging the amount of oil consumption, keep in mind that the oil may have become diluted, making it difficult to judge the true level accurately.

|

| 63. INSPECT IGNITION TIMING |

Warm up and stop the engine.

Allow the engine to warm up to a normal operating temperature.

When using the intelligent tester:

Connect the intelligent tester to the DLC3.

Start the engine and idle it.

Turn the intelligent tester on.

Enter the following menus: Powertrain / Engine and ECT / Data List / Primary / IGN Advance.

- HINT:

- Refer to the intelligent tester operator's manual for further details.

- Standard ignition timing:

- 8 to 12° BTDC @ idling (transmission in neutral and A/C switch off)

Disconnect the intelligent tester from the DLC3.

When not using the intelligent tester:

Connect the tester probe of a timing light to the wire of the ignition coil connector for the No. 1 cylinder.

- NOTICE:

- Use a timing light that detects primary signals.

Using SST, connect terminals 13 (TC) and 4 (CG) of the DLC3.

- SST

- 09843-18040

Text in Illustration *a Front view of DLC3 - NOTICE:

- Confirm the terminal numbers before connecting them. Connecting the wrong terminals can damage the engine.

- Switch off all accessories and the A/C before connecting the terminals.

Using the timing light, check the ignition timing.

- Standard ignition timing:

- 8 to 12° BTDC @ idling (transmission in neutral and A/C switch off)

Remove SST from the DLC3.

Check the ignition timing.

- Standard ignition timing:

- 7 to 24° BTDC @ idling (transmission in neutral and A/C switch off)

Disconnect the timing light from the engine.

| 64. INSPECT ENGINE IDLE SPEED |

Warm up and stop the engine.

Allow the engine to warm up to a normal operating temperature.

When using the intelligent tester:

Connect the intelligent tester to the DLC3.

- NOTICE:

- Switch off all accessories and the A/C before connecting the intelligent tester.

Race the engine at 2500 rpm for approximately 90 seconds.

Turn the intelligent tester on.

Enter the following menus: Powertrain / Engine and ECT / Data List / Primary / Engine Speed.

- Standard idle speed:

- 650 to 750 rpm (transmission in neutral and A/C switch off)

- HINT:

- Refer to the intelligent tester operator's manual for further details.

Disconnect the intelligent tester from the DLC3.

When not using the intelligent tester:

Using SST, connect the tachometer probe to terminal 9 (TAC) of the DLC3.

- SST

- 09843-18030

Text in Illustration *a Front view of DLC3 - NOTICE:

- Confirm the terminal number before connecting the probe. Connecting the probe to the wrong terminal can damage the engine.

- Switch off all accessories and the A/C before connecting the probe.

Race the engine at 2500 rpm for approximately 90 seconds.

Check the idle speed.

- Standard idle speed:

- 650 to 750 rpm (transmission in neutral and A/C switch off)

Disconnect the tachometer probe from the DLC3.

|

| 65. INSTALL FRONT FENDER APRON SEAL FRONT RH |

Install the fender apron seal with the 3 clips.

| 66. INSTALL FRONT FENDER APRON SEAL LH |

Install the fender apron seal with the 3 clips.

| 67. INSTALL NO. 2 ENGINE UNDER COVER |

Install the No. 2 engine under cover with the 2 bolts.

- Torque:

- 29 N*m{296 kgf*cm, 21 ft.*lbf}

| 68. INSTALL NO. 1 ENGINE UNDER COVER SUB-ASSEMBLY |

Install the No. 1 engine under cover with the 10 bolts.

- Torque:

- 29 N*m{296 kgf*cm, 21 ft.*lbf}

| 69. INSTALL COWL TOP VENTILATOR LOUVER SUB-ASSEMBLY |

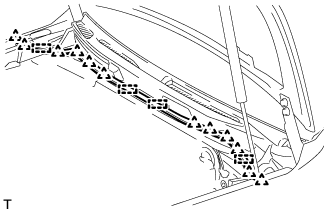

Attach the 17 claws and 2 clips and install the cowl top ventilator louver sub-assembly.

|

| 70. INSTALL HOOD TO COWL TOP SEAL |

Attach the 12 clips and 4 clamps to install the hood to cowl top seal.

|

Install the washer hose.

|

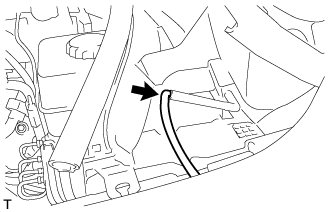

| 71. INSTALL FRONT FENDER MAIN SEAL LH |

Attach the 3 clips and 2 guides to install the front fender main seal LH.

|

| 72. INSTALL FRONT FENDER MAIN SEAL RH |

- HINT:

- Use the same procedure described for the LH side.

| 73. INSTALL FRONT WIPER ARM LH |

Stop the wiper motor at the automatic stop position.

Text in Illustration *a Wiper Arm Serrations *b Wiper Pivot Serrations

|

Clean the wiper arm serration with a round file or equivalent.

Clean the wiper pivot serration.

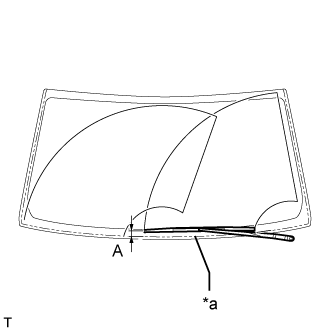

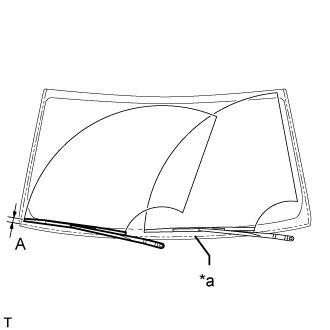

Install the wiper arm and blade with the nut. Make sure that the wiper arm and blade comes to the position shown in the illustration.

Text in Illustration *a Moulding Edge - Standard Measurement:

Position Specified Condition A 16.8 to 36.8 mm (0.661 to 1.45 in.)

- Torque:

- 25 N*m{255 kgf*cm, 18 ft.*lbf}

- HINT:

- Hold down the wiper arm hinge with your hand while tightening the nut.

|

| 74. INSTALL FRONT WIPER ARM RH |

Stop the wiper motor at the automatic stop position.

Text in Illustration *a Wiper Arm Serrations *b Wiper Pivot Serrations

|

Clean the wiper arm serration with a round file or equivalent.

Clean the wiper pivot serration.

Install the wiper arm and blade with the nut. Make sure that the wiper arm and blade comes to the position shown in the illustration.

Text in Illustration *a Moulding Edge - Standard Measurement:

Position Specified Condition A 20.0 to 40.0 mm (0.787 to 1.57 in.)

- Torque:

- 25 N*m{255 kgf*cm, 18 ft.*lbf}

- HINT:

- Hold down the wiper arm hinge with your hand while tightening the nut.

|

Operate the front wipers while spraying washer fluid on the windshield glass. Make sure that the front wipers function properly and there is no interference with the vehicle body.

| 75. INSTALL RADIATOR SIDE DEFLECTOR LH |

Install the radiator side deflector LH with the 4 clips.

| 76. INSTALL TRANSMISSION OIL COOLER AIR DUCT |

| 77. INSTALL FRONT BUMPER COVER |