Automatic Transmission System (For 1Ur-Fe) Pattern Select Switch 2Nd Start Mode Circuit

Drivetrain. Land Cruiser. Urj200, 202 Grj200 Vdj200

DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

DRIVING TEST

INSPECT ECT 2ND SWITCH (INTEGRATION CONTROL AND PANEL ASSEMBLY)

CHECK HARNESS AND CONNECTOR (INTEGRATION CONTROL AND PANEL ASSEMBLY - BODY GROUND)

CHECK HARNESS AND CONNECTOR (INTEGRATION CONTROL AND PANEL ASSEMBLY - ECM)

AUTOMATIC TRANSMISSION SYSTEM (for 1UR-FE) - Pattern Select Switch 2nd Start Mode Circuit |

DESCRIPTION

When 2nd mode is selected with the ECT 2nd switch (integration control and panel assembly), the ECM controls the solenoid valves and the transmission starts from 2nd gear.The 2nd mode is the system that operates the throttle motor to control engine output to reduce skidding of the driving wheels, and guarantee takeoff acceleration, driving straightness and turning stability.When the shift lever is in D, the transmission automatically shifts up through 3rd to 6th as usual.

WIRING DIAGRAM

Refer to Pattern Select Switch Power Mode Circuit (Click here).

INSPECTION PROCEDURE

When the ECT 2nd switch is pushed, switch contact is made and 2nd mode is selected. To cancel 2nd mode, push the ECT 2nd switch once again.- HINT:

- 2nd mode is automatically canceled when the engine switch is turned off.

- HINT:

- The driving test should be performed on a paved road (nonskid road).

Start the engine.

Turn the ECT 2nd switch off (normal drive mode).

Confirm vehicle response by driving from a parked position to fully depressing the accelerator pedal.

Turn the ECT 2nd switch on and perform the same check as above.

When driving the vehicle with the ECT 2nd switch on and off, check that there is a difference in acceleration.

- OK:

- There is a difference in acceleration.

| OK |

|

|

|

| PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE (Click here) |

|

| 2.INSPECT ECT 2ND SWITCH (INTEGRATION CONTROL AND PANEL ASSEMBLY) |

Remove the integration control and panel assembly (Click here).

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Switch Condition

| Specified Condition

|

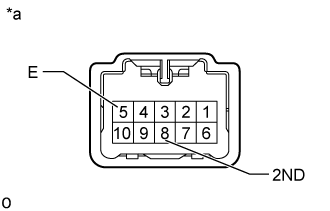

8 (2ND) - 5 (E)

| ECT 2nd switch on

| Below 1 Ω

|

8 (2ND) - 5 (E)

| ECT 2nd switch off

| 10 kΩ or higher

|

Text in Illustration*a

| Component without harness connected

(Integration Control and Panel Assembly)

|

| | REPLACE INTEGRATION CONTROL AND PANEL ASSEMBLY (Click here) |

|

|

| 3.CHECK HARNESS AND CONNECTOR (INTEGRATION CONTROL AND PANEL ASSEMBLY - BODY GROUND) |

Disconnect the integration control and panel assembly connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

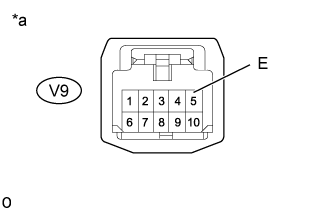

V9-5 (E) - Body ground

| Always

| Below 1 Ω

|

Text in Illustration*a

| Front view of wire harness connector

(to Integration Control and Panel Assembly)

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 4.CHECK HARNESS AND CONNECTOR (INTEGRATION CONTROL AND PANEL ASSEMBLY - ECM) |

Disconnect the ECM connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

for LHDTester Connection

| Switch Condition

| Specified Condition

|

A38-4 (SNWI) - Body ground

| ECT 2nd switch on

| Below 1 Ω

|

A38-4 (SNWI) - Body ground

| ECT 2nd switch off

| 10 kΩ or higher

|

for RHDTester Connection

| Switch Condition

| Specified Condition

|

A52-4 (SNWI) - Body ground

| ECT 2nd switch on

| Below 1 Ω

|

A52-4 (SNWI) - Body ground

| ECT 2nd switch off

| 10 kΩ or higher

|

Text in Illustration*1

| for LHD

|

*2

| for RHD

|

*a

| Front view of wire harness connector

(to ECM)

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| OK |

|

|

|

| PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE (Click here) |

|