Fuel Pressure Regulator -- Installation |

| 1. INSTALL FUEL PRESSURE REGULATOR ASSEMBLY |

Apply a light coat of gasoline or spindle oil to a new O-ring, and install it to the pressure regulator.

- NOTICE:

- Make sure that there are no scratches or foreign matter in or around the insertion hole of the delivery pipe.

- When inserting the injector, be careful not to damage the O-ring.

|

While turning the pressure regulator left and right, install it to the delivery pipe.

Install the 2 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

Connect the vacuum sensing hose to the pressure regulator.

Connect the No. 2 fuel tube to the pressure regulator (Click here).

| 2. INSTALL AIR CLEANER HOSE ASSEMBLY |

Install the air cleaner hose so that the protrusion of the air cleaner cap aligns with the groove of the hose as shown in the illustration.

Text in Illustration *1 Groove *2 Protrusion

|

Tighten the 2 clamps.

- Torque:

- 2.5 N*m{25 kgf*cm, 22 in.*lbf}

Connect the vacuum hose.

Connect the No. 2 ventilation hose.

| 3. INSTALL V-BANK COVER SUB-ASSEMBLY |

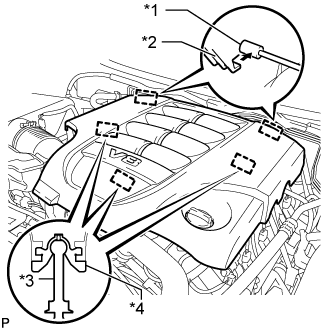

Attach the 2 V-bank cover hooks to the bracket. Then align the 3 V-bank cover grommets with the 3 pins, and press down on the V-bank cover to attach the pins.

Text in Illustration *1 Bracket *2 Hook *3 Pin *4 Grommet

|

| 4. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

- NOTICE:

- When disconnecting the cable, some systems need to be initialized after the cable is reconnected (Click here).

| 5. INSPECT FOR FUEL LEAK |

Connect the intelligent tester to the DLC3.

Turn the engine switch on (IG) and intelligent tester main switch on.

- NOTICE:

- Do not start the engine.

Enter the following menus: Powertrain / Engine and ECT / Active Test / Control the Fuel Pump / Speed.

Check that there are no fuel leaks after doing maintenance anywhere on the fuel system.