Automatic Transmission Unit Inspection

Drivetrain. Land Cruiser. Urj200, 202 Grj200 Vdj200

INSPECT NO. 1 BRAKE DISC

INSPECT FRONT PLANETARY GEAR ASSEMBLY

INSPECT PACK CLEARANCE OF NO. 1 BRAKE

INSPECT NO. 3 CLUTCH DISC

INSPECT PACK CLEARANCE OF NO. 3 CLUTCH

INSPECT OVERDRIVE DIRECT CLUTCH DISC

INSPECT REVERSE CLUTCH RETURN SPRING SUB-ASSEMBLY (REAR)

INSPECT PACK CLEARANCE OF OVERDRIVE DIRECT CLUTCH

INSPECT REVERSE CLUTCH RETURN SPRING SUB-ASSEMBLY (FRONT)

INSPECT REVERSE CLUTCH DRUM SUB-ASSEMBLY

INSPECT FORWARD MULTIPLE CLUTCH DISC

INSPECT FORWARD CLUTCH RETURN SPRING SUB-ASSEMBLY

INSPECT PACK CLEARANCE OF FORWARD MULTIPLE CLUTCH

INSPECT FORWARD CLUTCH DRUM SUB-ASSEMBLY

INSPECT SUN GEAR INPUT DRUM SUB-ASSEMBLY

INSPECT REAR PLANETARY SUN GEAR SUB-ASSEMBLY

INSPECT REAR PLANETARY GEAR ASSEMBLY

INSPECT NO. 1 ONE-WAY CLUTCH

INSPECT NO. 2 BRAKE DISC

INSPECT NO. 2 CLUTCH DISC

INSPECT NO. 2 BRAKE PISTON RETURN SPRING SUB-ASSEMBLY

INSPECT PACK CLEARANCE OF NO. 2 BRAKE

INSPECT DIRECT CLUTCH RETURN SPRING SUB-ASSEMBLY

INSPECT PACK CLEARANCE OF NO. 2 CLUTCH

INSPECT INDIVIDUAL PISTON OPERATION

INSPECT AUTOMATIC TRANSMISSION CASE SUB-ASSEMBLY

Automatic Transmission Unit -- Inspection |

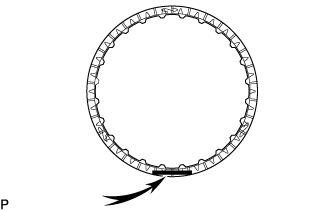

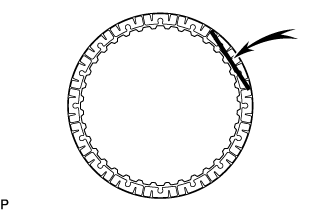

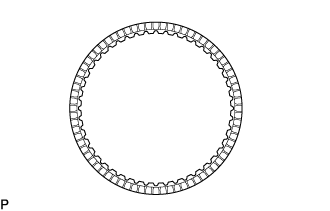

| 1. INSPECT NO. 1 BRAKE DISC |

Check whether the sliding surfaces of the No. 1 brake discs, No. 1 brake plates and the No. 1 brake flange are worn or burnt.

- NOTICE:

- If the linings of the No. 1 brake discs are peeled off or discolored, or if any part of the printed numbers is damaged, replace all the No. 1 brake discs.

- Before assembling new No. 1 brake discs, soak them in ATF for at least 2 hours.

If necessary, replace them.

| 2. INSPECT FRONT PLANETARY GEAR ASSEMBLY |

Using a feeler gauge, measure the clearance between the front planetary gear assembly and each pinion gear.

- Standard Clearance:

- 0.2 to 0.6 mm (0.00788 to 0.0236 in.)

If the clearance is not as specified, replace the front planetary gear assembly.

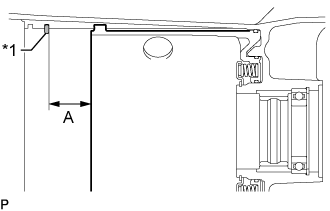

| 3. INSPECT PACK CLEARANCE OF NO. 1 BRAKE |

Using a vernier caliper, measure dimension A (from the step of the oil pump assembly installation surface of the automatic transmission case sub-assembly to the step of the No. 1 brake flange installation surface) in the illustration, and calculate the average.

