Cylinder Head Gasket (For Hatchback) -- Installation |

| 1. INSPECT CYLINDER HEAD SET BOLT |

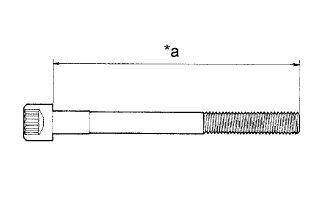

Using a vernier caliper, measure the length of the cylinder head set bolt from the seat to the end.

Text in Illustration *a Measurement Length - Standard length:

- 142.8 to 144.2 mm (5.6220 5.6772 in.)

- Maximum length:

- 147.1 mm (5.7913 in.)

|

| 2. INSTALL CYLINDER HEAD GASKET |

|

Place a new cylinder head gasket on the cylinder block with the Lot No. stamp facing upward.

Text in Illustration *a Lot No. - NOTICE:

- Remove any oil from the contact surfaces.

- Check the mounting orientation of the cylinder head gasket.

- Place the cylinder head on the cylinder head gently in order not to damage the gasket.

| 3. INSTALL CYLINDER HEAD SUB-ASSEMBLY |

- HINT:

- The cylinder head bolts are tightened in 2 successive steps.

- Perform "Inspection After Repairs" after replacing the cylinder head (YARIS_NCP93 RM000004NJD006X.html).

Apply a light coat of engine oil to the threads of the cylinder head bolts.

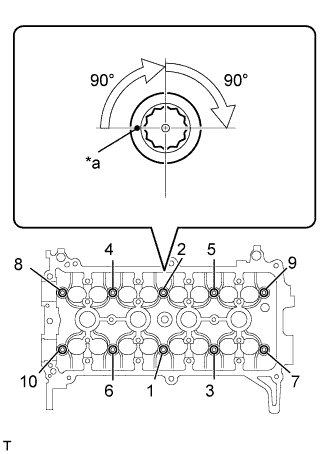

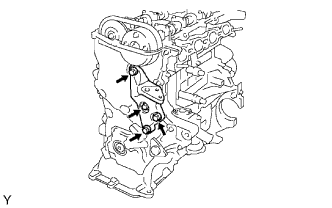

Using several steps, install and tighten the 10 cylinder head bolts and plate washers uniformly with an 8 mm bi-hexagon wrench, in the sequence shown in the illustration.

- Torque:

- 29 N*m{300 kgf*cm, 22 ft.*lbf}

|

Mark the front of the cylinder head bolt with paint.

Retighten the cylinder head bolts 90° and then an additional by 90° as shown in the illustration.

Text in Illustration *a Paint Mark

|

Check that the paint mark is now at a 180° angle from the front.

