Front Wheel Alignment (For Hatchback) -- Adjustment |

- NOTICE:

- For vehicles equipped with VSC, if wheel alignment has been adjusted, and if suspension or underbody components have been removed/installed or replaced, be sure to perform the following initialization procedure in order for the system to function normally:

- Perform zero point calibration of the yaw rate and acceleration sensor and test mode inspection (YARIS_NCP93 RM000000XHR078X.html).

| 1. INSPECT TIRES |

Check the tires for wear and proper inflation pressure.

Cold Tire Inflation Pressure Tire Size Front

kPa (kgf/cm2, psi)Rear

kPa (kgf/cm2, psi)P175/65R15 84H 230 (2.3, 33) 230 (2.3, 33) P195/50R16 83V 220 (2.2, 32) 200 (2.0, 29) 175/65R14 82T 220 (2.2, 32) 220 (2.2, 32) 185/60R15 84H 220 (2.2, 32) 220 (2.2, 32)

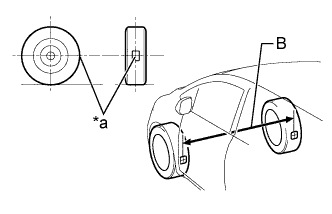

Using a dial indicator, check the tire runout.

- Tire runout:

- 1.4 mm (0.0551 in.) or less (Vertical)

2.0 mm (0.0787 in.) or less (Lateral)

|

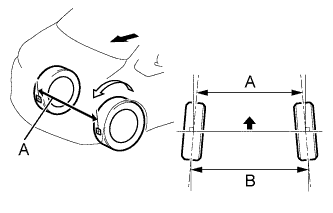

| 2. MEASURE VEHICLE HEIGHT |

|

| Tire Size | Front A-B | Rear C-D |

| P175/65 R15 | 97 mm (3.82 in.) | 32 mm (1.26 in.) |

| P195/50 R16 | 101 mm (3.98 in.) | 32 mm (1.26 in.) |

| 175/65 R14 | 69 mm (2.72 in.) | 4.0 mm (0.16 in.) |

| 185/60 R15 | 69 mm (2.72 in.) | 4.0 mm (0.16 in.) |

- Measuring points:

- A:

- Ground clearance of front wheel center

- B:

- Ground clearance of front lower arm set front bolt center

- C:

- Ground clearance of rear wheel center

- D:

- Ground clearance of axle beam set bolt center

- NOTICE:

- Before inspecting the wheel alignment, check the vehicle height.

- The standard value shown here is a value that is used for adjusting the wheel alignment and does not indicate the height of an actual vehicle.

- HINT:

- Bounce the vehicle up and down at the corners to stabilize the suspension before inspecting the vehicle height.

| 3. INSPECT WHEEL TURNING ANGLE |

|

Fully turn the steering wheel left and right, and measure the wheel turning angle.

Text in Illustration *a Inside *b Outside

Front of the Vehicle

If the right and left inside wheel angles are not within the specified range, check the right and left rack end lengths.Wheel Turning Angle (Unloaded Vehicle) Tire Size Inside Wheel Outside Wheel P175/65 R15 40°44 ' +/- 2°

(40.73° +/- 2°)35°03'

(35.05°)P195/50 R16 32°26' +/- 2°

(32.43° +/- 2°)29°26'

(35.43°)175/65 R14 41°33' +/- 2°

(41.55° +/- 2°)35°40'

(35.67°)185/60 R15 41°33' +/- 2°

(41.55° +/- 2°)35°40'

(35.67°)

| 4. INSPECT CAMBER, CASTER AND STEERING AXIS INCLINATION |

|

Put the front wheel on the center of the alignment tester.

Text in Illustration *1 Alignment tester *2 Camber-caster-steering axis inclination gauge

Remove the wheel cap.

Set the camber-caster-steering axis inclination gauge at the center of the axle hub or drive shaft.

Inspect the camber, caster and steering axis inclination.

