INSTALL DRIVE PLATE AND RING GEAR SUB-ASSEMBLY (for Automatic Transaxle)

INSPECT AND ADJUST CLUTCH COVER ASSEMBLY (for Manual Transaxle)

INSTALL AUTOMATIC TRANSAXLE ASSEMBLY (for Automatic Transaxle)

INSTALL TORQUE CONVERTER SETTING BOLT (for Automatic Transaxle)

INSTALL TRANSMISSION CONTROL CABLE ASSEMBLY (for Automatic Transaxle)

INSTALL TRANSMISSION CONTROL CABLE ASSEMBLY (for Manual Transaxle)

INSTALL COMPRESSOR WITH PULLEY ASSEMBLY (w/ Air Conditioning System)

INSTALL CLUTCH RELEASE CYLINDER ASSEMBLY (for Manual Transaxle)

INSPECT FOR AUTOMATIC TRANSAXLE FLUID LEAK (for Automatic Transaxle)

INSPECT FOR MANUAL TRANSAXLE OIL LEAK (for Manual Transaxle)

Engine Assembly (For Hatchback) -- Installation |

- NOTICE:

- As the engine assembly with transaxle is extremely heavy, the engine lifter may suddenly drop if the instructions listed in the repair manual are not followed. Therefore, always follow the instructions listed in the repair manual when performing this procedure.

- HINT:

- Perform "Inspection After Repairs" after replacing the engine assembly (YARIS_NCP93 RM000004NJD006X.html).

| 1. INSTALL ENGINE MOUNTING INSULATOR LH |

- HINT:

- Only perform this procedure when replacement of the engine mounting insulator LH is necessary.

Install the engine mounting insulator LH with the 5 bolts.

- Torque:

- 52 N*m{530 kgf*cm, 38 ft.*lbf}

| 2. INSTALL ENGINE MOUNTING INSULATOR RH |

- HINT:

- Only perform this procedure when replacement of the engine mounting insulator RH is necessary.

Install the engine mounting insulator RH with the 5 bolts.

- Torque:

- 52 N*m{530 kgf*cm, 38 ft.*lbf}

| 3. INSTALL DRIVE SHAFT HEAT INSULATOR SUB-ASSEMBLY |

Install the drive shaft heat insulator sub-assembly with the bolt and nut.

- Torque:

- 18 N*m{183 kgf*cm, 13 ft.*lbf}

| 4. CONNECT INLET HEATER WATER HOSE A |

Connect inlet heater water hose A to the cylinder head.

| 5. FIX ENGINE ASSEMBLY |

Using an engine sling device and a chain block, hold the engine assembly.

Use a belt with a tightening mechanism or a rope to secure the engine assembly with transaxle to the engine lifter.

- NOTICE:

- Set plate lift attachments so that the engine assembly with transaxle is level.

- Do not perform any procedure while the engine assembly is suspended because doing so may cause the engine assembly to drop, resulting in injury. However, the engine assembly needs to be suspended when it is installed to or removed from an engine stand.

- To prevent deformation of the oil pan, never set any attachments against the oil pan of the engine assembly.

| 6. INSTALL DRIVE PLATE AND RING GEAR SUB-ASSEMBLY (for Automatic Transaxle) |

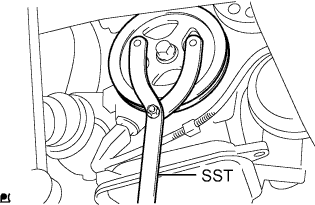

Using SST, hold the crankshaft.

- SST

- 09960-10010(09962-01000,09963-01000)

|

Clean the 6 bolts and their holes.

Install the front drive plate spacer.

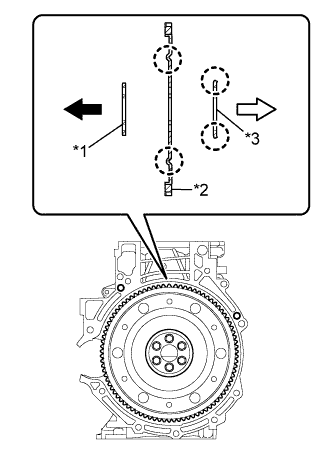

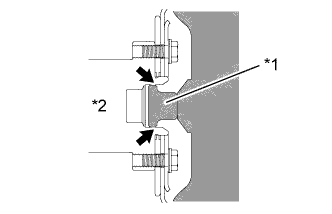

Text in Illustration *1 Front Drive Plate Spacer *2 Drive Plate and Ring Gear *3 Rear Drive Plate Spacer

Engine Side

Transaxle Side

Install the drive plate and rear drive plate spacer onto the crankshaft.

- HINT:

- The front drive plate spacer is reversible.

- As the drive plate and ring gear and the rear drive plate spacer are not reversible, make sure to install them in the direction as shown in the illustration.

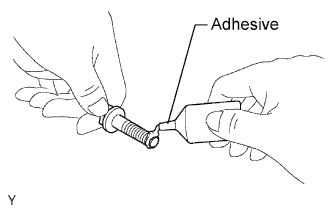

Apply adhesive to the end 2 or 3 threads of the 6 bolts.

- Adhesive:

- Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

|

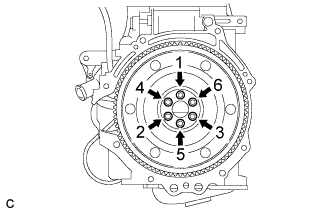

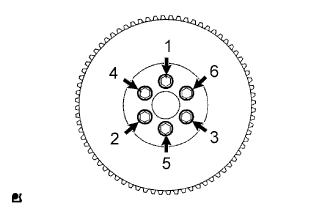

Install and uniformly tighten the 6 bolts in several steps, in the sequence shown in the illustration.