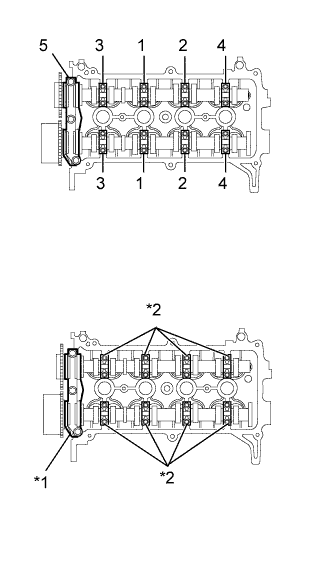

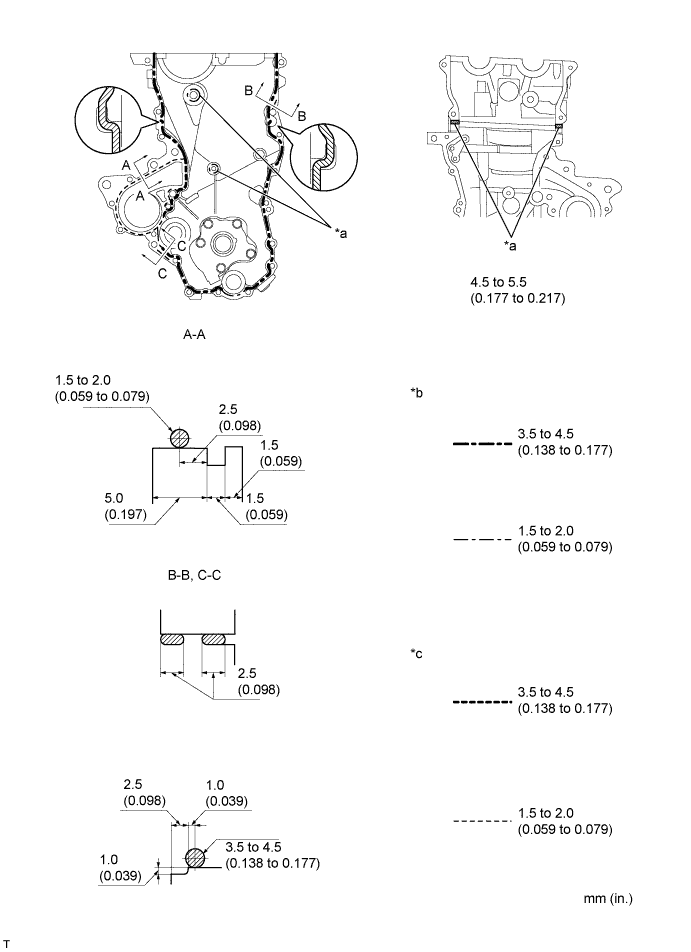

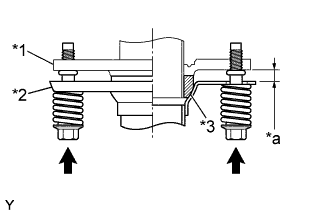

Apply a continuous bead of seal packing (Diameter 4.5 to 5.5 mm (0.177 to 0.217 in.)) as shown in the illustration.

- Seal Packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or Equivalent

Text in Illustration *1 Cylinder Head *2 Cylinder Head Gasket *3 Cylinder Block *a Seal Packing *b Diameter: 4.5 to 5.5 mm - NOTICE:

- Remove any oil from the contact surfaces.

- Install the oil pump assembly within 3 minutes and tighten the bolts within 15 minutes of applying the seal packing.

|

| 4. INSTALL CAMSHAFT |

|

- HINT:

- Perform "Inspection After Repairs" after replacing the camshaft (YARIS_NCP93 RM000004NJD006X.html).

- Perform "Inspection After Repairs" after replacing the camshaft timing gear assembly (YARIS_NCP93 RM000004NJD006X.html).

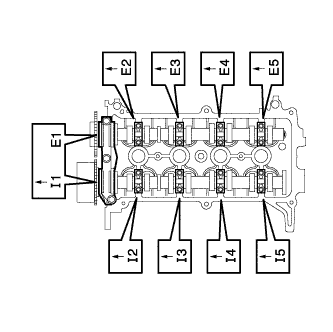

Examine the front marks and numbers and check that the sequence is as shown in the illustration. Then provisionally tighten the 19 bolts.

Uniformly tighten the bolts in several steps in the sequence shown in the illustration and install No. 1 camshaft bearing cap and No. 2 camshaft bearing cap.

Text in Illustration *1 No. 1 Bearing Cap *2 No. 2 Bearing Cap - Torque:

- No. 1 Camshaft bearing cap:

- 23 N*m{235 kgf*cm, 17 ft.*lbf}

- No. 2 Camshaft bearing cap:

- 13 N*m{129 kgf*cm, 9 ft.*lbf}

- NOTICE:

- Tighten each bolt uniformly while keeping the camshaft level.

|

| 5. INSTALL CHAIN SUB-ASSEMBLY |

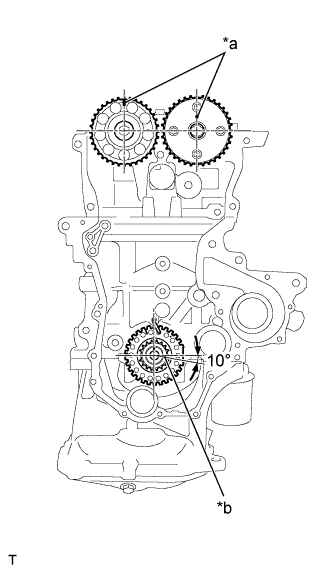

Make sure that all the timing marks are in the positions (TDC) shown in the illustration.

Text in Illustration *a Timing Marks *b Timing Mark - HINT:

- The positions of the timing marks may differ the predetermined positions due to the force of the valve spring.

|

Set the timing mark of the crankshaft in a position between 40 and 140° ATDC, as illustrated.

Text in Illustration *a Timing Mark *b 40° to 140° ATDC

|

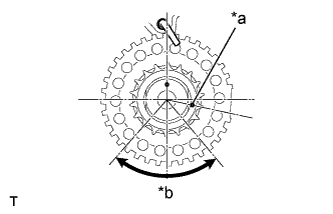

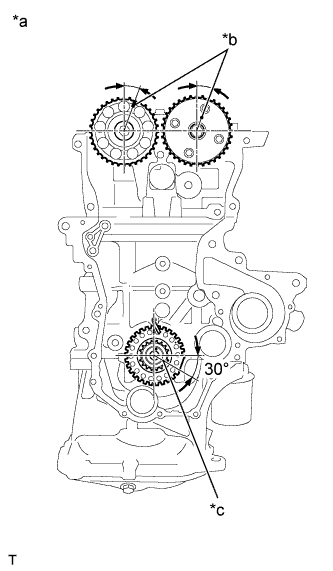

Set the camshaft timing gear and the camshaft timing sprocket in the positions (20° ATDC) shown in the illustration.

Text in Illustration *a 20° ATDC *b Timing Mark *c Timing Marks

|

Set the crankshaft in the position (20° ATDC) shown in the illustration.

