Lighting System Headlight Leveling Ecu Power Source Circuit

DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK VEHICLE TYPE

READ VALUE USING GTS (IGNITION POWER SUPPLY)

CHECK HARNESS AND CONNECTOR (HEADLIGHT LEVELING ECU ASSEMBLY - BATTERY AND BODY GROUND)

READ VALUE USING GTS (IGNITION POWER SUPPLY)

CHECK HARNESS AND CONNECTOR (HEADLIGHT SWIVEL ECU ASSEMBLY - BATTERY AND BODY GROUND)

LIGHTING SYSTEM - Headlight Leveling ECU Power Source Circuit |

DESCRIPTION

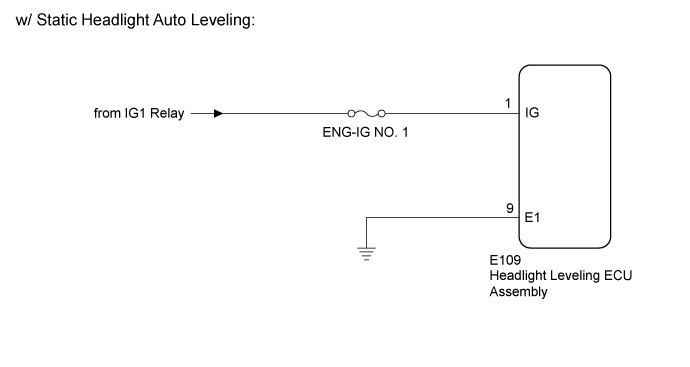

This circuit detects the state of the ignition switch, and sends it to the headlight leveling ECU*1 or headlight swivel ECU*2.- *1: w/ Static Headlight Auto Leveling

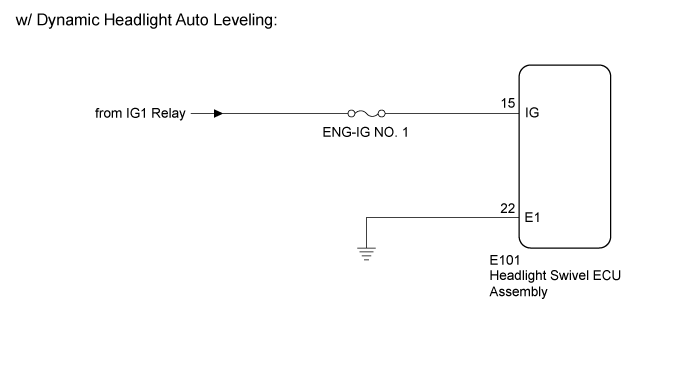

- *2: w/ Dynamic Headlight Auto Leveling

WIRING DIAGRAM

INSPECTION PROCEDURE

- NOTICE:

- Inspect the fuses for circuits related to this system before performing the following inspection procedure.

- After replacing the headlight leveling ECU*1 or headlight swivel ECU*2, initialization of the ECU is necessary (Click here).

- *1: w/ Static Headlight Auto Leveling

- *2: w/ Dynamic Headlight Auto Leveling

Check the vehicle type.

ResultResult

| Proceed to

|

w/ Static Headlight Auto Leveling

| A

|

w/ Dynamic Headlight Auto Leveling

| B

|

| 2.READ VALUE USING GTS (IGNITION POWER SUPPLY) |

Using the GTS, read the Data List (Click here).

HL Auto LevelingTester Display

| Measurement Item/Range

| Normal Condition

| Diagnostic Note

|

+B

| Ignition power supply voltage value / 0 to 19.75 V

| 11 to 14 V

| -

|

- OK:

- The display is as specified in the normal condition column.

| OK |

|

|

|

| PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE (Click here) |

|

| 3.CHECK HARNESS AND CONNECTOR (HEADLIGHT LEVELING ECU ASSEMBLY - BATTERY AND BODY GROUND) |

Disconnect the headlight leveling ECU connector.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

Tester Connection

| Switch Condition

| Specified Condition

|

E109-1 (IG) - Body ground

| Ignition switch ON

| 11 to 14 V

|

Ignition switch off

| Below 1 V

|

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

E109-9 (E1) - Body ground

| Always

| Below 1 Ω

|

Text in Illustration*a

| Front view of wire harness connector

(to Headlight Leveling ECU Assembly)

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| OK |

|

|

|

| REPLACE HEADLIGHT LEVELING ECU ASSEMBLY (Click here) |

|

| 4.READ VALUE USING GTS (IGNITION POWER SUPPLY) |

Using the GTS, read the Data List (Click here).

AFSTester Display

| Measurement Item/Range

| Normal Condition

| Diagnostic Note

|

+B

| Ignition power supply voltage value / 0 to 19.75 V

| 11 to 14 V

| -

|

- OK:

- The display is as specified in the normal condition column.

| OK |

|

|

|

| PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE (Click here) |

|

| 5.CHECK HARNESS AND CONNECTOR (HEADLIGHT SWIVEL ECU ASSEMBLY - BATTERY AND BODY GROUND) |

Disconnect the headlight swivel ECU connector.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

Tester Connection

| Switch Condition

| Specified Condition

|

E101-15 (IG) - Body ground

| Ignition switch ON

| 11 to 14 V

|

Ignition switch off

| Below 1 V

|

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

E101-22 (E1) - Body ground

| Always

| Below 1 Ω

|

Text in Illustration*a

| Front view of wire harness connector

(to Headlight Swivel ECU Assembly)

|

ResultResult

| Proceed to

|

OK (for LHD)

| A

|

OK (for RHD)

| B

|

NG

| C

|

| | REPLACE HEADLIGHT SWIVEL ECU ASSEMBLY (Click here) |

|

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| A |

|

|

|

| REPLACE HEADLIGHT SWIVEL ECU ASSEMBLY (Click here) |

|