- Torque:

- 88 N*m{897 kgf*cm, 65 ft.*lbf}

- NOTICE:

- Do not start the engine for at least 1 hour after performing the installation.

|

| 7. INSTALL FLYWHEEL SUB-ASSEMBLY (for Manual Transaxle) |

Hold the crankshaft with SST.

- SST

- 09960-10010(09962-01000,09963-01000)

|

Clean the 6 bolts and their holes.

|

Apply adhesive to the end 2 or 3 threads of new bolts.

- Adhesive:

- Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

Install the flywheel with the 6 bolts in the order shown in the illustration.

- Torque:

- 49 N*m{500 kgf*cm, 38 ft.*lbf}

|

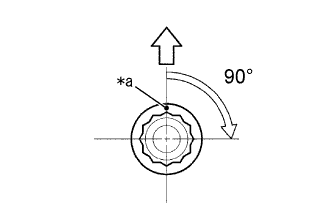

Mark a paint mark on each bolt head on the engine upper side.

Text in Illustration *a Paint Mark

|

Tighten the bolts 90° in the sequence shown in the illustration.

- NOTICE:

- Do not start the engine for at least 1 hour after performing the installation.

| 8. INSTALL CLUTCH DISC ASSEMBLY (for Manual Transaxle) |

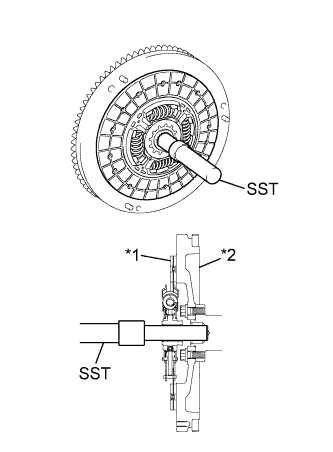

Insert SST into the clutch disc assembly, and then insert them both into the flywheel sub-assembly.

Text in Illustration *1 Clutch Disc Assembly *2 Flywheel Sub-assembly - SST

- 09301-00210

- NOTICE:

- Insert clutch disc assembly in the correct direction.

|

| 9. INSTALL CLUTCH COVER ASSEMBLY (for Manual Transaxle) |

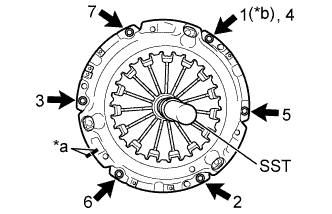

Align the matchmark on the clutch cover assembly with that on the flywheel sub-assembly.

Text in Illustration *a Matchmark *b Temporarily - SST

- 09301-00210

|

Following the procedures shown in the illustration, tighten the 6 bolts in order, starting with the bolt located near the knock pin at the top.

- Torque:

- 19 N*m{195 kgf*cm, 14 ft.*lbf}

- HINT:

- Following the order in the illustration, tighten the bolts evenly one at a time.

- Move SST up and down, right and left lightly after checking that the disc is in the center, and tighten the bolts.

| 10. INSPECT AND ADJUST CLUTCH COVER ASSEMBLY (for Manual Transaxle) |

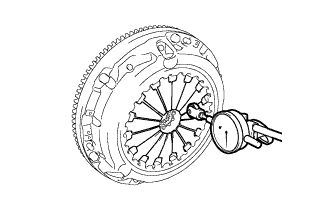

Using a dial indicator with a roller instrument, measure the diaphragm spring tip alignment.

- Maximum non-alignment:

- 0.5 mm (0.0197 in.)

|

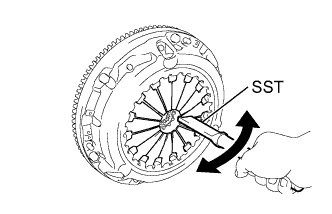

If the alignment is not as specified, using SST, adjust the diaphragm spring tip alignment.

- SST

- 09333-00013

|

| 11. INSTALL AUTOMATIC TRANSAXLE ASSEMBLY (for Automatic Transaxle) |

Apply clutch spline grease to the round of the crankshaft contact surface with the torque converter centerpiece.

Text in Illustration *1 Torque Converter Centerpiece *2 Crankshaft - Clutch spline grease:

- Toyota Genuine Clutch Spline Grease or equivalent

- Maximum spread:

- Approximately 1 g (0.0353 oz)

|

Keeping the engine and automatic transaxle assembly in a horizontal position, align the knock pins with each hole on the automatic transaxle assembly and tighten the 7 bolts.

Text in Illustration *1 Knock Pin - Torque:

- 30 N*m{301 kgf*cm, 22 ft.*lbf}

- NOTICE:

- Confirm that 2 knock pins are on the transaxle fitting surface of the engine block before transaxle installation.

- After installing the transmission, confirm that the torque converter rotates smoothly.

|

Install the wire harness bracket with the bolt.

- Torque:

- 13 N*m{130 kgf*cm, 9 ft.*lbf}

| 12. INSTALL MANUAL TRANSAXLE ASSEMBLY (for Manual Transaxle) |

Align the input shaft with the clutch disc and install the manual transaxle assembly onto the engine.

Install the 7 bolts.

- Torque:

- 33 N*m{336 kgf*cm, 24 ft.*lbf}

- NOTICE:

- Insert knock pins into the knock pin holes securely so that the end face of the manual transaxle fits close against the engine before tightening the bolts.

- Be careful not to pinch wire harness, etc.

- To avoid damage to the input shaft, do not forcefully shake the manual transaxle.

| 13. INSTALL CONTROL CABLE BRACKET (for Manual Transaxle) |

Install the control cable bracket with the 2 bolts.