Align the timing marks of the camshaft with the mark plates of the timing chain and install the timing chain.

Text in Illustration *a Mark Plates *b Timing Marks *c Mark Plate *d Timing Mark - HINT:

- Align the timing marks with the mark plates while turning the hexagonal service portion of the camshaft using a wrench.

|

| 6. INSTALL CHAIN TENSIONER SLIPPER |

Install the chain tensioner slipper.

|

| 7. INSTALL NO. 1 CHAIN TENSIONER ASSEMBLY |

Install the No. 1 chain tensioner assembly with the 2 bolts.

- Torque:

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}

|

Remove the bar from the No. 1 chain tensioner assembly.

| 8. INSTALL OIL PUMP SEAL |

|

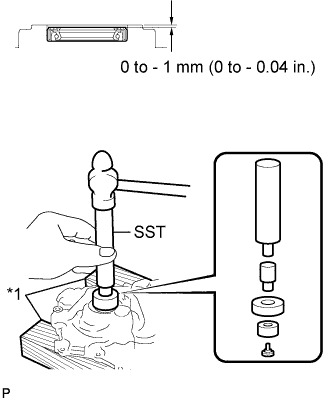

Using SST and a hammer, tap in a new oil seal until its surface is flush with the timing chain cover.

Text in Illustration *1 Splinter of Wood - SST

- 09950-60010(09951-00250,09951-00410,09952-06010)

09950-70010(09951-07100)

- NOTICE:

- Do not tap the oil seal at an angle.

Apply a light coat of MP grease to the oil pump seal lip.

- NOTICE:

- Keep the lip free of foreign matter.

| 9. INSTALL OIL PUMP ASSEMBLY |

|

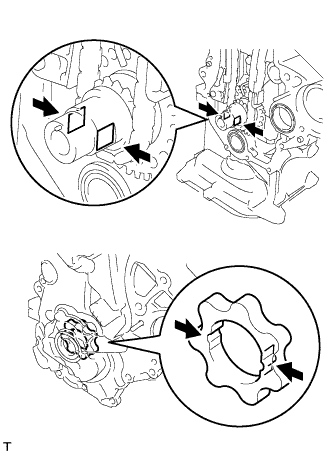

Install 2 new O-rings onto the 2 locations as shown in the illustration.

Apply seal packing to the oil pump assembly, cylinder head and cylinder block as shown in the illustration.

Text in Illustration *a Seal Packing *b Seal Width (Other Part) *c Seal Width (Water Pump Part) - - - Seal packing:

- Water pump part Toyota Genuine Seal Packing 1282B, Three Bond 1282B or equivalent

- Other part Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- NOTICE:

- Remove any oil from the contact surfaces.

- Install the oil pump assembly within 3 minutes and tighten the bolts and nut within 15 minutes of applying seal packing.

- Do not expose the seal to engine oil for at least 2 hours after the installation.

Align the keyway of the oil pump rotor with the rectangular portion of the crankshaft, and slide the oil pump into place.

|

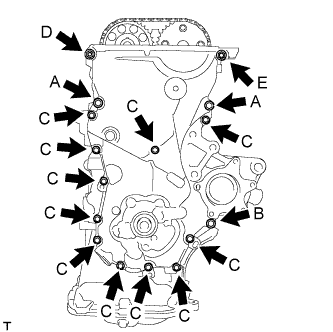

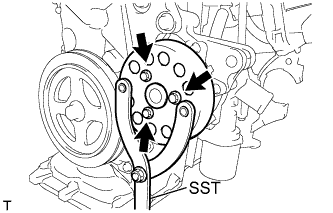

Install the oil pump assembly with the 15 bolts and the nut. Tighten the bolts and nut uniformly in several steps.

- Torque:

- bolt A:

- 32 N*m{326 kgf*cm, 24 ft.*lbf}

- bolt B:

- 11 N*m{112 kgf*cm, 8 ft.*lbf}

- bolt C:

- 11 N*m{112 kgf*cm, 8 ft.*lbf}

- nut D:

- 24 N*m{245 kgf*cm, 18 ft.*lbf}

- bolt E:

- 24 N*m{245 kgf*cm, 18 ft.*lbf}

- NOTICE:

- After installing the oil pump assembly, install the mounting bracket and water pump within 15 minutes.

- HINT:

- Each bolt length is as follows.

- A: 30 mm (1.181 in.)

- B: 35 mm (1.378 in.)

- C: 20 mm (0.787 in.)

- E: 14 to 20 mm (0.551 to 0.787 in.), Double ended bolt

|

| 10. INSTALL ENGINE WATER PUMP ASSEMBLY |

Install the engine water pump and a new gasket with the 3 bolts and 2 nuts.

- Torque:

- 11 N*m{112 kgf*cm, 8 ft.*lbf}

|

| 11. INSTALL TRANSVERSE ENGINE ENGINE MOUNTING BRACKET |

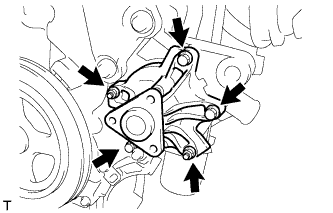

Install the transverse engine engine mounting bracket with the 4 bolts.

