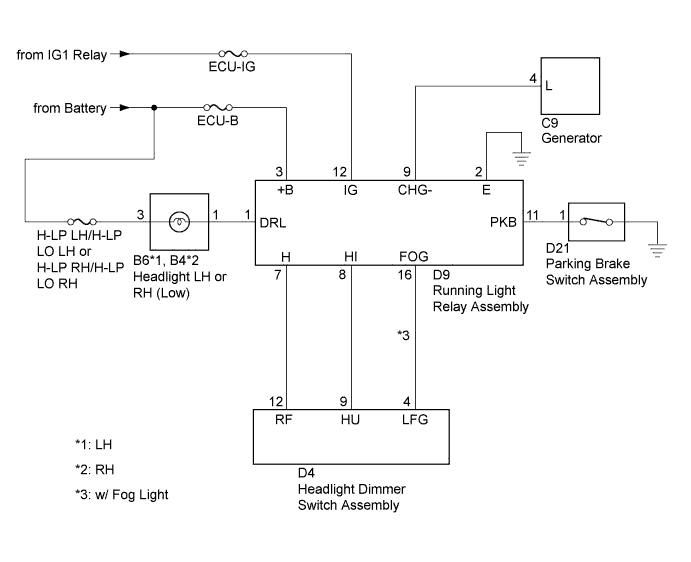

Lighting System (For Sedan) Drl Relay Circuit

DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK HARNESS AND CONNECTOR (RUNNING LIGHT RELAY ASSEMBLY - BATTERY, IG1 RELAY AND BODY GROUND)

CHECK HARNESS AND CONNECTOR (HEADLIGHT - RUNNING LIGHT RELAY ASSEMBLY)

CHECK HARNESS AND CONNECTOR (HEADLIGHT DIMMER SWITCH ASSEMBLY - RUNNING LIGHT RELAY ASSEMBLY)

CHECK HARNESS AND CONNECTOR (GENERATOR - RUNNING LIGHT RELAY ASSEMBLY)

CHECK HARNESS AND CONNECTOR (PARKING BRAKE SWITCH ASSEMBLY - RUNNING LIGHT RELAY ASSEMBLY)

LIGHTING SYSTEM (for Sedan) - DRL Relay Circuit |

DESCRIPTION

When the engine is started, signals are transmitted from the generator to the running light relay assembly, causing the headlights to illuminate.

WIRING DIAGRAM

INSPECTION PROCEDURE

- NOTICE:

- Inspect the fuses for circuits related to this system before performing the following inspection procedure.

| 1.CHECK HARNESS AND CONNECTOR (RUNNING LIGHT RELAY ASSEMBLY - BATTERY, IG1 RELAY AND BODY GROUND) |

Disconnect the D9 running light relay assembly connector.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

Tester Connection

| Switch Condition

| Specified Condition

|

D9-3 (+B) - Body ground

| Always

| 11 to 14 V

|

D9-12 (IG) - Body ground

| Ignition switch ON

| 11 to 14 V

|

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

D9-2 (E) - Body ground

| Always

| Below 1 Ω

|

Text in Illustration*a

| Front view of wire harness connector

(to Running Light Relay Assembly)

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 2.CHECK HARNESS AND CONNECTOR (HEADLIGHT - RUNNING LIGHT RELAY ASSEMBLY) |

Disconnect the B6 or B4 headlight connector.

Disconnect the D9 running light relay assembly connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

B6-1 or B4-1 - D9-1

| Always

| Below 1 Ω

|

B6-1 or B4-1 - Body ground

| Always

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 3.CHECK HARNESS AND CONNECTOR (HEADLIGHT DIMMER SWITCH ASSEMBLY - RUNNING LIGHT RELAY ASSEMBLY) |

Disconnect the D4 headlight dimmer switch assembly connector.

Disconnect the D9 running light relay assembly connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

D4-12 (RF) - D9-7 (H)

| Always

| Below 1 Ω

|

D4-9 (HU) - D9-8 (HI)

| Always

| Below 1 Ω

|

D4-4 (LFG) - D9-16 (FOG)*1

| Always

| Below 1 Ω

|

D4-12 (RF) - Body ground

| Always

| 10 kΩ or higher

|

D4-9 (HU) - Body ground

| Always

| 10 kΩ or higher

|

D4-4 (LFG) - Body ground*1

| Always

| 10 kΩ or higher

|

*1: w/ Fog Light

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 4.CHECK HARNESS AND CONNECTOR (GENERATOR - RUNNING LIGHT RELAY ASSEMBLY) |

Disconnect the C9 generator connector.

Disconnect the D9 running light relay assembly connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

C9-4 (L) - D9-9 (CHG-)

| Always

| Below 1 Ω

|

C9-4 (L) - Body ground

| Always

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 5.CHECK HARNESS AND CONNECTOR (PARKING BRAKE SWITCH ASSEMBLY - RUNNING LIGHT RELAY ASSEMBLY) |

Disconnect the D21 parking brake switch assembly connector.

Disconnect the D9 running light relay assembly connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

D21-1 - D9-11 (PKB)

| Always

| Below 1 Ω

|

D21-1 - Body ground

| Always

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| OK |

|

|

|

| REPLACE RUNNING LIGHT RELAY ASSEMBLY |

|