Manual Transaxle Unit (For Hatchback) Reassembly

INSTALL OUTPUT SHAFT COVER

INSTALL OUTPUT SHAFT FRONT BEARING

INSTALL FRONT TRANSAXLE CASE OIL SEAL

INSTALL INPUT SHAFT FRONT BEARING

INSTALL SHIFT AND SELECT LEVER SHAFT SLIDE BALL BEARING

INSTALL SHIFT AND SELECT LEVER SHAFT OIL SEAL

INSTALL FRONT DIFFERENTIAL CASE FRONT TAPERED ROLLER BEARING

INSTALL FRONT DIFFERENTIAL CASE REAR TAPERED ROLLER BEARING

ADJUST DIFFERENTIAL SIDE BEARING PRELOAD

INSTALL TRANSMISSION CASE OIL SEAL

INSTALL TRANSAXLE CASE OIL SEAL

INSTALL TRANSMISSION MAGNET

INSTALL BEARING LOCK PLATE

INSTALL NO. 1 OIL RECEIVER PIPE

INSTALL NO. 2 OIL RECEIVER PIPE

INSTALL REVERSE RESTRICT PIN ASSEMBLY

INSTALL MANUAL TRANSAXLE CASE RECEIVER

INSTALL DIFFERENTIAL CASE ASSEMBLY

INSTALL INPUT SHAFT ASSEMBLY

INSTALL REVERSE IDLER GEAR SUB-ASSEMBLY

INSTALL NO. 1 GEAR SHIFT FORK SHAFT

INSTALL NO. 3 GEAR SHIFT FORK SHAFT

INSTALL NO. 2 GEAR SHIFT FORK SHAFT

INSTALL REVERSE SHIFT ARM BRACKET ASSEMBLY

INSTALL MANUAL TRANSMISSION CASE

INSTALL REVERSE IDLER GEAR SHAFT BOLT

INSTALL NO. 2 LOCK BALL ASSEMBLY

INSTALL SHIFT DETENT BALL

INSTALL INPUT SHAFT REAR BEARING HOLE SNAP RING

INSTALL OUTPUT SHAFT REAR BEARING HOLE SNAP RING

INSTALL SHIFT FORK SHAFT SHAFT SNAP RING

INSTALL REAR BEARING RETAINER

INSTALL 5TH DRIVEN GEAR

INSTALL 5TH GEAR NEEDLE ROLLER BEARING

INSTALL 5TH GEAR

INSTALL NO. 3 SYNCHRONIZER RING

INSTALL NO. 3 TRANSMISSION CLUTCH HUB

INSPECT 5TH GEAR THRUST CLEARANCE

INSPECT 5TH GEAR RADIAL CLEARANCE

INSTALL NO. 3 GEAR SHIFT FORK

INSTALL MANUAL TRANSMISSION OUTPUT SHAFT REAR SET NUT

INSTALL MANUAL TRANSMISSION CASE COVER SUB-ASSEMBLY

INSTALL SHIFT AND SELECT LEVER SHAFT ASSEMBLY

INSTALL CONTROL SHAFT COVER OIL SEAL

INSTALL CONTROL SHAFT COVER

INSTALL SHIFT GATE PIN

INSTALL NO. 1 LOCK BALL ASSEMBLY

INSTALL SHIFT LEVER DAMPER

INSTALL FLOOR SHIFT CONTROL SHIFT LEVER

INSTALL SELECTING BELL CRANK ASSEMBLY

INSTALL BACK UP LIGHT SWITCH ASSEMBLY

INSTALL MANUAL TRANSMISSION FILLER PLUG

INSTALL DRAIN PLUG SUB-ASSEMBLY

Manual Transaxle Unit (For Hatchback) -- Reassembly |

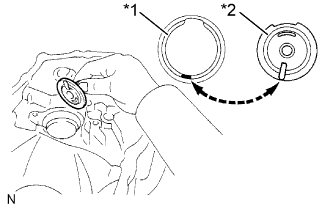

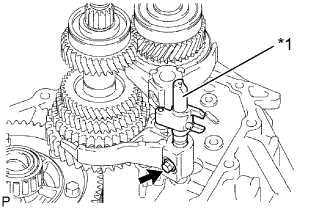

| 1. INSTALL OUTPUT SHAFT COVER |

Text in Illustration*1

| Front Transaxle Case

|

*2

| Output Shaft Cover

|

Coat the output shaft cover with MP grease and install it onto the front transaxle case.

