CHECK HARNESS AND CONNECTOR (ENGINE WIRE HARNESS)

CHECK INJECTOR COMPENSATION CODE

READ VALUE USING GTS (COMPENSATORY INJECTION VOLUME FOR EACH CYLINDER)

PERFORM ACTIVE TEST USING GTS (CONTROL THE SELECT CYLINDER FUEL CUT)

CHECK CYLINDER COMPRESSION PRESSURE OF MALFUNCTIONING CYLINDER

REGISTER INJECTOR COMPENSATION CODE AND PERFORM PILOT QUANTITY LEARNING

CHECK WHETHER DTC OUTPUT RECURS (DTC P0301, P0302, P0303, P0304, P0305, P0306, P0307 OR P0308)

CHECK ENGINE TO DETERMINE CAUSE OF LOW COMPRESSION

REPAIR OR REPLACE HARNESS OR CONNECTOR

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED

DTC P0301 Cylinder 1 Misfire Detected |

DTC P0302 Cylinder 2 Misfire Detected |

DTC P0303 Cylinder 3 Misfire Detected |

DTC P0304 Cylinder 4 Misfire Detected |

DTC P0305 Cylinder 5 Misfire Detected |

DTC P0306 Cylinder 6 Misfire Detected |

DTC P0307 Cylinder 7 Misfire Detected |

DTC P0308 Cylinder 8 Misfire Detected |

DESCRIPTION

- HINT:

- For more information on the injector assemblies and common rail system, refer to System Description (Click here).

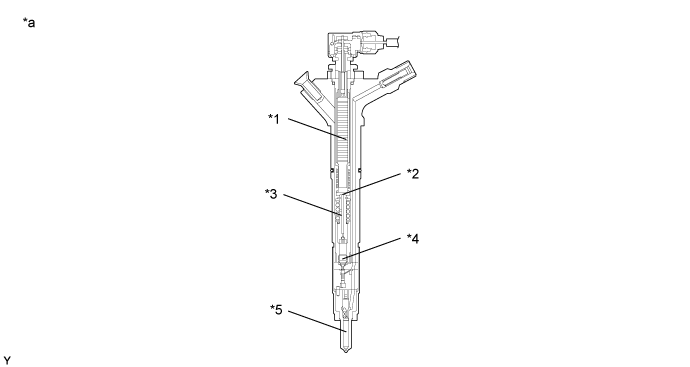

| *1 | Piezo Actuator | *2 | No. 1 Piston |

| *3 | No. 2 Piston | *4 | Three-Way Valve |

| *5 | Nozzle Needle | - | - |

| *a | Injector Assembly Cross Section Diagram | - | - |

- HINT:

- The cylinder which has the compensation value, indicated by Injection Feedback Val #1 to #8, that varies from the other cylinders may be malfunctioning.

- If DTC P0093 (fuel leaks from high-pressure area) is stored simultaneously, a leakage malfunction of a specific cylinder has probably occurred.

- If any of the DTCs from P0201 to P0208, P062D or P062E (open or short in the injector driver or injector circuit) is stored simultaneously, there is probably a faulty circuit located between the ECM and the injector assembly including the injector driver.

- If only DTC from P0301 to P0308 (injector malfunction) has been stored, an injector assembly mechanical malfunction or insufficient compression (valve clearance, etc.) has probably occurred. An open or short malfunction of the ECM, injector driver or injector circuit is unlikely.

| DTC Detection Drive Pattern | DTC Detection Condition | Main Trouble Area | Related Trouble Area |

| Warm up the engine and idle it for 60 seconds | Injector Feedback Val #1 to #8 is 5.0 mm3/st and the engine speed fluctuation of No. 1 to No. 8 cylinder is large during idling. (2 trip detection logic) |

|

|

| DTC No. | Data List |

| P0301 to P0308 |

|

- HINT:

- If any of DTCs from P0301 to P0308 is stored, the following symptoms may appear:

- Rough idle

- Poor driveability

- After confirming DTC P0301, P0302, P0303, P0304, P0305, P0306, P0307 or P0308, check the internal fuel pressure on the GTS by entering the following menus: Engine and ECT / Data List / Common Rail Pressure, Target Common Rail Pressure.