- Torque:

- 25 N*m{250 kgf*cm, 18 ft.*lbf}

| 14. INSTALL STARTER ASSEMBLY |

Install the starter assembly with the 2 bolts.

- Torque:

- 37 N*m{377 kgf*cm, 27 ft.*lbf}

Connect the connector.

Connect terminal 30 with the nut.

- Torque:

- 9.8 N*m{100 kgf*cm, 87 in.*lbf}

Close the terminal cap.

| 15. INSTALL FLYWHEEL HOUSING SIDE COVER |

Insert the protruding portion into the end of the cylinder block and while pushing it along the cylinder block, fit the claw into the cylinder block.

- NOTICE:

- Male sure that the claw make a click sound, indicating that it fits tightly.

- Replace the flywheel housing side cover with a new one if it does not fit tightly or is deformed.

| 16. INSTALL EXHAUST MANIFOLD |

|

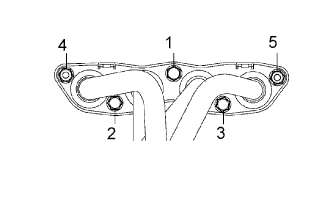

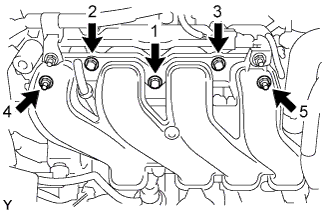

Tighten the exhaust manifold nuts and bolts, in the order shown in the illustration, through a new gasket.

- Torque:

- 27 N*m{275 kgf*cm, 20 ft.*lbf}

| 17. INSTALL MANIFOLD SUPPORT BRACKET |

Install the manifold support bracket with the 3 bolts.

- Torque:

- 44 N*m{449 kgf*cm, 33 ft.*lbf}

| 18. INSTALL NO. 1 EXHAUST MANIFOLD HEAT INSULATOR |

Install the No. 1 exhaust manifold heat insulator.

- Torque:

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}

| 19. INSTALL INTAKE MANIFOLD |

Install a new gasket onto the intake manifold.

Provisionally tighten the intake manifold 2 nuts and 3 bolts in the order shown in the illustration, and then tighten them to the specified torque.

- Torque:

- 30 N*m{306 kgf*cm, 22 ft.*lbf}

|

Connect the water by-pass hose to No. 1 water bypass pipe.

Connect the water by-pass hose to the cylinder head with the hose clamp.

Connect the union to connector tube hose to the booster vacuum tube with the hose clamp.

| 20. INSTALL WATER FILLER SUB-ASSEMBLY |

Install the water filler sub-assembly with the 2 nuts.

- Torque:

- 7.5 N*m{76 kgf*cm, 66 in.*lbf}

Connect the No. 1 radiator hose to the cylinder head with the hose clamp.

| 21. INSTALL VENTILATION HOSE |

Install the ventilation hose with the 2 hose clamps.

| 22. INSTALL ENGINE WIRE |

Connect all the wire harnesses and connectors.

Install the 2 ground bolts.

- Torque:

- 8.4 N*m{85 kgf*cm, 74 in.*lbf}

| 23. INSTALL NO. 1 IGNITION COIL |

Disconnect the 4 No. 1 ignition coil connectors.

|

Remove the 4 bolts and the 4 No. 1 ignition coils.

|

| 24. INSTALL FRONT SUSPENSION CROSSMEMBER SUB-ASSEMBLY |

Install the engine moving control rod with the through bolt.

- Torque:

- 120 N*m{1244 kgf*cm, 89 ft.*lbf}

| 25. REMOVE NO. 1 ENGINE HANGER |

Remove the 2 bolts and the No. 1 engine hanger.

| 26. INSTALL ENGINE ASSEMBLY WITH TRANSAXLE |

Place wooden blocks or plate lift attachments on an engine lifter, and then set the engine assembly with transaxle.

- NOTICE:

- Place the wooden blocks or plate lift attachments so that the engine assembly with transaxle is level.

- As the engine assembly with transaxle is very heavy, be sure to support it securely.

Operate the engine lifter and lift the engine assembly with transaxle and the front suspension crossmember to the position where the engine mounting insulators RH and LH can be installed.

Install the engine mounting insulator LH with the through bolt and nut.

- Torque:

- 52 N*m{530 kgf*cm, 38 ft.*lbf}

- HINT:

- Tighten by holding the nut and turning the bolt.

Install the engine mounting insulator RH with the bolt and 2 nuts.

- Torque:

- 52 N*m{530 kgf*cm, 38 ft.*lbf}

By inserting SST into the datum holes in the front suspension crossmember RH and LH alternately, tighten bolts A, B and C on both sides to the specified torque, in several steps.

Text in Illustration *a Datum Hole *b OK *c NG - -

Front of the Vehicle - - - SST

- 09670-00010

- Torque:

- Bolt A:

- 87 N*m{887 kgf*cm, 64 ft.*lbf}

- Bolt B:

- 151 N*m{1540 kgf*cm, 111 ft.*lbf}

- Bolt C:

- 98 N*m{999 kgf*cm, 72 ft.*lbf}

- NOTICE:

- Insert SST into the datum hole vertically.

- If impossible to insert SST vertically, loosen all bolts and then insert SST again.

| 27. INSTALL NO. 1 STEERING COLUMN HOLE COVER SUB-ASSEMBLY |

Install clip B onto the body portion and install the No. 1 steering column hole cover onto the body portion with clip A.

- NOTICE:

- Make sure that the lip portion of steering column hole cover is not damaged.

| 28. INSTALL STEERING SLIDING YOKE SUB-ASSEMBLY |

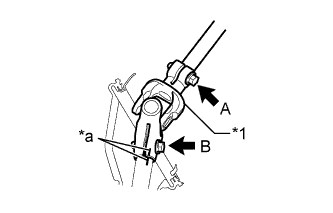

Align the matchmarks and install the steering sliding yoke sub-assembly onto the manual steering gear.