- NOTICE:

- Insert the output shaft cover projection into the case side hollow.

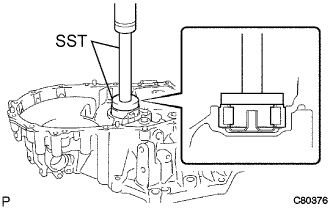

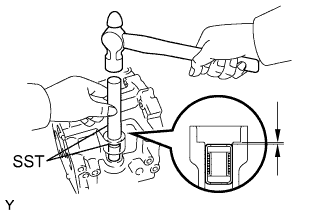

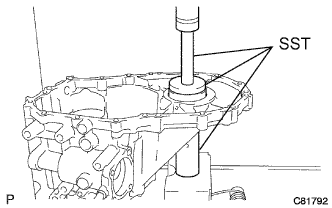

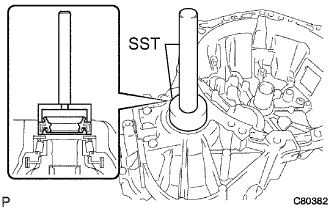

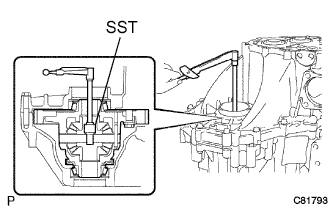

| 2. INSTALL OUTPUT SHAFT FRONT BEARING |

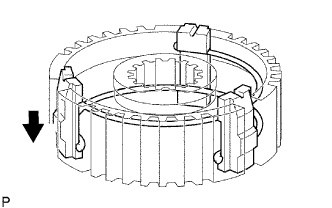

Coat a new output shaft front bearing with gear oil. Using SST and a press, install it onto the front transaxle case.

- SST

- 09950-60010(09951-00550)

09950-70010(09951-07150)

- NOTICE:

- Install the new bearing in the correct direction as shown in the illustration.

- When replacing the output shaft front bearing, replace the output shaft front bearing inner race at the same time.

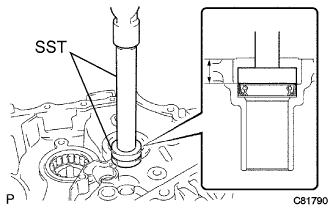

| 3. INSTALL FRONT TRANSAXLE CASE OIL SEAL |

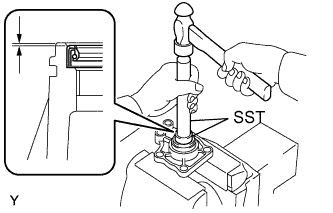

Using SST and a hammer, install a new front transaxle case oil seal onto the front transaxle case.

- SST

- 09950-60010(09951-00370)

09950-70010(09951-07150)

- Drive in depth:

- 15.6 to 16.0 mm (0.614 to 0.630 in.)

Coat the lip of the front transaxle case oil seal with MP grease.

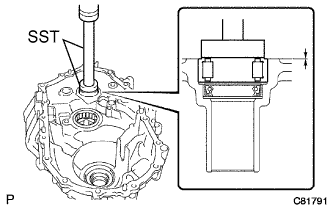

| 4. INSTALL INPUT SHAFT FRONT BEARING |

Coat a new input shaft front bearing with gear oil, and using SST and a press, install it onto the front transaxle case.

- SST

- 09950-60010(09951-00420)

09950-70010(09951-07150)

- Drive in depth:

- 0 to 0.3 mm (0 to 0.0118 in.)

| 5. INSTALL SHIFT AND SELECT LEVER SHAFT SLIDE BALL BEARING |

Using SST and a hammer, install the shift and select lever shaft slide ball bearing onto the manual transmission case.

- SST

- 09950-60010(09951-00220)

09950-70010(09951-07100)

- Drive in depth:

- 0 to 0.5 mm (0 to 0.00197 in.)

| 6. INSTALL SHIFT AND SELECT LEVER SHAFT OIL SEAL |

Using SST, install the shift and select lever shaft oil seal onto the manual transmission case.

- SST

- 09950-70010(09951-07150)

09950-60010(09951-00240)

- Drive in depth:

- 9.7 to 10.3 mm (0.382 to 0.406 in.)

