Exhaust Pipe -- Installation |

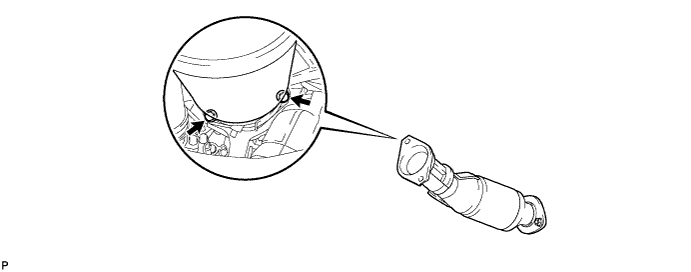

| 1. INSTALL FRONT EXHAUST PIPE ASSEMBLY |

Using a vernier caliper, measure the free length of the compression spring.

- Minimum length:

- 41.5 mm (1.63 in.)

|

Using a wire brush, remove any foreign matter from the gasket installation surface.

Install a new gasket by hand so that its surface is flush with the exhaust manifold.

- NOTICE:

- Make sure the gasket is facing the correct direction.

- Do not reuse the removed gasket.

- Do not push in the gasket while installing the front exhaust pipe.

|

Install the front exhaust pipe and 2 compression springs with the 2 bolts.

- Torque:

- 43 N*m{438 kgf*cm, 32 ft.*lbf}

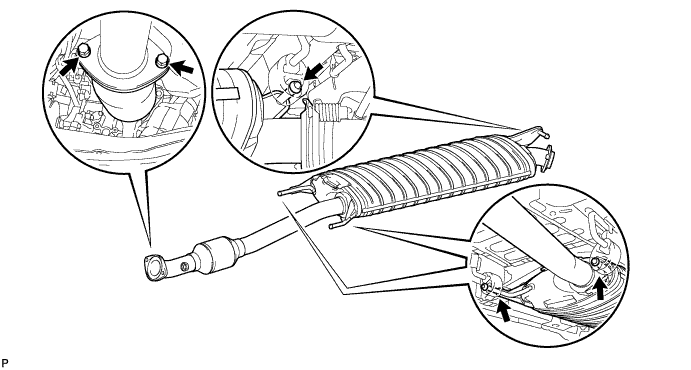

| 2. INSTALL CENTER EXHAUST PIPE ASSEMBLY |

Install a new gasket onto the front exhaust pipe.

Connect the 3 exhaust pipe supports to install the center exhaust pipe.

Install the 2 bolts.

- Torque:

- 43 N*m{438 kgf*cm, 32 ft.*lbf}

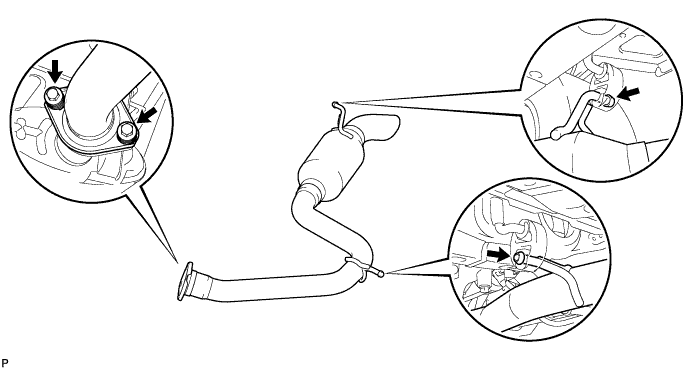

| 3. INSTALL TAILPIPE ASSEMBLY |

Using a vernier caliper, measure the free length of the compression spring.

- Minimum length:

- 38.5 mm (1.52 in.)

|

Install a new gasket by hand so that its surface is flush with the center exhaust pipe.

- NOTICE:

- Make sure the gasket is facing the correct direction.

- Do not reuse the removed gasket.

- Do not push in the gasket while installing the tailpipe.

|

Connect the 2 exhaust pipe supports to install the tailpipe.

Install the 2 compression springs and 2 bolts.

- Torque:

- 43 N*m{438 kgf*cm, 32 ft.*lbf}

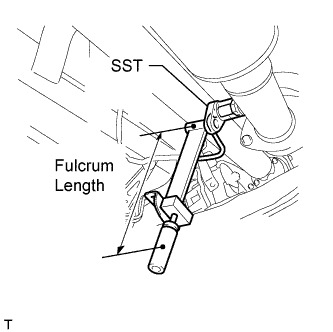

| 4. CONNECT HEATED OXYGEN SENSOR |

- NOTICE:

- Do not strike the metal part of the sensor.

Rotate the sensor counterclockwise the same number of times as recorded in the removal procedure, and then connect it to the front exhaust pipe by hand.

- NOTICE:

- After rotating the sensor counterclockwise the same number of times as in the removal procedure, connect it while making sure that the wire harness is not twisted.

Using SST, tighten the sensor.

- SST

- 09224-00010

- Torque:

- with SST:

- 40 N*m{408 kgf*cm, 30 ft.*lbf}

- without SST:

- 44 N*m{449 kgf*cm, 32 ft.*lbf}

- HINT:

- Make sure SST and the wrench are connected in a straight line.

- Use a torque wrench with a fulcrum length of 300 mm (11.8 in.).

|

Connect the grommet to the floor panel.

| 5. INSPECT FOR EXHAUST GAS LEAK |