Text in Illustration *1 Steering Sliding Yoke Sub-assembly *a Matchmarks

|

Install the bolt B.

- Torque:

- 35 N*m{360 kgf*cm, 26 ft.*lbf}

Tighten bolt A.

- Torque:

- 35 N*m{360 kgf*cm, 26 ft.*lbf}

| 29. INSTALL COLUMN HOLE COVER SILENCER SHEET |

Install the column hole cover silencer sheet with the 2 clips.

Install the floor carpet.

| 30. INSTALL TORQUE CONVERTER SETTING BOLT (for Automatic Transaxle) |

Remove any adhesive remaining in the 6 bolt holes of the torque converter clutch and 6 bolts.

|

Apply adhesive to 2 or 3 threads on the end of the 6 bolts.

- Adhesive:

- Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

Install the 6 torque converter set bolts while holding the crankshaft pulley bolt with a wrench.

- Torque:

- 28 N*m{286 kgf*cm, 21 ft.*lbf}

| 31. INSTALL FLYWHEEL HOUSING UNDER COVER |

Install the flywheel housing under cover.

| 32. INSTALL FRONT DRIVE SHAFT ASSEMBLY |

| 33. INSTALL EXHAUST PIPE GASKET |

Using a plastic hammer and a wooden block, tap in a new exhaust pipe gasket until its surface is flush with the exhaust manifold.

Text in Illustration *1 Exhaust Pipe Gasket *2 Wooden Block *3 Plastic Hammer *4 Exhaust Manifold - NOTICE:

- Install the gasket in the correct direction.

- Do not reuse the gasket.

- Do not damage the gasket by dropping it, etc.

- Do not damage the outer surface of the gasket.

- Do not push in the gasket with the exhaust pipe when connecting it.

|

| 34. INSTALL NO. 2 EXHAUST PIPE GASKET |

Using a plastic hammer and a wooden block, tap in a new No. 2 exhaust pipe gasket until its surface is flush with the front exhaust pipe assembly.

Text in Illustration *1 No. 2 Exhaust Pipe Gasket *2 Wooden Block *3 Plastic Hammer *4 Front Exhaust Pipe Assembly - NOTICE:

- Install the gasket in the correct direction.

- Do not reuse the gasket.

- Do not damage the gasket by dropping it, etc.

- Do not damage the outer surface of the gasket.

- Do not push in the gasket with the exhaust pipe when connecting it.

|

| 35. INSTALL FRONT EXHAUST PIPE ASSEMBLY |

Using a vernier caliper, measure the free length of the compression spring.

- Minimum Length:

- 41.5 mm (1.634 in.)

- HINT:

- If the length is not as specified, replace the compression spring.

|

Hang the front exhaust pipe assembly with the 3 exhaust pipe supports.

Install the front exhaust pipe assembly onto the exhaust manifold with the 2 compression springs and 2 bolts.

Text in Illustration *1 Exhaust Manifold *2 Front Exhaust Pipe Assembly *3 Exhaust Pipe Gasket *a Space between flanges: 8.5 mm (0.335 in.) - Torque:

- 43 N*m{438 kgf*cm, 32 ft.*lbf}

- HINT:

- After the installation, check that the gaps between the flanges of the exhaust manifold and front exhaust pipe assembly are consistent front-to-rear and left-to-right.

|

Using a vernier caliper, measure the free length of the compression spring.

- Minimum Length:

- 38.5 mm (1.516 in.)

- HINT:

- If the length is not as specified, replace the compression spring.

|

Connect the tail exhaust pipe assembly to the front exhaust pipe assembly with the 2 compression springs and 2 bolts.

Text in Illustration *1 Front Exhaust Pipe Assembly *2 Tail Exhaust Pipe Assembly *3 No. 2 Exhaust Pipe Gasket *a Space between flanges: 6.5 mm (0.256 in.) - Torque:

- 43 N*m{438 kgf*cm, 32 ft.*lbf}

- HINT:

- After the installation, check that the gaps between the flanges of the front exhaust pipe assembly and tail exhaust pipe assembly are consistent front-to-rear and left-to-right.

|

Pass the connector through the hole into the inside of the vehicle and install the oxygen sensor wire grommet.

Connect the oxygen sensor connector.

| 36. INSTALL FRONT FLOOR CENTER BRACE |

Install the front floor center brace onto the body with the 2 bolts.

- Torque:

- 30 N*m{307 kgf*cm, 22 ft.*lbf}

| 37. INSTALL REAR CONSOLE BOX ASSEMBLY |

| 38. INSTALL TRANSMISSION CONTROL CABLE ASSEMBLY (for Automatic Transaxle) |

Connect the transmission control cable assembly to the control shaft lever with the nut.

- Torque:

- 12 N*m{122 kgf*cm, 9 ft.*lbf}

Text in Illustration *1 No. 1 Transmission Control Cable Bracket *2 Clip *a Marking

|

Install the transmission control cable assembly to the No. 1 transmission control cable bracket with a new clip.

- NOTICE:

- Make sure that the marking on the cable is aligned with the slit in the No. 1 transmission control cable bracket before installing the cable.

Install the transmission control cable assembly to the control cable support.

Install the transmission control cable assembly with the 3 nuts.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

| 39. INSTALL TRANSMISSION CONTROL CABLE ASSEMBLY (for Manual Transaxle) |

Connect the 2 transmission control cable ends and install the 2 washers and the 2 clips.

Install 2 new clips onto the control cable bracket.

| 40. CONNECT ENGINE WIRE |

for Automatic Transaxle:

Engage the clamp and connect the wire harness to the automatic transaxle.