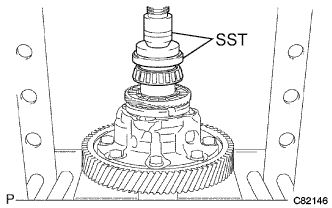

| 7. INSTALL FRONT DIFFERENTIAL CASE FRONT TAPERED ROLLER BEARING |

Using SST and a press, install the front differential case front tapered roller bearing (inner race) onto the front differential case.

- SST

- 09350-32014(09351-32120)

09950-60010(09951-00530)

Using SST and a press, install the front differential case front tapered roller bearing (outer race) together with the front differential case front plate washer onto the front transaxle case.

- SST

- 09950-60020(09951-00680)

09950-70010(09951-07150)

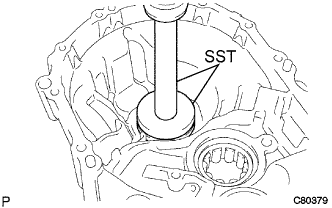

| 8. INSTALL FRONT DIFFERENTIAL CASE REAR TAPERED ROLLER BEARING |

Using SST and a press, install the front differential case rear tapered roller bearing (inner race) onto the differential case.

- SST

- 09350-32014(09351-32120)

09950-60010(09951-00530)

Using SST and a press, install the front differential case rear tapered roller bearing (outer race) with front differential case rear plate washer onto the manual transmission case.

- SST

- 09309-36010

09950-60020(09951-00710)

09950-70010(09951-07150)

- HINT:

- Use a plate washer of the same thickness as the removed one.

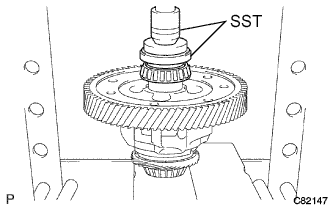

| 9. ADJUST DIFFERENTIAL SIDE BEARING PRELOAD |

Coat the differential case assembly with gear oil, and install it onto the front transaxle case.

Install the manual transmission case with the 16 bolts.

- Torque:

- 29 N*m{300 kgf*cm, 22 ft.*lbf}

Using SST and a torque wrench, turn the differential case assembly to the right and left 2 or 3 times to allow the bearings to settle.

- SST

- 09564-32011

|

Using SST and a torque wrench, measure the preload.

- SST

- 09564-32011

- Preload (at starting):

- New bearing:

- 0.78 to 1.57 N*m (8.0 to 16.0 kgf*cm, 7.0 to 13.8 in.*lbf)

- Used bearing:

- 0.49 to 0.98 N*m (5.0 to 9.0 kgf*cm, 4.4 to 8.6 in.*lbf)

If the preload is outside the specifications, select another plate washer.

- Plate Washer Thickness:

Part No.

| Mark

| Thickness mm (in.)

|

90564-41014

| AA

| 2.10 (0.0827)

|

90564-41015

| BB

| 2.15 (0.0846)

|

90564-41016

| CC

| 2.20 (0.0866)

|

90564-41017

| DD

| 2.25 (0.0886)

|

90564-41018

| EE

| 2.30 (0.0906)

|

90564-41019

| FF

| 2.35 (0.0925)

|

90564-41020

| GG

| 2.40 (0.0945)

|

90564-41021

| HH

| 2.45 (0.0965)

|

90564-41022

| JJ

| 2.50 (0.0984)

|

90564-41023

| KK

| 2.55 (0.1004)

|

90564-41024

| LL

| 2.60 (0.1024)

|

90564-41025

| MM

| 2.65 (0.1043)

|

90564-41026

| NN

| 2.70 (0.1063)

|

90564-41027

| PP

| 2.75 (0.1083)

|

90564-41028

| QQ

| 2.80 (0.1102)

|

90564-41029

| RR

| 2.85 (0.1122)

|

90564-41030

| SS

| 2.90 (0.1142)

|

90564-41031

| TT

| 2.95 (0.1161)

|

90564-41032

| UU

| 3.00 (0.1181)

|

- HINT:

- The preload changes by approximately 0.3 to 0.4 N*m (3.1 to 4.0 kgf*cm, 2.7 to 3.5 in.*lbf) per each 0.05 mm (0.00197 in.) change in plate washer thickness.

