Fuel Injector (For Sedan) Installation

INSTALL FUEL INJECTOR ASSEMBLY

INSTALL INJECTOR VIBRATION INSULATOR

INSTALL DELIVERY PIPE NO. 1 SPACER

INSTALL FUEL DELIVERY PIPE SUB-ASSEMBLY

CONNECT FUEL TUBE SUB-ASSEMBLY

INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY

CONNECT FUEL VAPOR FEED HOSE ASSEMBLY

CONNECT VENTILATION HOSE

INSTALL IGNITION COIL NO. 1

CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

CHECK FOR FUEL LEAKAGE

CHECK FOR ENGINE OIL LEAKAGE

INSTALL CYLINDER HEAD COVER NO. 2

Fuel Injector (For Sedan) -- Installation |

| 1. INSTALL FUEL INJECTOR ASSEMBLY |

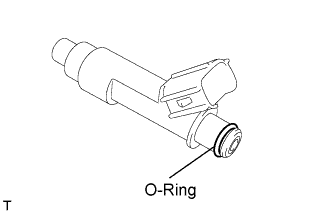

Apply a light coat of gasoline or spindle oil to new O-rings, then install one onto each fuel injector.

Apply a light coat of gasoline or spindle oil to the contact surfaces of the fuel delivery pipe and the O-ring of the fuel injector.

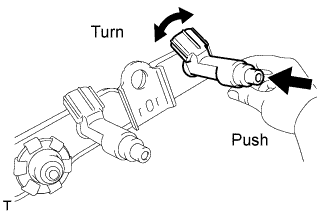

While turning the fuel injector left and right, install it onto the fuel delivery pipe.

- NOTICE:

- Do not twist the O-ring.

- After installing the fuel injectors, check that they turn smoothly. If not, replace the O-ring with a new one.

| 2. INSTALL INJECTOR VIBRATION INSULATOR |

Install 4 new injector vibration insulators onto the cylinder head.

| 3. INSTALL DELIVERY PIPE NO. 1 SPACER |

Install the 2 No. 1 delivery pipe spacers onto the cylinder head.

- NOTICE:

- Install the delivery pipe No. 1 spacer in the correct direction.

| 4. INSTALL FUEL DELIVERY PIPE SUB-ASSEMBLY |

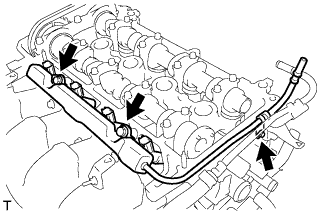

Install the fuel delivery pipe sub-assembly with the 4 fuel injectors, then provisionally install the 3 bolts.

- NOTICE:

- Do not drop the fuel injectors when installing the fuel delivery pipe sub-assembly.

- Check that the fuel injectors rotate smoothly after installing the fuel delivery pipe sub-assembly.

Tighten the 3 bolts to the specified torque.

- Torque:

- 19 N*m{194 kgf*cm, 14 ft.*lbf} for bolt A

- 9.0 N*m{92 kgf*cm, 80 in.*lbf} for bolt B

| 5. CONNECT FUEL TUBE SUB-ASSEMBLY |

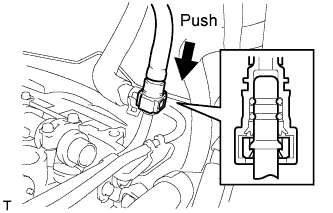

Insert the fuel tube connector into the fuel delivery pipe until a click sound can be heard.

- NOTICE:

- Check that there are no scratches or foreign matter around the disconnected parts of the fuel tube connector and pipe before performing this work.

- After connecting the fuel tube, check that the fuel tube connector and pipe are securely connected by pulling them.

Install the fuel pipe clamp.

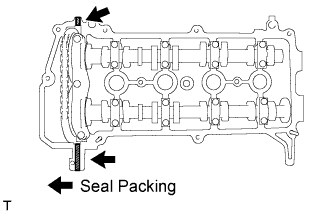

| 6. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY |

Install a new gasket to the cylinder head cover sub-assembly.

