Engine. Toyota Rav4. Aca30, 33, 38 Gsa33 Zsa30, 35

INSPECT NO. 1 VALVE ROCKER ARM SUB-ASSEMBLY

INSPECT VALVE LASH ADJUSTER ASSEMBLY

INSPECT CHAIN SUB-ASSEMBLY

INSPECT NO. 2 CHAIN SUB-ASSEMBLY

INSPECT OIL PUMP DRIVE GEAR

INSPECT OIL PUMP DRIVE SHAFT GEAR

INSPECT CAMSHAFT TIMING GEAR ASSEMBLY

INSPECT CAMSHAFT TIMING EXHAUST GEAR ASSEMBLY

INSPECT CRANKSHAFT TIMING GEAR

INSPECT CHAIN TENSIONER SLIPPER

INSPECT NO. 1 CHAIN VIBRATION DAMPER

INSPECT CHAIN TENSIONER PLATE

INSPECT NO. 1 CHAIN TENSIONER

INSPECT CYLINDER HEAD BOLT

INSPECT EXHAUST MANIFOLD

Engine Unit -- Inspection |

| 1. INSPECT NO. 1 VALVE ROCKER ARM SUB-ASSEMBLY |

Turn the roller by hand to check that it turns smoothly.

If the roller does not turn smoothly, replace the No. 1 valve rocker arm sub-assembly.

| 2. INSPECT VALVE LASH ADJUSTER ASSEMBLY |

- NOTICE:

- Keep the valve lash adjuster free from dirt and foreign matter.

- Only use clean engine oil.

Place the lash adjuster into a container full of new engine oil.

Insert the tip of SST into the lash adjuster plunger and use the tip to press down on the check ball inside the plunger.

- SST

- 09276-75010

Squeeze SST and the valve lash adjuster together to move the plunger up and down 5 to 6 times.

Check the movement of the plunger and bleed the air.

- OK:

- Plunger moves up and down.

- NOTICE:

- When bleeding high-pressure air from the compression chamber, make sure that the tip of SST is actually pressing the check ball as shown in the illustration. If the check ball is not pressed, air bleeding is not possible.

After bleeding the air, remove SST. Then try to quickly and firmly press the plunger with your fingers.

- OK:

- Plunger can be pressed 3 times.

If the plunger can still be compressed after pressing it 3 times, replace the valve lash adjuster with a new one.

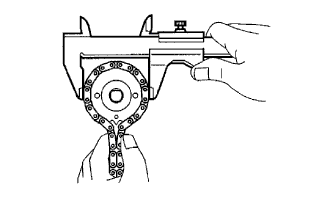

| 3. INSPECT CHAIN SUB-ASSEMBLY |

Pull the chain with a force of 147 N (15 kgf, 33.0 lbf) as shown in the illustration.

Using a vernier caliper, measure the length of 15 links.

- Maximum chain elongation:

- 115.2 mm (4.54 in.)

- NOTICE:

- Perform the measurement at 3 random places. Use the average of the measurements.

If the average elongation is more than the maximum, replace the chain sub-assembly.

| 4. INSPECT NO. 2 CHAIN SUB-ASSEMBLY |

Pull the chain with a force of 147 N (15 kgf, 33.0 lbf) as shown in the illustration.

Using a vernier caliper, measure the length of 15 links.

- Maximum chain elongation:

- 102.1 mm (4.02 in.)

- NOTICE:

- Perform the measurement at 3 random places. Use the average of the measurements.

If the average elongation is more than the maximum, replace the No. 2 chain sub-assembly.

| 5. INSPECT OIL PUMP DRIVE GEAR |

Place the chain around the oil pump drive gear.

Using a vernier caliper, measure the diameter of the oil pump drive gear and chain.

- Minimum gear diameter (with chain):

- 48.2 mm (1.90 in.)

- NOTICE:

- The vernier caliper must be in contact with the chain rollers when measuring.

If the diameter is less than the minimum, replace the chain and oil pump drive gear.

| 6. INSPECT OIL PUMP DRIVE SHAFT GEAR |

Place the chain around the oil pump drive shaft gear.

Using a vernier caliper, measure the diameter of the oil pump drive shaft gear and chain.

- Minimum gear diameter (with chain):

- 48.2 mm (1.90 in.)

- NOTICE:

- The vernier caliper must be in contact with the chain rollers when measuring.

If the diameter is less than the minimum, replace the chain and oil pump drive shaft gear.

| 7. INSPECT CAMSHAFT TIMING GEAR ASSEMBLY |

Place the chain around the camshaft timing gear assembly.

Using a vernier caliper, measure the diameter of the camshaft timing gear assembly and chain.

- Minimum gear diameter (with chain):

- 96.8 mm (3.81 in.)