Remove the 16 bolts and the manual transmission case.

Remove the differential case assembly from the front transaxle case.

| 10. INSTALL TRANSMISSION CASE OIL SEAL |

Using SST and a hammer, install a new transmission case oil seal onto the manual transmission case.

- SST

- 09316-60011(09316-00011)

- Drive in depth:

- 9.6 to 10.2 mm (0.378 to 0.402 in.)

Coat the lip of the front transmission case oil seal with MP grease.

| 11. INSTALL TRANSAXLE CASE OIL SEAL |

Using SST and a hammer, install a new transaxle case oil seal onto the front transaxle case.

- Drive in depth:

- 1.4 to 2.0 mm (0.0551 to 0.0787 in.)

- SST

- 09710-20011(09710-06071)

09950-70010(09951-07150)

Coat the lip of the transaxle case oil seal with MP grease.

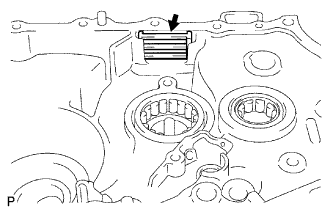

| 12. INSTALL TRANSMISSION MAGNET |

Clean the transmission magnet and install it onto the front transaxle case.

| 13. INSTALL BEARING LOCK PLATE |

Install the bearing lock plate onto the front transaxle case with the bolt.

- Torque:

- 11 N*m{115 kgf*cm, 8 ft.*lbf}

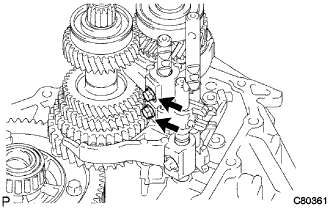

| 14. INSTALL NO. 1 OIL RECEIVER PIPE |

Install the No. 1 oil receiver pipe onto the manual transmission case with the bolt.

- Torque:

- 17 N*m{175 kgf*cm, 13 ft.*lbf}

- NOTICE:

- Do not deform the No. 1 oil receiver pipe.

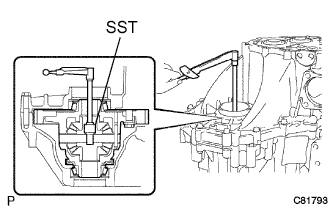

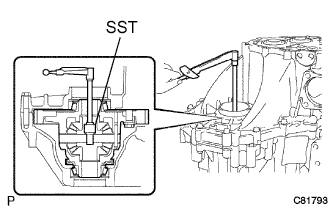

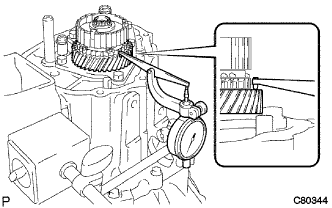

- Install the No. 1 oil receiver pipe while holding it against the manual transmission case as shown in the illustration.

| 15. INSTALL NO. 2 OIL RECEIVER PIPE |

Install the No. 2 oil receiver pipe onto the manual transmission case with the bolt.

- Torque:

- 17 N*m{175 kgf*cm, 13 ft.*lbf}

- NOTICE:

- Do not deform the No. 2 oil receiver pipe.

- Install the No. 2 oil receiver pipe while holding it against the manual transmission case as shown in the illustration.

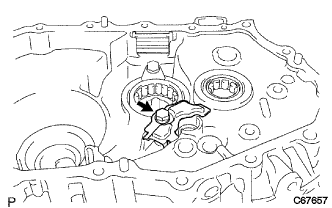

| 16. INSTALL REVERSE RESTRICT PIN ASSEMBLY |

Install the reverse restrict pin assembly onto the manual transmission case.

- NOTICE:

- Set the reverse restrict pin assembly in the correct orientation.

Using a pin punch (φ5 mm) and a hammer, install the slotted pin onto the reverse restrict pin assembly.

- Drive in depth:

- 15.5 to 16.5 mm (0.611 to 0.650 in.)

Apply adhesive to the reverse restrict pin plug.

- Adhesive:

- Toyota Genuine Adhesive 1344, Three Bond 1344 or Equivalent

Using a hexagon wrench and a torque wrench, install the reverse restrict pin plug onto the manual transmission case.