Text in Illustration*1

| Snap Ring

|

- HINT:

- Dimension A = 46.18 to 46.54 mm (1.8182 to 1.8322 in.)

Using a vernier caliper, measure dimension B (from the flange face of the oil pump assembly to the tip of the No. 1 brake piston) in the illustration, and calculate the average.

- HINT:

- Dimension B = 19.23 to 19.57 mm (0.7571 to 0.7704 in.)

Using a vernier caliper, assemble the 6 No. 1 brake plates, 6 No. 1 brake discs and No. 1 brake flange, measure dimension C in the illustration and calculate the average.

Text in Illustration*1

| No. 1 Brake Flange

|

*2

| No. 1 Brake Disc

|

*3

| No. 1 Brake Plate

|

- HINT:

- Dimension C = 25.15 to 26.45 mm (0.9902 to 1.0413 in.)

- Pack clearance = Dimension A - Dimension B - Dimension C

- Standard Clearance:

- 0.90 to 1.10 mm (0.0355 to 0.0433 in.)

If the pack clearance is outside the standard range, select and install a No. 1 brake flange that brings the pack clearance within the standard range.

- HINT:

- There are 7 types of No. 1 brake flanges that can be used to adjust the pack clearance. Select the one with the most appropriate thickness.

- No. 1 Brake Flange Thickness:

Part No.

| Mark

| Thickness

|

35676-60190

| 0

| 4.45 to 4.55 mm (0.1752 to 0.1791 in.)

|

35676-60200

| 1

| 4.55 to 4.65 mm (0.1792 to 0.1830 in.)

|

35676-60210

| 2

| 4.65 to 4.75 mm (0.1831 to 0.1870 in.)

|

35676-60220

| 3

| 4.75 to 4.85 mm (0.1871 to 0.1909 in.)

|

35676-60230

| 4

| 4.85 to 4.95 mm (0.1910 to 0.1948 in.)

|

35676-60240

| 5

| 4.95 to 5.05 mm (0.1949 to 0.1988 in.)

|

35676-60250

| 6

| 5.05 to 5.15 mm (0.1989 to 0.2027 in.)

|

| 4. INSPECT NO. 3 CLUTCH DISC |

Check whether the sliding surfaces of the No. 3 clutch discs, No. 3 clutch plates and the No. 3 clutch flange are worn or burnt.

- NOTICE:

- If the linings of the No. 3 clutch discs are peeled off or discolored, or if any part of the printed numbers is damaged, replace all the No. 3 clutch discs.

- Before assembling new No. 3 clutch discs, soak them in ATF for at least 2 hours.

If necessary, replace them.

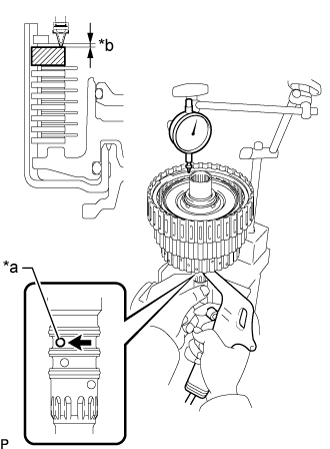

| 5. INSPECT PACK CLEARANCE OF NO. 3 CLUTCH |

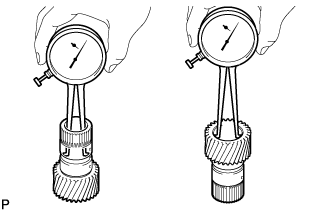

Using a dial indicator, measure the moving distance (distance A) of the No. 3 clutch flange at both ends across the diameter while blowing compressed air (196 kPa, 2.0 kgf/cm2, 28 psi) from the oil hole as shown in the illustration, and calculate the average.

Text in Illustration*a

| Oil Hole

| *b

| Distance A

|

*c

| Speed Sensor Hole

| -

| -

|

- Standard Clearance:

- 0.90 to 1.10 mm (0.0355 to 0.0433 in.)

If the pack clearance is outside the standard range, select and install a No. 3 clutch flange that brings the pack clearance within the standard range.

- HINT:

- There are 11 types of No. 3 clutch flanges that can be used to adjust the pack clearance. Select the one with the most appropriate thickness.