- Torque:

- 55 N*m{561 kgf*cm, 41 ft.*lbf}

|

| 12. INSTALL WATER PUMP PULLEY |

Using SST, install the water pump pulley with the 3 bolts.

- Torque:

- 15 N*m{153 kgf*cm, 11 ft.*lbf}

- SST

- 09960-10010(09962-01000,09963-00700)

|

| 13. INSTALL CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY |

Apply a light coat of engine oil to a new O-ring and install it onto the camshaft timing oil control valve assembly.

- NOTICE:

- Do not twist the O-ring.

Install the camshaft timing oil control valve assembly with the bolt.

- Torque:

- 7.5 N*m{76 kgf*cm, 66 in.*lbf}

- NOTICE:

- If a component has been dropped or subjected to a strong impact, replace it.

- Make sure that the O-ring is not damaged or does not jump out of position during installation.

Connect the camshaft timing oil control valve assembly connector.

| 14. INSTALL CRANKSHAFT POSITION SENSOR |

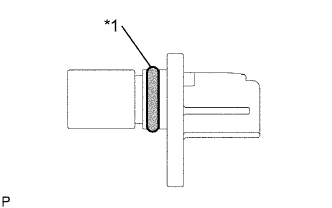

Apply a light coat of engine oil to the O-ring.

Text in Illustration *1 O-ring - NOTICE:

- If reusing the camshaft position sensor, be sure to inspect the O-ring.

|

Install the camshaft position sensor with the bolt.

- Torque:

- 8.0 N*m{82 kgf*cm, 71 in.*lbf}

- NOTICE:

- If a component has been dropped or subjected to a strong impact, replace it.

- Make sure that the O-ring is not damaged or does not jump out of position during installation.

Connect the camshaft position sensor connector.

| 15. INSTALL CRANKSHAFT DAMPER SUB-ASSEMBLY |

Align the pin hole of the crankshaft damper with the pin and install the crankshaft damper sub-assembly.

Provisionally install the bolt.

Using 2 SST, tighten the bolt while holding the crankshaft damper sub-assembly.

- SST

- 09213-14010(91651-60865)

09330-00021

- Torque:

- 128 N*m{1305 kgf*cm, 95 ft.*lbf}

- NOTICE:

- Check the SST installation positions when installing them, to avoid the SST fixing bolts from coming into contact with the oil pump assembly.

| 16. INSTALL ENGINE MOUNTING INSULATOR SUB-ASSEMBLY RH |

Install the engine mounting insulator sub-assembly RH with the 4 bolts and 2 nuts.

- Torque:

- 52 N*m{530 kgf*cm, 38 ft.*lbf}

| 17. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY |

|

| Seal Packing |

Apply seal packing to the cylinder head as shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- NOTICE:

- Remove any oil from the contact surfaces.

- Install the cylinder head cover within 3 minutes and tighten the bolts within 15 minutes after applying seal packing.

- Do not start the engine for at least 2 hours after the installation.

Install the cylinder head cover sub-assembly with the 9 bolts, 2 nuts and 2 seal washers.

|

Tighten the 9 bolts and 2 nuts in the sequence shown in the illustration.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

Install the wire harness bracket with the bolt.

- Torque:

- 13 N*m{130 kgf*cm, 9 ft.*lbf}

Connect the connector and 4 wire harness clamps and connect the engine wire harness.

Connect the 4 fuel injector connectors.

| 18. INSTALL FUEL VAPOR FEED HOSE ASSEMBLY |

Connect fuel vapor feed hose assembly.

| 19. INSTALL VENTILATION HOSE |

Connect the ventilation hose.

| 20. INSTALL GENERATOR ASSEMBLY |

| 21. INSTALL MANIFOLD SUPPORT BRACKET |

Install the manifold support bracket with the 3 bolts.

- Torque:

- 44 N*m{449 kgf*cm, 33 ft.*lbf}

| 22. INSTALL EXHAUST PIPE GASKET |

Using a plastic hammer and a wooden block, tap in a new exhaust pipe gasket until its surface is flush with the exhaust manifold.

Text in Illustration *1 Exhaust Pipe Gasket *2 Wooden Block *3 Plastic Hammer *4 Exhaust Manifold - NOTICE:

- Install the gasket in the correct direction.

- Do not reuse the gasket.

- Do not damage the gasket by dropping it, etc.

- Do not damage the outer surface of the gasket.

- Do not push in the gasket with the exhaust pipe when connecting it.

|

| 23. INSTALL FRONT EXHAUST PIPE ASSEMBLY |

Using a vernier caliper, measure the free length of the compression spring.

- Minimum length:

- 41.5 mm (1.634 in.)

