Dtc C1252 Brake Booster Pump Motor On Time Abnormally Long

Brake. Land Cruiser. Urj200, 202 Grj200 Vdj200

DESCRIPTION

INSPECTION PROCEDURE

CHECK PUMP MOTOR OPERATION

CHECK CONNECTION OF PUMP MOTOR WIRE HARNESS

CHECK RESISTANCE OF PUMP MOTOR WIRE HARNESS

READ VALUE USING GTS (ACCUMULATOR SENSOR)

RECONFIRM DTC

DTC C1252 Brake Booster Pump Motor on Time Abnormally Long |

DESCRIPTION

The motor relay (semiconductor relay) is built into the master cylinder solenoid and drives the pump motor based on a signal from the skid control ECU (master cylinder solenoid).DTC Code

| DTC Detection Condition

| Trouble Area

|

C1252

| The motor operates for 3 minutes or more.

| - Brake booster with accumulator pump assembly

- Pump motor wire harness condition

- Skid control ECU (Master cylinder solenoid)

- Hydraulic brake booster assembly

|

- HINT:

- The pump motor continues operation for the first 3 minutes, and then starts and stops repeatedly.

INSPECTION PROCEDURE

- NOTICE:

- After replacing the master cylinder solenoid, perform zero point calibration and store the system information (Click here).

- HINT:

- When DTC C1253, C1254, C1256 or C1452 is output together with DTC C1252, inspect and repair the trouble area indicated by DTC C1253, C1254, C1256 or C1452 first.

| 1.CHECK PUMP MOTOR OPERATION |

Turn the ignition switch off.

Depress the brake pedal more than 40 times.

Turn the ignition switch to ON.

Check how the pump motor operates.

ResultResult

| Proceed to

|

Pump motor does not operate

| A

|

Pump motor operates continuously and does not stop

| B

|

Pump motor operates intermittently

| C

|

Pump motor operates, and then stops

| D

|

- HINT:

- Refer to the hydraulic brake booster assembly installation procedures:

- for LHD (Click here)

- for RHD (Click here)

| | REPLACE HYDRAULIC BRAKE BOOSTER ASSEMBLY |

|

|

| |

|

| |

|

| 2.CHECK CONNECTION OF PUMP MOTOR WIRE HARNESS |

Remove the hydraulic brake booster assembly (for LHD: Click here, for RHD: Click here).

Check the tightening torque of the 2 screws which secure the wire harness connecting the master cylinder solenoid and brake booster with accumulator pump assembly (for LHD: Click here, for RHD: Click here).

- OK:

- The harness is tightened to the specified torque.

| 3.CHECK RESISTANCE OF PUMP MOTOR WIRE HARNESS |

Using a screwdriver, remove the 2 screws and pull out the wire harness from the master cylinder solenoid.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

Red wire terminal - Black wire terminal

| Always

| Below 2 Ω

|

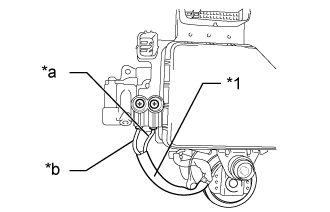

Text in Illustration*1

| Pump motor wire harness

|

*a

| Red wire

|

*b

| Black wire

|

- HINT:

Refer to the brake booster with accumulator pump assembly installation procedures:

- for LHD (Click here)

- for RHD (Click here)

| | REPLACE BRAKE BOOSTER WITH ACCUMULATOR PUMP ASSEMBLY |

|

|

| 4.READ VALUE USING GTS (ACCUMULATOR SENSOR) |

Turn the ignition switch off.

Connect the GTS to the DLC3.

Turn the ignition switch to ON.

Turn the GTS on.

Enter the following menus: Chassis / ABS/VSC/TRC / Data List.

ABS/VSC/TRCTester Display

| Measurement Item/Range

| Normal Condition

| Diagnostic Note

|

Accumulator Sensor

| Accumulator pressure sensor reading/ Min.: 0.00 V, Max.: 5.00 V

| 3.58 to 5 V

| If the value is constant regardless of the pump operation, an accumulator pressure sensor malfunction is suspected.

|

Check the accumulator output value.

ResultResult

| Proceed to

|

Output value is within "Normal Condition" range

| A

|

Output value is out of "Normal Condition" range

| B

|

Output value is constant regardless of pump operation

| C

|

- HINT:

- Refer to the hydraulic brake booster assembly installation procedures:

for LHD (Click here)

for RHD (Click here)

- Refer to the master cylinder solenoid installation procedures:

for LHD (Click here)

for RHD (Click here)

| | REPLACE MASTER CYLINDER SOLENOID |

|

|

| | REPLACE HYDRAULIC BRAKE BOOSTER ASSEMBLY |

|

|

Clear the DTCs (Click here).

Turn the ignition switch off.

Turn the ignition switch to ON.

Wait for more than 5 minutes.

Check if the same DTC is output (Click here).

ResultResult

| Proceed to

|

DTC is output

| A

|

DTC is not output

| B

|

- HINT:

- Reinstall the sensors, reconnect the connectors, etc. and restore the previous vehicle conditions before rechecking for DTCs.

- Refer to the hydraulic brake booster assembly installation procedures:

for LHD (Click here)

for RHD (Click here)

- Refer to the brake booster with accumulator pump assembly installation procedures:

for LHD (Click here)

for RHD (Click here)

| | REPLACE BRAKE BOOSTER WITH ACCUMULATOR PUMP ASSEMBLY |

|

|

| A |

|

|

|

| REPLACE HYDRAULIC BRAKE BOOSTER ASSEMBLY |

|