- No. 3 Clutch Flange Thickness:

Part No.

| Thickness

|

34649-60250

| 3.75 to 3.85 mm (0.1477 to 0.1515 in.)

|

34649-60260

| 3.85 to 3.95 mm (0.1516 to 0.1555 in.)

|

34649-60270

| 3.95 to 4.05 mm (0.1556 to 0.1594 in.)

|

34649-60280

| 4.05 to 4.15 mm (0.1595 to 0.1633 in.)

|

34649-60290

| 4.15 to 4.25 mm (0.1634 to 0.1673 in.)

|

34649-60300

| 4.25 to 4.35 mm (0.1674 to 0.1712 in.)

|

34649-60310

| 4.35 to 4.45 mm (0.1713 to 0.1751 in.)

|

34649-60320

| 4.45 to 4.55 mm (0.1752 to 0.1791 in.)

|

34649-60330

| 4.55 to 4.65 mm (0.1792 to 0.1830 in.)

|

34649-60340

| 4.65 to 4.75 mm (0.1831 to 0.1870 in.)

|

34649-60350

| 4.75 to 4.85 mm (0.1871 to 0.1909 in.)

|

| 6. INSPECT OVERDRIVE DIRECT CLUTCH DISC |

Check whether the sliding surfaces of the overdrive direct clutch discs, overdrive direct clutch plates and the overdrive clutch flange are worn or burnt.

- NOTICE:

- If the linings of the overdrive direct clutch discs are peeled off or discolored, or if any part of the printed numbers is damaged, replace all the overdrive direct clutch discs.

- Before assembling new overdrive direct clutch discs, soak them in ATF for at least 2 hours.

If necessary, replace them.

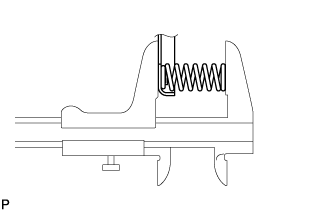

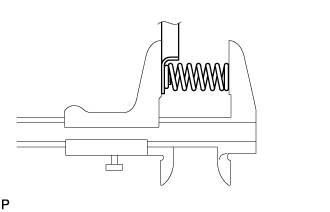

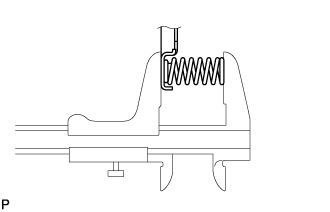

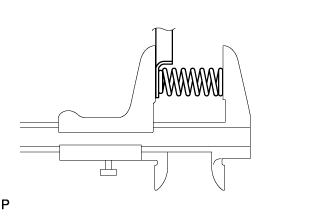

| 7. INSPECT REVERSE CLUTCH RETURN SPRING SUB-ASSEMBLY (REAR) |

Using a vernier caliper, measure the free length of the spring together with the spring seat.

- Standard Free Length:

- 22.21 mm (0.874 in.)

If the free length is shorter than the standard free length, replace the reverse clutch return spring sub-assembly (rear).

| 8. INSPECT PACK CLEARANCE OF OVERDRIVE DIRECT CLUTCH |

Using a dial indicator, measure the moving distance (distance A) of the reverse clutch flange at both ends across the diameter while blowing compressed air (300 kPa, 3.1 kgf/cm2, 44 psi) from the oil hole as shown in the illustration, and calculate the average.

Text in Illustration*a

| Oil Hole

| *b

| Distance A

|

*c

| Speed Sensor Hole

| -

| -

|

- Standard Clearance:

- 1.19 to 1.39 mm (0.0469 to 0.0547 in.)

If the pack clearance is outside the standard range, select and install a overdrive clutch flange that brings the pack clearance within the standard range.

- HINT:

- There are 11 types of overdrive clutch flanges that can be used to adjust the pack clearance. Select the one with the most appropriate thickness.