Camber Inclination (Unloaded Vehicle) Tire Size Camber P175/65 R15 -0°21' +/- 45'

(-0.35° +/- 0.75°)P195/50 R16 -0°24' +/- 45'

(-0.40° +/- 0.75°)175/65 R14 0°00' +/- 45'

(0.00° +/- 0.75°)185/60 R15 0°00' +/- 45'

(0.00° +/- 0.75°)Caster Inclination (Unloaded Vehicle) Tire Size Transmission Caster P175/65 R15 C50

U340E4°59' +/- 45'

(4.98° +/- 0.75°)P195/50 R16 C50

U340E5°00' +/- 45'

(5.00° +/- 0.75°)175/65 R14 C50 4°31' +/- 45'

(4.52° +/- 0.75°)U340E 4°30' +/- 45'

(4.50° +/- 0.75°)185/60 R15 C50 4°32' +/- 45'

(4.53° +/- 0.75°)U340E 4°31' +/- 45'

(4.52° +/- 0.75°)Steering Axis Inclination (Unloaded Vehicle) Tire Size Steering Axis Inclination

(Reference)P175/65 R15 11°21'

(11.35°)P195/50 R16 11°26'

(11.43°)175/65 R14 10°43'

(10.72°)185/60 R15 10°43'

(10.72°)- NOTICE:

- Perform the inspection while the vehicle is empty (without a spare tire or tools on board).

- The tolerance for the difference between the left and right wheels is 30' (0.5°) or less for both the camber and caster.

Remove the camber-caster-steering axis inclination gauge and attachment.

Install the wheel cap.

If the caster and steering axis inclination are not within the specified values after the camber has been correctly adjusted, recheck the suspension parts for damage and wear.

| 5. ADJUST CAMBER |

- NOTICE:

- Inspect the toe-in after the camber has been adjusted.

Remove the front wheel.

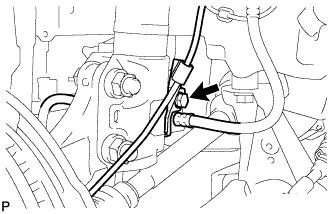

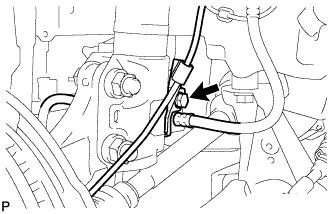

w/ ABS:

Remove the bolt and separate the speed sensor and flexible hose.

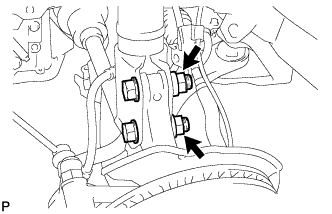

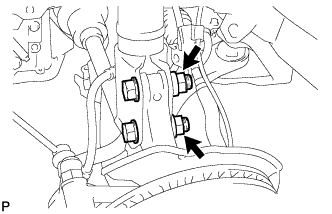

Remove the 2 nuts from the lower side of the shock absorber.

- HINT:

- Keep the bolt from rotating while loosening and removing the nuts.

|

Clean the installation surfaces of the shock absorber and steering knuckle.

Provisionally install the 2 nuts (Step A).

Fully push or pull the axle hub in the direction of the required adjustment (Step B).

|

Tighten the 2 nuts.

- Torque:

- 164 N*m{1672 kgf*cm, 121 ft.*lbf}

- HINT:

- Keep the bolt from rotating while loosening and removing the nuts.

|

w/ ABS:

Install the flexible hose and speed sensor with the bolt.

- Torque:

- 29 N*m{300 kgf*cm, 22 ft.*lbf}

- NOTICE:

- Install the flexible hose and speed sensor without twisting them.

Install the front wheel.

- Torque:

- 103 N*m{1050 kgf*cm, 76 ft.*lbf}

Check the camber.

If the measured value is not within the specifications, calculate the required adjustment amount using the formula below.

(Camber adjustment amount) = Center of specified range - Measured value

Check the combination of installed bolts. Select appropriate bolts from the table below to adjust the camber to within the specified range.- HINT:

- Try to adjust the camber to the center of the specified range.

Move axle toward (+) in step (B) Refer to table (1) (Move axle toward positive side) Move axle toward (-) in step (B) Refer to table (2) (Move axle toward negative side)

|

Table (1) (Move the axle toward the positive side)

Table (2) (Move the axle toward the negative side).