- Torque:

- 13 N*m{130 kgf*cm, 9 ft.*lbf}

| 17. INSTALL MANUAL TRANSAXLE CASE RECEIVER |

Install the manual transaxle case receiver onto the front transaxle case with the bolt.

- Torque:

- 11 N*m{115 kgf*cm, 8 ft.*lbf}

| 18. INSTALL DIFFERENTIAL CASE ASSEMBLY |

Coat the differential case tapered roller bearing with gear oil and install the differential case assembly onto the front transaxle case.

- NOTICE:

- Do not damage the tapered roller bearing.

| 19. INSTALL INPUT SHAFT ASSEMBLY |

Coat the sliding and rotating surfaces of the input shaft assembly and output shaft assembly with gear oil and install them onto the front transaxle case.

- NOTICE:

- Do not damage the oil seal.

| 20. INSTALL REVERSE IDLER GEAR SUB-ASSEMBLY |

Coat the reverse idler gear sub-assembly, reverse idler thrust washer and reverse idler gear shaft with gear oil and install them as shown in the illustration.

Text in Illustration

| Align Alignment Mark

|

- HINT:

- Align the mark on the reverse idler gear shaft with the bolt hole shown in the illustration.

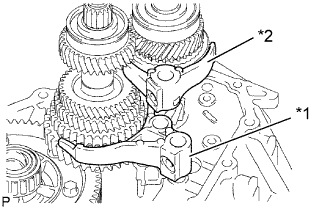

| 21. INSTALL NO. 1 GEAR SHIFT FORK SHAFT |

Coat the No. 1 gear shift fork and the No. 2 gear shift fork with gear oil and install them.

Text in Illustration*1

| No. 1 Gear Shift Fork

|

*2

| No. 2 Gear Shift Fork

|

Coat the No. 1 gear shift fork shaft with gear oil and install it.

Text in Illustration*1

| No. 1 Gear Shift Fork Shaft

|

Apply adhesive to the shift fork set bolt.

- Adhesive:

- Toyota Genuine Adhesive 1344, Three Bond 1344 or Equivalent

Install the shift fork set bolt.

- Torque:

- 16 N*m{160 kgf*cm, 12 ft.*lbf}

Using a brass bar and a hammer, install a new snap ring onto the No. 1 gear shift fork shaft.

| 22. INSTALL NO. 3 GEAR SHIFT FORK SHAFT |

Coat the 2 shift fork balls with MP grease and install them onto the reverse shift fork.

Install the reverse shift fork onto the No. 3 shift fork shaft gear.

Using a brass bar and a hammer, install 2 new snap rings onto the No. 3 shift fork shaft.

Coat the No. 3 shift fork shaft gear with gear oil and install it.

| 23. INSTALL NO. 2 GEAR SHIFT FORK SHAFT |

Coat the No. 1 gear shift head and the No. 2 gear shift fork shaft with gear oil and install them.

- NOTICE:

- To avoid interference by the 2 shift fork balls, lift up the No. 3 gear shift fork shaft to the position shown in the illustration.

Coat the 2 shift fork set bolts with adhesive and install them onto the No. 2 gear shift fork and the No. 1 shift head.

- Adhesive:

- Toyota Genuine Adhesive 1344, Three Bond 1344 or Equivalent

- Torque:

- 16 N*m{160 kgf*cm, 12 ft.*lbf}

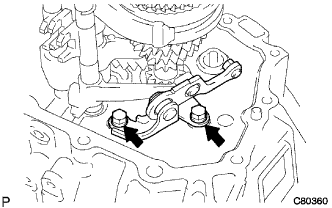

| 24. INSTALL REVERSE SHIFT ARM BRACKET ASSEMBLY |

Install the reverse shift arm bracket assembly onto the front transaxle case with 2 bolts.

- Torque:

- 17 N*m{175 kgf*cm, 13 ft.*lbf}

| 25. INSTALL MANUAL TRANSMISSION CASE |

Apply a continuous bead of seal packing (Diameter 1.2 mm (0.0472 in.)) to the manual transmission case as shown in the illustration.

Text in Illustration*a

| Seal Packing

(Seal Diameter: 1.2 mm (0.0472 in.))

|

- Seal Packing:

- Toyota Genuine Seal Packing 1281, Three Bond 1281 or Equivalent

- NOTICE:

- Remove any oil from the contact surfaces.

