Drive Belt On-Vehicle Inspection

INSPECT V-RIBBED BELT

INSPECT V-RIBBED BELT TENSION (w/ Viscous Heater)

INSPECT V-RIBBED BELT TENSIONER ASSEMBLY

Drive Belt -- On-Vehicle Inspection |

Check the belt for wear, cracks or other signs of damage.

If any of the following defects is found, replace the V-ribbed belt.

- The belt is cracked.

- The belt is worn out to the extent that the cords are exposed.

- The belt has chunks missing from the ribs.

Check that the belt fits properly in the ribbed grooves.

- HINT:

- Check with your hand to confirm that the belt has not slipped out of the groove on the bottom of the pulley.

- If it has slipped out, replace the V-ribbed belt. Install a new V-ribbed belt.

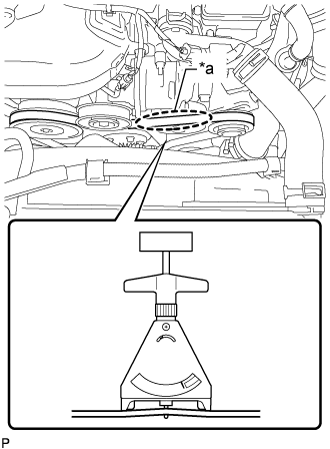

| 2. INSPECT V-RIBBED BELT TENSION (w/ Viscous Heater) |

Using a belt tension gauge, inspect the belt tension.

- Standard Belt Tension:

Item

| Condition

| Specified Condition

|

New belt

| 5 to 35°C (41 to 95°F)

| 550 to 800 N (56 to 82 kgf, 123.6 to 179.8 lbf)

|

Used belt

| 5 to 35°C (41 to 95°F)

| 300 to 500 N (31 to 51 kgf, 67.4 to 112.4 lbf)

|

Text in Illustration*a

| Measuring Point

|

- HINT:

- When measuring the tension of a new belt, measure the tension immediately after installing it to the engine but before starting the engine.

- A "new belt" is a belt which has been used for less than 5 minutes on a running engine.

- A "used belt" is a belt which has been used on a running engine for 5 minutes or more.

- After installing a new belt, run the engine for approximately 5 minutes and then recheck the tension.

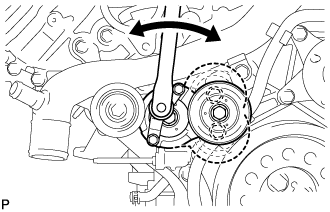

| 3. INSPECT V-RIBBED BELT TENSIONER ASSEMBLY |

Check that nothing gets caught in the tensioner by turning it clockwise and counterclockwise.

If a malfunction exists, replace the tensioner.