- HINT:

- If the length is not as specified, replace the compression spring.

|

Install the front exhaust pipe assembly onto the exhaust manifold with the 2 compression springs and 2 bolts.

Text in Illustration *1 Exhaust Manifold *2 Front Exhaust Pipe Assembly *3 Exhaust Pipe Gasket *a Space between flanges: 8.5 mm (0.335 in.) - Torque:

- 43 N*m{438 kgf*cm, 32 ft.*lbf}

- HINT:

- After the installation, check that the gaps between the flanges of the exhaust manifold and front exhaust pipe assembly are consistent front-to-rear and left-to-right.

|

| 24. CONNECT WIRE HARNESS |

Connect the wire harness with the 2 bolts.

- Torque:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

| 25. INSTALL NO. 1 WATER BY-PASS PIPE |

Install No. 1 water by-pass pipe with the bolt.

- Torque:

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}

| 26. CONNECT INLET HEATER WATER HOSE A |

Connect heater water inlet hose A.

| 27. CONNECT AIR FUEL RATIO SENSOR CONNECTOR |

Connect the air fuel ratio sensor connector.

Install the sensor bracket with the bolt.

- Torque:

- 61 N*m{622 kgf*cm, 45 ft.*lbf}

| 28. CONNECT ENGINE COOLANT TEMPERATURE SENSOR CONNECTOR |

Connect the engine coolant temperature sensor connector.

| 29. CONNECT CAMSHAFT POSITION SENSOR CONNECTOR |

Connect the camshaft position sensor connector.

| 30. CONNECT BOOSTER VACUUM TUBE |

Connect the booster vacuum tube.

| 31. CONNECT FUEL TUBE SUB-ASSEMBLY |

|

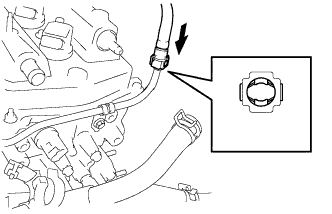

| Push |

Insert the fuel tube connector into the fuel delivery pipe until a click sound can be heard.

- NOTICE:

- Check that there are no scratches or foreign matter around the disconnected parts of the fuel tube connector and pipe before performing this work.

- After connecting the fuel tube, check that the fuel tube connector and pipe are securely connected by pulling them.

Install the EFI fuel pipe clamp.

| 32. INSTALL OIL LEVEL DIPSTICK GUIDE |

Apply engine oil to a new O-ring.

Install the O-ring onto the oil level dipstick guide.

Install the oil level dipstick guide with the bolt.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

Engage the clamp and connect the wire harness to the oil level dipstick guide.

| 33. INSTALL INTAKE MANIFOLD |

Install a new gasket onto the intake manifold.

Install the intake manifold with the 3 bolts and 2 nuts.

- Torque:

- 30 N*m{306 kgf*cm, 22 ft.*lbf}

Engage the 3 clamps and connect the wire harness to the intake manifold.

| 34. INSTALL OIL LEVEL DIPSTICK SUB-ASSEMBLY |

| 35. CONNECT UNION TO CONNECTOR TUBE HOSE |

Connect the union to connector tube hose.

| 36. CONNECT VENTILATION HOSE |

Connect the ventilation hose.

| 37. CONNECT THROTTLE BODY ASSEMBLY CONNECTOR |

Connect the throttle body assembly connector.

Connect the wire harness to the throttle body assembly with the nut.

- Torque:

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}

Engage the clamp and connect the wire harness to the wire harness bracket.

| 38. CONNECT WATER BY-PASS HOSE |

Connect the water by-pass hose.

| 39. CONNECT NO. 2 WATER BY-PASS HOSE |

Connect No. 2 water by-pass hose.

| 40. INSTALL WATER FILLER SUB-ASSEMBLY |

Install the water filler sub-assembly with the 2 nuts.

- Torque:

- 7.5 N*m{76 kgf*cm, 66 in.*lbf}

Install the No. 1 radiator hose to the cylinder head.

| 41. CONNECT RESERVE TANK HOSE |

Connect the reserve tank hose.

| 42. CONNECT NO. 3 RADIATOR HOSE |

Connect No. 3 radiator hose.

| 43. INSTALL NO.1 IGNITION COIL |

| 44. INSTALL AIR CLEANER CAP SUB-ASSEMBLY WITH NO. 1 AIR CLEANER HOSE |

Install the air cleaner cap sub-assembly with No. 1 air cleaner hose onto the throttle body assembly

Engage the 2 clamps and connect the air cleaner cap sub-assembly to the air cleaner case sub-assembly.

Tighten the hose clamp.

- Torque:

- 3.0 N*m{31 kgf*cm, 27 in.*lbf}

Connect the vacuum switching valve assembly connector.

Connect the mass air flow meter connector.

Engage the 2 clamps and connect the wire harness to the air cleaner cap sub-assembly and vacuum switching valve assembly.

Connect the No. 2 fuel vapor feed hose to the intake manifold.

