Manual Transaxle Unit Inspection

INSPECT REVERSE IDLER GEAR SUB-ASSEMBLY

INSPECT NO. 3 TRANSAXLE CLUTCH HUB

INSPECT NO. 3 TRANSAXLE HUB SLEEVE

INSPECT 5TH GEAR

Manual Transaxle Unit -- Inspection |

| 1. INSPECT REVERSE IDLER GEAR SUB-ASSEMBLY |

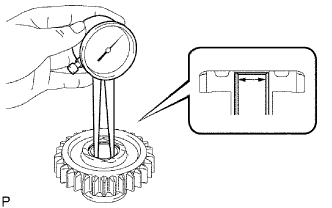

Using a caliper gauge, measure the inside diameter of the reverse idler gear.

- Standard inside diameter:

- 20.056 to 20.074 mm (0.7896 to 0.7903 in.)

- Maximum inside diameter:

- 20.074 (0.7903 in.)

If the inside diameter is greater than the maximum, replace the reverse idler gear.

Using a micrometer, measure the diameter of the reverse idler gear shaft.

- Standard diameter:

- 19.984 to 20.000 mm (0.7868 to 0.7874 in.)

- Minimum diameter:

- 19.984 mm (0.7868 in.)

If the diameter is less than the minimum, replace the reverse idler gear shaft.

| 2. INSPECT NO. 3 TRANSAXLE CLUTCH HUB |

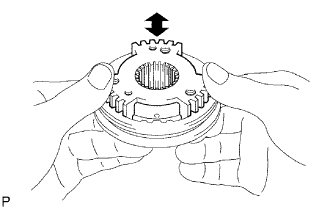

Inspect the sliding condition between the No. 3 transaxle clutch hub and the No. 3 transaxle hub sleeve.

Inspect the tip of the spline gear on the No. 3 transaxle hub sleeve for wear.

| 3. INSPECT NO. 3 TRANSAXLE HUB SLEEVE |

Using vernier calipers, measure the width of the No. 3 transaxle hub sleeve groove (A) and the thickness of the claw part on the No. 3 gear shift fork (B), and calculate the clearance.

- Standard clearance:

- A - B = 0.15 to 0.35 mm (0.0059 to 0.0138 in.)

If the clearance is out of the specification, replace the No. 3 transaxle hub sleeve and No. 3 gear shift fork with new ones.

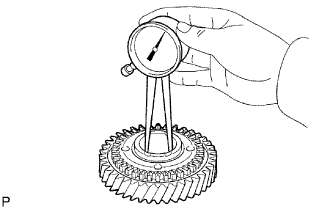

Using a caliper gauge, measure the inside diameter of the 5th gear.

- Standard inside diameter:

- 34.981 to 34.997 mm (1.3772 to 1.3778 in.)

- Maximum inside diameter:

- 34.997 mm (1.3778 in.)

If the inside diameter is greater the maximum, replace the 5th gear.