Install the wire harness to the automatic transaxle with the bolt.

- Torque:

- 26 N*m{260 kgf*cm, 19 ft.*lbf}

Connect the 2 connectors to the battery positive terminal.

Engage the 2 claws and connect the wire harness to the engine room relay block.

Connect the connector to the engine room relay block.

Engage the clamp and connect the wire harness to the body.

Pull down the lever to engage the lock and connect the connector to the ECM.

Engage the clamp and connect the wire harness to the wire harness bracket.

Connect all the wire harness and connectors.

| 41. INSTALL COMPRESSOR WITH PULLEY ASSEMBLY (w/ Air Conditioning System) |

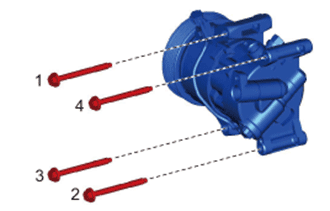

Install the compressor with the 4 bolts.

- HINT:

- Tighten the bolts in the order shown in the illustration.

- Torque:

- 25 N*m{250 kgf*cm, 18 ft.*lbf}

|

Connect the connector.

| 42. INSTALL FAN AND GENERATOR V BELT |

Provisionally install the fan and generator V belt onto each pulley.

- NOTICE:

- Make sure that there is no foreign matter or liquid, such as oil, on the belt and pulleys.

- Make sure that the V belt is securely fitted into the rib grooves of the pulley.

| 43. ADJUST FAN AND GENERATOR V BELT |

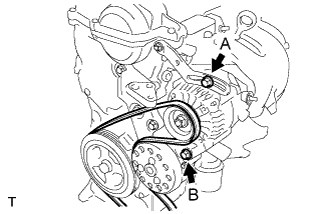

Insert an adjusting bar between the engine mounting bracket and generator assembly. Pull the adjusting bar toward the vehicle front to adjust the generator V belt tension.

Text in Illustration *a OK *b NG

Front of Vehicle - NOTICE:

- Do not insert the adjusting bar between the camshaft timing oil control valve assembly and generator assembly. It could damage the camshaft timing oil control valve assembly.

|

First tighten bolt A, then tighten bolt B.

- Torque:

- 19 N*m{189 kgf*cm, 14 ft.*lbf} for bolt A

- 54 N*m{551 kgf*cm, 40 ft.*lbf} for bolt B

|

| 44. INSTALL CLUTCH RELEASE CYLINDER ASSEMBLY (for Manual Transaxle) |

Install the clutch release cylinder assembly and clutch pipe with the 4 bolts.

- Torque:

- 12 N*m{120 kgf*cm, 9 ft.*lbf}

| 45. CONNECT INLET OIL COOLER HOSE (for Automatic Transaxle) |

Connect the oil cooler inlet hose with the clip.

| 46. CONNECT OUTLET OIL COOLER HOSE (for Automatic Transaxle) |

Connect the oil cooler outlet hose with the clip.

| 47. CONNECT INLET HEATER WATER HOSE A |

Connect inlet heater water hose A to the heater unit with the hose clamp.

| 48. CONNECT OUTLET HEATER WATER HOSE A |

Connect outlet heater water hose A to the heater unit with the hose clamp.

| 49. CONNECT UNION TO CHECK VALVE HOSE |

Connect the union to check valve hose to the booster vacuum tube with the hose clamp.

| 50. CONNECT FUEL TUBE SUB-ASSEMBLY |

Connect the fuel tube connector and fuel pipe.

- CAUTION:

- Align the fuel tube connector with the pipe, then push the fuel tube connector in until the retainer makes a click sound. If the connection is tight, apply a small amount of engine oil to the tip of the pipe. After connecting, pull the pipe and connector to make sure that they are securely connected.

| 51. INSTALL EFI FUEL PIPE CLAMP |

Install the EFI fuel pipe clamp.

| 52. CONNECT NO. 2 RADIATOR HOSE |

Connect the No. 2 radiator hose to the water inlet with the hose clamp.

| 53. CONNECT NO. 3 RADIATOR HOSE |

Connect No. 3 radiator hose to the water filler with the hose clamp.

| 54. CONNECT RADIATOR RESERVOIR TANK HOSE |

Connect the radiator reservoir tank hose to the water filler.

| 55. INSTALL FUEL VAPOR FEED HOSE ASSEMBLY |

Install fuel vapor feed hose assembly with the 2 hose clamps.

| 56. INSTALL BATTERY CARRIER |

Install the battery carrier with the 5 bolts.

- Torque:

- 17 N*m{173 kgf*cm, 13 ft.*lbf}

Engage the 6 clamps and connect the wire harness to the battery carrier.

| 57. INSTALL AIR CLEANER BRACKET |

Install the air cleaner bracket with the 2 bolts.

- Torque:

- 20 N*m{199 kgf*cm, 14 ft.*lbf}

Engage the clamp and connect the wire harness to the air cleaner bracket.

| 58. INSTALL AIR CLEANER ASSEMBLY |

Install the air cleaner case onto the air cleaner bracket with the 2 bolts.

- Torque:

- 7.8 N*m{80 kgf*cm, 69 in.*lbf}

Engage the clamp and connect the wire harness to the air cleaner case.

Install the air cleaner element onto the air cleaner case.

Install the air cleaner cap sub-assembly with No. 1 air cleaner hose onto the throttle body assembly

Engage the 2 clamps and connect the air cleaner cap sub-assembly to the air cleaner case sub-assembly.

Tighten the hose clamp.

- Torque:

- 3.0 N*m{31 kgf*cm, 27 in.*lbf}

Connect the vacuum switching valve assembly connector.