The body and suspension may be damaged if the camber is not correctly adjusted in accordance with the above table.- NOTICE:

- Replace the nut with a new one when replacing the bolt.

Repeat the steps mentioned above. At step (A), replace 1 or 2 selected bolts.

- HINT:

- Replace one bolt at a time when replacing 2 bolts.

| 6. INSPECT TOE-IN |

Bounce the vehicle up and down at the corners to stabilize the suspension.

Release the parking brake and move the shift lever to the neutral position.

Push the vehicle straight ahead approximately 5 m (16.4 ft.). (Step A)

Put tread center marks on the rearmost points of the front wheels and measure the distance between the marks (Dimension B).

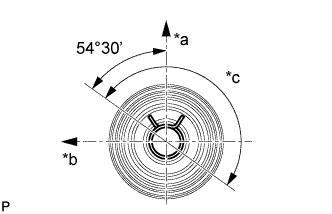

Text in Illustration *a Tread Center Mark

|

Slowly push the vehicle straight ahead to cause the front wheels to rotate 180° using the front tire valve as a reference point.

- HINT:

- Do not allow the wheels to rotate more than 180°. If the wheels rotate more than 180°, perform the procedure from (Step A) again.

Measure the distance between the tread center marks on the front side of the wheels (Dimension A).

Text in Illustration

Front of the Vehicle

If the toe-in is not within the specified value, adjust it at the rack ends.Toe-in (Unloaded Vehicle) Tire Size Specified Condition P175/65 R15 B-A: 1.2 +/- 2.0 mm

(0.0472 +/- 0.0787 in.)P195/50 R16 B-A: 0.9 +/- 2.0 mm

(0.0354 +/- 0.0787 in.)175/65 R14 B-A: 1.2 +/- 2.0 mm

(0.0472 +/- 0.0787 in.)185/60 R15 B-A: 1.3 +/- 2.0 mm

(0.0512 +/- 0.0787 in.)

|

| 7. ADJUST TOE-IN |

|

Measure the thread lengths of the right and left rack ends.

- Standard:

- Difference in thread length of 1.5 mm (0.0591 in.) or less

Remove the rack boot set clips.

Loosen the tie rod end lock nuts.

Adjust the rack ends if the difference in thread length between the right and left rack ends is not within the specified range.

Extend the shorter rack end if the measured toe-in deviates toward the outer-side.

Shorten the longer rack end if the measured toe-in deviates toward the inner-side.

Turn the right and left rack ends by an equal amount to adjust the toe-in.

- HINT:

- Try to adjust the toe-in to the center of the specified range.

Make sure that the lengths of the right and left rack ends are the same.

Toe-in (Unloaded Vehicle) Tire Size Specified Condition P175/65 R15 B-A: 1.2 +/- 1.0 mm

(0.0472 +/- 0.0394 in.)P195/50 R16 B-A: 0.9 +/- 1.0 mm

(0.0354 +/- 0.0394 in.)175/65 R14 B-A: 1.2 +/- 1.0 mm

(0.0472 +/- 0.0394 in.)185/60 R15 B-A: 1.3 +/- 1.0 mm

(0.0512 +/- 0.0394 in.)

Tighten the tie rod end lock nuts to the specified torque.

- Torque:

- 75 N*m{760 kgf*cm, 55 ft.*lbf}

- NOTICE:

- Provisionally tighten the lock nut while holding the hexagonal part of the steering rack end so that the lock nut and the steering rack end do not turn together. Hold the flat of the tie rod end and tighten the lock nut.

Place the boots on the seats.

Using pliers, install the RH and LH boot clips as shown in the illustration.

Text in Illustration *a Upper Side *b Front Side *c 180° (Clip installation range) - NOTICE:

- Install the clip so that its claws are within the clip installation range.

- Make sure that the rack boots are not twisted.

|

| 8. FRONT WHEELS FACING STRAIGHT AHEAD |

| 9. PERFORM YAW RATE SENSOR ZERO POINT CALIBRATION |