Generator (For 100 A Type) -- Reassembly |

| 1. INSTALL GENERATOR DRIVE END FRAME BEARING |

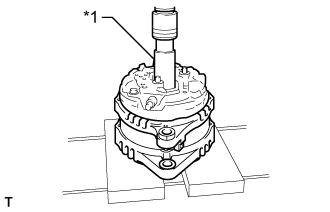

Using SST and a press, press in a new drive end frame bearing.

- SST

- 09950-60010(09951-00470)

09950-70010(09951-07100)

|

Fit the tabs on the retainer plate into the cutouts on the generator drive end frame to install the retainer plate.

Text in Illustration *1 Tab *2 Cutout

|

Install the 4 screws.

- Torque:

- 2.3 N*m{23 kgf*cm, 20 in.*lbf}

| 2. INSTALL GENERATOR ROTOR ASSEMBLY |

Install the generator rotor to the generator drive end frame.

Place a new generator washer on the generator rotor.

| 3. INSTALL GENERATOR COIL ASSEMBLY |

Using a deep socket wrench (21 mm) and press, slowly press in the generator coil.

Text in Illustration *1 Deep Socket Wrench (21 mm)

|

Install the 4 bolts.

- Torque:

- 5.9 N*m{60 kgf*cm, 52 in.*lbf}

| 4. INSTALL GENERATOR BRUSH HOLDER ASSEMBLY |

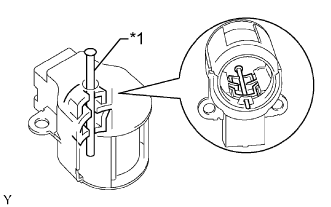

While pushing the 2 brushes into the brush holder, insert a pin with a diameter of 1.0 mm (0.0394 in.) into the brush holder hole.

Text in Illustration *1 Pin

|

Install the brush holder to the generator coil with the 2 screws.

- Torque:

- 1.8 N*m{18 kgf*cm, 16 in.*lbf}

Text in Illustration *1 Pin

|

Pull out the pin from the brush holder.

| 5. INSTALL TERMINAL INSULATOR |

Install the terminal insulator to the generator coil.

- NOTICE:

- Make sure the terminal insulator is installed facing the proper direction.

|

| 6. INSTALL GENERATOR REAR END COVER |

Install the generator rear end cover to the generator coil with the 3 nuts.

- Torque:

- 4.6 N*m{46 kgf*cm, 40 in.*lbf}

Install the cord clip with the nut.

- Torque:

- 6.2 N*m{63 kgf*cm, 55 in.*lbf}

| 7. INSTALL GENERATOR PULLEY WITH CLUTCH |

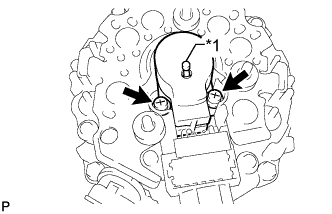

Temporarily install the generator pulley with clutch by hand.

Mount the generator in a vise between aluminum plates.

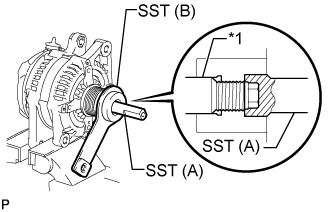

Install SST (A) and SST (B) to the generator pulley with clutch as shown in the illustration.

- SST

- 09820-63021

Text in Illustration *1 Rotor Shaft - NOTICE:

- Securely attach SST to the generator pulley with clutch and rotor shaft.

|

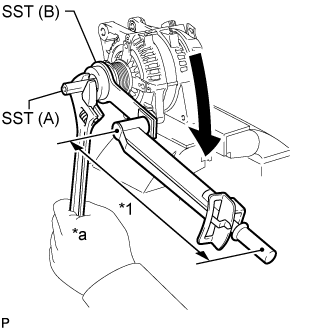

Using a wrench to hold SST (A), turn SST (B) clockwise to tighten the generator pulley with clutch.

- Torque:

- without SST:

- 80 N*m{816 kgf*cm, 59 ft.*lbf}

- with SST:

- 64 N*m{653 kgf*cm, 47 ft.*lbf}

Text in Illustration *1 Fulcrum Length *a Hold

Turn - NOTICE:

- Be careful as the generator pulley with clutch or rotor shaft may be damaged if the position of SST is not securely maintained while performing this operation.

- HINT:

- Use a torque wrench with a fulcrum length of 400 mm (15.7 in.). When using a torque wrench with a fulcrum length that is not 400 mm (15.7 in.), calculate the torque specification for the torque wrench and SST based on the "without SST" torque specification (Click here).

- Make sure SST and the wrench are connected in a straight line.

|

Remove SST from the generator.

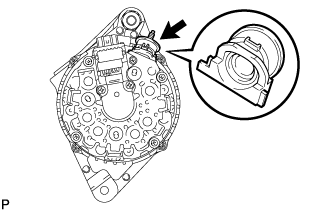

Check that the generator pulley with clutch rotates smoothly.

| 8. INSTALL GENERATOR PULLEY CAP |

Install a new generator pulley cap to the generator pulley with clutch.