Connect the mass air flow meter connector.

Engage the 2 clamps and connect the wire harness to the air cleaner cap sub-assembly and vacuum switching valve assembly.

Connect the No. 2 fuel vapor feed hose to the intake manifold.

Connect the fuel vapor feed hose assembly to the No. 1 air cleaner hose and vacuum switching valve assembly with the 2 hose clamps.

Engage the clamp and connect the fuel vapor feed hose assembly to the No. 1 air cleaner hose.

| 59. INSTALL BATTERY TRAY |

| 60. INSTALL BATTERY |

Install the battery onto the battery tray with the battery clamp.

- Torque:

- 3.5 N*m{36 kgf*cm, 31 in.*lbf}

Connect the cable to the battery terminal.

- Torque:

- 5.4 N*m{55 kgf*cm, 48 in.*lbf}

| 61. INSTALL OUTER COWL TOP PANEL |

Install the outer cowl top panel with the 8 bolts.

- Torque:

- 7.0 N*m{71 kgf*cm, 62 in.*lbf}

Engage the 2 clamps and install the wire harness.

| 62. INSTALL INNER COWL TOP TO COWL BRACE |

Install the cowl top to cowl brace with the 2 bolts.

- Torque:

- 7.0 N*m{71 kgf*cm, 62 in.*lbf}

| 63. INSTALL FRONT NO. 1 VENTILATOR SEAL |

Engage the clip and install the front No. 1 ventilator seal.

| 64. INSTALL FRONT AIR SHUTTER SEAL RH |

- HINT:

- Use the same procedure for the RH and LH sides.

| 65. INSTALL WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY |

| 66. INSTALL FRONT WHEELS |

- Torque:

- 103 N*m{1050 kgf*cm, 76 ft.*lbf}

| 67. ADD ENGINE COOLANT |

Tighten all the plugs.

Pour engine coolant into the radiator assembly until it overflows.

- Capacity:

- M/T 4.8 liters (5.1 USqts, 4.5 lmp. qts)

- A/T 4.7 liters (5.0 USqts, 4.4 lmp. qts)

- NOTICE:

- Do not substitute water for engine coolant.

- HINT:

- Use of improper engine coolant may damage the engine coolant system.

- Use only Toyota Super Long Life Coolant or similar high quality ethylene glycol based non-silicate, non-amine, non-nitrite, and non-borate engine coolant with long-life hybrid organic acid technology (coolant with long-life hybrid organic acid technology consists of a combination of low phosphates and organic acids).

Check the engine coolant level inside the radiator assembly by squeezing the inlet and outlet radiator hoses several times by hand. If the engine coolant level goes down, add engine coolant.

Install the radiator cap sub-assembly securely.

Slowly pour engine coolant into the radiator reservoir until it reaches the FULL line.

Bleed air from the cooling system.

Warm up the engine until the thermostat opens. While the thermostat is open, circulate the coolant for several minutes.

- HINT:

- The thermostat open timing can be confirmed by pressing the No. 2 radiator hose by hand, and checking when when the coolant starts to flow inside the hose.

Maintain the engine speed at 2,000 to 2,500 rpm and warm up the engine until the cooling fan operates.

Press the No. 2 radiator hose and No. 3 radiator hose several times by hand to bleed air.

- NOTICE:

- When pressing the radiator houses

- Wear protective glove.

- Be careful as the radiator hoses are hot.

- Keep your hands away form the radiator fan.

Stop the engine and wait until the coolant cools down.

If the engine coolant level is below the full level, perform steps (b) through (g) again and repeat the operation until the engine coolant level stays at the full level.

Recheck the engine coolant level inside the radiator reservoir tank assembly. If it is below the full level, add engine coolant.

| 68. INSPECT ENGINE OIL LEVEL |

Warm up and stop the engine, and then wait for 5 minutes.

Check that the engine oil level is between the low level and full level marks on the engine oil level dipstick.

If low, check for leakage and add oil up to the full level mark.- NOTICE:

- Do not fill with engine oil above the full level mark.

| 69. ADD AUTOMATIC TRANSAXLE FLUID (for Automatic Transaxle) |

- Automatic Transaxle Fluid:

Classification Capacity

(Reference)Toyota Genuine ATF WS Dry fill 6.4 liters (6.8 US qts, 5.6 Imp. qts) Drain and refill 2.5 liters (2.6 US qts, 2.2 Imp. qts)

| 70. INSPECT AUTOMATIC TRANSAXLE FLUID (for Automatic Transaxle) |

|

- HINT:

- Drive the vehicle until the engine and transaxle are at normal operating temperature.

- Fluid temperature:

- 70 to 80 °C (158 to 176 °F)

| *a | OK if hot |

| *b | Add if hot |

Park the vehicle on a level surface and engage the parking brake.

With the engine idling and the brake pedal depressed, shift the shift lever into all positions from P to L, and then return it to the P.

Pull out the oil level dipstick and wipe it clean.

Push it fully back into the pipe.

Pull it out and check that the fluid level is within the HOT range.

If there is any leakage, repair or replace O-rings, seal packing, oil seals, plugs or other parts.

| 71. ADD MANUAL TRANSAXLE OIL (for Manual Transaxle) |

Add manual transmission oil until the oil level is within 5 mm (0.197 in.) from the bottom of the manual transmission filler plug opening.

Text in Illustration *a 0 to 5 mm (0 to 0.197 in.) - Standard capacity (Reference):

- 1.9 liters (2.0 US qts, 1.7 Imp. qts)

- Gear oil type:

- Toyota Genuine Manual Transmission Gear Oil "LV GL-3 and SAE 75W-90" or "API GL-4 and SAE 75W"

|

Check for oil leakage when the oil level is low.

Install the transmission filler plug and a new gasket.