Connect the fuel vapor feed hose assembly to the No. 1 air cleaner hose and vacuum switching valve assembly with the 2 hose clamps.

Engage the clamp and connect the fuel vapor feed hose assembly to the No. 1 air cleaner hose.

| 45. INSTALL BATTERY TRAY |

| 46. INSTALL BATTERY |

Install the battery.

Install the battery clamp with the 2 nuts.

- Torque:

- 3.5 N*m{36 kgf*cm, 31 in.*lbf}

| 47. INSTALL OUTER COWL TOP PANEL |

Install the cowl top panel outer with the 8 bolts.

- Torque:

- 6.5 N*m{66 kgf*cm, 58 in.*lbf}

Install the cowl top to cowl inner brace with the 2 bolts.

- Torque:

- 6.5 N*m{66 kgf*cm, 58 in.*lbf}

Connect the wire harness clamp.

| 48. INSTALL INNER COWL TOP TO COWL BRACE |

Engage the 3 claws to install the front air shutter seal RH.

| 49. INSTALL FRONT NO. 1 VENTILATOR SEAL |

Engage the clip and install the front No. 1 ventilator seal.

| 50. INSTALL FRONT AIR SHUTTER SEAL RH |

- HINT:

- Use the same procedure for the RH and LH sides.

| 51. INSTALL WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY |

| 52. INSTALL FRONT WHEEL RH |

- Torque:

- 103 N*m{1050 kgf*cm, 76 ft.*lbf}

| 53. ADD ENGINE COOLANT |

Tighten all the plugs.

Pour engine coolant into the radiator assembly until it overflows.

- Capacity:

- M/T 4.8 liters (5.1 USqts, 4.5 lmp. qts)

- A/T 4.7 liters (5.0 USqts, 4.4 lmp. qts)

- NOTICE:

- Do not substitute water for engine coolant.

- HINT:

- Use of improper engine coolant may damage the engine coolant system.

- Use only Toyota Super Long Life Coolant or similar high quality ethylene glycol based non-silicate, non-amine, non-nitrite, and non-borate engine coolant with long-life hybrid organic acid technology (coolant with long-life hybrid organic acid technology consists of a combination of low phosphates and organic acids).

Check the engine coolant level inside the radiator assembly by squeezing the inlet and outlet radiator hoses several times by hand. If the engine coolant level goes down, add engine coolant.

Install the radiator cap sub-assembly securely.

Slowly pour engine coolant into the radiator reservoir until it reaches the FULL line.

Bleed air from the cooling system.

Warm up the engine until the thermostat opens. While the thermostat is open, circulate the coolant for several minutes.

- HINT:

- The thermostat open timing can be confirmed by pressing the No. 2 radiator hose by hand, and checking when when the coolant starts to flow inside the hose.

Maintain the engine speed at 2,000 to 2,500 rpm and warm up the engine until the cooling fan operates.

Press the No. 2 radiator hose and No. 3 radiator hose several times by hand to bleed air.

- NOTICE:

- When pressing the radiator houses

- Wear protective glove.

- Be careful as the radiator hoses are hot.

- Keep your hands away form the radiator fan.

Stop the engine and wait until the coolant cools down.

If the engine coolant level is below the full level, perform steps (b) through (g) again and repeat the operation until the engine coolant level stays at the full level.

Recheck the engine coolant level inside the radiator reservoir tank assembly. If it is below the full level, add engine coolant.

| 54. ADD ENGINE OIL |

Add fresh engine oil.

- Standard Oil Grade:

Oil Grade Oil Viscosity (SAE) API grade SL "energy-conserving", SM "energy-conserving" or ILSAC multigrade engine oil - 0W-20

- 5W-20

- 5W-30

- 10W-30

API grade SL or SM multigrade engine oil - 15W-40

- 20W-50

- 0W-20

- Oil capacity:

Item Capacity Drain and refill with oil filter change 3.7 liters (3.9 US qts, 3.3 Imp. qts) Drain and refill without oil filter change 3.4 liters (3.6 US qts, 3.0 Imp. qts) Dry fill 4.1 liters (4.3 US qts, 3.6 Imp. qts)

| 55. INSPECT FOR FUEL LEAK |

Check fuel pump operation.

Connect the Techstream to the DLC3.

Turn the ignition switch to ON and turn the Techstream main switch on.

- NOTICE:

- Do not start the engine.

Enter the following menus: Powertrain / Engine and ECT / Active Test / Control the Fuel Pump /Speed.

Check for pressure in the fuel inlet tube from the fuel line. Check that sounds of fuel flowing from the fuel tank can be heard. If no sounds can be heard, check the integration relay, fuel pump, ECM and wiring connectors.

Inspect for fuel leaks.

Check for fuel leaks from the fuel system after doing any maintenance or repairs. If there is a fuel leak, repair or replace parts if necessary.

Turn the ignition switch off.