- Overdrive Clutch Flange Thickness:

Part No.

| Thickness

|

34615-60010

| 2.85 to 2.95 mm (0.1123 to 0.1161 in.)

|

34615-60020

| 2.95 to 3.05 mm (0.1162 to 0.1200 in.)

|

34615-60030

| 3.05 to 3.15 mm (0.1201 to 0.1240 in.)

|

34615-60040

| 3.15 to 3.25 mm (0.1241 to 0.1279 in.)

|

34615-60050

| 3.25 to 3.35 mm (0.1280 to 0.1318 in.)

|

34615-60060

| 3.35 to 3.45 mm (0.1319 to 0.1358 in.)

|

34615-60070

| 3.45 to 3.55 mm (0.1359 to 0.1397 in.)

|

34615-60080

| 3.55 to 3.65 mm (0.1398 to 0.1437 in.)

|

34615-60090

| 3.65 to 3.75 mm (0.1438 to 0.1476 in.)

|

34615-60100

| 3.75 to 3.85 mm (0.1477 to 0.1515 in.)

|

34615-60110

| 3.85 to 3.95 mm (0.1516 to 0.1555 in.)

|

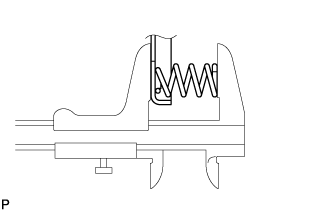

| 9. INSPECT REVERSE CLUTCH RETURN SPRING SUB-ASSEMBLY (FRONT) |

Using a vernier caliper, measure the free length of the spring together with the spring seat.

- Standard Free Length:

- 21.59 mm (0.850 in.)

If the free length is shorter than the standard free length, replace the reverse clutch return spring sub-assembly (front).

| 10. INSPECT REVERSE CLUTCH DRUM SUB-ASSEMBLY |

Using a caliper gauge, measure the inside diameter of the reverse clutch drum sub-assembly bush.

- Standard Inside Diameter (Front Side):

- 67.40 to 67.44 mm (2.6536 to 2.6551 in.)

- Standard Inside Diameter (Rear Side):

- 55.62 to 55.64 mm (2.1898 to 2.1905 in.)

If the inside diameter is not as specified, replace the reverse clutch drum sub-assembly.

| 11. INSPECT FORWARD MULTIPLE CLUTCH DISC |

Check whether the sliding surfaces of the forward multiple clutch discs, forward multiple clutch plates and forward clutch flange are worn or burnt.

- NOTICE:

- If the linings of the forward multiple clutch discs are peeled off or discolored, replace all the forward multiple clutch discs.

- Before assembling new forward multiple clutch discs, soak them in ATF for at least 2 hours.

If necessary, replace them.

| 12. INSPECT FORWARD CLUTCH RETURN SPRING SUB-ASSEMBLY |

Using a vernier caliper, measure the free length of the spring together with the spring seat.

- Standard Free Length:

- 20.82 mm (0.820 in.)

If the free length is shorter than the standard free length, replace the forward clutch return spring sub-assembly.

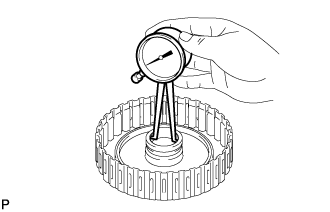

| 13. INSPECT PACK CLEARANCE OF FORWARD MULTIPLE CLUTCH |

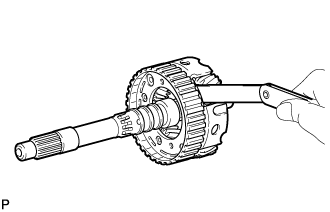

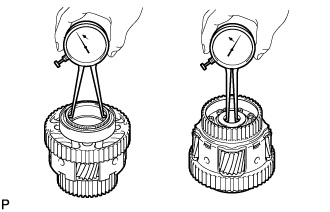

Temporarily assemble the front planetary gear assembly to the forward clutch drum sub-assembly.

Using a dial indicator, measure the moving distance (distance A) of the forward clutch flange at both ends across the diameter while blowing compressed air (196 kPa, 2.0 kgf/cm2, 28 psi) from the oil hole as shown in the illustration, and calculate the average.

Text in Illustration*a

| Oil Hole

|

*b

| Distance A

|

- Standard Clearance:

- 1.05 to 1.25 mm (0.0414 to 0.0492 in.)

If the pack clearance is outside the standard range, select and install a forward clutch flange that brings the pack clearance within the standard range.

- HINT:

- There are 9 types of forward clutch flanges that can be used to adjust the pack clearance. Select the one with the most appropriate thickness.