- Torque:

- 39 N*m{400 kgf*cm, 29 ft.*lbf}

| 72. INSPECT MANUAL TRANSAXLE OIL (for Manual Transaxle) |

|

| *a | 0 to 5 mm (0 to 0.197 in.) |

Stop the vehicle in a level place.

Remove the manual transmission filler plug and the gasket.

Check that the oil surface is within 5 mm (0.197 in.) of the bottom of the manual transmission filler plug opening.

- NOTICE:

- Excessively large or small amounts of oil may cause problems.

- After replacing the oil, drive the vehicle and check the oil level again.

Check for oil leakage when the oil level is low.

Install the manual transmission filler plug and a new gasket.

- Torque:

- 39 N*m{400 kgf*cm, 29 ft.*lbf}

| 73. INSPECT FOR FUEL LEAK |

Check fuel pump operation.

Connect the Techstream to the DLC3.

Turn the ignition switch to ON and turn the Techstream main switch on.

- NOTICE:

- Do not start the engine.

Enter the following menus: Powertrain / Engine and ECT / Active Test / Control the Fuel Pump /Speed.

Check for pressure in the fuel inlet tube from the fuel line. Check that sounds of fuel flowing from the fuel tank can be heard. If no sounds can be heard, check the integration relay, fuel pump, ECM and wiring connectors.

Inspect for fuel leaks.

Check for fuel leaks from the fuel system after doing any maintenance or repairs. If there is a fuel leak, repair or replace parts if necessary.

Turn the ignition switch off.

Disconnect the Techstream from the DLC3.

| 74. INSPECT FOR COOLANT LEAK |

- CAUTION:

- To avoid the danger of being burned, do not remove the water filler cap sub-assembly while the engine and radiator assembly are still hot. Thermal expansion will cause hot engine coolant and steam to blow out from the radiator assembly.

Fill the radiator assembly with engine coolant, and attach a radiator cap tester.

|

Pump the tester to 118 kPa (1.2 kgf/cm2, 17.1 psi), and then check that the pressure does not drop.

If the pressure drops, check the hoses, radiator assembly and water pump assembly for leaks. If there are no signs or traces of external engine coolant leaks, check the heater core, cylinder block and head.

| 75. INSPECT FOR ENGINE OIL LEAK |

| 76. INSPECT FOR AUTOMATIC TRANSAXLE FLUID LEAK (for Automatic Transaxle) |

| 77. INSPECT FOR MANUAL TRANSAXLE OIL LEAK (for Manual Transaxle) |

| 78. INSPECT FOR EXHAUST GAS LEAK |

- HINT:

- Perform "Inspection After Repairs" after repairing or replacing the exhaust system (YARIS_NCP93 RM000004NJD006X.html).

| 79. INSPECT FAN AND GENERATOR V BELT |

|

Check the fan and generator V belt for wear, cracks or other signs of damage.

If any of the following defects is found, replace the fan and generator V belt.- The fan and generator V belt is cracked.

- The fan and generator V belt is worn out to the extent that the cords are exposed.

- The fan and generator V belt has chunks missing from the ribs.

- The fan and generator V belt is cracked.

Check that the fan and generator V belt fits properly in the ribbed grooves.

Text in Illustration *a Correct *b Incorrect - HINT:

- Check with your hand to confirm that the fan and generator V belt has not slipped out of the grooves on the bottom of the pulley. If it has slipped out, replace the fan and generator V belt. Install a new fan and generator V belt correctly.

|

Inspect the V belt deflection and tension.

Text in Illustration *A w/o Air Conditioner *B w/ Air Conditioner - Deflection:

Item Specified Condition New belt 8.0 to 9.0 mm (0.31 to 0.35 in) Used belt 12.5 to 13.5 mm (0.49 to 0.53 in)

- Tension:

Item Specified Condition New belt 700 to 800 N (71 to 82 kg, 157 to 180 lb) Used belt 300 to 400 N (31 to 41 kg, 67 to 90 lb)

- HINT:

- When inspecting the V belt deflection, apply 98 N (10 kgf) tensile force to it.

- Perform the V belt inspection and adjustment while the engine is cold.

- V-ribbed belt tension and deflection should be checked immediately after installation of a new belt, and after cranking the engine when inspecting a used belt.

- Check the V belt deflection at the point between the specified pulleys where the deflection is greatest.

- When installing a new belt, set its tension to the intermediate value of the specification.

- When inspecting a belt which has been used for over 5 minutes, apply the Used Belt specifications.

- When reinstalling a belt which has been used for over 5 minutes, adjust its deflection and tension to the intermediate values of each Used Belt specification.

- V-ribbed belt tension and deflection should be checked after 2 revolutions of engine cranking.

- When using a belt tension gauge, confirm its accuracy by using a master gauge first.

|

| 80. INSPECT IGNITION TIMING |

When using an Techstream:

Warm up and stop the engine.

Connect the Techstream to the DLC3.

Turn the ignition switch to ON.

Turn the Techstream on.

Start the engine.

Enter the following menus: Powertrain / Engine and ECT / Active Test /Connect the TC and TE1 / ON.

- HINT:

- Refer to the Techstream operator's manual for further details.

Inspect the ignition timing during idling.

- Standard ignition timing:

Transaxle Ignition Timing Manual Transaxle 8 to 12 degrees BTDC Automatic Transaxle

- NOTICE:

- Check the ignition timing with the cooling fans off..

- Turn off all electrical systems and the A/C.

- When checking the ignition timing, the transaxle should be in neutral or park.

- HINT:

- Refer to the Techstream operator's manual for further details.

Select the following menu items: Connect the TC and TE1 / OFF.

Turn the ignition switch off.

Disconnect the Techstream from the DLC3.