- Assemble the parts within 10 minutes of application. Otherwise, the seal packing material must be removed and reapplied.

Install the 13 bolts onto the manual transmission side.

- Torque:

- 29 N*m{300 kgf*cm, 22 ft.*lbf}

Install the 3 bolts onto the manual transaxle side.

- Torque:

- 29 N*m{300 kgf*cm, 22 ft.*lbf}

| 26. INSTALL REVERSE IDLER GEAR SHAFT BOLT |

Coat the reverse idler gear shaft bolt with adhesive and install it with a new gasket.

- Adhesive:

- Toyota Genuine Adhesive 1344, Three Bond 1344 or Equivalent

- Torque:

- 29 N*m{300 kgf*cm, 22 ft.*lbf}

| 27. INSTALL NO. 2 LOCK BALL ASSEMBLY |

Coat the No. 2 lock ball assembly with adhesive and install it with a hexagon wrench.

- Adhesive:

- Toyota Genuine Adhesive 1344, Three Bond 1344 or Equivalent

- Torque:

- 29 N*m{300 kgf*cm, 22 ft.*lbf}

| 28. INSTALL SHIFT DETENT BALL |

Install the 2 shift detent balls, 2 compression springs and 2 spring seats onto the manual transmission case.

Coat the 2 shift detent ball plugs with adhesive and install them using a hexagon wrench.

- Adhesive:

- Toyota Genuine Adhesive 1344, Three Bond 1344 or Equivalent

- Torque:

- 22 N*m{224 kgf*cm, 16 ft.*lbf}

Install the shift detent ball, compression spring and the spring seat onto the front transaxle case.

Coat the shift detent ball plug with adhesive and install it using a hexagon wrench.

- Adhesive:

- Toyota Genuine Adhesive 1344, Three Bond 1344 or Equivalent

- Torque:

- 22 N*m{224 kgf*cm, 16 ft.*lbf}

| 29. INSTALL INPUT SHAFT REAR BEARING HOLE SNAP RING |

Using a snap ring expander, install the input shaft rear bearing hole snap ring onto the input shaft assembly.

| 30. INSTALL OUTPUT SHAFT REAR BEARING HOLE SNAP RING |

Using a snap ring expander, install the output shaft rear bearing hole snap ring onto the output shaft assembly.

| 31. INSTALL SHIFT FORK SHAFT SHAFT SNAP RING |

Using a brass bar and a hammer, install a new shift fork shaft shaft snap ring onto the No. 2 shift fork shaft.

| 32. INSTALL REAR BEARING RETAINER |

Coat the 5 bolts with adhesive, and install the rear bearing retainer onto the manual transmission case with the 5 bolts.

- Adhesive:

- Toyota Genuine Adhesive 1344, Three Bond 1344 or Equivalent

- Torque:

- 27 N*m{280 kgf*cm, 20 ft.*lbf}

| 33. INSTALL 5TH DRIVEN GEAR |

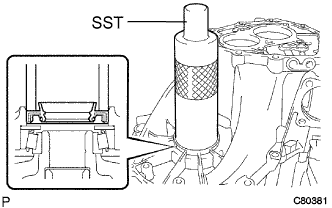

Using SST, install the 5th driven gear onto the output shaft assembly.

- SST

- 09309-12020

| 34. INSTALL 5TH GEAR NEEDLE ROLLER BEARING |

Coat the 5th gear needle roller bearing and 5th gear bearing spacer with gear oil, and install them onto the input shaft assembly.

Coat the 5th gear with gear oil and install it onto the input shaft assembly.

| 36. INSTALL NO. 3 SYNCHRONIZER RING |

Coat the No. 3 synchronizer ring with gear oil and install it onto the 5th gear.

| 37. INSTALL NO. 3 TRANSMISSION CLUTCH HUB |

Install the 3 synchromesh shifting keys and 2 synchromesh shifting key springs onto the No. 3 transmission clutch hub as shown in the illustration.

Text in Illustration

| Engine Side

|

- NOTICE:

- Do not set the 2 shifting key spring openings in the same position.

Using SST and a hammer, install the No. 3 transmission clutch hub onto the input shaft assembly.

- SST

- 09636-20010

Text in Illustration*1

| Wooden Block

|

*a

| Key Position

|

- NOTICE:

- Do not install the No. 3 transmission clutch hub in the wrong direction.