Under a stable condition such as idling or running the engine at 2500 rpm without load, Common Rail Pressure is within 5000 kPa of Target Common Rail Pressure.

MONITOR DESCRIPTION

- P0301 to P0308 (Injection malfunction, except open or short in injector circuit):

This DTC will be stored if the engine speed fluctuation between each cylinder is large. The ECM monitors changes in the crankshaft rotation speed using the crankshaft position sensor in order to detect improper combustion. The camshaft position sensor also plays a role in determining which cylinder has the problem. The fluctuation counter increases when irregular crankshaft rotation speed variation exceeds the threshold with the engine idling. Therefore, if any one of the cylinders is operating poorly (rough idle), the ECM stores this DTC.

WIRING DIAGRAM

Refer to DTC P0201 (Click here).INSPECTION PROCEDURE

- NOTICE:

- After replacing the ECM, the new ECM needs registration (Click here) and initialization (Click here).

- After replacing the fuel supply pump assembly, the ECM needs initialization (Click here).

- After replacing an injector assembly, the ECM needs registration (Click here).

- HINT:

- Read freeze frame data using the GTS. Freeze frame data records the engine condition when malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, and other data from the time the malfunction occurred.

- When this DTC is stored, be sure to carefully examine "Injection Feedback Val #1 to #8", "Injection Volume", "Common Rail Pressure", "Target Common Rail Pressure", "Engine Speed", "MAF", "Coolant Temp" and "Vehicle Speed" in the freeze frame data.

| 1.CHECK FOR ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P0301, P0302, P0303, P0304, P0305, P0306, P0307 OR P0308) |

Connect the GTS to the DLC3.

Turn the ignition switch to ON and turn the GTS on.

Enter the following menus: Engine and ECT / Trouble Codes.

Read the DTCs.

Result Result Proceed to P0301, P0302, P0303, P0304, P0305, P0306, P0307 or P0308 is output A P0301, P0302, P0303, P0304, P0305, P0306, P0307 or P0308 and other DTCs are output B - HINT:

- If any DTCs other than P0301, P0302, P0303, P0304, P0305, P0306, P0307 or P0308 are output, troubleshoot those DTCs first.

- If DTCs other than P0301, P0302, P0303, P0304, P0305, P0306, P0307 or P0308 are not output, check the fuel condition before proceeding to the next step.

|

| ||||

| A | |

| 2.CHECK HARNESS AND CONNECTOR (ENGINE WIRE HARNESS) |

Check the wire harness and connector connections.

- OK:

- The wire harness and connectors have been connected securely and there are good connections.

|

| ||||

| OK | |

| 3.CHECK INJECTOR COMPENSATION CODE |

Read the injector compensation codes (Click here).

- OK:

- Compensation codes stored in the ECM match compensation codes of the installed injector assemblies.

|

| ||||

| OK | |

| 4.READ VALUE USING GTS (COMPENSATORY INJECTION VOLUME FOR EACH CYLINDER) |

Connect the GTS to the DLC3.

Turn the ignition switch to ON and turn the GTS on.

Enter the following menus: Engine and ECT / Data List / Injection Feedback Val #1 to #8.

Read the value.

- Standard value:

- The compensatory injection volume is less than 3.0 mm3/st

- HINT:

- If the fuel injector assembly is malfunctioning, the compensatory injection volume remains at 5.0 mm3/st.

- If there is a disconnection, the feedback value will increase and +5.0 mm3/st will be indicated, because it will become impossible for the injector assembly to inject.

Inspect and repair the cylinder that has an improper compensation value according to the following steps.

| NEXT | |

| 5.PERFORM ACTIVE TEST USING GTS (CONTROL THE SELECT CYLINDER FUEL CUT) |

Connect the GTS to the DLC3.

Start the engine and turn the GTS on.

Enter the following menus: Engine and ECT / Active Test / Control the Select Cylinder Fuel Cut / #1 to #8.

Check the 8 cylinders in sequence to identify any faulty cylinders by performing the power-balance inspection.

- HINT:

- If the engine idle speed does not change when an injector assembly is disabled, the cylinder being tested is malfunctioning.