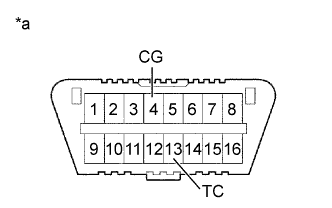

When not using an Techstream:

Using SST, connect terminals 13 (TC) and 4 (CG) of the DLC3.

Text in Illustration *a Front view of DLC3 - SST

- 09843-18040

- NOTICE:

- Be sure to connect the terminals correctly. Failure to do this can damage the engine.

- Check the ignition timing with the cooling fans off.

- Turn off all electrical systems and the A/C.

- When checking the ignition timing, the transaxle should be in neutral or park.

Remove the No. 2 cylinder head cover (YARIS_NCP93 RM000003VHK00GX_01_0007.html).

Pull out the wire harness (brown) shown in the illustration.

- NOTICE:

- After checking, wrap the wire harness with tape.

Warm up and stop the engine.

Connect the clip of the timing light to the wire harness.

- NOTICE:

- Use a timing light that detects the first signal.

Start the engine.

Inspect the ignition timing during idling.

- Standard ignition timing:

Transaxle Ignition Timing Manual Transaxle 8 to 12 degrees BTDC Automatic Transaxle

- NOTICE:

- Turn all the electrical systems and the A/C off.

- Inspect the ignition timing with the cooling fan off.

- When checking the ignition timing, shift the transaxle to the neutral position.

Turn the ignition switch off.

Remove the timing light.

Install the No. 2 cylinder head cover (YARIS_NCP93 RM000003VHI00GX_01_0008.html).

Disconnect terminals 13 (TC) and 4 (CG) of the DLC3.

| 81. INSPECT ENGINE IDLING SPEED |

When using an Techstream:

Warm up and stop the engine.

Connect the Techstream to the DLC3.

Turn the ignition switch to ON and turn the Techstream on.

Start the engine.

Select the following menu items: Powertrain / Engine and ECT / Data List / Engine Speed.

- HINT:

- Refer to the Techstream operator's manual for further details.

Inspect the engine idling speed.

- Standard Idle Speed:

Transaxle Idling Speed Manual Transaxle 550 to 650 rpm Automatic Transaxle 650 to 750 rpm

- NOTICE:

- Turn all the electrical systems and the A/C off.

- Inspect the idling speed with the cooling fan off.

- When checking the idling speed, shift the transaxle to the neutral position or the parking position.

Turn the ignition switch off.

Disconnect the Techstream from the DLC3.

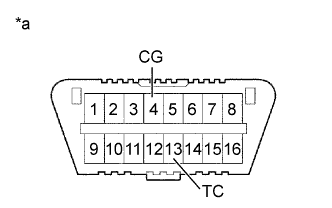

When not using an Techstream.

Warm up and stop the engine.

Install SST to terminals 13 (TC) and 4 (CG) of the DLC3.

Text in Illustration *a Front view of DLC3 - SST

- 09843-18040

- NOTICE:

- Examine the terminal numbers before connecting them. Connecting the wrong terminals can damage the engine.

Start the engine.

Inspect the engine idling speed.

- Standard Idle Speed:

Transaxle Idling Speed Manual Transaxle 600 to 700 rpm Automatic Transaxle 650 to 750 rpm

- NOTICE:

- Turn all the electrical systems and the A/C off.

- Inspect the idling speed with the cooling fan off.

- When checking the idling speed, shift the transaxle to the neutral position or the parking position.

Turn the ignition switch off.

Disconnect the tachometer.

Remove SST from terminals 13 (TC) and 4 (CG) of the DLC3.

| 82. INSPECT CO/HC |

Start the engine.

Run the engine at 2500 rpm for approximately 180 seconds.

Insert the CO/HC meter testing probe at least 40 cm (1.3 ft) into the tailpipe while idling.

Check the CO/HC concentration during idling and when running at 2500 rpm.

- HINT:

- When doing the 2 mode (with the engine idling/running at 2500 rpm) test, the measuring procedures are determined by applicable local regulations.

Check the air fuel ratio sensor operation (YARIS_NCP93 RM000000SXS05AX.html).

Check the heated oxygen sensor operation (YARIS_NCP93 RM000000SXS05AX.html).

See the table below for possible causes, then inspect the applicable parts and repair them if necessary.

CO HC Problems Possible Causes Normal High Rough idling - Faulty ignition:

- Incorrect timing

- Fouled, shorted or improperly gapped plugs

- Incorrect valve clearance

- Leakage from intake and exhaust valves

- Leakage from cylinders

Low High Rough idling

(Fluctuating HC reading)- Vacuum leaks:

- PCV hoses

- Intake manifold

- Throttle body

- Brake booster line

- Lean mixture causing misfire

High High Rough idling

(Black smoke from exhaust)- Restricted air cleaner filter element

- Plugged PCV valve

- Faulty EFI systems:

- Faulty pressure regulator

- Faulty engine coolant temperature sensor

- Faulty mass air flow meter

- Faulty ECM

- Faulty injectors

- Throttle body

- Faulty ignition:

| 83. INSPECT AND ADJUST FRONT WHEEL ALIGNMENT |

| 84. INSTALL ENGINE UNDER COVER RH |

| 85. INSTALL ENGINE UNDER COVER LH |

| 86. INSTALL NO. 2 CYLINDER HEAD COVER |

Install the No. 2 cylinder head cover with the 4 nuts.

- Torque:

- 7.0 N*m{71 kgf*cm, 62 in.*lbf}

| 87. INSPECT ABS SENSOR SIGNAL (w/o VSC) |

| 88. INSPECT VSC SPEED SENSOR SIGNAL (w/ VSC) |