- Install the No. 3 transmission clutch hub with the No. 3 synchronizer ring key groove and the No. 3 synchromesh shifting key aligned.

- Check that the 5th gear is rotating.

- Place a suitable sized wooden block to support the input shaft.

Select a No. 3 clutch hub shaft snap ring that will allow minimum axial play.

- Standard clearance:

- 0.1 mm (0.00394 in.) or less

- Snap Ring Thickness:

Part No.

| Mark

| Thickness mm (in.)

|

90520-18002

| A

| 2.25 (0.0886)

|

90520-18003

| B

| 2.31 (0.0909)

|

90520-18004

| C

| 2.37 (0.0933)

|

90520-18006

| D

| 2.43 (0.0957)

|

90520-18007

| E

| 2.49 (0.0980)

|

90520-18008

| F

| 2.55 (0.1004)

|

90520-18009

| G

| 2.61 (0.1028)

|

Using a brass bar and a hammer, install the No. 3 clutch hub shaft snap ring onto the input shaft assembly.

| 38. INSPECT 5TH GEAR THRUST CLEARANCE |

Using a dial indicator, measure the 5th gear thrust clearance.

- Standard clearance:

- 0.1 to 0.55 mm (0.00394 to 0.0217 in.)

- Maximum clearance:

- 0.55 mm (0.0217 in.)

If the clearance exceeds the maximum, replace the No. 3 transmission clutch hub, the 5th gear or input shaft rear radial ball bearing.

| 39. INSPECT 5TH GEAR RADIAL CLEARANCE |

Using a dial indicator, measure 5th gear radial clearance.

- Standard clearance:

- JTEKT made:

- 0.015 to 0.058 mm (0.000591 to 0.00228 in.)

- NSK made:

- 0.015 to 0.056 mm (0.000591 to 0.00220 in.)

- Maximum clearance:

- JTEKT made:

- 0.058 mm (0.00228 in.)

- NSK made:

- 0.056 mm (0.00220 in.)

If the clearance exceeds the maximum, replace the 5th gear, 5th gear needle roller bearing or input shaft.

| 40. INSTALL NO. 3 GEAR SHIFT FORK |

Coat the No. 3 transmission hub sleeve with gear oil and install it together with the No. 3 gear shift fork onto the No. 3 transmission clutch hub.

- HINT:

- Set the No. 3 transmission clutch hub in the correct orientation.

Coat the shift fork set bolt with adhesive, and install it onto the No. 3 gear shift fork.

- Adhesive:

- Toyota Genuine Adhesive 1344, Three Bond 1344 or Equivalent

- Torque:

- 16 N*m{160 kgf*cm, 12 ft.*lbf}

| 41. INSTALL MANUAL TRANSMISSION OUTPUT SHAFT REAR SET NUT |

Engage the 2 gears simultaneously to lock the transmission.

Coat a new manual transmission output shaft rear set nut with adhesive.

- Adhesive:

- Toyota Genuine Adhesive 1344, Three Bond 1344 or Equivalent

Install the new manual transmission output shaft rear set nut.

- Torque:

- 118 N*m{1200 kgf*cm, 87 ft.*lbf}

Using a chisel and a hammer, stake the manual transmission output shaft rear set nut.

Disengage the 2 gears.

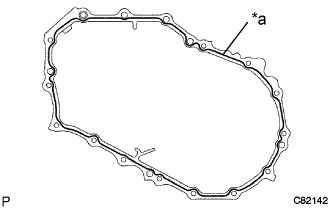

| 42. INSTALL MANUAL TRANSMISSION CASE COVER SUB-ASSEMBLY |

Apply a continuous bead of seal packing (Diameter 1.2 mm (0.0472 in.)) to the manual transaxle case cover sub-assembly as shown in the illustration.

Text in Illustration*a

| Seal Packing

(Seal Diameter: 1.2 mm (0.0472 in.))

|

- Seal Packing:

- Toyota Genuine Seal Packing 1281, Three Bond 1281 or Equivalent

- NOTICE:

- Remove any oil from the contact surfaces.

- Assemble the parts within 10 minutes of application. Otherwise, the seal packing material must be removed and reapplied.

Apply adhesive to 2 or 3 threads on the end of the 9 bolts.

