Underdrive Planetary Gear Reassembly

INSTALL UNDERDRIVE PLANETARY RING GEAR

INSTALL UNDERDRIVE PLANETARY GEAR ASSEMBLY

Underdrive Planetary Gear -- Reassembly |

| 1. INSTALL UNDERDRIVE PLANETARY RING GEAR |

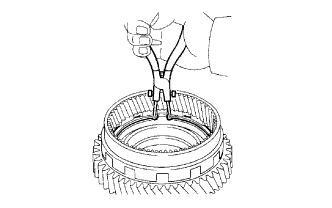

Install a new snap ring to the outer race of the tapered roller bearing.

Using a piston ring compressor, squeeze the snap ring.

Using SST a press, press in the outer race of the tapered roller bearing.

- SST

- 09950-60020(09951-00890)

09950-70010(09951-07100)

Install the underdrive planetary ring gear to the counter driven gear.

Using snap ring pliers, install the snap ring.

| 2. INSTALL UNDERDRIVE PLANETARY GEAR ASSEMBLY |

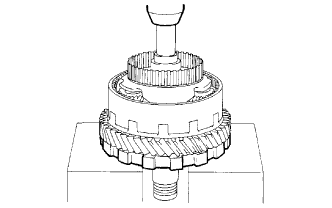

Using a press, install the tapered roller bearing.

Install the counter driven gear with planetary ring gear to the underdrive planetary gear.

Using SST and a press, press in the tapered roller bearing.

- SST

- 09316-60011(09316-00011)

- NOTICE:

- Press in the counter driven gear while rotating it.

Using a press, press in the parking lock gear.

- NOTICE:

- Press in the counter driven gear while rotating it.

Using SST and a press, press in the differential drive pinion.

- NOTICE:

- Press in the counter driven gear while rotating it.

- SST

- 09506-35010

09950-60010(09951-00250)

Using SST and a press, press in the cylindrical roller bearing inner race.

- NOTICE:

- Press in the counter driven gear while rotating it.

- SST

- 09506-35010

09950-60010(09951-00250)

Clamp the underdrive planetary gear in a soft jaw vise.

- NOTICE:

- Be careful not to damage the differential drive pinion.

Using SST, install a new lock nut.

- Torque:

- 280 N*m{2,855 kgf*cm, 207 in.*lbf}

- SST

- 09564-16020

- HINT:

- Use a torque wrench with a fulcrum length of 750 mm (29.53 in.)

Using SST and a torque wrench, measure the turning torque of underdrive planetary gear assembly while rotating the torque wrench at 60 rpm.

- SST

- 09564-16020

09387-00050

- Torque:

- Standard turning torque at 60 rpm:

- 0.23 to5.01 N*m{2 to 51 kgf*cm, 2.0 to 44.3 in.*lbf}

- HINT:

- Use a torque wrench with a fulcrum length of 160 mm (6.30 in.).

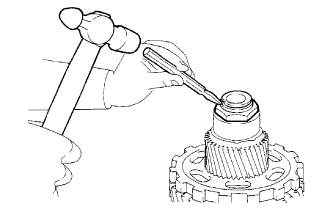

Using a pin punch and hammer, stake the lock nut.

- NOTICE:

- Make sure that there are no cracks on the nut.