Apply seal packing to the cylinder head as shown in the illustration.

- Seal Packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or Equivalent

- NOTICE:

- Remove any oil from the contact surface.

- Install the cylinder head cover sub-assembly within 3 minutes of applying the seal packing.

- Do not start the engine for at least 2 hours after the installation.

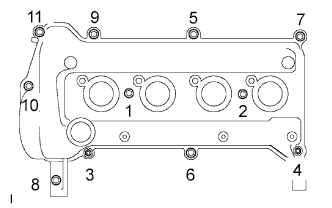

Install the cylinder head cover sub-assembly with the 9 bolts, 2 nuts and 2 seal washers.

Tighten the 9 bolts and 2 nuts in the sequence shown in the illustration.

- Torque:

- 10 N*m{102 kgf*cm, 7.0 ft.*lbf}

Install the wire harness bracket with the bolt.

- Torque:

- 13 N*m{133 kgf*cm, 9.6 ft.*lbf}

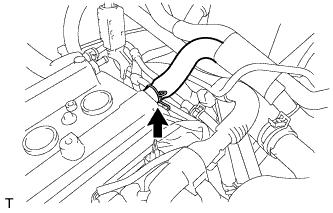

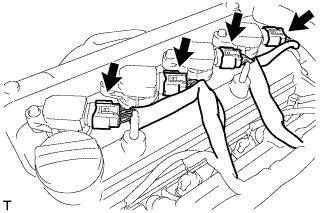

Connect the connector and wire harness clamp shown in the illustration and connect the engine wire harness.

Connect the fuel injector connectors.

| 7. CONNECT FUEL VAPOR FEED HOSE ASSEMBLY |

Connect fuel vapor feed hose assembly.

| 8. CONNECT VENTILATION HOSE |

Connect the ventilation hose.

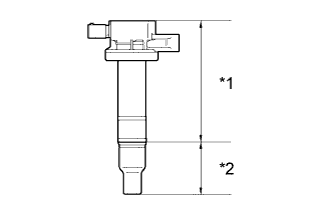

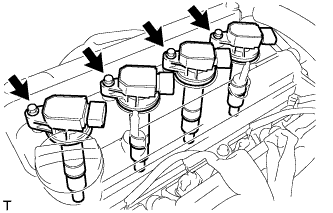

| 9. INSTALL IGNITION COIL NO. 1 |

Install the 4 ignition coils with the 4 bolts.

- Torque:

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}

- NOTICE:

- If the body or cap of the ignition coil is dropped or subjected to a strong impact, replace the ignition coil with a new one.

Text in Illustration*1

| Body

|

*2

| Cap

|

Connect the 4 ignition coil connectors.

| 10. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

- Torque:

- 5.4 N*m{55 kgf*cm, 48 in.*lbf}

| 11. CHECK FOR FUEL LEAKAGE |

When using the Techstream.

Connect the Techstream to the DLC3.

Turn the ignition switch to ON and turn the tester ON.

- NOTICE:

- Do not start the engine.

Select the following menu items: Powertrain / Engine and ECT / Active Test / Control the Fuel Pump / Speed.

- HINT:

- Refer to the Techstream operator's manual for further details.

Check that there is no fuel leakage anywhere on the fuel system after doing maintenance.

| 12. CHECK FOR ENGINE OIL LEAKAGE |

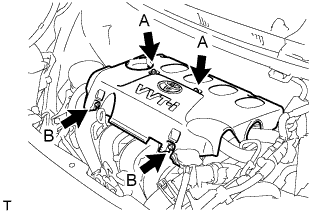

| 13. INSTALL CYLINDER HEAD COVER NO. 2 |

Tighten the 2 A nuts, then the 2 B nuts.

- Torque:

- 7.0 N*m{71 kgf*cm, 62 in.*lbf}