Entry And Start System (For Entry Function) Driver Side Door Entry Lock Function Does Not Operate

DESCRIPTION

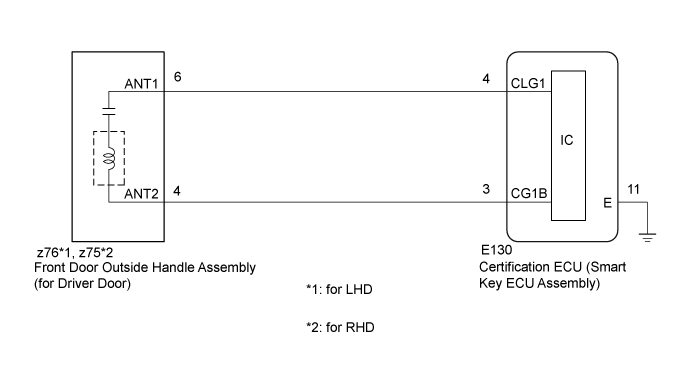

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK POWER DOOR LOCK CONTROL SYSTEM

READ VALUE USING GTS (D-DOOR TRIGGER SWITCH)

CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU [SMART KEY ECU ASSEMBLY] - FRONT DOOR OUTSIDE HANDLE ASSEMBLY [FOR DRIVER DOOR])

CHECK FRONT DOOR OUTSIDE HANDLE ASSEMBLY (FOR DRIVER DOOR) (INPUT TO DRIVER DOOR LOCK SENSOR)

ENTRY AND START SYSTEM (for Entry Function) - Driver Side Door Entry Lock Function does not Operate |

DESCRIPTION

If the entry lock function does not operate for the driver door only, but the entry unlock function operates, the request code is being transmitted properly from the driver door. In this case, there may be a problem related to the lock sensor (connection between the certification ECU [smart key ECU assembly] and front door outside handle assembly [for driver door]).

WIRING DIAGRAM

INSPECTION PROCEDURE

- NOTICE:

- The entry and start system (for Entry Function) uses the LIN communication system and CAN communication system. Inspect the communication function by following How to Proceed with Troubleshooting. Troubleshoot the entry and start system (for Entry Function) after confirming that the communication systems are functioning properly (Click here).

- When using the GTS with the engine switch off, connect the GTS to the DLC3 and turn a courtesy light switch on and off at intervals of 1.5 seconds or less until communication between the GTS and the vehicle begins. Then select Model Code "KEY REGIST" under manual mode and enter the following menus: Body Electrical / Entry&Start(CAN). While using the GTS, periodically turn a courtesy light switch on and off at intervals of 1.5 seconds or less to maintain communication between the GTS and the vehicle.

- Check that there are no electrical key transmitter sub-assemblies in the vehicle.

- Before replacing the certification ECU (smart key ECU assembly), refer to entry and start system (for Entry Function) (Click here).

- After repair, confirm that no DTCs are output by performing "DTC Output Confirmation Operation".

| 1.CHECK POWER DOOR LOCK CONTROL SYSTEM |

When the door control switch on the multiplex network master switch assembly is operated, check that the doors unlock and lock according to the switch operation (Click here).

- OK:

- Door locks operate normally.

| 2.READ VALUE USING GTS (D-DOOR TRIGGER SWITCH) |

Connect the GTS to the DLC3.

Turn the engine switch on (IG).

Turn the GTS on.

Enter the following menus: Body Electrical / Entry&Start / Data List.

Read the Data List according to the display on the GTS.

Entry&Start Tester Display

| Measurement Item/Range

| Normal Condition

| Diagnostic Note

|

D-Door Trigger Switch

| Driver door touch sensor (lock sensor) / ON or OFF

| ON: Driver door touch sensor (lock sensor) touched

OFF: Driver door touch sensor (lock sensor) not touched

| - Displays whether the lock sensor is on or off (even if the sensor is touched and contact is maintained, "ON" is displayed only momentarily).

- Use this Data List item to help determine if there is a lock sensor malfunction when the entry lock function does not operate.

|

- HINT:

- When checking the operation of the entry lock function several times, it can be operated up to 2 times consecutively. To operate the function 3 times or more consecutively, the doors need to be unlocked once. However, this is only for the entry lock function, other door lock operations, such as a wireless door lock operation can be performed consecutively.

