Emission Control System (For Sedan) -- On-Vehicle Inspection |

| 1. INSPECT FUEL CUT-OFF RPM |

Start and warm up the engine.

Increase the engine speed to approximately 3,500 rpm.

Using a sound scope, check the operation sound of the injector.

Release the accelerator pedal. Check that the operation noise stops momentarily and then resumes.

| 2. VISUALLY INSPECT HOSES, CONNECTIONS AND GASKETS |

|

Check that there are no cracks, leakage or scratches on the hoses, connections or gaskets.

- HINT:

- Removing the oil level gauge, oil filter cap or PCV hose may cause the engine to malfunction or stall.

- Disconnections, looseness or cracks in the parts of the air induction system between the intake system and cylinder head will allow air suction and cause the engine to run improperly.

| 3. CHECK LINE AND CONNECTORS |

Visually check for loose connections, sharp bends and damage.

| 4. CHECK FUEL TANK ASSEMBLY |

Visually check for deformation, cracks and fuel leakage.

| 5. CHECK FUEL TANK AND VENT LINE |

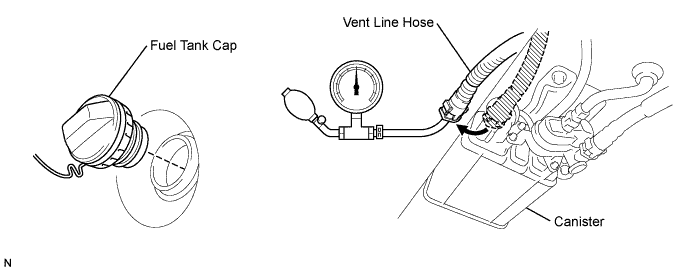

Disconnect the vent line hose from the canister.

Connect the pressure gauge to the vent line hose.

Apply 4 kPa (41 kgf/cm2, 30 mmHg) of pressure to the vent line of the fuel tank.

- HINT:

- Perform this inspection with the fuel tank less than 90% full. When the fuel tank is full, the fuel cutoff valve closes and the pressure is released through the 2 mm orifice. As a result, when the fuel tank cap is removed, the pressure does not decrease smoothly.

Check that the fuel tank pressure is maintained for some time, and does not decrease immediately.

- HINT:

- If the pressure decreases immediately, one of the following may apply:

- The fuel tank cap is not completely tightened.

- The fuel tank cap is damaged.

- Air is leaking from the vent line.

- The fuel tank is damaged.

When the fuel tank cap is removed, check that the pressure is released smoothly.

- HINT:

- If the pressure does not drop, replace the fuel tank assembly.

Reconnect the vent line hose to the canister.

| 6. CHECK AIR INLET LINE |

Disconnect the air inlet line hose from the canister.

Check that air flows freely into the air inlet line.

- HINT:

- If air does not flow freely into the air inlet line, repair or replace it.

Reconnect the air inlet line hose to the canister.