Disconnect the Techstream from the DLC3.

| 56. INSPECT FOR ENGINE COOLANT LEAK |

- CAUTION:

- To avoid the danger of being burned, do not remove the water filler cap sub-assembly while the engine and radiator assembly are still hot. Thermal expansion will cause hot engine coolant and steam to blow out from the radiator assembly.

Fill the radiator assembly with engine coolant, and attach a radiator cap tester.

|

Pump the tester to 118 kPa (1.2 kgf/cm2, 17.1 psi), and then check that the pressure does not drop.

If the pressure drops, check the hoses, radiator assembly and water pump assembly for leaks. If there are no signs or traces of external engine coolant leaks, check the heater core, cylinder block and head.

| 57. INSPECT ENGINE OIL LEVEL |

Warm up and stop the engine, and then wait for 5 minutes.

Check that the engine oil level is between the low level and full level marks on the engine oil level dipstick.

If low, check for leakage and add oil up to the full level mark.- NOTICE:

- Do not fill with engine oil above the full level mark.

| 58. INSPECT FOR ENGINE OIL LEAK |

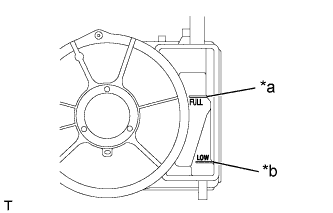

| 59. INSPECT RADIATOR RESERVOIR TANK COOLANT LEVEL |

The engine coolant level should be between the LOW and FULL lines when the engine is cold.

Text in Illustration *a FULL Line *b LOW Line - HINT:

- If it is below the LOW line, check for leakage and add Toyota Super Long Life Coolant (SLLC) or similar high quality ethylene glycol based non-silicate, non-amine, non-nitrite, and non-borate coolant with long-life hybrid organic acid technology up to the FULL line.

|

| 60. INSPECT FOR EXHAUST GAS LEAK |

- HINT:

- Perform "Inspection After Repairs" after repairing or replacing the exhaust system (YARIS_NCP93 RM000004NJD006X.html).

| 61. INSPECT IGNITION TIMING |

When using an Techstream:

Warm up and stop the engine.

Connect the Techstream to the DLC3.

Turn the ignition switch to ON.

Turn the Techstream on.

Start the engine.

Enter the following menus: Powertrain / Engine and ECT / Active Test /Connect the TC and TE1 / ON.

- HINT:

- Refer to the Techstream operator's manual for further details.

Inspect the ignition timing during idling.

- Standard ignition timing:

Transaxle Ignition Timing Manual Transaxle 8 to 12 degrees BTDC Automatic Transaxle

- NOTICE:

- Check the ignition timing with the cooling fans off..

- Turn off all electrical systems and the A/C.

- When checking the ignition timing, the transaxle should be in neutral or park.

- HINT:

- Refer to the Techstream operator's manual for further details.

Select the following menu items: Connect the TC and TE1 / OFF.

Turn the ignition switch off.

Disconnect the Techstream from the DLC3.

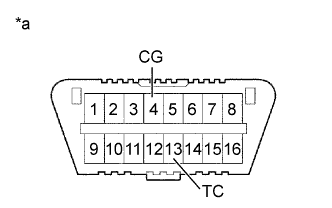

When not using an Techstream:

Using SST, connect terminals 13 (TC) and 4 (CG) of the DLC3.

Text in Illustration *a Front view of DLC3 - SST

- 09843-18040

- NOTICE:

- Be sure to connect the terminals correctly. Failure to do this can damage the engine.

- Check the ignition timing with the cooling fans off.

- Turn off all electrical systems and the A/C.

- When checking the ignition timing, the transaxle should be in neutral or park.

Remove the No. 2 cylinder head cover (YARIS_NCP93 RM000003VHK00GX_01_0007.html).

Pull out the wire harness (brown) shown in the illustration.

- NOTICE:

- After checking, wrap the wire harness with tape.

Warm up and stop the engine.

Connect the clip of the timing light to the wire harness.

- NOTICE:

- Use a timing light that detects the first signal.

Start the engine.

Inspect the ignition timing during idling.

- Standard ignition timing:

Transaxle Ignition Timing Manual Transaxle 8 to 12 degrees BTDC Automatic Transaxle

- NOTICE:

- Turn all the electrical systems and the A/C off.

- Inspect the ignition timing with the cooling fan off.

- When checking the ignition timing, shift the transaxle to the neutral position.

Turn the ignition switch off.

Remove the timing light.

Install the No. 2 cylinder head cover (YARIS_NCP93 RM000003VHI00GX_01_0008.html).

Disconnect terminals 13 (TC) and 4 (CG) of the DLC3.

| 62. INSPECT ENGINE IDLING SPEED |

When using an Techstream:

Warm up and stop the engine.

Connect the Techstream to the DLC3.

Turn the ignition switch to ON and turn the Techstream on.

Start the engine.

Select the following menu items: Powertrain / Engine and ECT / Data List / Engine Speed.

- HINT:

- Refer to the Techstream operator's manual for further details.

