Underdrive Planetary Gear Reassembly

INSTALL UNDERDRIVE PLANETARY RING GEAR

INSTALL UNDERDRIVE PLANETARY GEAR ASSEMBLY

INSTALL CYLINDRICAL ROLLER BEARING INNER RACE

INSTALL UNDERDRIVE INPUT SHAFT NUT

INSPECT UNDERDRIVE PLANETARY GEAR PRELOAD

Underdrive Planetary Gear -- Reassembly |

| 1. INSTALL UNDERDRIVE PLANETARY RING GEAR |

Install a new snap ring to the outer race of the tapered roller bearing.

Using a piston ring compressor, squeeze the snap ring.

Using SST a press, press in the outer race of the tapered roller bearing.

- SST

- 09950-60020(09951-00890)

09950-70010(09951-07100)

Install the underdrive planetary ring gear to the counter driven gear.

Using snap ring pliers, install the snap ring.

| 2. INSTALL UNDERDRIVE PLANETARY GEAR ASSEMBLY |

Using a press, press in the rear tapered roller bearing to the underdrive planetary gear.

- NOTICE:

- Press in the bearing until it becomes flat at the bottom

Install the counter driven gear with planetary ring gear to the underdrive planetary gear.

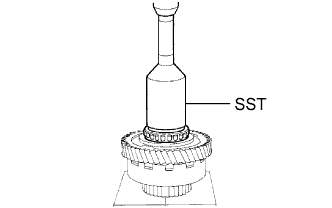

Using SST and a press, press in the front tapered roller bearing.

- SST

- 09214-76011

- NOTICE:

- Press in the counter driven gear while rotating it.

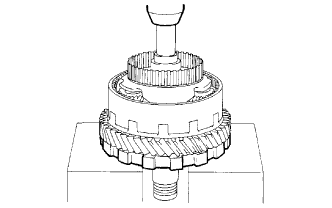

Using a press, press in the parking lock gear.

- NOTICE:

- Press in the counter driven gear while rotating it.

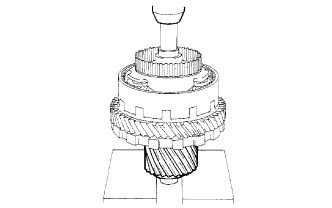

Using a press, press in the differential drive pinion.

- NOTICE:

- Press in the counter driven gear while rotating it.

| 3. INSTALL CYLINDRICAL ROLLER BEARING INNER RACE |

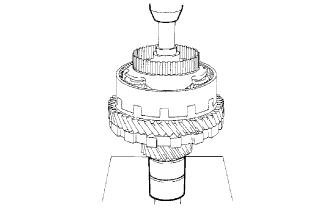

Using a press, press in the cylindrical roller bearing race inner.

- NOTICE:

- Press in the counter driven gear while rotating it.

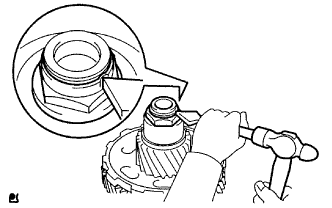

| 4. INSTALL UNDERDRIVE INPUT SHAFT NUT |

Clamp the underdrive planetary gear in a soft jaw vise.

- NOTICE:

- Be careful not to damage the differential drive pinion.

Using a socket wrench, install a new lock nut.

- Torque:

- 280 N*m{2,855 kgf*cm, 207 in.*lbf}

- HINT:

- Use a torque wrench with a fulcrum length of 750 mm (29.53 in.)

| 5. INSPECT UNDERDRIVE PLANETARY GEAR PRELOAD |

Using SST and a torque wrench, measure the turning torque of underdrive planetary gear assembly while rotating the torque wrench at 60 rpm.

- SST

- 09387-00050

- Torque:

- Turning torque at 60 rpm:

- 0.10 to 4.41 N*m{1.0 to 45 kgf*cm, 0.9 to 39 in.*lbf}

- HINT:

- Use a torque wrench with a fulcrum length of 160 mm (6.30 in.)

Using a pin punch and a hammer, stake the lock nut.

- NOTICE:

- Make sure that there are no cracks on the nut.