- Forward Clutch Flange Thickness:

Part No.

| Mark

| Thickness

|

35635-50090

| 0

| 4.35 to 4.45 mm (0.1713 to 0.1751 in.)

|

35635-50100

| 1

| 4.45 to 4.55 mm (0.1752 to 0.1791 in.)

|

35635-50110

| 2

| 4.55 to 4.65 mm (0.1792 to 0.1830 in.)

|

35635-50120

| 3

| 4.65 to 4.75 mm (0.1831 to 0.1870 in.)

|

35635-50130

| 4

| 4.75 to 4.85 mm (0.1871 to 0.1909 in.)

|

35635-50140

| 5

| 4.85 to 4.95 mm (0.1910 to 0.1948 in.)

|

35635-50150

| 6

| 4.95 to 5.05 mm (0.1949 to 0.1988 in.)

|

35635-50160

| 7

| 5.05 to 5.15 mm (0.1989 to 0.2027 in.)

|

35635-50170

| 8

| 5.15 to 5.25 mm (0.2028 to 0.2066 in.)

|

| 14. INSPECT FORWARD CLUTCH DRUM SUB-ASSEMBLY |

Using a caliper gauge, measure the inside diameter of the forward clutch drum bush.

- Standard Inside Diameter:

- 33.200 to 33.225 mm (1.3071 to 1.3080 in.)

If the inside diameter is not as specified, replace the forward clutch drum sub-assembly.

| 15. INSPECT SUN GEAR INPUT DRUM SUB-ASSEMBLY |

Using a caliper gauge, measure the inside diameter of the sun gear input drum bush.

- Standard Inside Diameter:

- 45.066 to 45.091 mm (1.7743 to 1.7752 in.)

If the inside diameter is not as specified, replace the sun gear input drum sub-assembly.

| 16. INSPECT REAR PLANETARY SUN GEAR SUB-ASSEMBLY |

Using a caliper gauge, measure the inside diameter of the rear planetary sun gear bush.

- Standard Inside Diameter:

- 28.760 to 28.781 mm (1.1323 to 1.1331 in.)

If the inside diameter is not as specified, replace the rear planetary sun gear sub-assembly.

| 17. INSPECT REAR PLANETARY GEAR ASSEMBLY |

Using a feeler gauge, measure the rear planetary gear pinion long and short thrust clearance.

- Standard Clearance:

- 0.2 to 0.6 mm (0.00788 to 0.0236 in.)

If the clearance is not as specified, replace the rear planetary gear assembly.

Using a caliper gauge, measure the inside diameter of the rear planetary gear bush.

- Standard Inside Diameter (Front Side):

- 70.60 to 70.63 mm (2.7796 to 2.7807 in.)

- Standard Inside Diameter (Rear Side):

- 28.700 to 28.721 mm (1.1300 to 1.1307 in.)

If the inside diameter is not as specified, replace the rear planetary gear assembly.

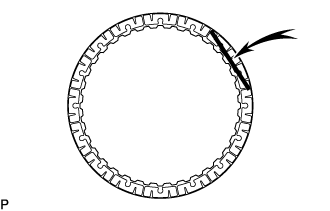

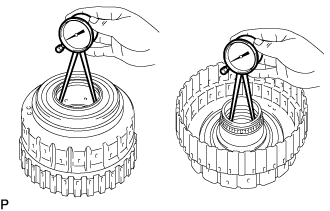

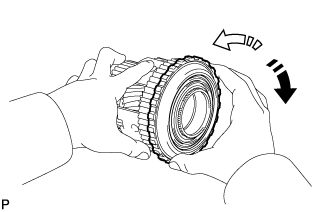

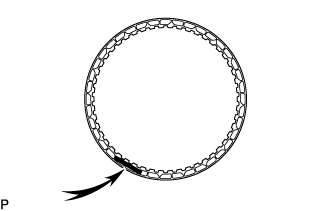

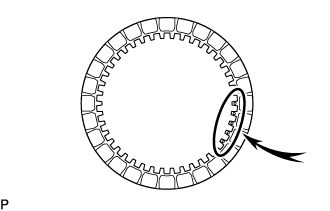

| 18. INSPECT NO. 1 ONE-WAY CLUTCH |

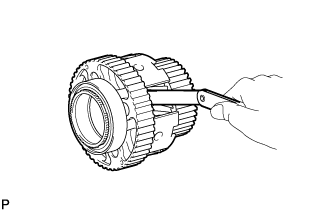

Install the No. 1 one-way clutch to the rear planetary gear assembly.