- If the cylinder being tested is normal, there will be a significant change in idle speed when the fuel injection is stopped for that cylinder.

| NEXT | |

| 6.CHECK CYLINDER COMPRESSION PRESSURE OF MALFUNCTIONING CYLINDER |

- HINT:

- Measure the compression of the cylinder that had a high speed during the "Check the Cylinder Compression" Active Test.

Check the cylinder compression pressure (Click here).

|

| ||||

| OK | |

| 7.REPLACE INJECTOR ASSEMBLY |

Replace the injector assembly (Click here).

- NOTICE:

- When replacing the injector assembly for a cylinder, always be sure to use a new injection pipe.

- Follow the procedure in the repair manual and temporarily install the injection pipes and nozzle leakage pipe, and then correctly position the injector assemblies. After that, tighten parts according to the torque specifications.

- If the installation procedure is not performed correctly, injector assemblies may become out of position, which may cause the injector assemblies to deteriorate, resulting in malfunctions.

- If an injector assembly deteriorates and malfunctions, other problems such as knocking, rough idle, etc. may occur.

- If an injector assembly becomes out of position, it is possible that the seal between the injector assembly and injection pipe may become incomplete, resulting in a fuel leak.

| NEXT | |

| 8.BLEED AIR FROM FUEL SYSTEM |

Bleed the air from the fuel system (Click here).

Perform PM forced regeneration (Click here).

- HINT:

- When fuel lines are disconnected, air may enter the fuel lines, leading to engine starting trouble. Therefore, perform forced regeneration and bleed the air from the fuel lines.

| NEXT | |

| 9.REGISTER INJECTOR COMPENSATION CODE AND PERFORM PILOT QUANTITY LEARNING |

Register the injector compensation code (Click here).

Perform the injector pilot quantity learning (Click here).

| NEXT | |

| 10.CHECK WHETHER DTC OUTPUT RECURS (DTC P0301, P0302, P0303, P0304, P0305, P0306, P0307 OR P0308) |

Connect the GTS to the DLC3.

Turn the ignition switch to ON and turn the GTS on.

Clear the DTCs (Click here).

Turn the ignition switch off for 30 seconds or more.

Start the engine.

Warm up the engine (engine coolant temperature is 70°C (158°F) or higher) and idle it for 60 seconds (the shift lever should be in neutral, and the A/C switch and all accessory switches should be off).

Enter the following menus: Powertrain / Engine and ECT / Trouble Codes.

Read the pending DTCs.

- HINT:

- If no pending DTCs are output, proceed to the next step to check "All Readiness".

- Perform the following procedure using the GTS to determine whether or not the DTC judgment has been carried out.

Enter the following menus: Engine and ECT / Utility / All Readiness.

Input DTC P0301, P0302, P0303, P0304, P0305, P0306, P0307 or P0308.

Check the DTC judgment result.

Result GTS Display Result Proceed to Pending DTC P0301, P0302, P0303, P0304, P0305, P0306, P0307 or P0308 is output A All Readiness ABNORMAL A NORMAL B - HINT:

- If STATUS is INCOMPLETE or N/A, increase the idling time.

|

| ||||

| A | |

| 11.REPLACE ECM |

Replace the ECM (Click here).

|

| ||||

| 12.CHECK ENGINE TO DETERMINE CAUSE OF LOW COMPRESSION |

|

| ||||

| 13.REPAIR OR REPLACE HARNESS OR CONNECTOR |

Repair or replace the harness or connector.

| NEXT | |

| 14.CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED |

Connect the GTS to the DLC3.

Clear the DTCs (Click here).

Turn the ignition switch off for 30 seconds or more.

Start the engine.

Warm up the engine (engine coolant temperature is 70°C (158°F) or higher) and idle it for 60 seconds (the shift lever should be in neutral, and the A/C switch and all accessory switches should be off).

Confirm that the DTC is not output again.

- HINT:

- Perform the following procedure using the GTS to determine whether or not the DTC judgment has been carried out.

Enter the following menus: Engine and ECT / Utility / All Readiness.

Input DTC P0301, P0302, P0303, P0304, P0305, P0306, P0307 or P0308.

Check that STATUS is NORMAL. If STATUS is INCOMPLETE or N/A, increase the idling time.

| NEXT | ||

| ||