Inspect the engine idling speed.

- Standard Idle Speed:

Transaxle Idling Speed Manual Transaxle 550 to 650 rpm Automatic Transaxle 650 to 750 rpm

- NOTICE:

- Turn all the electrical systems and the A/C off.

- Inspect the idling speed with the cooling fan off.

- When checking the idling speed, shift the transaxle to the neutral position or the parking position.

Turn the ignition switch off.

Disconnect the Techstream from the DLC3.

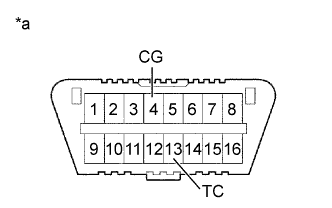

When not using an Techstream.

Warm up and stop the engine.

Install SST to terminals 13 (TC) and 4 (CG) of the DLC3.

Text in Illustration *a Front view of DLC3 - SST

- 09843-18040

- NOTICE:

- Examine the terminal numbers before connecting them. Connecting the wrong terminals can damage the engine.

Start the engine.

Inspect the engine idling speed.

- Standard Idle Speed:

Transaxle Idling Speed Manual Transaxle 600 to 700 rpm Automatic Transaxle 650 to 750 rpm

- NOTICE:

- Turn all the electrical systems and the A/C off.

- Inspect the idling speed with the cooling fan off.

- When checking the idling speed, shift the transaxle to the neutral position or the parking position.

Turn the ignition switch off.

Disconnect the tachometer.

Remove SST from terminals 13 (TC) and 4 (CG) of the DLC3.

| 63. INSPECT COMPRESSION |

Warm up and stop the engine.

Remove the No. 2 cylinder head cover (YARIS_NCP93 RM000003VHK00GX_01_0007.html).

Remove the 4 ignition coils (YARIS_NCP93 RM000002YO404IX_01_0003.html ).

Remove the 4 spark plugs (YARIS_NCP93 RM000002YO404IX_01_0004.html).

Disconnect the 4 fuel injector connectors.

Inspect the cylinder compression pressure.

Insert a compression gauge into the spark plug hole.

Fully open the throttle.

While cranking the engine, measure the compression pressure.

- Compression:

- 980 kPa (10.0 kgf/cm2, 142 psi)

- Minimum pressure:

- 784 kPa (8.0 kgf/cm2, 114 psi)

- Difference between each cylinder:

- 98 kPa (1.0 kgf/cm2, 14 psi) or less

- NOTICE:

- Use a fully-charged battery so the engine speed can be increased to 250 rpm or more.

- Inspect the other cylinders in the same way.

- Measure the compression in as short a time as possible.

If the cylinder compression is low, pour a light coat of engine oil into the cylinder through the spark plug hole, then inspect it again.

- HINT:

- If adding oil increases the compression, the piston rings and/or cylinder bore may be worn or damaged.

- If the pressure stays low, the valve may be stuck or seated improperly, or there may be leakage from the gasket.

|

Connect the 4 fuel injector connectors.

Install the 4 spark plugs (YARIS_NCP93 RM000002YO204IX_01_0001.html).

Install the 4 ignition coils (YARIS_NCP93 RM000002YO204IX_01_0002.html).

Install the No. 2 cylinder head cover (YARIS_NCP93 RM000003VHI00GX_01_0008.html).

Clear the DTC (YARIS_NCP93 RM000000PDK0T5X.html).

| 64. INSPECT CO/HC |

Start the engine.

Run the engine at 2500 rpm for approximately 180 seconds.

Insert the CO/HC meter testing probe at least 40 cm (1.3 ft) into the tailpipe while idling.

Check the CO/HC concentration during idling and when running at 2500 rpm.

- HINT:

- When doing the 2 mode (with the engine idling/running at 2500 rpm) test, the measuring procedures are determined by applicable local regulations.

Check the air fuel ratio sensor operation (YARIS_NCP93 RM000000SXS05AX.html).

Check the heated oxygen sensor operation (YARIS_NCP93 RM000000SXS05AX.html).

See the table below for possible causes, then inspect the applicable parts and repair them if necessary.

CO HC Problems Possible Causes Normal High Rough idling - Faulty ignition:

- Incorrect timing

- Fouled, shorted or improperly gapped plugs

- Incorrect valve clearance

- Leakage from intake and exhaust valves

- Leakage from cylinders

Low High Rough idling

(Fluctuating HC reading)- Vacuum leaks:

- PCV hoses

- Intake manifold

- Throttle body

- Brake booster line

- Lean mixture causing misfire

High High Rough idling

(Black smoke from exhaust)- Restricted air cleaner filter element

- Plugged PCV valve

- Faulty EFI systems:

- Faulty pressure regulator

- Faulty engine coolant temperature sensor

- Faulty mass air flow meter

- Faulty ECM

- Faulty injectors

- Throttle body

- Faulty ignition:

| 65. INSTALL ENGINE UNDER COVER RH |

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}