- Adhesive:

- Toyota Genuine Adhesive 1324, Three Bond 1324 or epuivalent.

Install the manual transmission case cover sub-assembly onto the manual transmission case with the 9 bolts.

- Torque:

- 21 N*m{214 kgf*cm, 15 ft.*lbf}

| 43. INSTALL SHIFT AND SELECT LEVER SHAFT ASSEMBLY |

Coat the shift and select lever shaft assembly with gear oil, and install it onto the manual transmission case.

| 44. INSTALL CONTROL SHAFT COVER OIL SEAL |

Using SST and a hammer, install a new control shaft cover oil seal onto the control shaft cover.

- Drive in depth:

- 0.2 to 1.2 mm (0.00787 to 0.0472 in.)

- SST

- 09950-60010(09951-00280)

09950-70010(09951-07150)

Coat the control shaft cover oil seal with MP grease.

| 45. INSTALL CONTROL SHAFT COVER |

Coat the 4 bolts with adhesive. Install a new gasket and control shaft cover onto the manual transmission case with the 4 bolts.

- Torque:

- 20 N*m{200 kgf*cm, 14 ft.*lbf}

- Adhesive:

- Toyota Genuine Adhesive 1344, Three Bond 1344 or Equivalent

- NOTICE:

- Set the claws of the shift interlock plate into the shift head part of the gear shift fork shaft securely.

| 46. INSTALL SHIFT GATE PIN |

Coat the shift gate pin with adhesive.

- Adhesive:

- Toyota Genuine Adhesive 1344, Three Bond 1344 or Equivalent

Install the washer and shift gate pin.

- Torque:

- 11 N*m{112 kgf*cm, 8 ft.*lbf}

| 47. INSTALL NO. 1 LOCK BALL ASSEMBLY |

Coat No. 1 lock ball assembly with adhesive, install it onto the manual transmission case.

- Torque:

- 29 N*m{300 kgf*cm, 22 ft.*lbf}

- Adhesive:

- Toyota Genuine Adhesive 1344, Three Bond 1344 or Equivalent

| 48. INSTALL SHIFT LEVER DAMPER |

Install the dust boot onto the control shaft cover.

Install the shift lever damper with the lock pin onto the shift and select lever shaft assembly.

Install the spring washer with the nut.

- Torque:

- 12 N*m{120 kgf*cm, 9 ft.*lbf}

| 49. INSTALL FLOOR SHIFT CONTROL SHIFT LEVER |

Install the dust boot onto the shift and select lever shaft oil seal.

Install the floor shift control shift lever with the lock pin onto the shift and select lever shaft assembly.

Install the spring washer with the nut.

- Torque:

- 12 N*m{120 kgf*cm, 9 ft.*lbf}

| 50. INSTALL SELECTING BELL CRANK ASSEMBLY |

Install the selecting bell crank assembly together with the control bell crank dust cover onto the manual transmission case with the 2 bolts and nut.

- Torque:

- for Bolt:

- 25 N*m{250 kgf*cm, 18 ft.*lbf}

- for Nut:

- 12 N*m{120 kgf*cm, 9 ft.*lbf}

- NOTICE:

- Apply MP grease to the inside circumferential surface of the control bell crank dust cover.

| 51. INSTALL BACK UP LIGHT SWITCH ASSEMBLY |

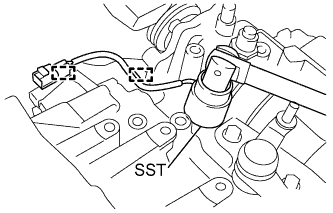

Using SST, install the back up light switch assembly onto the manual transmission case with a new gasket.

- SST

- 09817-16011

- Torque:

- 40 N*m{410 kgf*cm, 30 ft.*lbf}

Install the back up light switch wire harness into the 2 clamps.

| 52. INSTALL MANUAL TRANSMISSION FILLER PLUG |

Install the manual transmission filler plug onto the manual transmission case with a new gasket.

- Torque:

- 39 N*m{400 kgf*cm, 29 ft.*lbf}

| 53. INSTALL DRAIN PLUG SUB-ASSEMBLY |

Install the drain plug sub-assembly onto the manual transmission case with a new gasket.

- Torque:

- 39 N*m{400 kgf*cm, 29 ft.*lbf}