Automatic Transaxle System (For Hatchback) -- Hydraulic Test |

| PERFORM HYDRAULIC TEST |

Measure the line pressure.

- CAUTION:

- The line pressure test should always be carried out with at least 2 people. One person should observe the condition of wheels and wheel chocks while the other is performing the test.

- NOTICE:

- Perform the test at the normal operating ATF (Automatic Transmission Fluid) temperature 50° to 80°C (122° to 176°F).

- Prevent the SST hose from interfering with the exhaust pipe.

- This test must be conducted after checking and adjusting the engine.

- Perform this test with the air conditioning off.

- Do not continue the stall test for more than 5 seconds.

Warm up the ATF.

Lift the vehicle up.

Remove the engine under cover.

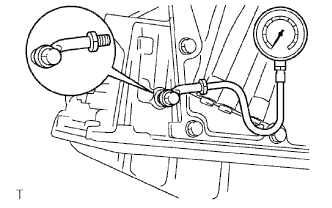

Remove the test plug on the transmission case center right side and connect SST.

- SST

- 09992-00095(09992-00231,09992-00271)

Connect the Techstream to the DLC3.

Turn the ignition switch to ON.

Turn the Techstream on.

Enter the following menus: Powertrain / Engine and ECT / Data List / All Data.

Fully apply the parking brake and chock all 4 wheels.

Start the engine and check the idling speed.

Keep your left foot pressing firmly on the brake pedal and Move the shift lever to D.

Measure the line pressure when the engine is idling.

Depress the accelerator pedal all the way down. Quickly read the highest line pressure when engine speed reaches stall speed.

Perform the test in the R position in the same manner.

- Standard Line Pressure:

Condition D position kPa (kgf/cm2, psi) R position kPa (kgf/cm2, psi) Stall 1126 to 1226 kPa

(11.5 to 12.5 kgf/cm2, 163 to 178 psi)1664 to 1864 kPa

(17.0 to 19.0 kgf/cm2, 241 to 270 psi)

Evaluation Problem Possible Cause Measured values are higher than specified values in all positions - Shift solenoid valve SLT defective

- Regulator valve defective

Measured values are lower than specified values in all positions - Shift solenoid valve SLT defective

- Regulator valve defective

- Oil pump defective

Pressure is low in D position only - D position circuit fluid leak

- Forward clutch defective

Pressure is low in R position only - R position circuit fluid leak

- Reverse clutch defective

- 1st and reverse brake defective

|