- OK:

- The GTS display changes correctly in response to the operation of the front door outside handle assembly (for driver door).

| OK |

|

|

|

| REPLACE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

|

| 3.CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU [SMART KEY ECU ASSEMBLY] - FRONT DOOR OUTSIDE HANDLE ASSEMBLY [FOR DRIVER DOOR]) |

- *1: for LHD

- *2: for RHD

Disconnect the E130 certification ECU (smart key ECU assembly) connector.

Disconnect the z76*1 or z75*2 front door outside handle assembly (for driver door) connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

- for LHD:

Tester Connection

| Condition

| Specified Condition

|

E130-4 (CLG1) - z76-6 (ANT1)

| Always

| Below 1 Ω

|

E130-3 (CG1B) - z76-4 (ANT2)

| Always

| Below 1 Ω

|

E130-4 (CLG1) or z76-6 (ANT1) - Body ground

| Always

| 10 kΩ or higher

|

E130-3 (CG1B) or z76-4 (ANT2) - Body ground

| Always

| 10 kΩ or higher

|

- for RHD:

Tester Connection

| Condition

| Specified Condition

|

E130-4 (CLG1) - z75-6 (ANT1)

| Always

| Below 1 Ω

|

E130-3 (CG1B) - z75-4 (ANT2)

| Always

| Below 1 Ω

|

E130-4 (CLG1) or z75-6 (ANT1) - Body ground

| Always

| 10 kΩ or higher

|

E130-3 (CG1B) or z75-4 (ANT2) - Body ground

| Always

| 10 kΩ or higher

|

Reconnect the z76*1 or z75*2 front door outside handle assembly (for driver door) connector.

Reconnect the E130 certification ECU (smart key ECU assembly) connector.

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

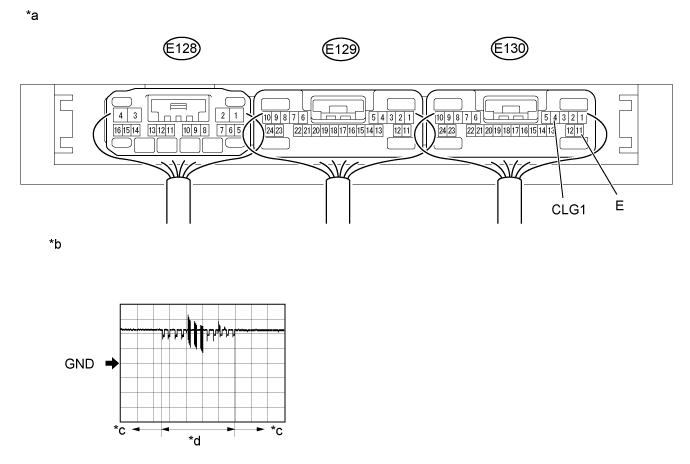

| 4.CHECK FRONT DOOR OUTSIDE HANDLE ASSEMBLY (FOR DRIVER DOOR) (INPUT TO DRIVER DOOR LOCK SENSOR) |

Text in Illustration*a

| Component with harness connected

(Certification ECU [Smart Key ECU Assembly])

| b

| Waveform 1

|

*d

| Lock sensor not touched

| *c

| Lock sensor touched

|

Using an oscilloscope, check the waveform.

- OK:

Tester Connection

| Switch Condition

| Tool Setting

| Specified Condition

|

E130-4 (CLG1) - E130-11 (E)

| Procedure:

- Engine switch off

- Electrical key transmitter sub-assembly brought outside vehicle

- All doors closed

- All doors locked through wireless operation (electrical key transmitter sub-assembly brought outside detection area*)

- Driver door lock sensor touched

| 5 V/DIV., 40 ms/DIV.

| Pulse generation (See waveform 1)

|

- *: For details about the entry function detection area, refer to Operation Check (Click here).

| | REPLACE DOOR OUTSIDE HANDLE ASSEMBLY (FOR DRIVER DOOR) (Click here) |

|

|

| OK |

|

|

|

| REPLACE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

|