Hold the rear planetary gear assembly and turn the No. 1 one-way clutch.

Text in Illustration

| Lock

|

| Free

|

Check that the No. 1 one-way clutch turns freely counterclockwise and locks clockwise.

If the No. 1 one-way clutch does not operate normally, replace it.

| 19. INSPECT NO. 2 BRAKE DISC |

Check whether the sliding surfaces of the No. 2 brake discs, brake plate, No. 2 brake plates and the No. 2 brake flange are worn or burnt.

- NOTICE:

- If the linings of the No. 2 brake discs are peeled off or discolored, or if any part of the printed numbers is damaged, replace all the No. 2 brake discs.

- Before assembling new discs, soak them in ATF for at least 2 hours.

If necessary, replace them.

| 20. INSPECT NO. 2 CLUTCH DISC |

Check whether the sliding surfaces of the No. 2 clutch discs, No. 2 clutch plates and the No. 2 clutch flange are worn or burnt.

- NOTICE:

- If the linings of the No. 2 clutch discs are peeled off or discolored, replace all the No. 2 clutch discs.

- Before assembling new discs, soak them in ATF for at least 2 hours.

If necessary, replace them.

| 21. INSPECT NO. 2 BRAKE PISTON RETURN SPRING SUB-ASSEMBLY |

Using a vernier caliper, measure the free length of the spring together with the spring seat.

- Standard Free Length:

- 23.36 mm (0.920 in.)

If the free length is shorter than the standard free length, replace the No. 2 brake piston return spring sub-assembly.

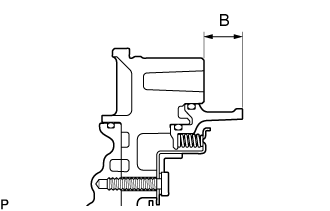

| 22. INSPECT PACK CLEARANCE OF NO. 2 BRAKE |

Using a vernier caliper, measure dimension A (from the tip of the No. 2 brake piston to the step in the automatic transmission case sub-assembly) in the illustration, and calculate the average.

Text in Illustration*1

| Snap Ring

|

- HINT:

- Dimension A = 35.75 to 36.25 mm (1.4075 to 1.4271 in.)

Using a vernier caliper, assemble the 6 No. 2 brakes discs, brake plate, 5 No. 2 brake plates and No. 2 brake flange as shown in the illustration. Then with a weight fixture of 500 g (17.64 oz) or less placed on the flange, measure dimension B, and calculate the average.

Text in Illustration*1

| No. 2 Brake Flange

|

*2

| Brake Plate

|

*3

| No. 2 Brake Plate

|

*4

| No. 2 Brake Disc

|

*a

| Weight

|

- HINT:

- Dimension B = 33.73 to 35.07 mm (1.3280 to 1.3807 in.)

- Pack clearance = Dimension A - Dimension B

- Standard Clearance:

- 0.90 to 2.18 mm (0.0355 to 0.0858 in.)

If the pack clearance is outside the standard range, select and install a No. 2 brake flange that brings the pack clearance within the standard range.

- HINT:

- There are 11 types of No. 2 brake flanges that can be used to adjust the pack clearance. Select the one with the most appropriate thickness.

- No. 2 Brake Flange Thickness:

Part No.

| Mark

| Thickness

|

35678-60190

|

| 9.75 to 9.85 mm (0.3839 to 0.3877 in.)

|

35678-60200

|

| 9.85 to 9.95 mm (0.3878 to 0.3917 in.)

|

35678-60210

|

| 9.95 to 10.05 mm (0.3918 to 0.3956 in.)

|

35678-60220

|

| 10.05 to 10.15 mm (0.3957 to 0.3996 in.)

|

35678-60230

|

| 10.15 to 10.25 mm (0.3997 to 0.4035 in.)

|

35678-60240

|

| 10.25 to 10.35 mm (0.4036 to 0.4074 in.)