- NOTICE:

- The vernier caliper must be in contact with the chain rollers when measuring.

If the diameter is less than the minimum, replace the chain and camshaft timing gear assembly.

| 8. INSPECT CAMSHAFT TIMING EXHAUST GEAR ASSEMBLY |

Place the chain around the camshaft timing exhaust gear assembly.

Using a vernier caliper, measure the diameter of the camshaft timing exhaust gear assembly and chain.

- Minimum gear diameter (with chain):

- 96.8 mm (3.81 in.)

- NOTICE:

- The vernier caliper must be in contact with the chain rollers when measuring.

If the diameter is less than the minimum, replace the chain and camshaft timing exhaust gear assembly.

| 9. INSPECT CRANKSHAFT TIMING GEAR |

Place the chain around the crankshaft timing gear.

Using a vernier caliper, measure the diameter of the crankshaft timing gear and chain.

- Minimum gear diameter (with chain):

- 51.1 mm (2.01 in.)

- NOTICE:

- The vernier caliper must be in contact with the chain rollers when measuring.

If the diameter is less than the minimum, replace the chain and crankshaft timing gear.

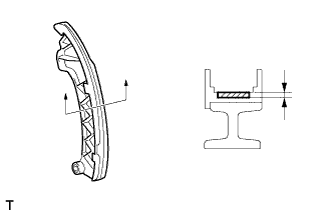

| 10. INSPECT CHAIN TENSIONER SLIPPER |

Using a vernier caliper, measure the chain tensioner slipper wear.

- Maximum wear:

- 1.0 mm (0.0394 in.)

If the wear is more than the maximum, replace the chain tensioner slipper.

| 11. INSPECT NO. 1 CHAIN VIBRATION DAMPER |

Using a vernier caliper, measure the No. 1 chain vibration damper wear.

- Maximum wear:

- 1.0 mm (0.0394 in.)

If the wear is more than the maximum, replace the No. 1 chain vibration damper.

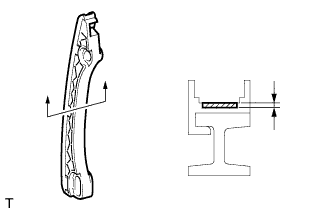

| 12. INSPECT CHAIN TENSIONER PLATE |

Using a vernier caliper, measure the chain tensioner plate wear.

- Maximum wear:

- 1.0 mm (0.0394 in.)

If the wear is more than the maximum, replace the chain tensioner plate.

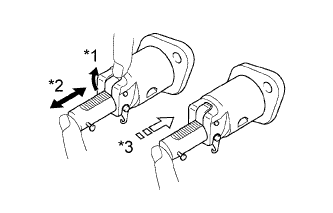

| 13. INSPECT NO. 1 CHAIN TENSIONER |

Check that the plunger moves smoothly when the cam is raised with your finger.

Text in Illustration*1

| Raise

|

*2

| Move

|

*3

| Lock

|

Release the cam, and then check that the plunger is locked in place by the cam and does not move when pushed with your finger.

If necessary, replace the No. 1 chain tensioner.

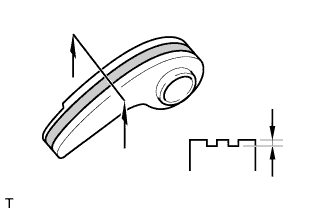

| 14. INSPECT CYLINDER HEAD BOLT |

Using a vernier caliper, measure the length of the cylinder head bolt from the seat to the end.

- Standard length:

- 146.8 to 148.2 mm (5.78 to 5.83 in.)

- Maximum length:

- 149.2 mm (5.87 in.)

If the length is more than the maximum, replace the cylinder head bolt.

Using a vernier caliper, measure the diameter of the elongated thread at the measuring area.

- Distance:

- 115 mm (4.53 in.)

- Standard diameter:

- 9.77 to 9.96 mm (0.385 to 0.392 in.)

- Minimum diameter:

- 9.4 mm (0.370 in.)

If the diameter is less than the minimum, replace the cylinder head bolt.

- HINT:

- If a visual check reveals no excessively thin areas, check the center of the bolt (refer to illustration) and find the area that has the smallest diameter.

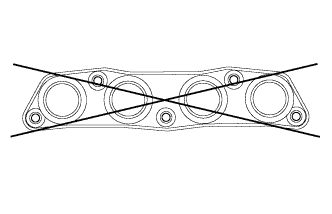

| 15. INSPECT EXHAUST MANIFOLD |

Using a precision straightedge and feeler gauge, measure the warpage on the surface that contacts the cylinder head.

- Maximum warpage:

- 0.7 mm (0.0276 in.)

If the warpage is more than the maximum, replace the exhaust manifold.