|

35678-60250

|

| 10.35 to 10.45 mm (0.4075 to 0.4114 in.)

|

35678-60260

|

| 10.45 to 10.55 mm (0.4115 to 0.4153 in.)

|

35678-60270

|

| 10.55 to 10.65 mm (0.4154 to 0.4192 in.)

|

35678-60280

|

| 10.65 to 10.75 mm (0.4193 to 0.4232 in.)

|

35678-60290

|

| 10.75 to 10.85 mm (0.4233 to 0.4271 in.)

|

| 23. INSPECT DIRECT CLUTCH RETURN SPRING SUB-ASSEMBLY |

Using a vernier caliper, measure the free length of the spring together with the spring seat.

- Standard Free Length:

- 20.76 mm (0.817 in.)

If the free length is shorter than the standard free length, replace the direct clutch return spring sub-assembly.

| 24. INSPECT PACK CLEARANCE OF NO. 2 CLUTCH |

Using a dial indicator, measure the moving distance (distance A) of the No. 2 clutch flange at both ends across the diameter while blowing compressed air (196 kPa, 2.0 kgf/cm2, 28 psi) from the oil hole as shown in the illustration, and calculate the average.

- Standard Clearance:

- 1.05 to 1.25 mm (0.0414 to 0.0492 in.)

Text in Illustration*a

| Oil Hole

|

*b

| Distance A

|

If the pack clearance is outside the standard range, select and install a No. 2 clutch flange that brings the pack clearance within the standard range.

- HINT:

- There are 9 types of No. 2 clutch flanges that can be used to adjust the pack clearance. Select the one with the most appropriate thickness.

- No. 2 Clutch Flange Thickness:

Part No.

| Mark

| Thickness

|

35635-50181

| 40

| 3.95 to 4.05 mm (0.1556 to 0.1594 in.)

|

35635-50231

| 41

| 4.05 to 4.15 mm (0.1595 to 0.1633 in.)

|

35635-50191

| 42

| 4.15 to 4.25 mm (0.1634 to 0.1673 in.)

|

35635-50241

| 43

| 4.25 to 4.35 mm (0.1674 to 0.1712 in.)

|

35635-50201

| 44

| 4.35 to 4.45 mm (0.1713 to 0.1751 in.)

|

35635-50251

| 45

| 4.45 to 4.55 mm (0.1752 to 0.1791 in.)

|

35635-50211

| 46

| 4.55 to 4.65 mm (0.1792 to 0.1830 in.)

|

35635-50261

| 47

| 4.65 to 4.75 mm (0.1831 to 0.1870 in.)

|

35635-50221

| 48

| 4.75 to 4.85 mm (0.1871 to 0.1909 in.)

|

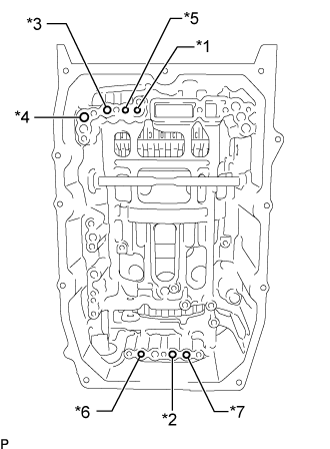

| 25. INSPECT INDIVIDUAL PISTON OPERATION |

Check the operating sound while applying compressed air into the oil holes indicated in the illustration.

Text in Illustration*1

| Forward Clutch

|

*2

| Direct Clutch

|

*3

| Overdrive Clutch

|

*4

| Reverse Clutch

|

*5

| No. 1 Brake

|

*6

| No. 2 Brake (IN)

|

*7

| No. 2 Brake (OUT)

|

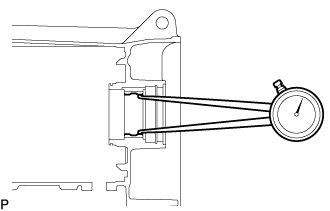

| 26. INSPECT AUTOMATIC TRANSMISSION CASE SUB-ASSEMBLY |

Using a caliper gauge, measure the inside diameter of the automatic transmission case sleeve bush.

- Standard Inside Diameter:

- 51.470 to 51.555 mm (2.027 to 2.029 in.)

If the inside diameter is not as specified, replace the automatic transmission case sub-assembly.